|

Boeing 777-200

by Dan Lee

|

|

|

Boeing 777-200 |

Hasegawa's 1/200 scale Boeing 777-200 is

available online from Squadron

The Boeing 777 was designed

to fill the airliner gap between its 747 and 767 product lines. It was

meant to replace the aging DC-10 and L1011 fleets and to compete with the

McDonnell Douglas MD-11 and Airbus A340/330. These were already in

development when Boeing started on the 777 project.

The 777 followed after the development of the 747-400 and as a result

employed the latest technological advances at that time. A two crew

cockpit, LCD displays, digital data buses, and composite structures just

to name a few. The 777 was also Boeing’s first airliner to employ digital

fly-by-wire for all control surfaces.

First flight was on June 20 1994. And at the time, it was the largest twin

engine passenger aircraft in the world. Today that title goes to its

stretched version, the 777-300. The –300 variant is intended to replace

the early 747-100/200s. Development of the 777 was an international

project with customers having input during the entire development cycle.

The plane is powered by either the Pratt & Whitney PW4000, General

Electric GE90 or Rolls-Royce Trent 800.

From its original offering (-200), a total of five variants are offered (

-200, -200ER, -300, -200LR, -300ER). As of July 2003 there have been 622

orders and 443 deliveries covering all variants.

The 777-200 is of particular interest to me, since I was at Allied Signal

Aerospace in Toronto, Canada during the development of the pneumatic

control system for the aircraft.

Hasegawa’s

1/200 B777-200

|

This one of Hasegawa’s many

releases of its 777-200 kit and was purchased for $26CDN.

The kit decals are for Japan

Airlines, with individual aircraft named after particular constellations.

The kit features recessed panel lines, openings for passenger windows, a

clear cockpit windshield, and display stand. Engines are the Pratt &

Whitney variety.

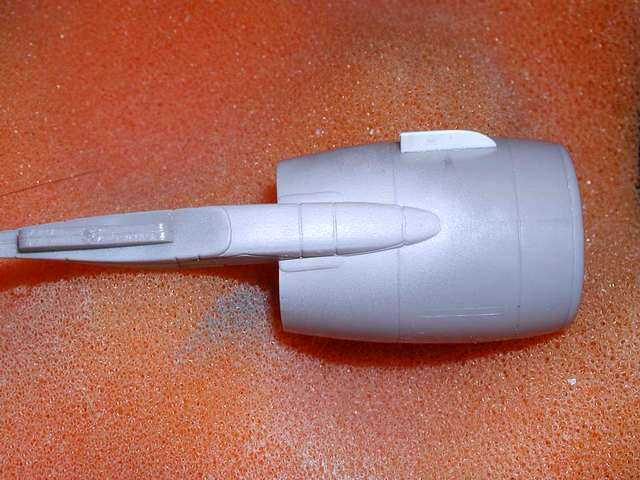

The kit went together

without any major problems. A bit of filler was required on the left wing

root and around the engine nacelle intake lips which weren’t cleanly

molded on my copy.

Construction started with the fuselage. The provided nose weight ballast

was installed which consisted of machine screw being screwed into the

cockpit bulkhead. The interior was sprayed flat black. Passenger windows

are depicted by holes which for some reason I prefer; instead of window

decals. Window counters will need to fill in the appropriate windows for

the particular airline they are modelling or use window decals.

With the fuselage halves glued, a slight peak is noticeable along the join

line for both top and bottom joints. Sanding is required to eliminate this

artifact. All antennas were removed and replaced with thinner parts made

from 10 thou plastic card. Provision is provided for the builder to mount

the aircraft on a display stand. A hole must be opened in the fuselage and

the stand mounting plug installed to use the display stand.

The wings were assembled next which consist of upper/lower halves. A nice

feature about the wings are that the under wing fairings are all separate

and were left off until after everything was painted. This makes masking

and painting the underside corrogard panels painless.

I decided to glue the wings to the fuselage before any painting since test

fitting revealed a slight gap/ mismatch on the forward left fuselage/wing

joint. Here putty was used to fix the problem. Otherwise you could paint

the wings and fuselage separately and join them afterwards.

The engine nacelle fan discs require painting before they are installed

between the nacelle halves. Testors steel for the fan blades and Tamiya

Semi-gloss black for the hub were used. The interior ducting was painted

Testors steel enamel which turned out to look metallic grey. New engine

vanes were made with 10thou plastic card. The engine hot sections were

left off until painting was done.

