|

Classic Airframes' 1/48

scale

Messerschmitt Bf 109D

by Brett Green

|

|

|

Messerschmitt Bf 109D Night Fighter

11.(N)/JG2, Trondheim-Vaernes, Norway, 1940 |

Classic Airframes' 1/48 scale Messerschmitt Bf 109 C/D is

available online from Squadron

For a detailed examination

of the kit contents,

see my in-box review elsewhere on HyperScale

Although modellers have a large choice of good quality Messerschmitt

Bf 109E, F, G and K kits, the situation has been fairly grim for fans of

the early Jumo powered prototypes and early production models.

Hobbycraft's 1/48 scale kits are widely available and inexpensive, but

they are seriously flawed in terms of accuracy. Problems include too

shallow and misplaced gun slots, incorrectly positioned carburetor

intake scoop, inaccurate panel lines and cooling slots on the cowling,

poorly shaped and poorly detailed radiator intake, very poor Schwartz

propeller, short wing slats, undersized canopy (and one-piece too),

cockpit configuration more typical of a later model and some 109E

attributes on the fuselage.

Classic Airframes' Bf 109C/D in the box

Classic Airframes continues its family of Jumo 109s with a new 1/48

scale Messerschmitt Bf 109C/D kit. This offering shares the basic

components with the recent Classic Airframes Bf 109 A, with new parts

included for the major characteristics of these later models.

Classic Airframes' 1/48 scale Bf 109C/D kit comprises 34 parts in

grey styrene; 17 parts in grey colored resin; a photo-etched fret; 3

clear injection molded parts; printed clear acetate sheet (instruments);

instructions; plus a decal sheet and painting guide for four aircraft.

In common with the Bf 109 A kit, the plastic parts are absolutely first

rate.

Moulding quality is excellent, and the highly polished finish does

not reveal any moulding imperfections on the exterior surfaces. This

shiny surface will be especially useful for modellers who plan a bare

metal finish for their Bf 109. Panel lines are crisply recessed, and

fabric control surfaces are quite subtly done.

The main differences between the 109 A kit and this new release are

the engine cowl and the wings. The resin cowl is cast with the ejector

exhausts in place (the 109B cowl is also included), while the wings are

equipped with the short leading edge slats.

Parts Preparation

Careful preparation is the key to a successful and

enjoyable project when building any limited-run kit. Although the

surface quality and detail of Classic Airframes' smooth plastic parts

are the equal of many of today's best mainstream manufacturers, absence

of locating pins and the inclusion of resin parts means that clean-up

and regular test-fitting is essential.

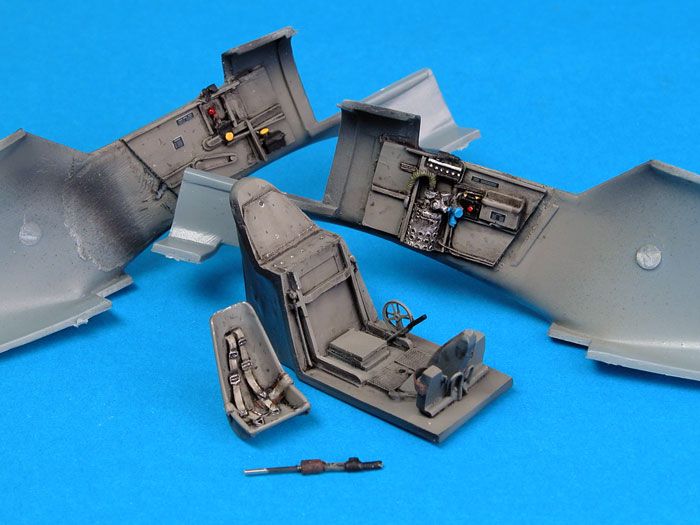

I started by preparing the resin parts. These are

beautifully cast and superior to the detail moulded onto most

conventional plastic kits.

This time I used a motor tool fitted with a cutting

wheel to quickly dispatch the casting blocks. Take care though - this

method kicks up a lot of dangerous resin dust. I wore a ventilator mask

and ran an extension cord outside to minimise the risk to both myself

and my family.

