|

Videmus Agamus

“We see, let us strike”

F-111C

|

|

|

F-111C |

by Anthony Papadis

HyperScale is proudly supported by Squadron.com

I was recently given a Hasegawa

1/72 F111C kit, as the previous owner had decided that after ten years

he was never going to finish it, and that I would probably appreciate

the kit, as I have a known soft spot for the “Pig”.

I will not review the kit here,

as the kit is neither new nor unknown, suffice to say that when care is

used, the kit assembles quickly and with few traps for the unwary. In my

opinion, the F-111 kits are some of the best detailed 1/72 kits Hasegawa

has produced and are easily the best kits on the subject in 1/72. Having

said that, there is always room for improvement in any kit, and I chose

to add a few extra touches during this build.

I had decided early on to mount

the kit ‘in-flight’ as this is really the only way to appreciate the

sleek lines of the F-111. I wanted my pig to carry a pretty tough

looking load and to be going quick, two things the Pig does well.

The kit’s previous owner had

already begun the kit when it was handed to me. The fuselage had been

assembled, but otherwise, the majority of the kit was intact and still

on the sprues. Unfortunately, the cockpit was poorly painted and the

instrument decals had been applied directly to flat paint without a

sealer coat, with the result that they had curled up. There was no other

option but to strip the cockpit. After carefully prying loose the seats,

control columns and instrument panel, the fuselage and other items were

all given a spray with Mr Muscle oven cleaner, and these parts were

slipped into a resealable plastic bag and set aside.

Note: Mr Muscle fumes are extremely

caustic, Make sure you work in a well ventilated area and use

appropriate skin and eye protection when using it!

Whilst I was waiting for Mr

Muscle to do its thing, I began to work on the other sub-assemblies. I

cleaned up the horizontal stabilisers, a few quick strokes with a

sanding stick was all that was required. Since this Pig would be

depicted in flight, I would not require the undercarriage components. I

cut the undercarriage components and put these into the spares box. This

reduced the parts count considerably and really only left the

afterburner and wings to assemble.

Wings

Since I wanted this F-111 to be

going like the proverbial cut cat, the wings would have to be swept back

to 72.5º and the flaps and slats would have to be tucked in. I t seems

ironic that we, as modellers are always complaining when things like

flaps and slats are not moulded separately, and yet here I am gluing

the separately moulded flaps and slats back in, there’s just no pleasing

some people!

The first problem was sweeping

the wings back. The Hasegawa F-111 kits do not (thankfully) feature

‘swinging’ wings. They instead have two slots in the wing root which

enable the builder to choose from one of two options, fully forward with

16º sweep-back or pinned fully back at 72.5º, as I wanted.

The instructions make no mention

of the fully swept back option, however the second slot corresponds with

this position. To allow the wings to fit however, part of the wing seals

will need to be removed. Hasegawa have thought of the modeller here and

there is actually a shoulder behind the wing seal portion inside the

fuselage. All that was required was for the plastic to be trimmed away

up to the shoulder, and there would be an opening corresponding to the

fully swept back position.

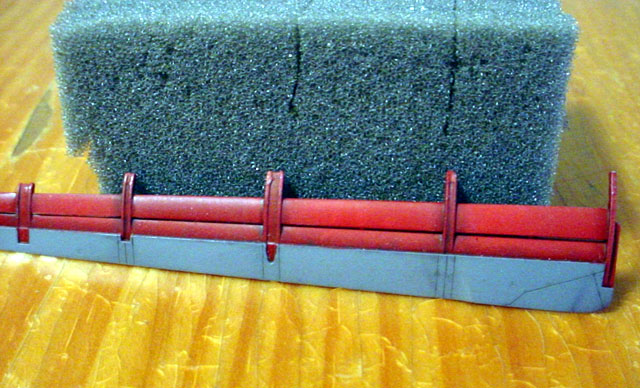

Pic 1 Wing seal shoulder

My next hurdle was fitting the

flaps/slats back into the wing. Hasegawa has done a brilliant job

depicting the slats and double-slotted Fowler flaps, however gluing

these back into the wing took some repeated filing and test fitting.

