|

Monogram's 1/72 scale

F-16C

A Tale of Two

Falcons

by

Rafe Morrisey

|

|

|

General Dynamics F-16C |

HyperScale is proudly supported by

Squadron

At the beginning of the

year I took my first foray into the realm of professional model making

by accepting a commission to build a Monogram 1/72 scale F-16C.

Since I wanted to do a

good job and had wanted an F-16 in my own collection I decided to build

two kits at the same time using the first to identify problems and

determine solutions that could be applied to the customerís model. I

will dispense with the usual historical overview of the aircraft and

simply refer you to the multitude of other articles on this site and

others that cover the development of the airplane in great detail.

With respect to the

Monogram kit, let me say that the kit represents great value for the

money combining numerous options to build a well-detailed model of most

variants of the F-16 with a very complete selection of under-wing

stores.

At the same time, the

model contains some peculiar design elements and inconsistent quality

control that make for some extremely frustrating moments during

construction. Ultimately, the model builds into a fine replica of the

prototype and will make a worthy addition to the display shelf.

Cockpit

As with most airplane

models, construction began with the cockpit. Since I was working under a

deadline, I elected to use the kit cockpit and it turned out to be very

nice indeed. Actually, the hardest part was determining which parts to

use since there are no fewer than three instrument panels on the sprues.

Iím not an F-16 expert but it looks like to me that the builder could

make almost any production model of the Falcon including some export

variants from the parts contained in this kit. Both standard and

wide-mouth intake configurations are provided along with different

tails, engine nozzles and the aforementioned cockpit options.

The only enhancement I

elected to make was to carve out the CRT screens and replace them with

bits of green plastic confetti. This is a technique I picked up here on

Hyperscale and it greatly improved the appearance of the cockpit. The

remaining parts were painted and dry brushed to bring out the excellent

molded detail. I encountered the first of the design quirks I mentioned

at this stage, however. The ejection seat is an extremely tight fit and

the throttle assembly hangs over the seat preventing installation after

painting. Since the seat fit so tight I inserted it without glue and

left it tipped forward to aid in masking the cockpit.

Click the thumbnails below to view larger

images:

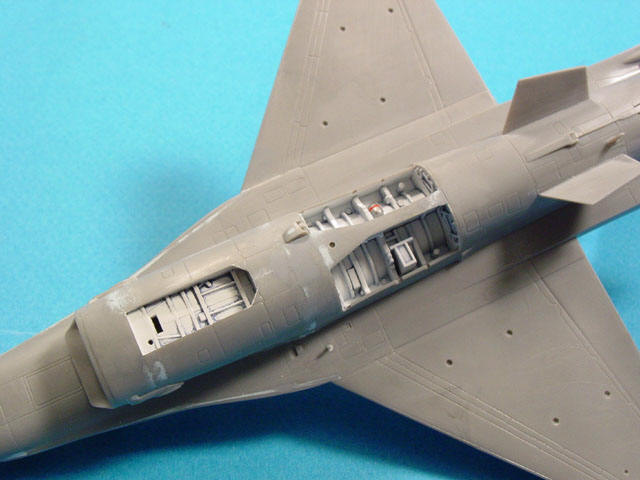

Airframe

I proceeded to assemble

the rest of the airframe and encountered some issues in fitting the

intake pieces. Modern aircraft have very complex forms and they present

major design hurdles for model makers. In this case the fit of the

intake underneath the fuselage was not great and it was very difficult

to fill and sand the seam between the top of the intake and the bottom

of the fuselage. I applied 3M Acryl Blue putty as neatly as possible and

used q-tips dipped in nail polish remover to wipe away most of the putty

from the surfaces around the seam. This minimized the sanding that was

required. I also used tissue paper coated with diluted white glue to

form FOD covers over the intakes. These were removed when dry for

painting and installation at the end.

It was at this stage that

I faced probably the most frustrating design element (dare I say flaw)

of the kit. Rather than mold the exhaust cone for the engine as a

separate piece, the kit designer elected to mold it to a section of the

rear fuselage. This made it impossible to paint and weather the exhaust

cone later in the assembly sequence. Instead, I had to paint and finish

the exhaust cone and then mask it. The fit of the rear fuselage/exhaust

assembly was not great requiring a good deal of filling and sanding near

the finished exhaust cone. This is one area I wish had been engineered

differently but in the end it worked out all right.

Landing Gear

The kit landing gear is

very detailed but the parts are extremely small. A lot of tedious

scraping was needed to remove mold-parting lines and manipulating the

gear assembly with my big fingers was tricky. It looks convincing once

installed, though. The kit wheels are very nice but quality control was

an issue since the main wheels in one of the kits had severe sink marks

rendering them useless. Each kit comes with two types of wheels,

however, so I used the alternate set for my Falcon.

