To say that I love Flying boats is like

saying ants like picnics. They have grace, character and a utility

that no other type of aircraft has, the ability to make 2/3’s of the

world’s surface their runway. My love for them was fostered in part

by my Dad, a licensed pilot from the “old school” of pilots that

learned to fly literally by the seat of their pants, and his passion

for flying and landing on water.

When I first saw the story of the

Curtiss NC series trip across the Atlantic in 1919, the airplanes

caught my attention. Immediately I knew I wanted to build a model of

one, and I knew it was going to end up being a scratchbuilt model.

Even though I have scratchbuilt a few aircraft before this, this was

going to be the first of this size and complexity.

Gathering the reference data proved to be fairly

easy. A quick email to John Bayer, Director of the First

Across Organization, (http://www.geocities.com/firstacross/)

resulted in several sources of plans and reference materials.

Another website that gave invaluable information was The Naval

Aviation History Office (http://www.history.navy.mil/branches/nc-4mono.htm).

I also thought a trip to Pensacola Naval Air Museum to photograph

Nancy was in order, so a quick email to the fine folks there to

explain what I wanted to do resulted in a

very quick response. It said in a nutshell, “Sure come on down,

we’ll be glad to help.” A trip in April of 2003 resulted in over 130

digital photos and 72 35mm Color Slides. The people there were very

accommodating. Not only did they allow me full access to Nancy, but

they also rolled out a small electric scaffold to lift me up and

over Nancy, allowing me to photograph the airplane from the top, as

well as the bottom. I was also able to poke my head inside and get

some very helpful interior pictures. I can’t recommend the Naval Air

Museum enough, very nice people to deal with and a fantastic array

of displays there.

With

references ready, and raw materials purchased, it was time to begin

construction. I decided to begin with some of the smaller

subassemblies first to get a feel if I was actually going to be able

to finish this beast. The more I looked at the plans, examined the

forest of struts, the maze of rigging, the more I started to think…

“

Riiiiiiiight. I’m really going to build this… sure I am.”

Along

with that, the drawings that I obtained from Model Airplane News had

some features that did not agree with the photos I had taken in a

lot of areas. The Nacelles weren’t drawn quite right, some of the

rigging was misdrawn, and many details were left off the plans all

together. Items like the wind driven fuel pumps on the rear deck,

and the “tunnel” underneath the rear pusher engine to keep

crewmembers from getting whacked by a spinning prop. Another bugaboo

that would bite me good later on in construction was the fact they

were drawn in two scales, 1/32nd and 1/48th. I

was building the model in 1/48th scale, so it wasn’t a

major issue, but there were a few times I had to get out the

calculator to refigure a certain dimension. Rather than go into a

full-blown step by step construction article, I decided to give a

brief outline of each subassembly, and the materials and techniques

used to construct the model. That, and some In-Progress

photo’s should give you a good idea of

the amount of work and time invested.

As

always if you have any specific questions on how I did a certain

part of the model, please feel free to email me and ask away.

Fabrication

/ Consruction

|

Fuselage/Hull

-

Hull master

was carved from a block of basswood.

-

Hull halves

vacuum-formed from .040 plastic sheet

-

Internal

Hull stringers made from .010 and .005 strip.

-

Ribs and

formers made from .030 sheet.

-

Cockpit

floor and slat seats made from .040 plastic for frames and.010

strips for slats.

-

Instrument

Panel from .010 with Reheat Gages and Foto-Cut bezels

-

Control

Wheels, Rudder Bars, Throttles and Engine Controls made from

brass wire and solder as needed, and spare photo etch.

-

All control

cables present.

-

Interior

finished to represent varnished

mahogany.

-

Cockpit

fairings vacuum-formed and faired in, with Compass and

Windscreens made from Rod and clear sheet.

-

Hull

fittings made from brass or steel wire, solder, strips of

plastic as needed.

-

4

wind driven Fuel Pumps made from

Evergreen Channel and rod.

