|

Dornier Do 26

by

Bryan "Tuck" Tucker

|

|

|

Dornier Do 26 |

Mach

2's 1/72 scale Dornier Do 26 Seaplane is available online from

Squadron

Arguably the most beautiful

flying boat ever manufactured, the Dornier Do 26 was constructed for

Lufthansa to meet the requirement of a trans-Atlantic mail and passenger

carrier.

Dornier by this time had

extensive experience in manufacturing flying boats, as well as the novel

tandem engine approach seen on so many of his aircraft. The rear engines

were hinged upward during takeoff to avoid the propeller tips striking the

water.

|

Kit Summary |

|

Kit |

1/72 Scale Mach 2

Dornier Do 26 |

|

Cost |

USD$60.00 (from

Squadron) |

|

Markings |

Kit decals for two

aircraft |

|

Comments |

Better eat your Wheaties

for this oneÖ.. |

Upon the outbreak of war,

the Luftwaffe took charge of all six Do 26s and utilized them for

operations in the fiords of Norway, as well as general patrol and staff

transport duties. In service, it was armed with a 20mm MG151 in the nose

turret and MG15s in the beam hatch positions and mid-fuselage blisters. No

bombs or depth charges were carried.

The boats were quite weakly

armed and slow, so they were quickly relegated to behind-the-lines duties,

where general attrition and lack of spares caused them to fade from

service.

None survive today.

Mach 2's 1/72

scale Do 26

|

Mach 2 from France has a bad

reputation amongst modelers. This is not undeserved, as their kits are

somewhat crude and difficult to build. Having already built their Arado

232 transport, I had a good idea what I was in for.

The kit is molded in light

gray plastic, and the moldings are rough in texture, soft in detail and

have flash and general imperfections all over.

The clear parts are hardly

that. They are opaque and extremely thick!

This kit was unusual, as it

had a decently detailed cockpit compartment and rear gunner blister

compartment. All bulkheads, seats, radios, navigation tables, control

columns, etc. are included. All other Mach 2 kits I have built have

minimal cockpit detail.

You have the option to build

the kit as either the Lufthansa ĎSeafalkeí (Seafalcon) prototype from 1939

or a military boat used in Norway in 1940. Decals are provided for both

versions. A rudimentary display stand is also included.

Pay close attention to the

instruction sheet for different parts to use between the civil and

military version. The instruction sheet is minimalist, and no painting

guides are provided other than the box top 3-view (and that is only for

the military version!).

I spent the first two nights

of construction removing all parts from the sprues and cleaning them up as

much as I could. This included fixing small shape errors, sanding away

rough surface texture, sanding mating surfaces, etc.

I first glued the outrigger float bay sidewall parts to the lower wing

halves, and then glued the wing halves together. Masking tape held the

parts together until dry. After drying, I removed the tape and began

working on the seams. It took many applications of super glue and setting

solution to fill all the imperfections in the leading and trailing seams,

but I got the worst of them. The wings were then gently sanded all over to

remove more pebbly texture.

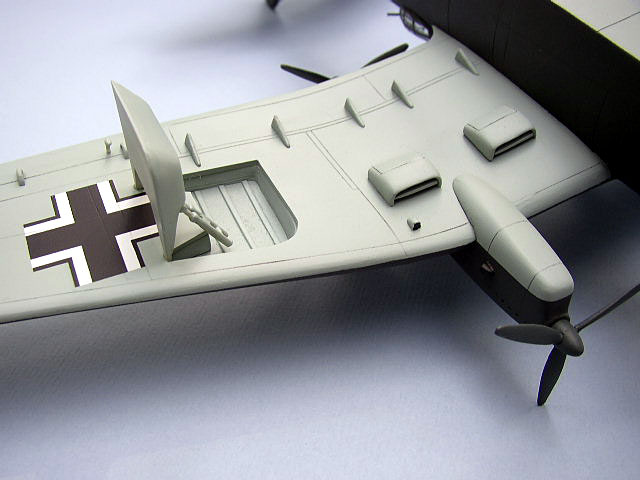

Next I began work on the under wing radiators, two per wing. Luckily,

these parts fit fairly well, with only a little trimming and sanding

necessary for a good fit. I painted the wing surface and radiators at this

time, as they would be very difficult to reach after assembly. I then

added the flap hinge fairings to each wing. These are simple butt joints

and were glued with super glue. I left off the aileron balances until

construction was complete to avoid constantly ripping them off.

I then added the engines to each completed wing assembly. The parts are

designed to give you the option to raise the rear engines to the take-off

position, but this will require scratch building. I did not want the

hassle, so I left my engines in the in-flight position. Each front and

rear engine is assembled in halves, and these assemblies are then glued

onto the wing. Massive gaps and holes were the result of this

construction, so more time was spent applying and sanding filler.

