Background

The mighty Buccaneer was an aircraft so tough as to be apparently

forged from solid steel. It still ranks as the best-loved post-war

attack aircraft in the UK. So much so that on the night when the Bucc

was officially retired in March 1994, one of the officers in the

Officers Mess RAF Lossiemouth pointed out that "The only replacement for

a Buccaneer is a Buccaneer".

The Buccaneer, designed to fulfill a Royal Navy requirement for a

long-range carrier-based attack aircraft, first entered service in July

1962. From its first operational missions to its last in 1994, it

remained one of the fastest low-level aircraft in any service. This was

due to its high-thrust engine, small wings and extremely robust design

which gained it many nicknames such as the Brick.

Back in the early 1960s, the first production Buccaneer S.1 was

underpowered, criticized and unappreciated by their users. Only three

years later, with the arrival of the Spey-engined S.2, the full

potential of the airframe was revealed.

The Royal Navy's requirement for a bomber to fly subsonic,

under-the-radar missions to penetrate enemy airspace without detection

proved successful and the Bucc was better suited for that role than the

Mirage III or F-4.

In the 1970s, a political decision was made to retire Royal Navy's large

carriers and fixed-wing aircraft. The S.2 examples were progressively

transferred to shore bases and to the Royal Air Force. The RAF

re-designated some of the aircraft as S.2As and later, after more

modifications, as S.2Bs. A small number of new production S.2Bs were

also built, beginning in early 1970, and all earlier unmodified Buccs

were updated and redesignated S.2C and S.2D.

Meanwhile, the Buccaneer Mk 50 version had been supplied to the South

African Air Force (SAAF) in 1965, these were fitted with a supplementary

twin-chamber rocket motor in the aft fuselage to facilitate takeoffs

from hot, high-altitude airfields. It is in South Africa that the

Buccaneer first saw combat in the 1970s, but it was not until the very

end of its career that the Buccaneer was able to prove itself in the

service of its home country. In 1991, after almost 30 years of service,

Operation Granby in 1991 was the last active deployment of the Blackburn

Buccaneer. Thirteen modernized RAF Buccaneer S Mk.2B aircraft fought

very successfully from Bahrain for the duration of the Gulf War.

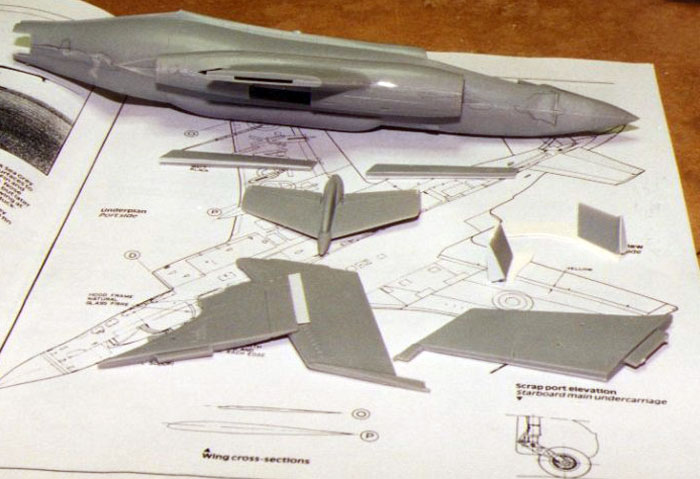

The Airfix 1/72 scale Buccaneer S.2

The kit was first released as an S1 in the early seventies and was

reissued in the late 1980s as an S2, but still most of the original

shortcomings were present. The tail is not accurate and the cockpit is

sparse, to say the least! The panel lines are raised and detail is

nonexistent. The kit includes optional parts for the flush or bulged

bomb bay door and also present are the slipper under wing tanks. The

shape of the kit is inaccurate in some areas, the most notable being the

engine air intakes and the nose. Itís still easy to recognize the kit as

a Buccaneer, but that is because this airplane looks like nothing else!

I bought the kit when it was reissued in the eighties, together with the

Aeroclub tail hook and landing gear set, the Squadron cockpit canopy and

the Airwaves detailing set. The obscure box was placed in my stockpile

of kits as a bad conscience for fifteen years until I finally opened it

again!

For reference I used the old Aeroguide no 5. All panel lines on the

airframe were sanded down on each separate part of the kit. Comparing

the drawings in the book with photographs I decided which panel lines to

scribe and which to leave out. Before assembly started I scribed the

panel lines on the wings and the tail plane, the fuselage panel lines

were done later, after assembly of the fuselage.