Pic 2 Wing flap portion to be

removed

I began by removing the upper

row of flap segments on parts E5 and E6 as these fold into the wing when

not deployed. After some careful sanding, the flaps fit into the wing.

The slat guides at the front of the wing were sliced off with a new

scalpel blade, as these prevented the slats from fitting flush with the

leading edge of the wing. After more test fitting, I discovered that the

slots at the front of the wing needed just the slightest sanding so that

the slats could sit flush. The wings were now assembled and set aside.

Fuselage

After about four hours, removed

the fuselage and other bits from the yucky jelly like mess that was the

dissolved paint/Mr Muscle. A few minutes scrubbing with an old

toothbrush and cold water rewarded me with some pristine plastic. Once

the fuselage was thoroughly dry, I sprayed the cockpit, seats and

instrument panel FS 36231 (Dark Gull Grey). I also sprayed the intakes,

intake cowlings and inlet spikes (D4, D8) semi-gloss white. I decided to

leave the inlet spikes and cowlings off until painting was finished.

I had a spare F-111C decal sheet

handy (‘gotta luv garage sales!) and I used cockpit decals from this

sheet. These were then sealed with a coat of matt varnish. The kit does

not include aircrew figures, so the spares box was robbed. I modified

the helmets to depict the more modern ‘lightweight’ items currently used

by sanding off the visor covers. Whilst I was at it I made a radar

indicator hood from some shaped sprue. RAAF F-111 seats have black

lamb’s wool covers. I painted the seat cushions black to depict this.

The control columns are also matt black with semi-gloss black grips. The

canopy bow part (B17) was painted and glued into the canopy. Once the

canopy sprue stubs were sanded off, the whole thing was dipped into a

tray of Future and set aside to dry.

Pic 3 Cockpit

Wheels-Up

I glued some sprue strips along

the inside edges of the nosewheel bay to support the nosegear flipper

doors (A9, A10) when they were glued into the closed position. I also

glued some sprue inside both flipper doors themselves to re-enforce them

further.

The main gear door (B26), which

also functions as a speedbrake, was simply glued into place. The second

door (B28), will leave a gap through which some undercarriage detail

will be visible (this is how the real thing is too!). I used the rear of

the kit undercarriage well (A18) but cut the lower “V” shaped structure

away and repositioned it at 90º. The two long thin arms were also cut

off and replaced with some stretched sprue, also re-positioned at 90º to

their original position. Most of this will not be visible when the rear

door is glued on.

Pic 4 Rear main gear door gap

The final part was to glued the

tail bumper guard (B9) apart from its actuators and glue it flush into

its fairing between the engines at the lower rear fuselage. This unit

always extends and retracts in concert with the undercarriage.

Pic 5 Tail bumper guard

Final Assembly

I replaced the kit LCOSS (gunsight)

with thin clear acetate from some blister packaging. The canopy was now

attached and the masking applied. The ventral strakes and ‘figure 8’

panel (fuel dump panel) was added and seams filled. The vertical fin and

the stab fairings were next. I cut the rudder out and repositioned it

deflected to the right. I replaced the kit nose pitot probe with a

hypodermic syringe.

Pic 6 Rudder deflection

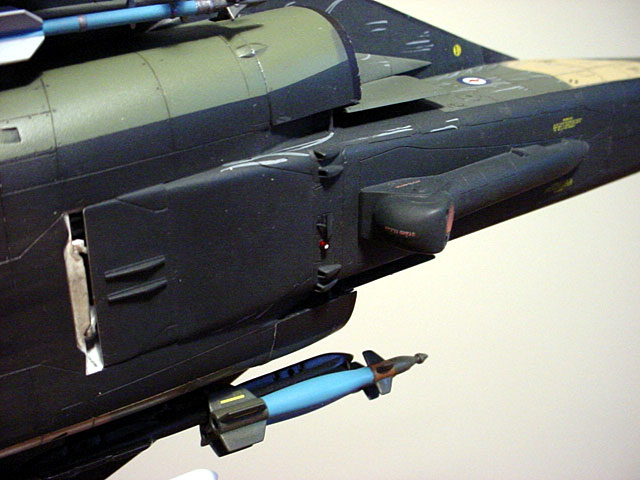

Ordnance

I wanted an interesting load,

but not necessarily one that is typically carried. This ‘Pig’ is

carrying practice ordnance, as evident by the blue bands and bomb

bodies. The ordnance was taken from the different Hasegawa weapons sets,

while the kits provided the pylons and the BRU-3 (bomb rack ) and LAU-7

(missile rail).