Finally, I plucked up the courage to start the cockpit interior. These

parts suffer from soft detail, but end up making a decent representation

of the front office. I could find not photos inside of the Do 26, so I

cannot comment on accuracy. I painted the interior RLM 02 gray with silver

seats and black instrument panels. The bulkheads offer adequate detail,

but again this is soft. The rear gunners blister station interior was

completed in the same manner.

Now for the decisive moment. The completed cockpit assemblies were placed

in the fuselage for test fitting. I cringed as I started to close the

halves, but was extremely happy to find that they fitted with no

adjustment required! Before gluing the fuselage halves together, I glued

the lower rear gunnerís trough (under the boat at the tail) in with slow

setting glue so I could adjust it. It is impossible to install this after

the fuselage halves are joined, so be careful! If you chose to do the

civil version, this trough is replaced with a fairing (provided). Again,

all completed subassemblies were filled, sanded, and cleaned up to remove

as many imperfections as possible.

The horizontal stabilizers were assembled without incident. By now, the

drill of filling seams and sanding was well established, and these items

were quickly completed. I also assembled the propellers at this time. I

would like to meet the Mach 2 designer who decided to make each propeller

blade separate! Each (count them Ė 12) requires massive cleanup, including

bending, trimming, etc. The prop spinners and hubs were awful as well. I

highly recommend replacing these with spares box replacements, but I was

on a mission to use all of the kitís parts, no matter how bad they were!

The completed props were painted according to standard practice. The

spinner is RLM 70 and the propeller blades, which are metal, are RLM 70.

Now for the next challenge: joining the wings and horizontal stabilizers

to the fuselage! The gull wing attachment to the fuselage of the real bird

is graceful, elegant, and aesthetically pleasing. No, so on the plastic

kit. I glued the wing on with super glue, then made three separate

applications of filler and sanded away at the joints. The process was

repeated, albeit smaller scale, on the horizontal stabilizers. I left off

the support struts until after painting to ease final assembly.

Before painting, the entire model was again wet sanded with progressively

finer papers in an attempt to smooth out all final flaws. Then on to the

paint booth.

All

paints were Model Master Acrylics. All military seaplanes were painted RLM

72 and 73 over RLM 65. Since these paints have a tendency to lift off with

masking, I used Tamiya masking tape for the splinter pattern. I highly

recommend this tape when using the Model Master Acrylics. Since I have

been using the tape, I have had minimal lift of paint. All

paints were Model Master Acrylics. All military seaplanes were painted RLM

72 and 73 over RLM 65. Since these paints have a tendency to lift off with

masking, I used Tamiya masking tape for the splinter pattern. I highly

recommend this tape when using the Model Master Acrylics. Since I have

been using the tape, I have had minimal lift of paint.

I first sprayed the entire model with RLM 65 as a primer coat to see if

there were any flaws. Letís just say this, there were many, and I fixed

them as best I could. I re-sprayed the RLM 65 color. I then masked the

upper/lower demarcation line as the real aircraft had a hard edge between

the colors. I covered all the lower areas to remain RLM 65 and sprayed the

upper surface colors.

I shot the kit with Model Master Gloss in preparation for decals. Iíve had

mixed results with Mach 2 decals, and I can say these were a pleasant

surprise. On my sample, there was no carrier film between any of the

fuselage code letters, making the risk of silvering non-existent. All wing

and fuselage crosses went on without incident, and all reacted well to

Micro-Sol. I chose to use aftermarket swastikas.

The canopies were then cleaned of flash, test-fitted, and trimmed to fit

the fuselage. Ambroid Liquid Mask was used, slathered on in three coats.

Each window was cut using a sharp No. 11 blade, and the canopies painted.

After the mask was removed, each clear part was dipped in future. This

cleared up the windows significantly, but made the window frame color

deepen significantly. This makes the canopy parts look like they were

painted with different paint. I was quite tired of this kit by then, so I

lived with it. Micro Kristal Kleer was used on all small windows and

portholes. After a shot of Dullcoat, the rear struts were installed,

canopies glued, and display stand assembled. DONE!

Well, it has been over five

months since construction started, and I tired of it many times, but

another Mach 2 dragon has been slain. I can proudly say I used every part

the kit offered, from aileron balance horns to machineguns. These kits are

indeed tough, but Mach 2 has a nasty tendency to produce kits that no

mainstream kit maker will ever produce, making their products curiously

desirable. However, they are so tough that they wear you down, and I swear

I will never do another one. Dang!, I forgot the Ju 352 in my stash. Itís

looking at meÖmake it stop! AAARRRGGGH!!!

Seriously, itís tough, but it can be done. Itís also the only injected

molded kit in town of this subject, so good luck!

-

The Monogram Painting Guide

to German Aircraft 1939-1945, Creek and Hitchcock

-

Warplanes of the Third

Reich, William Green

Click on the thumbnails

below to view larger images:

Model, Images and Text Copyright ©

2003 by Bryan "Tuck" Tucker

Page Created 29 July, 2003

Last Updated

17 March, 2004

Back to

HyperScale Main Page |

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search