The Fuselage

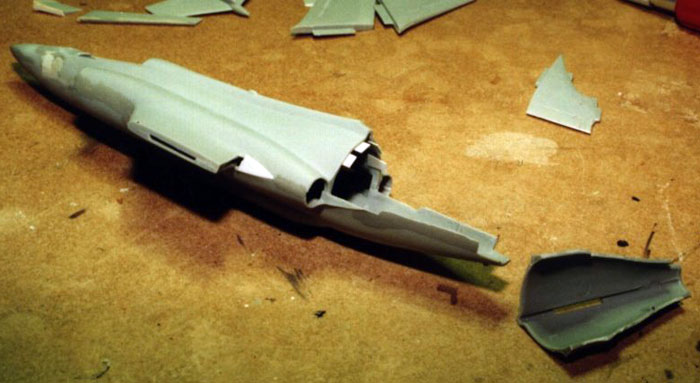

The main part of the fuselage is split horizontally, only the nose

radome is a separate piece. The fuselage halves didnít match as they

were warped differently, and some cuts had to be made to the fuselage

halves.

Backing plates for the photo etched engine fans were glued in the rear

of the air intakes before the halves were mated in a very painstaking

process.

The fin was slightly corrected in the rear to get the profile right, the

rudder received some plastic to change the angle slightly. The small

blade antennas were exchanged to new better-looking ones and the cooling

air inlet at the base of the fin was reshaped to its correct form. The

fit between the fin and the fuselage is undefined and called for a few

dry fitting sessions.

The radome is reasonably correct in profile with some work on the

fuselage front end. Some Milliput was still needed to blend the two

differently shaped objects after the radome had been glued to the

fuselage.

The intakes are not the kits best features! I cut a piece of thin

styrene sheet and inserted one in each intake to get a smooth inner

surface. It was not really difficult to do this and the seam of the

inner lining is in the top so it doesnít show unless you pick up the

model. They were painted with Humbrol Metalcote Aluminum together as was

the photo etched turbine fan, which was polished and inserted through

the intake and glued to the backing plate. Finally I added the small

bump on the fuselage side in front of the intakes, made from plastic

card.

On the tail plane I tried to minimize the size of the front and rear

cones as they are way too large in the kit (I think there is a resin set

on the market now correcting this area).

The prominent split-tail air brake was modeled open. The details of

this area were plain wrong in the kit, so I scratch built the inner

structure and hydraulics using mostly brass plate and sheet styrene,

completed with the Airwaves PE air brake interior.

Click the

thumbnails below to view larger images:

I had some pictures but not all information, as I became aware of when I

saw the Buccaneer live in the Fleet Air Arm Museum. In true British

spirit the air brake does not open as you would expect! From closed

position the two halves open simultaneously but nor symmetrically to the

fuselage center line; they go slightly to the left! I will not rebuild

the air brake on this model, but for sure do right the next time!

The ill-fitting front windshield was glued to the fuselage now with

epoxy glue, itís lower edge faired in to blend with the fuselage. The

weak bond of the epoxy glue caused some problems as I managed to tear

off the windshield with the masking tape and had to repeat the whole

process.

The Wings

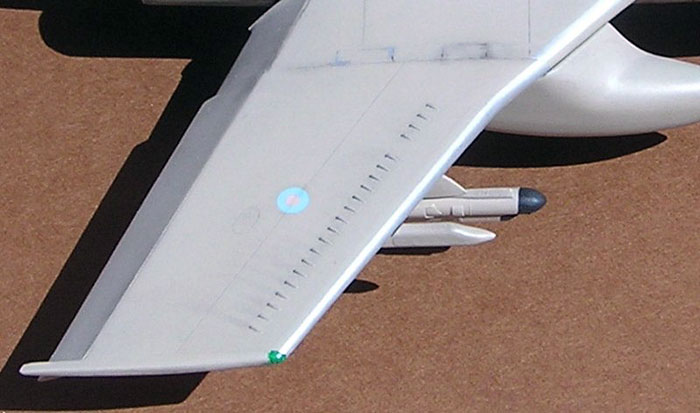

I had decided to have the flaps in the dropped position, not realizing

how difficult this would be! The flap on the top wing half was removed

with a razor saw and on the bottom wing half I had to guess the size of

the flaps to be removed and because the flap is much thicker towards the

fuselage the geometry of the dropped flap was anything but easy to

reproduce. I had some photos of the flaps in my old Aeroguide book to

help me, but still the task was not an easy one! The result is

acceptable to me, judge for your self.

