|

Lockheed C130-H Hercules

by Mick O'Brien

|

|

|

C-130H Hercules |

Italeri's 1/48 scale C-130H Hercules is available online from

Squadron.com

Australia was the first country outside of the United States to

operate the C-130 Hercules. Australia’s 36 Squadron received the

first of twelve C-130A Hercules in 1958. These were replaced with

C-130H models in 1978.

The Italeri 1/48 scale C130-H Hercules kit was used as the basis

for 36 Squadron’s aircraft A97-001 in early 1999. The kit is for an

earlier version of the H model so considerable work was required to

bring the model up to Australian specifications.

The model is huge and when built. It is 63cm long and has a

wingspan of 84cm. I decided right from the start to detail the

interior. The flight deck was bland, and the cargo compartment

detail was almost non existent.

Flight Deck

The flight deck was built then detailed using Flightpath photo

etch and scratch built parts. The Flight Crew and Loadmaster were

pilots from the Hasegawa Ground Crew/Pilot sets with the heads

removed and replaced with ground crew heads and boom mikes made from

wire. A 3 volt light bulb was also installed to show the detail

after the fuselage was joined together.

The crew entrance and under the flight deck was scratch built and

a light bulb installed. Crew entrance steps used the Flightpath

parts and a scratch built closing/support lanyard of wire.

Click on the thumbnails

below to view larger images:

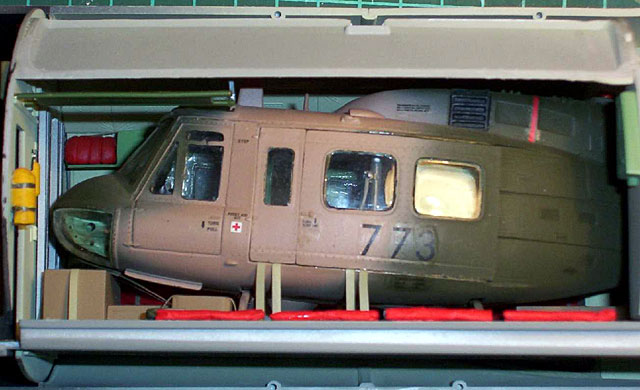

Cargo Compartment

To fill the cargo compartment a Italeri Iroquois was built and

loaded as an Army Aviation slick for C130 transport.

Equipment boxes were four firestorm resin boxes the rest were

scratch built. Restraint straps were 1/16” masking tape and white

metal ratchets. Front webbing seats are printed on color over head

projection sheets, rear seats and paratroop door interiors are from

Flightpath. The rest of the interior detail was scratch built

The interior was painted light green up to the paratroop doors

and matt black from doors aft. Five light bulbs were installed in

the cargo compartment.

The ramp surface and some detail is from Flightpath. Most of the

side detail is scratch built including the hand beams, toilet,

urinal, curtains, and paratroop door litter bracket arms. The

exterior scrape plate was shaped using card and putty.

Exterior

Aerials consisted of kit and scratch built parts. The HF antenna

masts were thinned and the wires made of stretched sprue and

turnbuckles from super glue.

Static wicks were made from cleaning brush bristles. Dump masts

on each wing tip were drilled out and leading edge, landing and taxi

lights were inserted. Flightpath wingtip navigation light indicators

and windscreen wipers were installed and wing access panels were

blended into the top of wing. Each propeller spinner was reshaped

and drilled out.

Ron's Resin sponsons were fitted and flight deck aircon pack

installed on R/H side. L/H sponson APU bump was made using putty and

the APU exhaust port drilled.

The nose wheel used kit parts with Flightpath rims and flattened.

Main wheels are Ron’s Resin with a contact plate for light wiring on

L/H wheels. Flightpath parts were used to detail the undercarriage

doors and nose wheel strut scissor link.

My Hercules was painted in three tone camouflage (FS34079 Dark

Green, FS34159 SAC Bomber Green, FS34201 SAC Bomber Tan) using Model

Master enamels then sprayed with Future.

Decals were applied using Hawkeye and Aussie Decal sheets.

Walkway lines were painted except around the rudder where decals

were used. Testor’s Dullcote was applied to the aircraft giving the

aircraft a semi matt finish.

Click on the thumbnails

below to view larger images:

Review and Images Copyright © 2002 by

Mick O'Brien

Page Created 14 June, 2003

Last updated

17 March, 2004

Back to HyperScale Main

Page

Back to Reviews

Page

|

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search