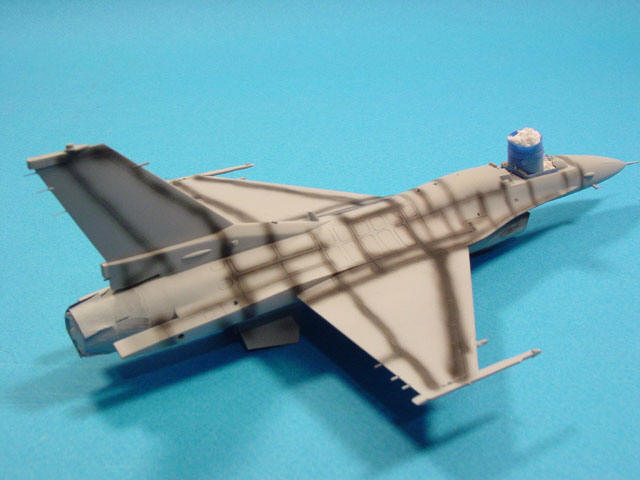

Painting,

Markings and Weathering

|

Painting

I used this model as an

opportunity to try pre-shading since I would not have a lot of time for

weathering the customerís model due to the deadline I had been given. I

sprayed a dark gray color along the panel lines over a light gray

primer. I like to mix my own colors so I then mixed and applied the

necessary tactical grays beginning by filling in the center of the

panels and working outwards. I finished with a light over spray over the

panel lines to tone them down to a realistic level. I was quite pleased

with the ultimate effect. You will notice that the top color is

different between the two models. This is because the customer had

specified Nellis AFB markings for his aircraft.

I found a TwoBobs ďTaxi

Cab VipersĒ sheet on sale and knew it must be fate. The markings on the

TwoBobs sheet were quite dark, however, requiring a dark base color in

order to show up. I checked the reference pictures on the instruction

sheet and some photos reflected a darker color than Iíve seen in most

photos, so I did what I had to do.

On my F-16, I used a

lighter gray for the top color in keeping with most of my other

reference photos.

Decals

As mentioned above, the

TwoBobs ďTaxi Cab VipersĒ sheet was used for the customerís F-16. At

first I was very concerned about how it would turn out since TwoBobs

uses multiple layers for complex designs to ensure accurate

registration. The small school badge was comprised of four separate

layers including a decal no bigger than a pencil point. My fears were

unfounded, however, as the decals performed flawlessly. I allowed ample

time for each layer to dry and used Micro Set and a touch of Solvaset

here and there. The decals even conformed over several antenna bulges on

the nose and base of the tail that thought would cause big problems. I

also made a custom decal for the nose reflecting the customerís name as

the crew chief per his request. One of my good friends, Mike Teel,

helped me design the decal in Photoshop.

For the airplane I was to

keep I decided to try the kit decals since I live in the Washington, DC

area and the sheet included markings for one of our ANG units. Again

quality control seems to vary between kits as the clear film on one of

the decal sheets had yellowed. Using the good sheet, I pressed on and

was very pleased with how they performed. Though much thicker than the

aftermarket sheet, the kit decals conformed to all the bumps and bulges.

I did have one mini disaster in that the Solvaset reacted with one of

the kit decals causing it to leach out a green stain. I think this is

because the markings were metallic and the acid in the solvent caused

the brass particles in the ink to corrode producing the green color. I

was able to remove the affected decals and replace them with ones from

the other kit sheet. I only used Micro Sol on the substitutes and had no

other problems.

Weathering

On

both models I applied a diluted wash of Payneís Gray oil paint thinned

with Testorís enamel thinner to the gear bays and landing gear following

a gloss coat. On

both models I applied a diluted wash of Payneís Gray oil paint thinned

with Testorís enamel thinner to the gear bays and landing gear following

a gloss coat.

On my model I also applied

a light wash of Raw Umber oil paint in the panel lines over the

pre-shaded paint finish. I applied a pastel sludge wash to the various

vents and control surfaces removing the excess with a damp Q-tip.

Pastels were also lightly

applied to the drop tanks of my model to represent grime from fuel

spills. Everything was sealed in with an over spray of Testorís Acryl

clear flat.

Base and Figures

The customer had requested

a base for his model so I pulled out an old copy of Air and Space

Magazine with a picture of airplanes sitting on the runway at Edwards

AFB. Assuming the landscape at Nellis would look fairly similar, I did

my best to match the tarmac and ground colors. Matt board was used to

replicate the tarmac. I t has the right texture and came in a nice tan

color. I over sprayed it with light mixtures of tan and light gray in a

random pattern to match the photos and added cracks and expansion joints

with different artists pencils. The groundwork consisted of tile grout

that was painted a desert tan after drying. I added some dark washes and

dry brushing and then applied a few random foliage bits from Woodland

Scenics.

The figures and

accessories in the shots of my F-16 came from a Hasegawa ground support

set.

Images were taken with a

Sony DSC-85 digital camera. I used a piece of cloud pattern poster board

from Office Depot for the backdrop. The camera was set in manual mode

with the maximum f-stop setting of f.8, film speed of ISO 200 and preset

focal distance of 20 centimeters. The photos were cropped and lightened

as necessary in Photoshop.

My thanks go out to Ian

Robertson for helping me learn to use my camera.

Click the thumbnails below to view larger

images:

Images and Text Copyright ©

2004 by Rafe Morrisey

Page Created 03 September, 2004

Last Updated

04 September, 2004

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search