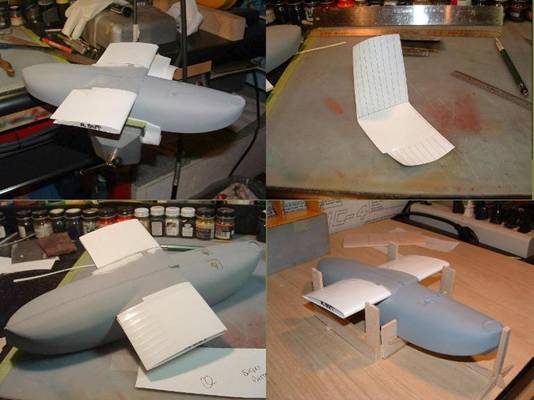

Hull begins life as paper templates pinned

to the wood block and band sawed to shape, then a small block plane

was used to rough carve the hull to close to final shape.

Hull after final sanding and wing center

section glued in place, and cockpit

cutouts chiseled out.

Hull after vacu-forming.

The basswood master was cut in half at the Cockpit Bulkhead and left

in the rear portion of the hull for strength. This allowed for brass

tube sockets for the lower wings to plug into. (and

to prevent me from being loony enough to build a second one)

Hull interior

showing slat floors, Control Bar, Rudder Pedals and Slat Seats and

all control cable runs.

Wings

-

Lower Wing

Center made from .040 ribs and brass tube spar, sheeted with

.010 plastic with ribs embossed from underneath. Upper Wing

Center Section constructed of a 3/16 balsa core sanded to

airfoil shape and sheeted with .005 plastic, ribs embossed from

below.

-

Outer wing

panels, both top and bottom made from 3/16 Balsa core sanded to

shape, with 1/8 Rod embedded in wood at strut locations. Wings

then sheeted with embossed .005 plastic, Strut locating holes

and rigging holes predrilled.

-

Ailerons cut

from Top Wing panels, Aerodynamic mass balances added, and then

sheeted with embossed .005 plastic.

-

Struts made

from Contrail Strut material, each strut cut and fitted as model

sat in jig. Ends pinned with brass wire, and each strut is

embedded into the plastic sockets installed in the wings. Epoxy

was used to secure them.

Lower Wing structure, sans skins

assembled and fitted. The assembly Jig is started.

Clockwise from top left.

Wing skins being test fitted. Ribs embossed from underneath. Skins

are being glued in place along lead edges. Skins

being cemented along outer ribs and trail edge and completed.

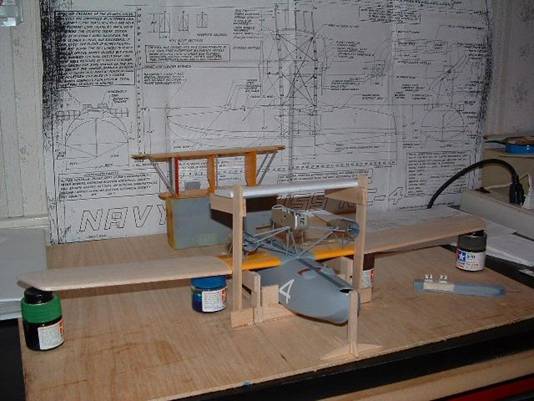

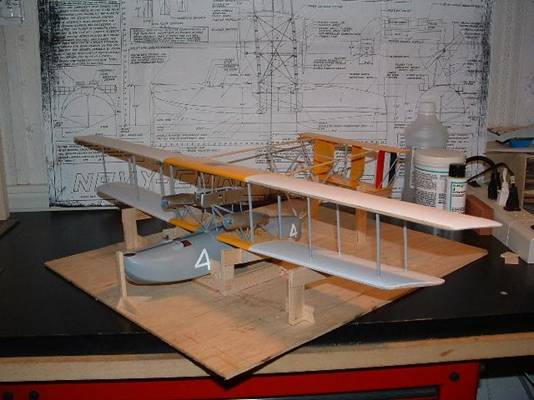

Hull completed, Painted, decaled and

Lower Wing Center Section Completed.

Lower Outer

Wings temporarily set in place and Top Wing Center section jigged

into place. Balsa Cores with .005 sheeting was used for Wing

construction. Small white items under left wing are wind driven Fuel

Pumps.

Wing Center

Section Struts cut and fitted, Tail Booms started.