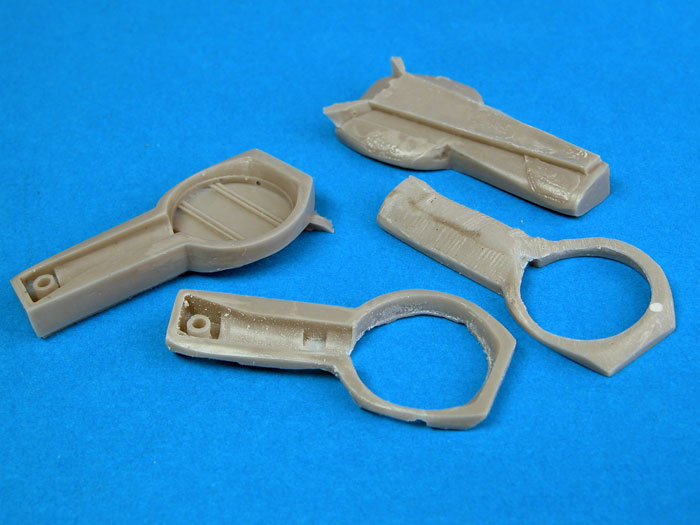

I also took a different approach to the wheel wells

compared to the 109 A kit that I built recently. I ground off the roofs

of the wheel wells, based on the theory that the shallower part might

fit more easily, and that I might not have to thin the inside top of the

wings. I figured that it would be a simple matter to restore the

structural detail directly to the inside of the upper wing.

Cockpit

I rushed through construction when I built Classic

Airframes' 109 V4 earlier this year. One of the consequences was that I

was not entirely happy with my paint job in the cockpit. This time I

determined to do better justice to the well-detailed resin interior.

The only after-market part I used was the seat. This was

from Ultracast. The kit-supplied seat is very nice, but the Ultracast

seat with its cast-on harness saved a little time, and does look

terrific.

Click the

thumbnails below to view larger images:

Before assembling the cockpit components I thinned the

fuselage sidewalls. I used a cutting wheel in my Dremel motor tool,

lightly grazing the edge of the wheel along the plastic to remove small

lengths of material at a time. I cleaned up the ragged edges left after

thinning with a coarse sanding stick.

I clumsily managed to knock off the top of one of the

delicate seat rails cast to the rear cockpit bulkhead, so I restored

this feature with two fine strips of styrene.

The bottom of the control column was drilled out and a

length of steel rod was installed to reinforce the join with the

fuselage floor. Toe straps were added to the rudder pedals from lead

foil.

Instead of gluing the trim wheels to the port sidewall,

I secured them either side of a triangle of plastic, then glued the

triangular mount to the fuselage floor beside the pilot's seat.

The resin sidewalls were glued to the inside of the

fuselage after carefully measuring against the main cockpit tub

part.

The cockpit paint job commenced with a coat of

Tamiya Flat Black followed by Gunze RLM 02 Grey, mixed with a spot

of Tamiya Flat Base. The 02 colour was misted in several thin coats

onto the parts at a high angle, leaving natural shadow areas in

black. A pin point wash of Raw Umber oil paint was applied to the

edges of structural details and panels, representing grime and wear.

After the wash had dried overnight, details were picked out with

acrylic paints and a fine brush. Chipping was simulated here and

there with a well-sharpened 2B pencil.

I also applied cockpit placards from a Reheat decal

sheet.

Wheel Wells and Wings

With the tops of the wheel wells ground off,

assembly of the wings was a snap.

The wheel wells were glued onto the bottom wing half

and the top halves were test fitted. A little further sanding of the

top fronts of the wheel well resin was all that was required for an

easy fit.

When the wings were glued, clamped and set, the

positions for the wing-mounted machine gun openings were marked in

the leading edges and drilled with a pin vise.