Although not typically carried

in multiples on the BRU-3, when used, Mk.82/GBU-12’s are usually carried

in the ‘slant 4’ configuration, which means that the inner shoulder

stations are not used. GBU-12’s are too long to allow more than 2 per

BRU-3.

The AGM-84 Harpoon is also used

in configuration with a data link pod. Since this is not a warshot

round, I saved myself the trouble of having to scratch-build one.

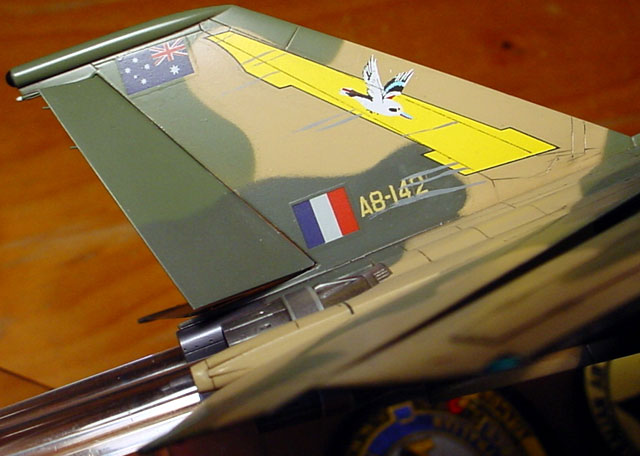

I wanted to depict a 1SQN

aircraft in the SEA (South East Asia) scheme, but with the big yellow 1

which some aircraft sported for a little while. I remembered that

Aussie Decals had issued these markings some time ago but these are no

longer available. Luckily, the ever helpful Dave Turner came to my

rescue with these decals. Whilst doing the research, I discovered that

the tail art varied depending on the aircraft. The stylised yellow one

features a Kookuburra (an Australian native bird) diving down its

length. The variation is with the orientation of the bird’s body. The

decals depict the bird’s body pointed down vertically. Most pictures

that I found showed that the Kookuburra’s body was rotated slightly

upwards instead of straight down. I came across a picture of A8-142

which had the Kookuburra shown as depicted in the decals, so that is the

aircraft I would build.

Aussie Decals 1/48 sheet

(48004) has the Kookaburra printed separately and a full complement of

tan and green numbers allowing the builder to make any tail number that

they want.

Pic 8, A8-142 in a very clean

state

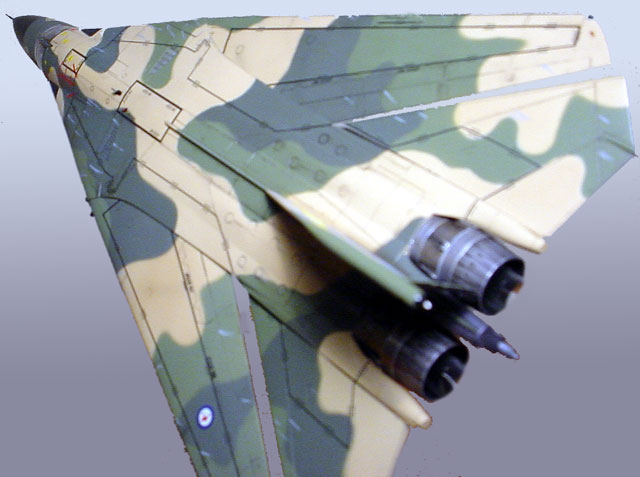

I used Gunze Sanyo paints H309 &

H303 for FS34079, FS34102 but used the Light Tan H27, instead of the

FS30219 as this tan looked a little too red and dark. The black used was

Tamiya NATO black, as straight flat black would be too dark, and I

wanted to contrast the radome and glove antennas which were painted in

semi-gloss black.

