|

Flying Dorito

in 1/48 scale

A-12 Avenger II

by "Bondo" Phil Brandt

|

|

|

A-12 Avenger II |

HyperScale is proudly sponsored by Squadron

The distinctively shaped A-12 "Avenger II", popularly known as the "Dorito,"

was the Navy's mid-Nineties stealth answer to the Air Force's F-117.

Planned to replace the entire A-6 fleet, the joint General

Dynamics/McDonnell Douglas venture instead suffered the ignominy in 1991

of being the largest DOD contract ever cancelled.

At a cost of approximately

$100 million per airplane, this was a Very Big Deal...620 to the Navy,

283 to the Marines, and even the Air Force considered a buy of 400! The

financial repercussions have lasted over a decade, as the builders sued

the DOD for axing the program for "convenience of the government", not

because of cost overruns and non-performance, as DOD had claimed. The

courts ruled in favor of GD/McD in 1998, allowing the contractors to

recover almost $ 3.9 billion in engineering/construction cost incurred.

The DOD, naturally, appealed, and the appeal is still under

consideration.

Fortunately the full scale Avenger II mockup was never destroyed by

General Dynamics and has been fully restored by volunteers at Fort

Worth, Texas. Additionally, there is a wealth of reference material,

including detailed structural isometric drawings, on the Internet.

Collect-Aire's

1/48 scale Avenger II

|

Down and Dirty

With the rollout of the

Collect-Aire Avenger II, weary employees of the Weirdness Works Division

of Bondo Industries feel as they've been in a barroom fight. But, all's

well that end's...

The "Patient"

Presents...

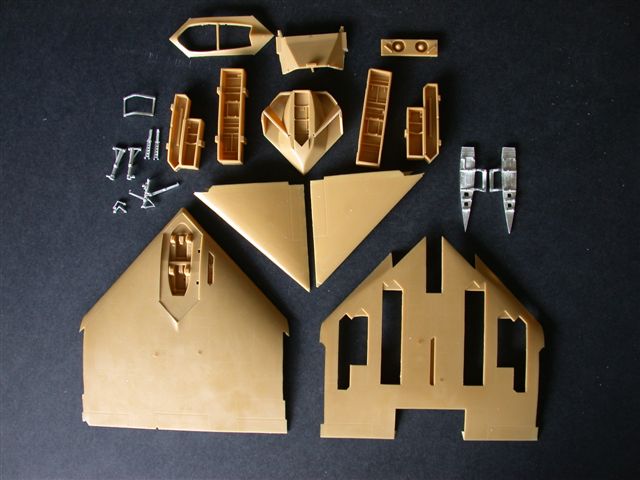

The kit's overall molding is very good, with

exceptionally smooth surfaces and petite, crisp engraving that rivals

any of the Big Dogs. But, then there's the problem of fit, which is

always troubling when there are large sections of resin that solidify at

different rates, and the Dorito has such large resin components in

spades!

When I read an earlier construction article

on the A-12 which stressed the poor fit of the outer wings to the main

wing/fuselage, I decided to fold the wings, which not only minimizes a

group of modeling sins, but also breaks up the large, monochromatic

surface of a flying wing design. Admittedly, folded wings are offered as

a kit option, but the way-out-of-scale sheetmetal thicknesses, relative

lack of detail and clunky cast metal hinge mechanisms ruled out the use

of stock kit components unless one could stand a distinctly toylike

appearance, and " 'Homey' don't play dat" here at Bondo Industries.

Wingfolds

The stock OOB skin

thickness scaled out to about four inches! Industrial strength

Dremmeling shaved the wingskin surrounding the wingfold bulkheads to

cardstock thickness. Now that the skin was scale, none of the thick,

stock resin bulkheads fit.

Four new bulkheads were

scratchbuilt from plastic sheet and detailed to include hinge locking

mechanisms. The cast metal hinges themselves were modified to fit behind

the new bulkheads.

