|

Hasegawa 1/48 scale conversion

Post-Kahu

A-4K Skyhawk

|

|

|

A-4K Skyahwk

Royal New Zealand Air Force |

by

Anthony Papadis

Hobbycraft's 1/48 scale A-4E Skyhawk is

available online from Squadron.com

The A-4 Skyhawk is an aircraft that almost needs

no introduction.

Designed by ‘Ed’ Heinemann, the aircraft was

affectionately referred to as ‘Heinemann’s Hotrod’

and the ‘Bantam Bomber’ due to its spritely

performance and diminutive size. The aircraft has

seen conflict in several theatres, including

Vietnam, The Middle East and the Falkland Islands,

and has served the in numerous armed forced across

the globe.

My model depicts a Royal New Zealand Air Force

(RNZAF) A-4K “Kahu”, and is painted in the overall

green, the final scheme these aircraft wore before

they were retired. The aircraft depicted is NZ6201,

which was involved in a potentially fatal incident.

On the 20th March 2001, this aircraft struck a

110,000Volt power line whilst on a low –level

navigation exercise. The collision almost tore the

fin tip completely off.

Fortunately, the pilot was able to safely recover

the aircraft to RNZAF Base Woodbourne, which was

nearby. The fin tip was still hanging by a few

threads on the starboard side!

This kit is the

Hobbycraft 1/48 A-4E/F “Aggressor”. The Hasegawa kit

surpasses the Hobbycraft kit in both detail and ease

of conversion to A-4K, however I have used this kit

as it was bought for a very modest sum thanks to a

swap and sell at the local model club.

Whilst the Hasegawa A-4E/F kit contains just about

everything you need to build a “Kahu”, the

Hobbycraft kit has several deficiencies which I will

outline below. Although the list may seem extensive,

the majority of the items listed were fashioned from

common modelling items and each took no longer than

a few minutes to add or correct.

My changes/additions included:

-

Improving the

rear cockpit shelf behind the seat

-

Adding a pilot,

whose head was re-positioned and oxy hose added

-

Hud glass

-

Adding the VOR

antennas to the fin

-

Adding the rear

ECM antennas

-

Adding the strobe

light to the upper fuselage

-

Replacing all

blade aerials with plastic card

-

Re-positioning

the Nav beacon from the lower left undercarriage

fairing to the right fairing

-

Adding the

wingtip ECM antennas

-

Adding the

underside wingtip lights

-

Adding the

wingtip navigation lights

-

Detailing the

brake parachute opening mechanism

-

Adding the pylon

sway braces

The kit instructions are brief, which posed no

problems. Construction is both straight-forward and

brief.

Starting with the cockpit, a few additional details

were added. The “Kahu” was upgraded substantially in

comparison to the original A-4E. They were fitted

with an APG-66 radar, which is what is fitted to the

F-16. The instrument panel also differs greatly in

that it has two Cathode Ray Tubes (CRT’s) ‘TV’

screens. I decided that since this was to be a

canopy down kit in a flying pose, the extra effort

involved in making the new panel would be wasted as

it would not be seen. This would also be true of the

area behind the seat as it turns out as the canopy

framing obscures this area as well!

This

picture shows the pilot installed in the

‘office’ with the head moved to the left and

a scratchbuilt oxygen hose added complete

with the microphone lead. I have also added

a small HUD glass from some clear acetate. This

picture shows the pilot installed in the

‘office’ with the head moved to the left and

a scratchbuilt oxygen hose added complete

with the microphone lead. I have also added

a small HUD glass from some clear acetate. |

Here

is a picture of the added oxy hose. I

wrapped 8 Amp fuse wire around 16 Amp fuse

wire and added the mike lead from stretched

sprue. The rings were made from some wine

bottle foil. Here

is a picture of the added oxy hose. I

wrapped 8 Amp fuse wire around 16 Amp fuse

wire and added the mike lead from stretched

sprue. The rings were made from some wine

bottle foil. |

Another

view, after painting. The oxy hose was

painted dark grey and then dry brushed with

a lighter shade. The mike lead was then

picked out as were the green velcro bands Another

view, after painting. The oxy hose was

painted dark grey and then dry brushed with

a lighter shade. The mike lead was then

picked out as were the green velcro bands |

|

The original kit tub to which was added a

basic throttle quadrant and a scratchbuilt

canopy actuator bay. The rear cockpit

bulkhead had the noise absorbent quilting

added using some ‘sparkling white wine’ foil

and bits of plastic strip and fuse wire.

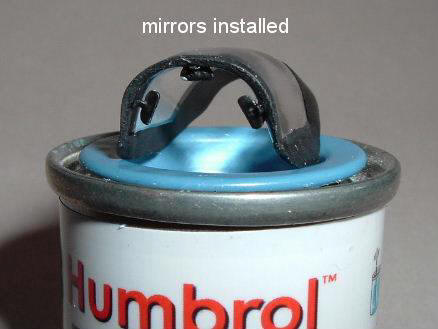

I

also added a small map to the instrument

coaming as well as the seat ejection handle.

