|

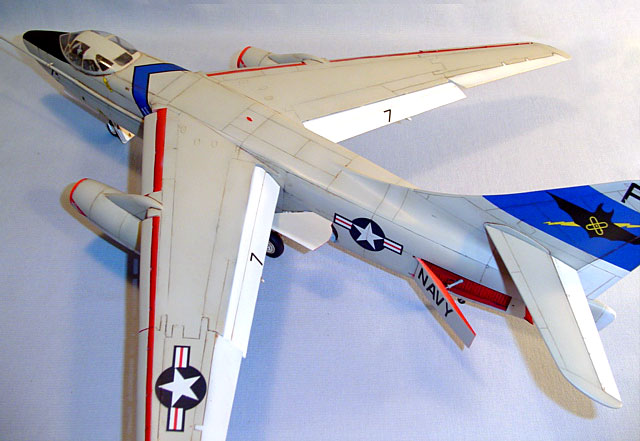

Collect-Aire 1/48 Scale

EA-3B Skywarrior

by Gil

Hodges

|

|

|

EA-3B Skywarrior |

HyperScale is proudly supported by

Squadron.com

For the few of you not familiar with the CollectAire company, they

make resin kits, primarily in 1/48 scale. You can check out their

selections at www.CollectAire.com. They have a wide range of subjects

that the mainstream injection molding companies have ignored either

because the subject was too obscure, or they just didn't think it would

be something that would sell well enough to justify the costs of making

it. The CollectAire kits are more expensive than the average model kit.

However, that's due to the limited numbers of kits molded per run

(hundreds instead of tens of thousands), the expense of the resin

(including the cost of decals, cast metal, and photo-etched parts); as

well as that "collectable" moniker!

I built the original issue of CA's 1/48 scale Skywarrior about ten years

ago. It built up into an impressive model.

But the newest issue of the EA-3B is an all new tooling. It puts the

original to shame!

To start with, the resin is a much higher quality. It

appears as smooth and shiney as plastic, and the engraved markings are

petite and well done. There was no evidence of warping on any of my kit

parts. The fuselage is hollow cast WITH the ECM consoles cast into the

inside of one of the halves. The cockpit interior is complete with

photo-etched consoles and main panels. The bottom crew access door is

separate, as is the fuselage side door. The wings are cast in one piece

from fold-line to fold-line, with the outer panels cast separately.

Metal hardware is included to provide detail and strength if you choose

to show the wings folded. The flaps and slats are all separate. The main

gear well is correctly molded with the appropriate "see through" area.

The landing gear are cast metal. They're both well detailed and strong

enough to support the model. The speed brakes and tail bumper are also

separate items that can be displayed in the open position. Two vacuform

canopies are provided, as well as the side windows. All in all, this new

kit gives you a lot of building optons that the original issue didn't

have.

If there's a downfall to this kit, it would be the instructions. They

are adequate, but could be better detailed and more precise in some

areas (like adding the landing gear). I highly recommend that you have

some extra reference material to help flesh out the instructions. Also,

although the decals are well printed and go on the model superbly,

there's only one option. As much as this kit costs, one or two more

schemes would be a nice addition. After all, there aren't any

aftermarket 1/48 Skywarrior sheets around!

Modeling started with the "clean-up" of the resin parts. Unlike

regular kits, the resin kit parts have some flash on them that needs to

scraped and sanded off. This isn't difficult and takes little time.

Also, it was mostly the smaller parts that needed this. The larger parts

were more cleanly cast.

Once clean-up was accomplished , the next step was to test fit the parts

together. The test fitting revealed that the CA Skywarrior is one of

their better fitting kits. The fuselage interior parts all fit without

any adjustments, and the seams were no worse than a regular injection

molded kit. The slat slots in the wing leading edges need to be filed a

bit to open them up more and allow the slats to fall into place. The

wing to fuselage joint was a mixture of good and bad news. The wing fit

to the body well on the bottom and on the top in the front. However,

there was a significant step at the back on the top of the fuselage that

took some work to get everything flush. Also, the outer wing panels

took some filling and sanding. This isn't unusual for most folding wing

kits, and I'd rate these wing joints as "good" for a resin kit, and

"average" when compared to the regular injection kit.

