|

Dijun's 1/72

scale

EKW C-36

by Thomas

Muggli

|

|

|

EKW C-36 |

HyperScale is proudly supported by Squadron

For some time, I wanted a C-36 for my collection of Swiss Air Force

aircraft. I had long considered scratchbuilding a C-36 when I came

across the resin kits made by the French company Dijun. They offered

resin kits of several versions of the C-36. I shelled out a small

fortune for kits of the original C-3603 combat aircraft, the advanced

C-3604 and the C-3605 target tug. I decided to get started with the

C-3603 and the C-3605. The C-3604 wound up on the “to be built at a

later date” pile, since I don’t have much reference material about this

type.

Background

The C-36 was designed in 1942 by the Swiss Federal Constructions

Works (Eidgenoessische Konstruktionswerkstaette, or EKW for short) in

Thun, Switzerland as a multi-purpose fighter-bomber. It serves as an

example of longevity. Replaced as a combat aircraft by jets shortly

after WWII, it remained in service as a trainer and target tug for many

more years. In the late 1960s the remaining C-36’s ancient Hispano-Suiza

engines had become a maintenance nightmare. It was time for the Swiss

Air Force to look for a new target tug aircraft.

After careful evaluation the choice was made: the C-36. 24 of the old

C-3603 airframes were retrofitted with Lycoming turboprops. The result

was the C-3605, a sleek looking aircraft, which reminds me of a

pocket-sized Lockheed Constellation. The 45-year service history of the

C-36 finally ended in 1987 when the last C-3605 target tugs were

retired.

The Kits

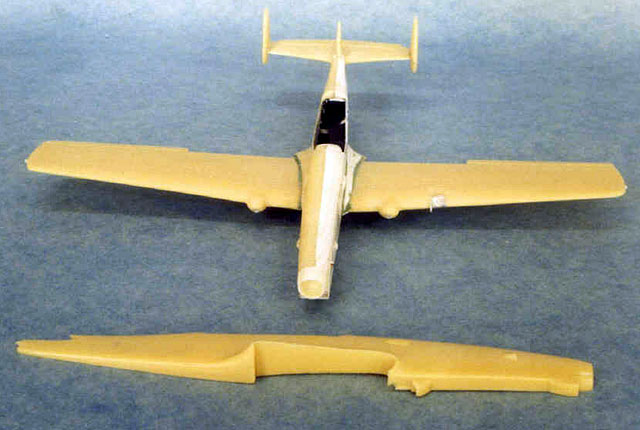

I realized that I would be in for a challenge as soon as I received

the kits in the mail. The parts come in a plastic bag. There is no box,

instructions or decals provided. The only “instructions” are a

three-view drawing and a photocopied picture of the aircraft.

Thankfully, I had a number of good photos from magazines and some I had

taken at the Swiss Air Force Museum, in Dubendorf, Switzerland, of the

real aircraft. If I had just used the information provided with the

kits, it would have been impossible to complete the project. The wings

and fuselage were loose in the bag, while the smaller parts were molded

into a thin resin sheet. There were no pour stubs. It did not take me

long to notice the most serious problem: The

C-3605 kit contained two left fuselage halves, but was missing the right

half! Normally, I would have returned the faulty kit. But since I had

ordered the kits from overseas and wanted to get the project underway, I

decided to scratchbuild the right fuselage half instead. Further

examination also revealed that the C-3603 was missing the tip of the

fuselage.

The first step of the construction was to replace the missing left

fuselage half of the C-3605. Other than the rounded top, the cross

section of the C-36’s fuselage is square. I built the square fuselage

portion first. Using the right fuselage half as a guide, I cut a new

fuselage side and bottom for the left side from sheet styrene. I also

made four bulkheads, which where glued evenly spaced to the front and

rear portions of the intact right fuselage half. For added strength I

also made two horizontal bulkheads and installed them to the upper

portion of the right fuselage half, between the vertical bulkheads

already in place.

The cockpit interior was next. I fashioned internal bracing from strip

styrene and also added thin copper wiring and electrical boxes made from

stryrene scraps to the cockpit walls. At the same time, I also glued the

cockpit floor, instrument panel, throttle and control columns to the

cockpit assembly. I used the seats provided in the kit, but installed

them after the model was painted. The cockpit was painted dark grey. I

also applied a wash of thinned, black acrylic paint and dry brushed some

aluminum to accentuate the various details. The cockpit details were

built up and painted the same way on the intact C-3603 model.