The canopy interior had some rear view

mirrors installed after it was polished and

dipped in Future. I

also added a small map to the instrument

coaming as well as the seat ejection handle.

The canopy interior had some rear view

mirrors installed after it was polished and

dipped in Future. |

I

also added a small map to the instrument

coaming as well as the seat ejection handle.

The canopy interior had some rear view

mirrors installed after it was polished and

dipped in Future. I

also added a small map to the instrument

coaming as well as the seat ejection handle.

The canopy interior had some rear view

mirrors installed after it was polished and

dipped in Future.

The mirrors were made from 10 thou

plastic sheet to which a strip of thin

copper was added to provide an attachment

point.

Once the canopy was completed, it was

attached to the cockpit and attention was

then focussed onto the lower fuselage. |

|

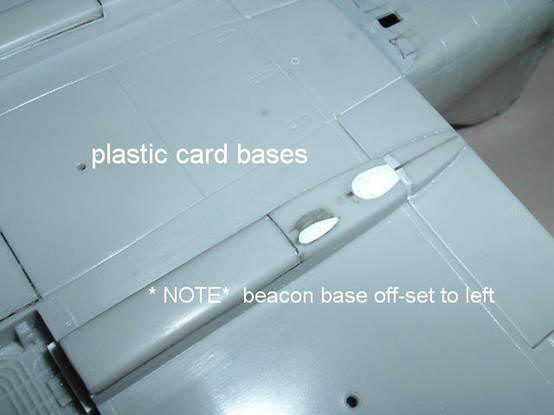

The RNZAF A-4K’s had the lower navigation

beacon situated on the rear of the right

main gear nacelle. This is contrary to most

operators. The beacon was carefully shaved

off the left undercarriage fairing and

transplanted to the right.

|

I intended to have the kit mounted in

flight, moments after striking the power

line. This would require the undercarriage

doors to be closed. The kit’s undercarriage

doors fit poorly and I had to use plastic

strips along their edges to fill some of the

gaps.

The nose gear door did not match the

rounded fuselage contour and required some

putty to blend the shape in.

Note the diamond shaped panel. This is

the base for a small antenna found on late

model A-4K’s. |

|

At this point the wings came in for some

attention.

There is a small ECM antenna at each

wingtip. Also missing are the clear round

lights. I also wanted to add a little detail

to the antenna housing under the left wing

tip. There is also an aerial missing from

the right wing. I made a simple plastic card

base and antenna from some 10 thou sheet.

The slats were fitted in the retracted

position and fit with minimal use of putty.

The

round discs were made from some 10 thou

plastic sheet and punched out with a punch

and die set. The

round discs were made from some 10 thou

plastic sheet and punched out with a punch

and die set. |

The next area to receive attention was

the rear fuselage. There are two ECM bumps

missing (one per side), just forward of the

exhaust. After making a base from plastic

card, the bumps were made from some suitably

shaped sprue pieces. |

I

also added the chaff/flare bucket covers and

some drainage pipes from bits of plastic

card and sprue. I

also added the chaff/flare bucket covers and

some drainage pipes from bits of plastic

card and sprue.

The covers are in place and the drainage

pipes have yet to be added to their drilled

holes. |

|

The final part of the lower fuselage that

needed work was the parachute brake housing.

I added some more detail to the actuator

mechanism from some plastic strip.

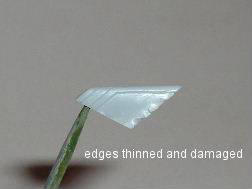

Moving to the upper fuselage, I still had

some work to do on the fin. The pictures

showed that the aircraft landed with the fin

tip hanging over the right side of the fin.

This would necessitate the removal of the

fin tip and adding some interior detail to

the fin itself.

A rib was added to the inside of the fin

after the edges were scraped down to a

thinner section. A scalpel was then used to

create a jagged edge to simulate torn metal.

A similar effort was applied to the fin tip |

A

similar effort was applied to the fin tip A

similar effort was applied to the fin tip |

|

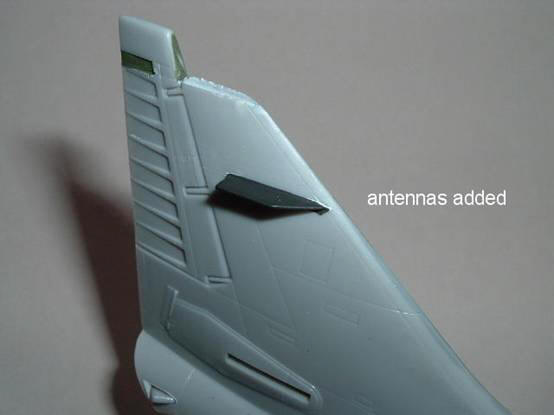

The addition of the VOR antennas either side of

the fin completed work on the tail.

At this point I returned to the wings. I glued all

the pylons to the wings and ran a bead of Mr

Surfacer 500 around them. Once dry a cotton bud

soaked in methylated spirits was used to clean off

most of the Mr Surfacer and fill any small gaps.