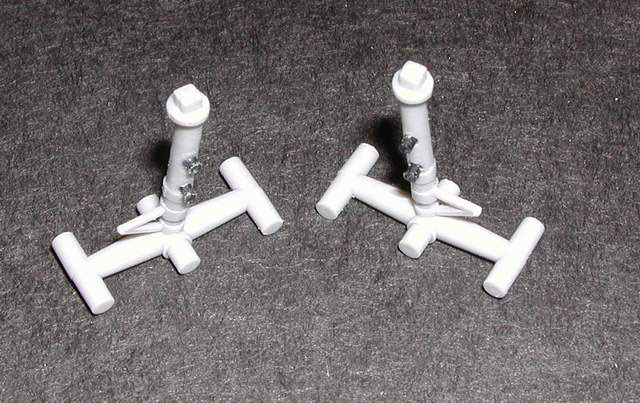

The main landing gears are

molded to fit either the left or right gear bays. As such they have

mounting holes for the main gear doors on both sides of the struts.

However the struts are quite thin and the holes quite large. Therefore I

decided to fill the extra holes in with stretches spruce and have mounting

posts for the gear doors.

All the gear doors are

overly thick. The main landing gear doors were sanded thinner. Nose doors

and auxiliary main landing gear doors were replaced with thinner ones made

from plastic card.

The engines, horizontal stabilizers, and landing gear were left off during

the painting session.

Long ago I decided that the

JAL scheme was too boring. It was the Korean Air decals from Flying Colors

that caught my attention and became the target scheme for this kit.

Paint

Wings were paint first.

Gunze Sanyo H338 Light Grey was used for the wings and horizontal

stabilizers. Tamiya neutral grey was used for the corrogard on the wings.

Gunze Sanyo H45 Light Blue mixed with white was then used for the upper

fuselage. The blue was then masked off and Tamiya White was used for the

lower fuselage. During painting of the fuselage, the wings were masked to

prevent any overspray from contaminating the wing’s finish.

I found that painting the engine pylons light grey and then masking the

pylon and painting the nacelle white the easiest sequence.

The leading edges for the wings and horizontal stabilizers were masked off

and Testors silver was then sprayed.

Testor's Metallizer Exhaust and burnt metal was used to for the engine hot

section. Once all engine nacelle parts were painted, all parts were

superglued.

Future was applied prior to decal application.

The cockpit windshield, landing gear, landing gear doors and engines were

installed as the last step prior to decal application.

Decals

The Korean Air, Flying

Colors decals ($10.95CDN) cover both 777-200 and 777-300 variants that

Korean Air fly. Registration numbers are provided for HL7526,7530,7531 for

777-200s and HL7532-7534 for 777-300s. The default registration number is

HL7533.

There are two challenges with the decals; the silver band and the fin

airline emblem. The silver band along the fuselage consisted of two

segments per side. Plenty of Mircoscale Micro Sol setting solution and

time was required to soften the decals to get them to conform to the

complex curves at the nose and the rear fuselage. The end result is that

the silver band looks like it was painted on. One hicup was the silver

bands needs a cut out over the wing. Otherwise the decal spills onto the

wing which happened to me; such is life.

The circular fin emblem sits on top of the rudder hinge line which is

quite deep. The port side also has three lumps for the rudder trim tab

actuators which adds a further complex surface for which the decal must

conform against. Again Micro Sol solution and time was required to get the

decal to sit down. However I did manage to get the decals to crack along

the rudder hinge line; looked like more time with Micro Sol was required

unfortunately.

The final hiccup was with the registration number. To make any aircraft

other than default 7533, the last digit ‘3’ must be cut off and the

desired digit selected from the spare numbers. However the font size for

the spare numbers is slightly smaller than that of the default. This is

quite noticeable on the nose door numbers and slightly noticeable on the

fin numbers.

There was plenty of silver decal left which I used for the cockpit

framing.

Otherwise the decals were great to work with and are highly recommended.

Hasegawa’s 777 was a simple

and easy kit to put together. The Korean Air is definitely one of the more

colorful and easier paint schemes for the B777. Highly recommended as an

diversion from your normal subjects.

Click the

thumbnails below to view larger images:

Model, Images and Text Copyright ©

2003 by Dan Lee

Page Created 08 September, 2003

Last Updated

17 March, 2004

Back to

HyperScale Main Page |

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search