|

MPM / HML 1/48

scale

Blohm und Voss BV 138

by

John Valo

|

|

|

Blohm und Voss BV 138 |

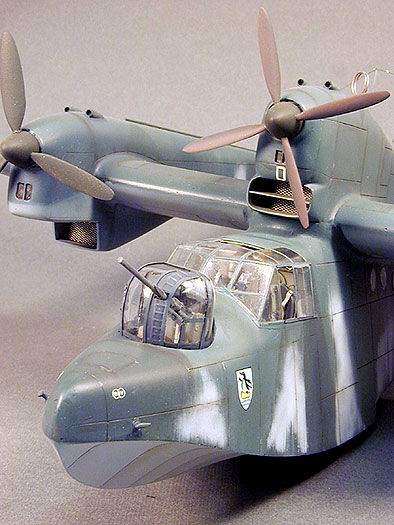

As part of MPM's HML (Hand Molded Limited, I believe)

line of large resin-cast model kits, the BV138 exhibits the three major

characteristics of the line: it's big, it's rather pricey, and it's

heavy!

The parts are very well molded, including the hollow fuselage, but the

wings, booms and empennage are solid (read: heavy) resin. The kit

provides a rather complete cockpit and armament group, with simple

turret interiors and beautifully molded guns. Vacuformed transparencies

are provided for the cockpit and turrets; these look very nice after a

bath in Future.

Propagteam provides a beautifully-printed decal sheet

with three marking options.

From the outset, I noticed a number of pinholes in the

major parts, which I filled with putty and coated with primer. All of

the smaller resin detail parts were clear of pinholes, but I did spend a

considerable amount of time liberating the parts from their casting

blocks and cleaning up the resin flash. All of the smaller parts were

bagged in groups according to which assembly step they pertained to.

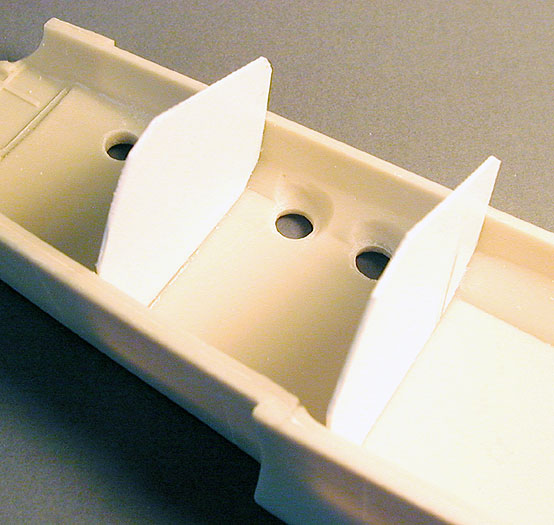

After studying the fuselage halves and test-fitting the cockpit

structure, I elected to scratchbuild bulkheads for the aft fuselage, to

avoid the 'see-through' effect through the portholes. These were made

from .040 styrene with the assistance of a contour gauge. Frankly, I

don't think anyone has ever noticed...

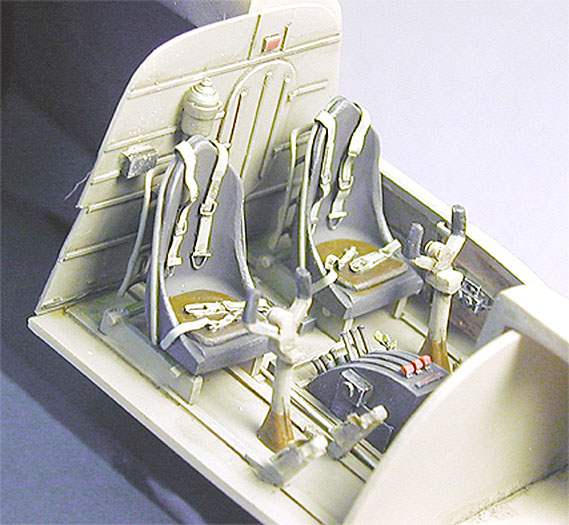

The cockpit is very nicely done, and fits well. I chose to make a new

instrument panel from .020 styrene, and used a punch and die set to make

the instrument holes. A Black-painted backer was scribed with the

instrument markings, then a drop of Future was placed in each hole. This

sandwich panel was then glued to the resin instrument panel/coaming.

The seats are molded without seatbelts, so I cobbled up my own using

electrical tape strips and fine wire for the buckles. Once painted, they

were quite convincing.

The balance of the cockpit was assembled per the instructions. I added a

bit of detail to the dorsal gunner's interior, and opened the hatch on

the side of the fuselage. Both interior assemblies were installed before

joining the fuselage halves and top. The turrets were left for later, as

they could be installed after assembly was complete.

Click the thumbnails below to view larger images:

Before continuing assembly, I added brass mesh radiator

faces to the center and boom engines. Now came the fun! Common sense

advised me to build a jig to assemble the fuselage (hull?) and

wings/booms, but some perverse sense of adventure led me astray. The

constituent parts fit together with only a bit of sanding and tweaking,

but the things are heavy! It's amazing what gravity can to to skew

things when you're trying to assemble them. After a few false starts, I

did set up some supports for the tail booms and made a small jig to hold

the fuselage in the vertical position (recall that these flying boat

things have a double-concave bottom with a pronouced step - they don't

just sit on the workbench straight up-and-down). Once the booms and

horizontal stabilizer were aligned and glued into place, the major

battle was won. The solid outer wings are mere butt joints, but I felt

there was plenty of surface area, and didn't reinforce them

structurally.

I

painted the model with PollyScale acrylics that I mixed to approximate

the maritime colors of RLM 72/73/65. I

painted the model with PollyScale acrylics that I mixed to approximate

the maritime colors of RLM 72/73/65.

The decals worked great, after cautiously applying lots

of water before positioning and floating them into place. After decaling

and clear-coating with Future, I lightly sprayed Badger Air-Opaque White

for the splotches, giving each a very quick and light wipe with a

dampened soft cloth to streak them a bit.

I applied a wash of artists' oil paints thinned with

mineral spirits, then a final coat of flat/satin PollyScale clear.

Weathering was completed with chalk pastels.

The floats were then painted and weathered before

attachment. The floats are each a three-piece affair that need some care

in aligning also as there are no positive locating guides - just scribed

lines showing the position.

The turret assemblies consist of vacuformed front and back halves which

join on a frame line. After gluing the halves together, I framed the

turrets with strips of electrical tape painted the appropriate color.

The resin cannons are beautifully molded, but needed to be shortened at

the breech end to fit into the turrets. Likewise, I wound up replacing

some of the turret interior parts as the kit parts wind up being too

crowded for everything to fit. The turret interiors were glued into the

fuselage, then the transparencies were fitted and glued in place.

I elected to open the top hatch of the canopy, as well as the pilot's

side window. These sections were replaced with clear sheet styrene. I

used a sharpened brass tube to punch out the porthole windows from clear

acetate, and glued them into place with thinned white glue.

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search