|

1/32 Hasegawa F-16C Conversion

F-16C Barak

by Michael Ibbotson

|

|

|

F-16C Barak |

Hasegawa's

1/32 scale F-16C is

available online from Squadron

You cannot be interested in

modern military history without reading a great deal about Middle Eastern

conflicts.

From a modelling

perspective, such conflicts offer a wealth of aircraft colour schemes. In

a world where most air forces paint their aircraft grey, Middle Eastern

countries persist with far more interesting two or three tone colour

schemes. In this regard, aircraft from the Israeli Air Force (IAF) have

always attracted me. The IAF use a striking paint scheme for their modern

aircraft involving light grey undersides and swirls of yellow/sand, brown

and green on the upper surfaces.

I chose to build an Israeli

F-16C ‘Barak’ using the 1/32 Hasegawa kit. Construction of the F-16 is

fairly straightforward, with the majority of parts fitting very well. On

the down side, the majority of panel lines are raised, so I was forced to

sand them off. As was the trend when the kit was first produced, there are

some recessed panel lines but they are very deep and somewhat unrealistic.

The cure for this was to sand the areas around the recessed lines until

they were very shallow, therefore producing a better scale effect. This is

particularly important for the panel lines on the spine of the aircraft.

The good news is that the plastic is very thick in these areas, thus

allowing a lot of sanding without going through the surface. Having

pointed out this bad area of the kit, it is worth noting that Hasegawa

most certainly got the overall shape of the jet correct. There is no doubt

that once built the Hasegawa F-16 looks like the real thing, which cannot

be said for the Revell kit.

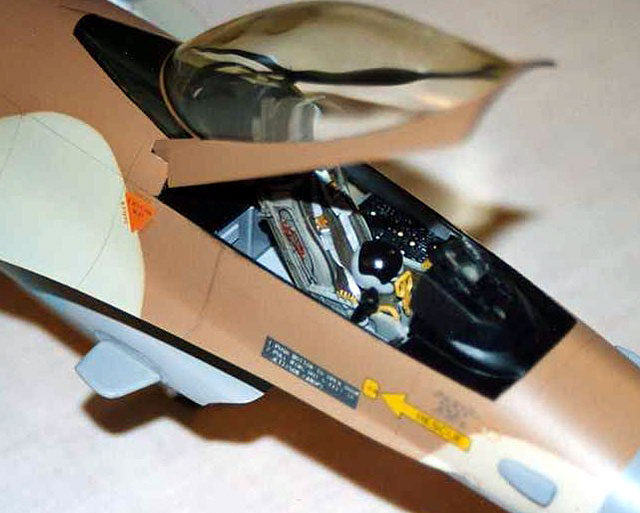

As normal, I started with cockpit construction and I had to make sure that

I chose the F-16C instrument panels because the F-16A instruments are also

supplied. I think the cockpit looks good and doesn’t need a resin

replacement. I used a spare ACES II ejector seat from a Tamiya F-15C kit,

which is far better than the white metal seat provided by Hasegawa.

I cut some lead strips from

the top of a brandy bottle and some 1/32 scale etched-brass buckles from

Reheat to create the harnesses. I liked the helmet that came with the

original kit, so I made it and placed it on the ejector seat. The only

really hard work in the cockpit area was the canopy. I had to remove a

very large seam, which required a great deal of sanding. Toothpaste was

used to polish out all of the sanding scratches after the seam had been

removed. Once done, I sprayed the inside of the canopy with Tamiya clear,

which had been mixed with a drop of yellow. This gave the canopy an

authentic golden tint. The canopy was then dipped in Future and allowed to

dry in a very warm room. It is important that drying occurs quickly

because the Future will dissolve the Tamiya clear, thus generating yellow

streaks.

As I was building a late model Israeli F-16C, I used the ‘new tool’

exhaust components that come in the kit. They replicate the petals found

on the GE 110 engine, which requires more air than its predecessor and

consequently needs a wider air intake. To solve this problem on the model,

I purchased the Seamless Suckers wide-mouth resin update set. According to

the instructions, it should be possible to simply slot this resin part

into the kit to replace the plastic intake components. However, the resin

part is enormously over scaled in the vertical dimension and I couldn’t

work out how to modify it easily to fit. Having said that, the redeeming

feature of the resin component was that the mouth of the inlet did have

the correct width and height. So, what to do? After much thought, I cured

the problem by cutting off the rear of the resin component and discarding

it.

I used the inlet section from the plastic kit as a cutting guide such that

the resin part was the same length as the plastic component. I sanded the

top and bottom of the resin component until it had the correct vertical

size. The resin is so thick that I had no problems sanding many

millimetres of material away. The sanding process had the added advantage

that it removed all the ugly recessed and raised surface details from the

resin block. I then glued the resin part to the front of the inlet ducting

of the plastic kit using super glue. To my great joy, I discovered that

the inner dimensions of the resin part matched the diameter of the plastic

component. I glued strips of plastic onto the kit to match the width of

the fuselage to the width of the resin inlet.

Once done, I applied a lot

of putty both in and out of the inlet. Also, the upper splitter plate on

the inlet is way too long and needs to be carved and sanded into a more

accurate shape. I spent a lot of time sanding, washing, painting and

refilling to get a smooth finish (F-16C_intake_spray.jpg). Finally, you

end up with an air intake that you can look into without any apparent

seams. I also added the little ECM winglets to the sides of the intake,

which were scratch built from thick plastic strips (F-16C_intake.jpg).

