|

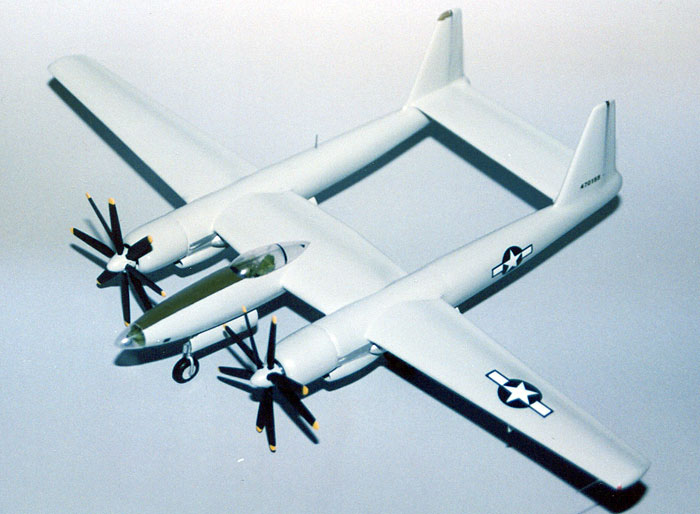

Execuform's 1/72 scale

Hughes D 5, USAAF F-11

by

Tom Conte

|

|

|

Hughes D 5, USAAF F-11 |

HyperScale is proudly supported by

Squadron

Considered to be the first purposed built aircraft for

photoreconnaissance, the F-11 quickly passed into history due to its

late arrival after WWII. Using speed and altitude as protection against

interception, the F-11 represented the peak of the piston engine

aircraft design. During testing, even contemporary jet fighters had

difficulty in getting a good shot at it.

The famous aviator, Howard Hughes was obsessed with speed and setting

records. He used a custom made single engine aircraft to capture US

speed and distance records and commercially built machines to win world

records. Not being satisfied with his record time around the world, he

had his engineers start on a twin engine project for his next attempt.

The beginning of WWII in Europe interfered with his plans because of

restrictions placed on high performance engines, which he needed to

complete the plane now called D-2. In order to obtain the engines he

wanted and try to recoup some of the cost in developing the D-2, he

offered it to the Army Air Force. The plane was too big for a fighter

and had inadequate capacity for a bomber therefore it was suggested to

be used as a dedicated reconnaissance aircraft. Most recon aircraft of

the time were modification of existing types. However, it was built out

of molded plywood; while this type of construction resulted in a smooth

surface required for high speed flight, the AAF did not want a wooden

combat aircraft. Hughes desired a military contract and after prolong

negations, his designers came up with the D 5 concept that finally

became the F-11, the F designation for photorecon.

The delay in being given a contact is not the main reason that the F-11

missed participating in WWII. The demand for the engine in other

aircraft already in production prevented any being delivered so that the

F-11 test flights could be completed in time. When the F-11 finally flew

in April 1946, the first flight ended in a crash with Hughes at the

controls. Two more F-11 were finished and delivered to the now US Air

Force. While it was a great performing aircraft, budget cuts and jet

aircraft prevented the F-11, later XR-11, from entering into productions

or operation.

Execuform's

1/72 scale Vacform F-11

|

I came across the many F-11 years ago. My references date from the

1970ís. Running out of things to build, I was planning a scratchbuild

effort. Procrastinating again came to my rescue as Execuform offered the

F-11 as a vacuform kit in the late 80s. About a year ago I decided to

build the kit and started the process of freeing the molded parts from

the sheets. The pieces were waiting for some type of progress until last

month when I heard of a movie called the Aviator that was about Hughes.

I wasnít interested because there were other films made about him

before. But this one was different, while the other films used a P-38

Lighting to represent the F-11, this movie went to the trouble of

depicting the F-11. Hurray for big budgets and CGI technology. Of course

now I had to finish the F-11.

I donít want to say the Execuform kit is a difficult kit. Iím thankful

that it was available, However this project consumed a whole tube of

filler and six sheets of sanding paper. But it was complete with parts

for the counter-rotating props and landing gear made out white metal. It

also contained resin cast wheels as well as a nice set of drawings and

good instructions.

A big challenge in constructing any vacuform kit is sanding down the

shaped pieces after they are removed from the sheet. If you are not

careful, due to the unequal force of your fingers, the part may not come

out evenly sanded and the seam winds up not being a straight line. This

shows up as an irregular shape structure on the model. To avoid this, I

used a flat piece of wood taped to the top of the wings to apply even

pressure across them while sanding. This worked out great.

The tail booms were held by a piece of wood that was first cut and

sanded to conform with the pieces before they were removed from the

sheet, this also provided something easier to grip. Final results were a

straight edge between the tail boom halves.

Testorís liquid cement quickly joined the pieces and held the thin

trailing edges of the wings and tail together.

Included

in the information was both interior and exterior color suggestions. I

felt that the recommended exterior gray was too dark based on the photos

I had and lighten it up a bit to match the gloss gray of the early P-80.

The model was finished with Testorís enamels. Included

in the information was both interior and exterior color suggestions. I

felt that the recommended exterior gray was too dark based on the photos

I had and lighten it up a bit to match the gloss gray of the early P-80.

The model was finished with Testorís enamels.

There were bare metal surfaces on the F-11 and these were depicted

using Bare Metal Foil.

Decals came from after market sheets.

To attach the white metal landing gear parts to the fuselage and the

wheels, super glue or CA was used. A minimal cockpit was created, and

finally the canopy was attached with canopy glue.

Two really trick tasks was mating the canopy and creating the props.

Only one canopy was provided with the kit and I wanted to avoid ruining

it. I poured resin inside the canopy after applying mold release and

once cured removed it and used that to cut and file to match the

cockpit. When I was satisfied with its fit, it was then used as a

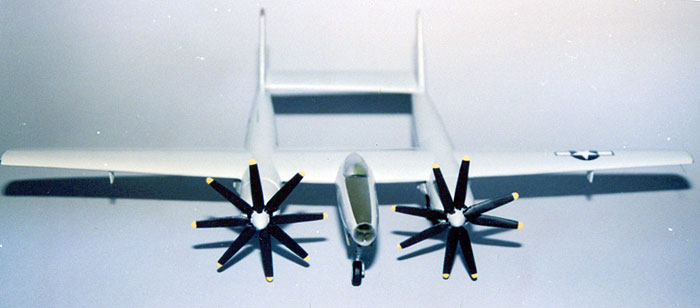

template to cut the canopy. Pour A Cast resin helped in making the props

too. I could not see an easy way to cut up the spinner to fit around the

eight props blades. The resin was again poured into the piece, but this

time I did not remove it. It provided a solid base to drill into and

firmly hold the blades. The weight of the metal props is needed to make

the model sit on its nose wheel.

The F-11 was a large aircraft. Its wingspan was only two feet shorter

than the span of a B-17! This results in a model with a nearly 17 inch

wingspan in 1/72 scale.

It is an impressive model and definitely belongs in a post WWII

collection; I hope I can enjoy the movie after spending so much time in

researching the project!

Model, Images and Text Copyright ©

2005 by Tom Conte

Page Created 18 January, 2005

Last Updated

17 January, 2005

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search