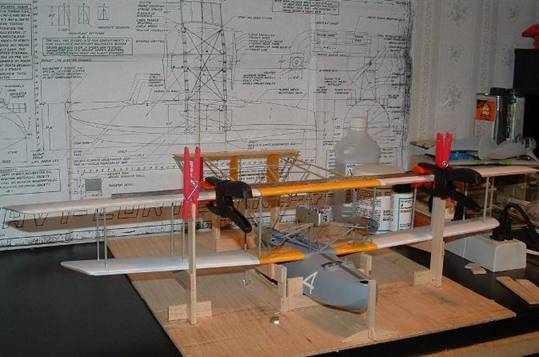

Top Wing

Outer Panels being test fitted

If in doubt…

Jig it. One of the most gratifying features about this model is that

in spite of the complexity of the construction, it all stayed in

good alignment because of the care and double-checking taken during

construction to ensure everything stayed straight. The jig was a bit

of extra work, but the end results were worth the effort. Here the

Wing Struts are all cut to length, and numbered for their particular

location.

Voila!

Removing the jig and nothing moved or “tweaked” out of alignment.

Tail Surfaces

-

Both

Horizontal Stabilizers and all three Rudders and Fins made from

.010 plastic cores, sanded to shape, and skinned with .005

embossed plastic. All surfaces were built separate and hinged

with brass wire.

-

Struts made

from Contrail Strut material, cut to length and anchored with

brass pins in ends.

-

Assembly was

pre-assembled and painted, and rigged using Lycra thread,

anchored in pre-drilled holes with CA glue.

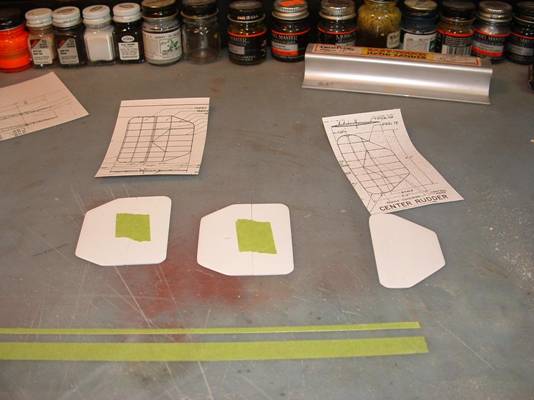

Fin/Rudder Cores made from .010

Sheet.

Components test fitted for fit and

alignment.

Owwww my eyes! My first attempt at “Yellowed

NDL” was woefully too orange. Testor’s Lemon Yellow was

deemed adequately close and Tail was repainted. Tail is complete

here except for rigging.

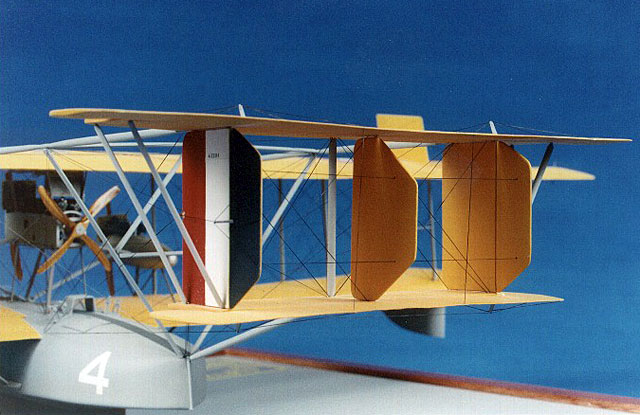

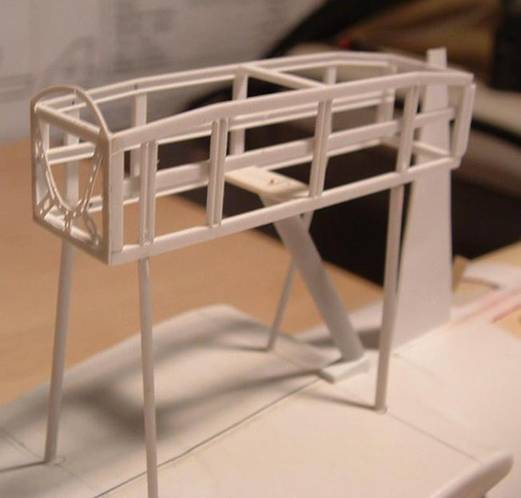

Engine Nacelles

- Center

Nacelle built up from Evergreen Channel, internally rigged, and

engine bearers added from .060 plastic. Front Cowl and Lower

Cowl Vacu-formed from .010, side panels made from .005 plastic

with foot and inspection cutouts punched out. Nacelle Struts

made from Contrail Struts, cut and fitted to length in a jig.