Other scratch built additions included the slightly enlarged ECM bulges on

the nose (carved plastic), a small starter intake under the right wing

root (built up from plastic strip), the ECM probes on the wing leading

edges (plastic rod) and several parts on the tail (carved plastic and

brass rod). I had great fun finding the reference material!

Click the thumbnails below to view larger

images:

The fit of the nose cone to

the fuselage is not very precise. I had to do some careful filling and

sanding to get the nose to fit properly. I filled the nose cone space with

metal weights to prevent building a tail sitter, which isn’t a problem if

you use the white-metal seat provided by Hasegawa.

Two

tail planes are supplied in the kit and I used the ‘C’ version, which is

the one with the large base and the recessed panel lines. The Israeli

Barak has a parachute housing at the rear of the tail base and I used the

Seamless Suckers resin parachute housing as a way of modify the kit. Two

tail planes are supplied in the kit and I used the ‘C’ version, which is

the one with the large base and the recessed panel lines. The Israeli

Barak has a parachute housing at the rear of the tail base and I used the

Seamless Suckers resin parachute housing as a way of modify the kit.

The Seamless Suckers resin

part is a replica of the Norwegian F-16A tail extension. It has the

correct length, height and shape but is too narrow for the F-16C. I glued

the resin tail base extension onto the plastic kit component after

removing the short tail extension that comes as standard on the kit part.

I then thickened the resin part with plastic sheet and smoothed the

surface with putty. Again, the very roughly molded recessed panel lines

and ECM bulges on the resin component were filled and sanded and more

accurate parts scratch built from plastic strip and rod.

I shortened the front undercarriage strut slightly by cutting 2 mm from

the top and filing the wheel flat at the bottom. This gave the F-16C a

level appearance, which simply looks better! In doing this, I made the

centre-line fuel tank hang too low, so I sanded 1 mm from the base of the

pylon before attachment.

I did not add the large

under-wing fuel tanks but I think the kit offerings look very good if you

did want to attach them. I also chose not to add many weapons to my model

as they spoil the beauty of the F-16. The exceptions were the AIM-9Ls on

the wing tips, which I scavenged from a Tamiya F-15 kit.

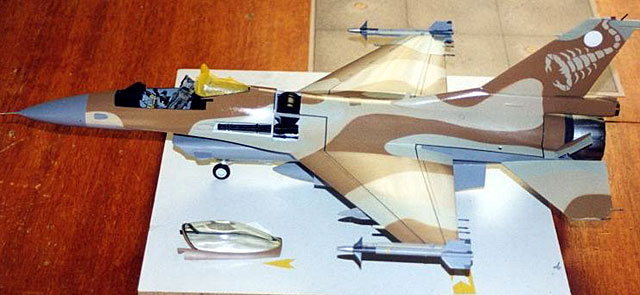

The F-16 has a three-tone

camouflage scheme on the upper surfaces and a light ghost grey underside

(F-16C_rear.jpg). The aircraft was painted using Gunze-Sangyo acrylics.

The grey underside was painted with light ghost grey (H308, FS36375) and

then the top surfaces were sprayed with yellow (H313, FS33531). The pale

green was concocted by mixing G-S duck-egg green (H74) with light ghost

grey and a drop of flat white. The quoted colour for the light green is

FS34424, which is supposedly the same as G-S H74. However, H74 is far too

bright and needed toning down with grey and lightening with white. The

exact mix is unknown as I played with the mixtures until I felt that I had

matched the colour to my references. The final colour for the camouflage

pattern was brown (H310, FS30219). The nose cone was painted neutral grey

(H306, FS36270), as were the flat side panels inboard of the horizontal

stabilizers, the wing tip pylons and the insides of the air brakes. All

the walkways were spray painted dark grey after masking (H333). This was

necessary because the walkways that come with the kit decal sheet are

light grey, which is appropriate for USAF aircraft but not IAF planes. I

spray painted the large scorpion on the tail using a template constructed

by correctly scaling a photocopy of the tail plane and then cutting out

the shape of the scorpion. The small white disk at the top of the tail was

also sprayed using a circular mask. The model was then coated in gloss

prior to applying decals.

Most stencilling is in English so the decals from the kit can be used.

Stars of David, squadron insignia and tail codes are available on the

Cutting Edge F-4 decal set, which is excellent. The decals are very thin

and react with Set and Sol beautifully. Other features such as the red and

white chevrons on the tail base were made by cutting triangles of red and

white from the Cutting Edge decal sheet and placing them in layers onto

the model. I then drew black edges around the decals using a fine

permanent marker pen. After applying the first dull coat, I re-applied the

panel lines using a sharp HB pencil. Following from early modelling

experiences in which I tried to re-scribe panel lines into plastic, I

simply don’t do it any more. I personally think that fine pencil lines

give a far better scale effect than re-scribed lines. I guided the pencil

using Tamiya tape or the edge of a ruler (when I had access to flat

surfaces such as the wings).

Weathering was done using

overcoats of flat clear mixed with a drop of H313 and a little H308. This

flattened the surface, made the pencil lines blend into the model and

added colour balance. I then used pastels to add some grime in places.

So there it is, a 1/32 scale

replica of an IAF F-16C. I highly recommend the project. As far as 1/32

scale projects are concerned, the F-16 doesn’t even come out that large

when finished!

Click the

thumbnails below to view larger images:

Model, Images and Text Copyright ©

2003 by Michael Ibbotson

Page Created 17 October, 2003

Last Updated

17 March, 2004

Back to

HyperScale Main Page |

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search