I used the Aussie Decals tail

art as well as their wing and fuselage walkways. The Hasegawa decals

provided the RAAF roundels (the ‘rats’) and the flag, as well as all the

stencilling. I needed to have “A8-142” in white for the nosewheel

flipper doors and the same in tan and dark green for the fin, tan

letters on the dark green and vice versa.

Richard Chafer of Gekko Graphics

was able to help here by supplying the white door numbers.

Unfortunately, the Aussie Decals 1/72 sheet does not supply a full

complement of numbers in the tan/green colours. I found an old

Roodecals sheet that had what I needed and I was able to mix’n’match my

A8-142 using this sheet. Incidentally, this sheet also included 3 x

F/A-18 Sqn’s as well as 2 x F-111 Sqn’s as well as a FULL complement of

numbers so that you could make any tail number that you want, value for

money indeed!

I gave the panel lines a dark

brown wash using thinned oil paints. The area behind the main gear was

weathered with several light brown, black and grey streaks to simulate

the leaking oil, fuel and dirt which accumulates here

The kit had a coat of Testor’s

Dullcoat applied and the nav lights, formation lights and the wings and

ordnance were added. The cowl intakes as well as the stabs were also

glued into place.

I now added the ‘goop’ streaks

(anyone who has worked on the pig knows all about these!). ‘Goop’, or to

give it its formal name of ‘reversion’ is a two part caulking compound

used to seal panels on the aircraft. When subjected to the high skin

temperatures of supersonic flight (a “Mach Run”) the compound breaks

down or ‘reverts’ back to its uncured liquid state. It then oozes out of

gaps between panels or injection holes, creating ‘goop’ streaks all over

the airframe. I used some thin grey paint and a fine brush to reproduce

these in the usual locations.

Pic 9 “goop”

I added new VHF, IFF and UHF

antennas from plastic card. These antennas have protective tape at their

leading edge to prevent them delaminating (peeling apart). I also

drilled out the upper and lower rotating beacon locations and simulated

these with some clear rod painted Tamiya clear red. These beacons are

always on and extended when the aircraft is flying (in peace time

anyway) I also depicted the ECS cooling door, a small door behind the

AN/ASQ-26 PAVE TACK pod, using some aluminium sheet and stretched sprue.

This door is always fixed open. Finally some stretched sprue was used to

simulate the alpha/beta probes on each side and underneath the radome.

The kit has 8mm acrylic tubes

fed into the afterburners. The rods simply slide into 8mm holes drilled

into the 3mm Perspex stand, which in turn is screwed to the wooden base.

The whole thing can be dismantled for transport in under a minute.

When the F-111 has the wings

swept beyond 45º the spoiler panels in the wings are ‘locked-out’ and

the primary roll control comes from the horizontal stabilators (‘stabs).

I have deflected the rudder to the right in order to put in ‘top

rudder’, as if the aircraft is performing a knife edge pass at an

airshow whilst the ‘stabs have been deflected differentially to give the

model the impression of motion, in this case mid-roll.

As I have said, this is a sweet

kit which doesn’t have any really bad pitfalls for the unwary. The kit

is well detailed out of the box and is a real stunner when some extra

work is put in.

I cannot finish without thanking

the following people, without whose help this project could not have

been finished,

Take a bow:

Andrew Dunstone: The kit! And

info

Kevin Curtis:

Pictures and info

Dave Turner: The Tail

Art decals

Richard Chafer: The

nosewheel door decals

And my long suffering

girlfriend for putting up with me!

Enjoy!!

Click

the thumbnails below to view larger images:

Model, Images and Text Copyright ©

2003 by Anthony Papadis

Page Created 31 October, 2003

Last Updated

17 March, 2004

Back to

HyperScale Main Page |

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search