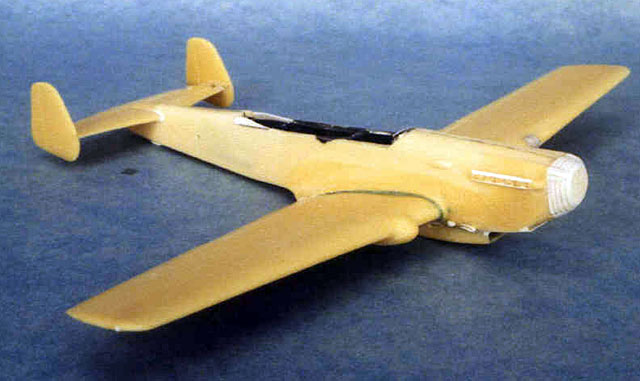

The next order of business was to join the fuselage halves. On the

C-3603 this was the standard procedure even though there were no

locating tabs. The fit was fairly good. At this point, I also added a

new fuselage tip made from laminated sheet styrene. The seams were

filled with superglue and sanded smooth. On the C-3605 on the other

hand, the operation was a bit more complicated. I sawed the turbine

intake portion off the right resin fuselage half. Then, I glued the new

left fuselage side and bottom to the bulkheads and let them dry

thoroughly. Next, I laminated several strips of 1mm-styrene strips and

glued them to the top of the left fuselage parts in front, and behind

the cockpit. Using a coarse sanding stick I shaped the laminated styrene

pieces to match the rounded top of the intact right fuselage half. I

closed the tip of the fuselage with a piece of 1mm sheet styrene shaped

to match the fuselage contour. Any seams and holes were filled with

superglue and sanded smooth. Panel lines on the new left fuselage half

were scribed to match the right half. I made a new circular turbine

intake for the tip of the fuselage from a section of a wing tank from my

spares box.

The wings were a pleasant surprise. They were molded in one piece and to

my delight there was no warpage, sinkholes or air bubbles. The only

items missing from the wings were the landing lights. I cut gaps into

the wing’s leading edges. Next, I glued pieces of chrome bare metal foil

into the gaps and added a piece of clear stretched sprue to each gap, to

simulate the light bulb. Finally, I fashioned the lenses from pieces of

stretch formed clear acetate and installed them with superglue. After

only a few passes with a sanding stick around the edges the wings were

ready for installation. Again, on the C-3603 this was not very

difficult. Only a few gaps appeared which were easily filled with

styrene strips and superglue.

However, due to the fuselage surgery, the wing installation on the

C-3605 was a bit more difficult. Careful test fitting was required

before the wing could be glued in place with liberal amounts of

superglue. Since the fairing between the wing and fuselage is molded as

part of the fuselage half, it needed to be replaced on the left side. I

glued several styrene strips to the wing/fuselage joint and gave them

the proper shape with a coarse round file and sandpaper. After carefully

checking that the new fairings on both sides matched, I filled some

holes and gaps with superglue and smoothed the seams using various grits

of sandpaper. The kit parts for the tail are not great, but they were

good enough for my taste. To strenghten the joints between the

horizontal and vertical tail surfaces, I drilled holes to accept steel

wire plugs. I glued the tail assemblies in place with superglue paying

careful attention to proper alignment.

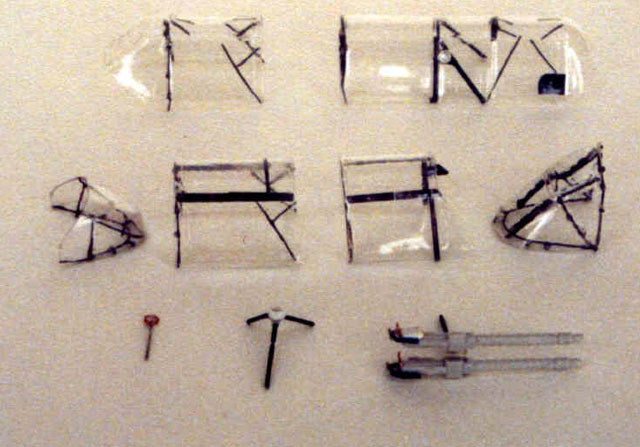

The Canopies

My Dijun kits came with two canopies each. After literally spending

hours nipping, sanding and test-fitting, I had two canopies that would

fit my models halfway decently. Notably, there were no spare canopies

left when I was done. The windshield supplied in the kit is not correct

for a wartime C-3603. I stretchformed a new windshield from sheet

acetate. This did not create any additional fit problems since I

intended to pose the canopy of the C-3603 in the open position. I gave

all the canopy parts a bath in Future floor polish and let the dry

thoroughly.