Click the

thumbnails below to view larger images:

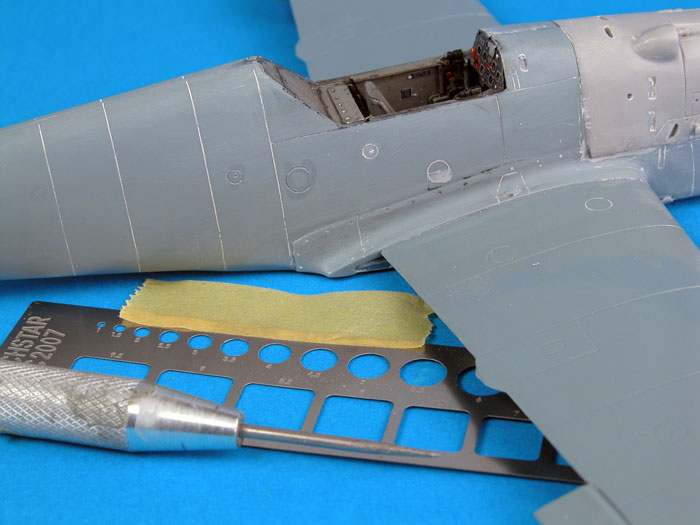

Fuselage and Main Assembly

The balance of construction was similar to the 109 V4.

Before joining the fuselage halves I hollowed out the space on the

fin where the horizontal stabilizer adjusts up and down. This was

achieved by drilling several holes and "joining the dots" with a

sharp hobby blade.

I fitted the instrument panel then glued the fuselage halves

together. When the fuselage halves had set I installed the cockpit

tub from the opening underneath.

Just to be different this time, I glued the nose parts to the

fuselage before attaching the wing. Somehow I managed to slightly

twist the nose. No excuses - I should have taken more notice of my

own mantra to test fit and test fit some more. As it is, when viewed

from directly above, the nose takes a very slight right turn at the

front of the windscreen. Having now done it both ways, I recommend

attaching the wings before the nose is glued to the front of

the fuselage.

At this stage the wings were offered to the fuselage. The wings are

cleverly designed so that the front centre section forms the top of

the outlet ramp for the radiator. I lightly sanded and test-fitted

the joining surface at the centre rear of the wing several times

until a perfect gap-free fit was achieved. The important thing here

is not to shave too much plastic from the back of the wing centre

section - just sand lightly, test-fit and repeat as required.

Click the

thumbnails below to view larger images:

With a nice tight fit between the wing and the fuselage, Tamiya

Extra Thin Liquid Cement was flowed into the join lines at the wing

root, and the front and rear of the wing assembly. A length of

Tamiya tape was stretched across the top of the model from wingtip

to wingtip to ensure there would be no gaps at the wing root.

Dihedral is set by the wing spar, but Tamiya tape was used to

guarantee a gap-free join at the wing root.

The resin radiator intake includes nicely cast detail for the

radiator face, but even better detail is available on the supplied

photo-etched part. This metal face was glued inside the resin

intake. Reference photos show that the radiator was fitted with two

diagonal and one vertical brace. These were added from fine brass

and steel wire.

Horizontal stabilizers are supplied without locating tabs. To

reinforce this join, I drilled holes in the mating surfaces of the

stabilizers and through the fin. A steel pin was inserted to assist

alignment and strengthen the join. Stabilizer struts, parts 25 and

26, fitted perfectly.

The electrical socket and oxygen filler point on the

fuselage are correct for Bf 109 prototypes and the "B" production

variant, but should be relocated aft for the Bf 109 C and D. If you feel

so inclined, this is not a difficult task. I filled the existing

electrical socket and oxygen filler on the starboard side with Gunze Mr

Surfacer and sanded them smooth. New points were then scribed into the

correct positions using Techstar templates and a pointed scriber. I ran

a small amount of liquid cement in the newly-scribed circles to blend in

the rough edges.

Lengths of copper wire were glued to the bottom of the

empennage representing rudder actuator rods.