- Wing

Nacelles vacuum-formed from .040 plastic over a wooden master

turned on lathe. Front cowls vacu-formed separately and added

after engines were installed. Radiators resin cast from a master

made from a Chevy Pickup Radiator, hoses are Solder Wire. Struts

made from Contrail Strut material. A special jig was made for

strut locations and lengths, and for cutting and fitting the

Main Struts between all three nacelles.

- Engines and

propellers are commercial items. The Engines are Aeroclub white

metal engines, with separate exhaust stacks made from solder and

drilled out. Propellers are custom ordered props from Martin

Digimyer and Copper State Models.

Center Nacelle framed up with Evergreen.

This was then covered with Vacu-formed lower cowl and front cowl,

and .005 sheet side panels. Large triangle thingy in the front is an

alignment aid. Struts are Contrail Strut pinned with brass wire in

the ends.

Wing Nacelles vacu-formed over wood

master. A scrap

piece of balsa was made to the same size as the lower wing to make

an assembly jig for cutting struts to length.

Nacelles after

being painted, and the forest of struts

cut to fit. Cradle for Assembly Jig helps hold everything in

constant alignment to keep things square and even.

Engines and

Radiators installed. Remember the comment on the two scales being

used in the plans? This is where it bit me good. I made masters to

cast the Engine Crankcases and the Cylinders. After casting 4 really

nice crankcases, and 50 really nice cylinders, it was then I

discovered that I made the crankcases in 1/48th scale,

and the cylinders in 1/32nd scale. As Homer Simpson would

say… DOH! So I said to heck with it and used the white metal

Liberty’s from Aeroclub. They clean up nice and look good when

painted, and the props I had custom made by Martin Digimyer, through

Copper State Models.

Tail Booms

- The Main

Booms are 1/8 inch dowel sanded to a taper on the ends. Center

Fittings are aluminum tube, drilled for Cross Tree and braces.

Cross Tree made from Contrail Strut Material, cut to length and

pinned for strength. Center Tail Boom also made from Dowel. All

were painted with Gray Lacquer and epoxied into place into holes

predrilled in wings and tail.

Tail Booms being built. All were cut to

length with the while model was firmly held in place in jig.

Rigging

- Rigging is a

combination of Lycra thread used for wing bay and control line

rigging, and Nylon Monofilament used in the Tail Booms for

strength. All holes pre-drilled, and CA used to anchor lines in

holes.

Lycra was used for Wing Bay and Control

Line rigging, Monofilament was used for the Tail Booms for strength

and to hold it all in place.

- Hull painted

with Gray Auto Acrylic Lacquer, with strips of white decal paper

used to form the Numeral 4 at all 5 locations.

- Wings and

Tail painted with Model Master Insignia Yellow, fin flash

painted using Insignia Red, White, and Blue, with Serial Number

from scrap decals.

- Wing

National Insignia made using PC and Detail Master

decal paper.

- Struts and

booms painted with Gray Auto Lacquer

- Nothing

unusual in assembly once parts were fabricated. Epoxy and CA

used almost exclusively for strength and for filling seams.

Wooden hull master was cut at the forward bulkhead and left

inside the assembled halves for strength. A special jig was

constructed to hold airframe in alignment as construction

progressed, and also serves as a transport caddy. Finished base

is ½ inch particleboard, sealed and painted with the same gray

used to finish model, and the pedestal is a block of mahogany.

Altogether about 734 hours were put into building the model.

This was a

rewarding project, in that I not only had a chance to exercise some

techniques I’ve used before, but I also had a chance to learn some

new ones along the way, talking to other modelers and seeking their

input. Is this model perfect? Heck no. I’ll be the first to admit

it’s not… it has it’s share of flaws and I know there’s a few places

that I had to make some “ejimicated” guesses due to lack of

reference material, but over all I am very pleased with the results.

It never fails to draw it’s share of ooo’s and ahhh’s wherever I

take it, and it has won two awards so far, First place in

Scratchbuilt Class at BUFCON 25, and First Place in Scratchbuilt

Class at NOREASTCON 2004. It’s a unique model of a unique subject,

and I had a ball building it, which is after all, what modeling is

supposed to be.

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search