Real C-36s have a unique canopy construction. The plexiglas canopy is

mounted on a steel tube frame. This framework is quite noticeable, but

would be a challenge to create on a small scale model. Nevertheless, I

felt that this was an important characteristic of these aircraft and

should be represented on my models. So I went to work with fine copper

wire, stretched sprue and superglue to build the parts of the framework

that are visible on my reference photos. After painting them with the

interior color, I installed the various portions of the framework to the

inside of the canopies with tiny amounts of superglue. This was quite

delicate and time-consuming work but looking at the finished models I am

happy that I made the effort. I left the installation of the canopies

until the very end of the project after painting and decaling were

completed. For the external canopy frames I used clear decal film which

I first airbrushed with the interior color then the external color and

the same final clear coat I used on the model. The decal film was then

cut in thin stripes and applied to the canopies after they were

installed.

More Details

A number of detail parts on the underside of the C-3605 needed to be

scratchbuilt. I fashioned an air intake under the nose, the turbine

exhaust as well as the box containing the target reeling mechanism from

sheet styrene and scraps. The twin machine guns for the C-3603 came from

my spares box. The stand for the gun was made from steel wire. I also

detailed the gun with styrene scraps, copper wire and bits of brass left

over from a photoetched detail set.

I was fortunate enough that none of the landing gear legs, or propeller

blades, broke while being removed from their resin sheet backing, or

during the extensive cleanup which was necessary for these parts. The

landing gear legs, which would be bearing the weight of the model,

seemed particularly fragile. I could have made new ones from wire but

instead decided to cover the resin parts with a coat of superglue to

give them added strength. The landing gear actuator arms were missing

from the kits. I scratchbuilt them from bits of styrene strip. I used

the kit-supplied wheels for the C-3605. The wheels provided in the

C-3603 kit are incorrect, so I raided my spares box for a more accurate

set. I made the wheel covers from thin sheet styrene stretch-formed over

the upper portion of a kit-supplied wheel mounted on a wood dowel.

The kit-supplied tail wheels were too small for my taste. Once again I

reached for my spares box to find better-looking replacements. The

landing gear doors provided in the kits were not completely convincing,

but I decided to use them anyway. A number of additional details such as

aileron counterweights, pitot tubes were made from styrene scraps and

installed after the models were painted.

I painted my C-3603 in “Neutrality” markings. They were applied to

all Swiss aircraft between September 1944 and the end of the war.

All markings with the exception of the registration numbers, which

are dry transfer decals, were airbrushed. I used acrylic paints from

Tamiya and Model Master.

First,

I airbrushed flat white over most of the model, which also helped

identify some blemishes, which needed to be eliminated. The areas, which

were to remain white were masked off, then I airbrushed flat red. After

masking the red areas I airbrushed light blue gray (similar to Hellblau

RLM 65) for the undersides and masked once more before finishing the First,

I airbrushed flat white over most of the model, which also helped

identify some blemishes, which needed to be eliminated. The areas, which

were to remain white were masked off, then I airbrushed flat red. After

masking the red areas I airbrushed light blue gray (similar to Hellblau

RLM 65) for the undersides and masked once more before finishing the

upper surfaces with dark green (similar to Schwarzgrun RLM 71). For

weathering I applied a light sludge wash and airbrushed exhaust stains,

then applied a final coat of clear flat.

The C-3605 received the high visibility lemon yellow and black paint

scheme, which was applied to all aircraft during their whole careers.

Again, I used acrylic colors. For the bare metal areas, I airbrushed

Testor non-buffable aluminum. The decals for the national insignias came

from a Shadow decal sheet while dry transfer decals were used for the

registration numbers. I also made some small maintenance stencils on my

computer and printed them on clear decal sheet on my inkjet printer. My

spares box was the source of some other small markings. A final coat of

Future floor polish gave the model a nice sheen.

My two C-36s were my first resin project. It was a bit tougher than I

expected, but it showed that with patience and bit of elbow grease even

challenging resin kits can be made into quite presentable models. I am

positively ready for more resin!

Click the thumbnails below to view larger images:

Model, Images and Text Copyright © 2005

by Thomas Muggli

Page Created 11 November, 2005

Last Updated

10 November, 2005

Back to

HyperScale Main Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search