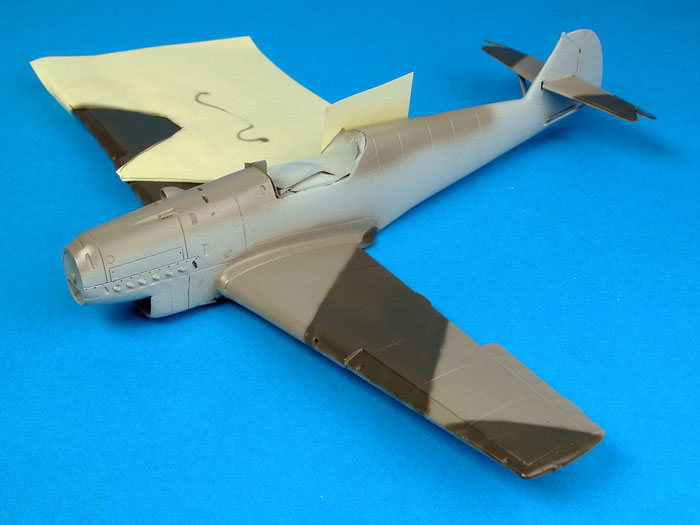

The first coat of paint was Tamiya Light Blue. This was

the AS-5 spray can colour, but decanted into a jar and applied with my

Testor Aztek A470 airbrush.

Next, the model received a coat of RLM 02 Grey on the

top of the wings and the spine. The disruptive colour of RLM 71 Dark

Green was sprayed with the aid of self-adhesive paper masks. When the

masks were removed, I sprayed fine lines of RLM 71 freehand along the

camouflage lines to slightly soften the demarcation between the colours.

Click the

thumbnails below to view larger images:

RLM 65 Light Blue was then applied up the fuselage sides

to meet the upper surface camouflage colours.

Paler shades of each colour were mixed and sprayed in fine lines and

random mottles as an initial weathering measure.

The exhaust panels were masked and sprayed Tamiya's

German Grey.

Markings

Markings were sourced from Cutting Edge Decals' CED

48265 "Bf 109D Early Messerschmitts Part 2".

The markings performed perfectly despite the fact

that I had not applied any gloss coat. I simply polsihed the

semi-gloss Gunze finish with a nail buffer, then applied the decals

with the assistance of Micro Set and Micro Sol.

One of the advantages of Classic Airframes' early Bf

109 kits is that, in addition to the attractive marking options

supplied with the kit, there are plenty of after-market decals

available for even more variety.

Weathering

First, Tamiya X-18 Semi-Gloss Black was thinned with

water and run into panel lines.

Then a thin mix of Tamiya Red Brown and Flat Black

was sprayed along selected panel lines. I focused on panels around

the rear and bottom of the engine cowling. Light stains were also

sprayed around the wing roots, and on the bottom of the fuselage

behind the radiator outlet.

A thin wash of Raw Umber oil paint was applied with a fine brush to

a few areas including rivets on the wing root fairing, filler

hatches, fin fairing, gun troughs, fuselage vents, and release

latches.

A silver pencil was used to apply some subtle

chipping on the wing walkways.

A thin coat of Gunze Flat Clear was sprayed over the decals to tone

down the glossy markings.

Finishing Touches

Hydraulic lines were added to the main gear legs from Up

North tin wire, secured with straps of thin Tamiya tape.

Aerial wire is E.Z. Line, a very elastic material that

lessens the risk of drooping or breaking after installation.

E.Z. Line was also used for the canopy restraining wire.

I found that the resin slats sat more naturally when the

mounting pegs were thinned and trimmed.

This is the second time I have built one of Classic

Airframes' 1/48 scale Jumoschmitts, and it was as enjoyable this

time as it was the first.

Classic Airframes' Bf 109C/D kit is impressively

detailed, fits together well, has some very attractive marking options

and is by far the most accurate 109C/D kit available today.

The only problem I encountered - slightly misaligning

the engine cowl - was entirely my fault and simply reinforces the

importance of continually test-fitting.

If you do not object to a little extra time preparing

resin parts and confirming alignment during construction, there is

nothing terribly daunting about building one of these excellent kits.

The biggest disadvantage is probably the limited

availability of Classic Airframes Bf 109s. With their small production

runs, once they're gone, they're gone. I am advised that the

manufacturer has already sold out of the 109A kit (although distributors

and retailers should still have some in stock).

If you think you'd like to build one of Classic

Airframes' 1/48 scale Messerschmitt Bf 109C/D kits, you'd better get one

now!

Click the

thumbnails below to view larger images:

Model,

Images & Text Copyright © 2006 by

Brett Green

Page Created 07 April, 2006

Last Updated

10 April, 2006

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search