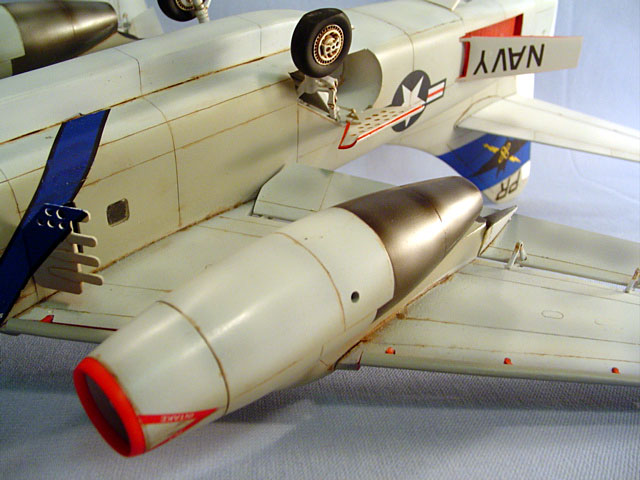

The kit engine pods are well cast and include turbine faces and

intake splitter vanes, as well as the "flame holder" exhuast plates. The

front of each intake is a separately cast cylinder. That allows you to

assemble the engine pod with NO seams inside the intakes! The fit of the

pods to the wings are pretty good too. Just be sure to get the right one

on the correct side; they are "handed".

Construction was straightforward with supeglue used throughout for

assembly. The interior was painted light gray with black consoles. The

PE parts for the panels in the cockpit are "blackened nickle-silver".

They can be glued in place without any painting needed! Don't forget to

add nose weight before closing up the fuselage. I used lead fishing

sinkers for this.

One of the trickier parts of "podded" engines is painting the red

intake lip. I did this by painting the red FIRST, and then masking it

off, inside and outside. Next, the interior was painted silver (to cover

the excess red) and then gloss white. The intake could then be glued in

place over the painted and assembled engine parts. The pods were filled

and sanded BEFORE they were added to the wings. In fact, next time I'll

even paint them before gluing them on!

I used the second canopy to make masks for the one on the model. I first

outlined all of the windows with a fine tipped black marker. Next, I

applied frosted Scotch tape to the canopy and cut the masks out. I then

carefully peeled off the Scotch tape masks and applied them to 3M Blue

masking tape (low-tack stuff) using them as patterns to cut the blue

tape masks for the canopy on the model.

Paint

The model was painted in the USN scheme of gull gray over white.

Model Master gloss paints were used.

The metallic areas of the engine pods were painted with Aclad2 dark

aluminum and steel. That allowed me to keep them masked for most of the

painting steps. The gear doors were outlined with gloss red and a fine

pointed brush.

The interior of the slat beds and speed brake wells, as

well as the speed brake interiors were all painted red. That really adds

some color to the scheme! MM lacquer gloss was used for the gloss coat.

The model was given a wash of burnt-sienna oil paint, thinned with

turpentine (mixed up in a plastic soda bottle cap). The excess oil wash

was removed with an almost dry paper towel, that had a SMALL amount of

turpentine on it. Another gloss coat sealed the wash and prepared the

model for decals.

Decals

The decals went down well, but the fit of the fuselage stripes

weren't as precise as they could be. To compound that, there was no

allowance on the decals for displaying the side door open. That meant I

had to do some fancy cutting around the door frame to get a piece that I

could apply to the door! Also, the instructions are weak on where some

of the smaller stencils and rescue arrows go. One more gloss coat was

added to seal the decals, and allow me to add a wash in their panel

lines.

It was now time to add the final parts, and this is when I ran into

the only bug-a-boo on this kit. The main gear are well cast and

detailed. But, their engineering does't really allow for the "testing"

of the sit of the model. It was at this point that I found that one gear

was about 1/8" longer than the other! I had no choice but to snip off

one oleo, file it shorter, and then glue it back in place. That,

combined with a bit of differential sanding on the tires got the model

to sit level.

The rest of the gear parts all went on with little to no

problems. Flaps, slats, actuators, and all of the rest of the fiddy

parts were added to complete assembly. A final flat coat was sprayed on,

the clear parts unmasked, and the model was done!

I enjoyed building this kit. Since I have to give it to it's rightful

owner, I plan to get another one in the future for my own collection.

The CollectAire EA-3B Skywarrior isn't cheap. But, it is a fine kit of

an important US Navy plane; and you're not likely to see this one put

out by a major manufactutrer. I recommend it to anyone who has some

experience with resin kits and who also has access to some reference

materials on the Skywarrior. Happy modeling!

Click on the thumbnails

below to view larger images:

Model, Images and Text Copyright ©

2004 by Gil Hodges

Page Created 15 March, 2004

Last Updated

15 March, 2004

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search