|

Beech Model 18

by

Fotios Rouch

|

|

|

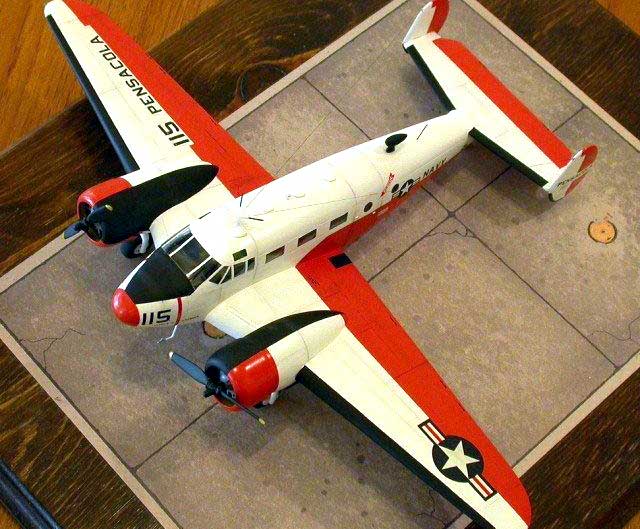

Beech Model 18 |

Battle Axe's 1/48

scale Beech Model 18 is available online from

Squadron.com

Imagine this.

The Beech Model 18 first flew in 1937. The Army started using it in

1940. Beech made over 4,000 units for the U.S. Army Air Force and over

1,500 for the U.S. Navy. The C-45 version stayed in service with the

U.S.A.F. until 1963 and the civilian version of the Model 18 was

produced all the way up to 1969.

This plane's production run was 32 years!

I still see them flying around in one guise or another. While in

service with U.S.A.F. Navy or Marines it was called AT-7, AT-11, UC-45,

C-45, SNB-# or JRB-#, where # denotes the different variants.

It was used early during WWII as bombardier trainer and navigation

trainer. It was also used for reconnaissance, aerial mapping, VIP

transport, administrative and logistic duties.

There were also 309 Expeditors supplied to the RAF, RCAF and the

Royal Navy's Fleet Air Arm.

Battle Axe 1/48

Scale Beech Model 18

|

I had been frustrated for some years not being able to find a kit of

it in 1/48 scale. Some years ago I noticed that Collect-Aire had added

in the upcoming releases in their Advisor catalog that they were

planning to make one in resin. Boy, I have it made I thought. A few

months later Battle Axe came out with theirs and unfortunately Collect-Aire

never made one.

Why unfortunately?

Well, my Battle Axe C-45 copy is easily the worst injected kit I ever

purchased. I understand the concept of limited run kits and the level of

work required but this kit was something else. Every single piece had a

defect of some sort. Some were easy to fix and some took days to

correct.

I have included some pictures of various kit parts to give you an

idea of what I am talking about. Personally I like the French, I admire

their engineering, their cuisine and I have certainly have had the

pleasure of owning some great injected kits from Heller. The C-45 I

purchased for over $50.00 did not look like any other limited run

injection kit I ever saw.

Click the thumbnails below

to view larger images:

Battle Axe took the meaning of limited run and redefined it for me! I

never thought that low pressure injection can be so low that the kit

parts would have depressions and valleys running through them. The wing

and fuselage surfaces were rough and the panel lines were of

inconsistent depth, width and alignment. The wing trailing edges were a

scale foot thick. Every where there was an ejection stub you were sure

to find a huge depression on the other side of the part.

In any case since I was pretty sure now that nobody else is going to

produce another Beech-18 variant I decided to put in the labor and

complete it for my collection. Initially I wanted to do a USAF C-45 in

white and natural metal. I thought that I would never be able to get

this model to such a good shape so that natural metal finish would look

good on it. My second choice was to make a Navy SNB-2 variant in white

and international orange scheme. The Monogram Publications book came in

handy with many photos of this pretty variant.

The plastic parts were prepared one item at a time. I started with the

the tough ones. The tails and the wings were first.