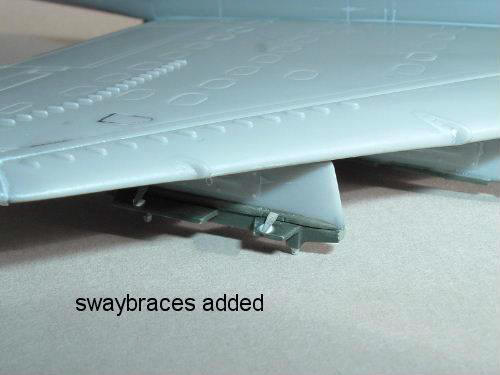

NZ6201 was carrying an empty AIM-9 rail and

centreline drop tank on the flight of 20 March. I

decided to add a little interest to the lower

fuselage by adding the pylon sway braces and the

ejector pistons to each pylon.

I used a rotary tool

to open some holes in the base of the pylons. To

this was added some plastic strip and some discs

using a punch and die set. I also added the

electrical ‘umbilical’ to the rear of each pylon

using some fine copper wire.

I made the pylon sway

braces from some soft drink can aluminium and

plastic discs punched out with a punch and die set.

Construction was

rapidly nearing an end. I masked the canopy and

primed the model to inspect it for any flaws or

blemishes. Satisfied, I moved onto the painting.

Painting

I sprayed a coat of

Testors FS 34709 overall to begin with. My

references showed that the aircraft exhibited a very

starkly weathered airframe resulting in a ‘patchwork

effect. I lightened the dark green with some white

and a dash of yellow and sprayed the masked off

panels with the new shade. The result looked a

little too stark so I softened the effect by

spraying a darker shade freehand along the panel

lines. I didn’t want to blend the border though,

merely to soften the colour transition a little.

The radome was masked and sprayed black at this

point.

My references stated that this aircraft featured a

port aileron, nose gear door and starboard slat in

the previous “Euro I” grey scheme that the overall

green scheme replaced. My references were not

conclusive about the nose gear door or aileron, so I

painted them “Euro I” scheme. I did have however a

front on shot taken on the day of the incident. I

was not convinced that the slat was in the old

scheme so this was painted in the ‘faded’ green.

I also

picked out various wing access panels in a faded

green to add interest, but not based on any evidence

whatsoever!

Th model was then given a gloss coat in preparation

for decals.

Decals

I used the Gekko

Graphics sheet on this kit. These decals are

superbly printed and performed flawlessly. I

experienced some minor silvering, however that was

due entirely to poor surface preparation on my part.

The sheet allows you to build up to six machines and

is thoroughly researched, and even includes

conversion notes pertaining to the Hasegawa kit.

I was initially

concerned that since these decals were designed to

fit the Hasegawa kit,

I might have problems with the wing walkways.

My concerns were

unfounded as they fit the kit beautifully.

I did have to apply

several applications of Microsol to the outboard

walkway decals in order to get them to conform to

the many small vortex generators. Eventually, after

about eight applications I was happy !

Weathering

Now for the fun part!

I applied a dark brown wash to the panel lines. This

was then removed with a cotton bud. Several streaks

were added ranging in colour from black to reddish

brown. Once satisfied, I gave the kit a coat of matt

varnish. I now used powdered pastels to apply small

graphite streaks behind control surfaces and the

vortex generators at the wing tips. I applied black

pastel to the area around the cannon ports as well

as streaking back from the shell ejector ports.

Another matt coat was applied to seal the pastels.

It was now time to

remove all the canopy and radome masking and add all

the delicate bits. The fuselage centreline tank was

atached as was the AIM-9 rail. The lower rotating

beacon was added as were all the pylon sway braces.

I also glued the clear wingtip lights into their

previously drilled holes. The lights were made from

clear sprue. The upper beacon (red) and the High

Intensity Strobe Light (HISL) was added. This was

made from clear sprue suitable sanded to shape then

dipped in Future. The little probe in front of the

windshield and fin tip was was glued in place with a

small electrical cable added to add interest ( I

don’t think there are actually any cables here in

real life!)

He model is mounted on a 10mm acrylic rod that is

inserted into a perspex back plate, which in turn is

screwed into a Jarrah base. The rod is ‘keyed’ to

fit into the exhaust which has plastic strips glued

inside to receive the rod.

The Hobbycraft kit

builds quickly and easily into a fine replica of the

Skyhawk. I still have several RNZAF Skyhawks to

build, and I will be using the Hasegawa kits as

there is much less manufacturing required. Having

said that, the majority of the additions were easily

accomplished and apart from the decals and pilot

figure (Hasegawa), which was taken from the spares

box, I used no after market detail sets which I

found very satisfying.

I would like to thank the following for their

assistance. They helped provide very useful

reference material to complete this project.

Click the thumbnails

below to view larger images:

Model, Images and Text Copyright

© 2004 by

Anthony

Papadis

Page Created 23 September, 2004

Last Updated

29 September, 2004

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search