Click on the thumbnails

below to view larger images:

Weapons Bay

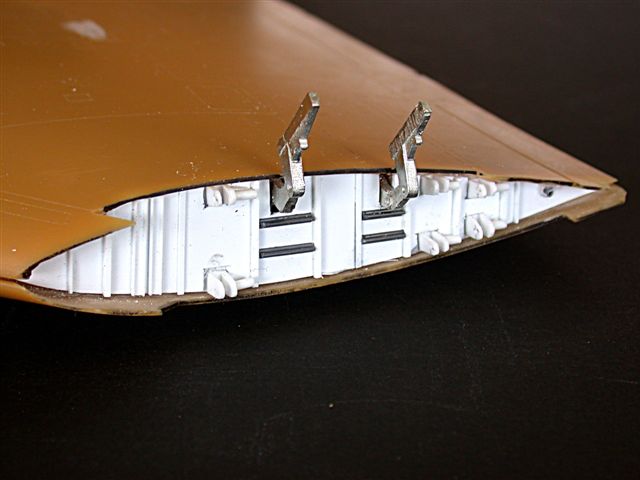

It was decided to pose one

weapon bay open on each side of the airframe.The kit's large bays were

painfully plain, so I substituted the old High Flight aftermarket F-117

LGB bay. The nicely detailed bay came with cast metal trapeze arms, a

detailed resin pylon and distinctive GBU-27 "bunker buster." The AAMRAM

bay suffered the same lack of detail, so I adapted the multi-piece

missile erection trapeze from the Monogram F-102 kit.

Click on the thumbnails

below to view larger images:

Cockpit/Canopy

Next to the wingfolds, the

large, one-piece canopy was the biggest headache. Instead of simply

creating the canopy and surrounding sheetmetal as one vacuformed piece,

the master modeler unfortunately chose to do a large resin canopy

perimeter, a separately vacuformed canopy and cast metal canopy arches.

Fitting the complex contours of the trimmed canopy to the resin

perimeter was excruciating and required delicate masking and filling of

the mating surface with Blue Acryl. The interior canopy arches were

separated from their clunky joining members and individually trimmed and

fitted to the canopy rails. A scratchbuilt transverse strengthening beam

was also fitted. The funky, hollowed out inside area of the resin canopy

perimeter was filled with A&B epoxy putty, adding much strength to the

whole assembly.

Click on the thumbnails

below to view larger images:

Posing the large canopy

open, as in the case of the wingfolds, clears up fit problems and allows

for detailing of the large cockpit. F-4 resin side panels were adapted

to add to the "busy-ness factor." Also added were resin aftermarket

seats.

As per custom at Bondo Industries, multiple iterations of automotive

lacquer primer, applications of Blue Acryl and wetsanding through 8000

grit preceded multiple color coats of Model Master Acryl Light Ghost

Grey. Next, three coats of Model Master gloss clear paved the way for

decalling.

The first nasty surprise

here was when the properly stored Collect-Aire decals (European "MPD"

brand) disintegrated in water. Collect-Aire's Lou Maglio kindly sent two

extra sheets, but these also tended to break up. Applying MicroFilm to

the decal sheet saved the day. Low viz F-18 stencils were added to break

up the airframe's significant top area. Flat Testors Acryl was "dusted"

on which blended in the decals nicely.

Although only the full scale mockup of this innovative-but-expensive

aircraft remains, the program was truly a going deal, not pie-in-the-sky

machinations of aeronautical engineers. This largest of all DOD

cancellations has been fully documented in the book, "The $5 Billion

Misunderstanding; the Collapse of the Navy's A-12 Stealth Bomber

Program" by James P. Stevenson.

Click on the thumbnails

below to view larger images:

Model, Images and Text Copyright ©

2004 by Phil Brandt

Page Created 13 June, 2004

Last Updated

14 April, 2005

Back to

HyperScale Main Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search