I had to use Acryl Blue and automotive primer, lots of sanding paper

and water. Once the parts looked smooth and level I sprayed them with

Mr. Surfacer 500 and then re-scribed them. The fuselage was next. It was

cleaned up from the blobs of plastic that were present here and there

and then was lightly sanded down to remove the surface coarseness. I

noticed that the side windows, provided in vac plastic would not have

fitted well in the openings. I decided to use a little trick that Eli

Raphael told me about some time ago. He told me to go to Michael's (an

arts supply store) and buy their clear epoxy kit. It is really meant to

be used as a nice high gloss protective cover over table tops for

example. It dries clear and hard. I placed tape on the outer surface of

the fuselage parts over the window openings, mixed some clear epoxy and

poured it in small quantities on the inside of the fuselage making

little puddles over the window openings. After it dried I removed the

tape and polished the outside plastic and clear resin with various

grades of polishing cloths. This method gave me very smooth, perfectly

integrated and shiny side windows. Eli advised me to use a blow drier to

remove the possible air bubbles from the resin mix. I did not have many

at all in such small quantities. The little I had I removed with a

toothpick. In the end I had perfect fitting windows that I could have

never reproduced with regular vac plastic.

The next big thing to conquer was the big vac canopy piece. This part

had to be trimmed and adjusted so many times it's not even funny. The

good thing is that two canopies are provided. They are fairly clear and

hard.

The way I went about trimming and adjusting the canopy was to tape

the fuselage parts together and try to get a rough idea of how the

canopy would fit. At that point I had left plenty of excess of vac

plastic so I would have plenty to trim. I like trimming better than

running short! I made sure to use tape as a guide and placed it over the

vac canopy as a guide for cutting. I kept sanding the canopy all around

until I got a satisfactory fit with the fuselage. It took me two

evenings to get the canopy right. I then dipped it in Future and set it

aside for later. I worked on the interior but did not do much since very

little would show at the end. After major parts cleanup the cockpit area

looked ok out of the box. The only thing I added was some seatbelts. I

spent some time on the engines, cleaning the blobs of plastic found

between the cylinders and adding some detail like the pushrods. Since I

wanted to do a later variant of the aircraft I had decided to use epoxy

putty to lengthen the engine nacelles.

My good buddy Boyd Waechter saved me a few days worth of work by

pointing me to Mike West. Apparently Lone Star Models had already

created the proper nacelles for the later Expeditors (like G and H,

etc). Soon afterwards I had a package coming from Mike loaded with a

bunch of goodies he markets (did you think that I was just going to

order only what I needed?).

After the airframe was together I sprayed many layers of automotive

primer, lots of sanding under water and finally I had something

respectable. The canopy went on next. I had already glued many strips of

styrene on the fuselage so the canopy would have good footing to rest

on. Then I masked it with Tamiya tape and applied more putty and primer

until I had a seamless joint. More parts were added to the airframe and

lastly a final coat of Mr.Surfacer 1000 primer was applied. Final

polishing was next. Last step was to re-scribe the model were it was

needed. The many layers of primer reduced the depth and width of the

panel lines a bit which was a good thing.

Every antenna was scratchbuilt since the items in the kit were of

gigantic thickness. Windshield wipers were made out of thin styrene

strips. The landing gear doors were scratchbuilt per photo references.

Check your info on this subject. Many variants had different types of

landing gear doors.

Some had the long ones some had short ones and some had none. The one

I built had the short main landing gear doors and none for the tail

gear.

This of course caused me some more trouble since the kit's tail wheel

is really bad. I scratchbuilt a new one and solved my problem in less

than an hour. I made my own decals, using my inkjet printer, which is

pretty good for black and white jobs. I chose to make a SNB stationed at

Pensacola in white/international orange style. As usual my good wife

supplied me with another long piece of her hair donated for the good

cause.

I am fairly happy with the results even though the model has many

mistakes (thick original landing gear, sharp corner side windows instead

of rounded, some antennas still missing, etc.).

I had to work unreasonably hard for such a small kit. I do not mind

the labor but this was ridiculous. There was no reason for the kit to be

so substandard. I wonder if there is a way for Battle Axe to fine-tune

their production methods.

Do I recommend this kit?

It depends on how bad you want a Beech 18 in your collection!

Artwork

Lastly, I want to include here a drawing my wife made of the plane as

she was keeping me company while I was trying to build it! I have to say

that she is turning to an aviation artist.

It is so much more fun watching her making drawings of my planes

instead of watching her painting landscapes!

To see more of my wife's airplane art go to

http://home.earthlink.net/~m.rouch/retail/aviation.html

Click on the thumbnails

below to view larger images:

Model, Images and Text Copyright © 2003 by

Fotios Rouch

Page Created 10 October, 2003

Last Updated 17 March, 2004

Back to HyperScale

Main Page

|

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search