For this version the wing tips are short and excess plastic was cut off.

Assembly

When assembling the main airframe components - fuselage with wings

and stabilizers - I use a simple jig to ensure correct alignment. On a

hard surface, I fix the fuselage in an exactly upright position, mate

the wigs/stabilizers and then support them with a paint jar or other

suitable item with just the right size to ensure that all angles are

straight. I then let the model rest until the glue has cured. Adjusting

the jig can take some time, so I never use superglue for wings and

stabilizers but rather liquid poly with its comfortably long bonding

time. At this stage I also scribed the remaining panel lines.

Click the

thumbnails below to view larger images:

Cockpit

Only now my attention turned to the cockpit, realizing the Airwaves PE

set would not improve the cockpit much. But, in a model like this, the

cockpit interior can be built from the outside and this is what I would

do! My Dremel and knife was put to work and soon all traces of the old

cockpit were gone. Guided by photographs of the real thing, I furnished

the interior with styrene bits with the addition of a few Airwaves photo

etched panels.

The cockpit interior was painted dark gray and dry brushed.

One thing that should be noted with the Buccaneer is that the forward

seat is offset a little to the port side, while the rear seat is offset

to starboard. The seats themselves were white metal items from Aeroclub.

I completed them with seat belts added from strips of lead foil

(Bordeaux 1993) and Reheat buckles, and the Perspex shield for the rear

cockpit made from Lexan.

Click the

thumbnails below to view larger images:

Final Detailing

More antennas were added around the airframe, all scratch built items.

The camera blister under the nose was also scratch built. In-flight

refueling probe was another white metal part from Aeroclub.

Now was the time for the final bits. Airfix chunky undercarriage parts

were replaced with white metal ones from Aeroclub. Wheel well interior

had to be scratch built and detailed with copper wire. The wheel bay

doors were replaced with new ones made from 0,2 mm brass plate.

Under wing pylons were also scratch built. As for the stores, I have

chosen the following configuration often seen on Gulf War missions:

-

Station 1: AN/ALQ-101(V)-10 electronic countermeasures pod (Hasegawa)

-

Station 2: External fuel tank (kit item)

-

Station 3: AN/ASQ-153 Pave Spike laser designator (Scale cast)

-

Station 4: AIM-9L Sidewinder (Hasegawa)

Additionally, there are radar warning pods under each wing (scratch

built).

I finished my model as a Gulf War machine, RAF Buccaneer S.2B serial no.

XX885/L nicknamed Hello Sailor/Caroline. It also carried the name Famous

Grouse after a well-known Whisky brand, but personally I prefer malt

whisky. On the nose there is also a strike mission tally and a

silhouette of an An-12 Cub, one of two such aircraft that this Buccaneer

pointed with a Pave Spike and that were bombed by another Bucc during a

mission on Shayka Mayhar on February 27, 1991. The decals for this

machine came from Modeldecal.

For the painting, I used Xtracolor enamels, X32 Desert Pink. Xtracolor

paints are glossy, so the decals were applied directly on the paint

coat, and then followed multiple layers of Future which were gently

sanded after each application. This procedure was repeated until no

trace of decal film edges could be seen.

Having the basic paint scheme ready, I applied a wash of black-brown oil

color mixed with white spirit, applied by brush over the entire model.

The wash added emphasis to panel lines and more variety to surface in

general. After some ten minutes the excess wash was wiped off with a

soft rag. This step allows precise control over the degree of weathering

left on the model - in this case, quite plenty of it!

The "dirt" was now sealed with a layer of Tamiya Clear acrylics mixed

with Tamiya Flat Base. Additional touches were made with dry pastel

chalk applied by soft brush in the areas that required more dirt;

particularly the dirt arcs forming behind the main wing vortex breakers

is typical.

A layer of Tamiya Clear and Flat Base sealed the pastels, and finally I

used the old piece of rag to gently rub the correct shine to some areas

of the airframe.

The canopy is in the far back position, and as it slides back along the

canopy sill it would have had its rear way up in the air on the model. I

fixed the canopy with the rear end down so it looks like the real

machine, but the line from the canopy sill to the canopy is strange to

say the least. I chose to use the kit canopy even though I bought the

Squadron replacement as it had some flaws.

In an old kit like this there are bound to be problems, but this is

probably the worst kit I have ever built for the last thirty years! I

could have done much more but you have to limit your effort in some way,

to me thatís around one hundred hours.

What an aircraft!

Click the

thumbnails below to view larger images:

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search