|

Building Revell's new

1/48 scale

F/A-18E Super

Hornet

Part Two

by

John Chung

Revell's 1/48 scale F/A-18E Super Hornet is available online

from Squadron

For more information about the new

1/48 scale Revell

F/A-18E Super Hornet, please visit my

in-box review here on Hyperscale.

Wings

The kit inner wings were molded integral to the fuselage halves with

the outer wing split roughly where the wing fold is. While this

eliminates problematic wing-fuselage joints, test fitting reveals

careful alignments of outer wing sections would still be necessary (see

title image)

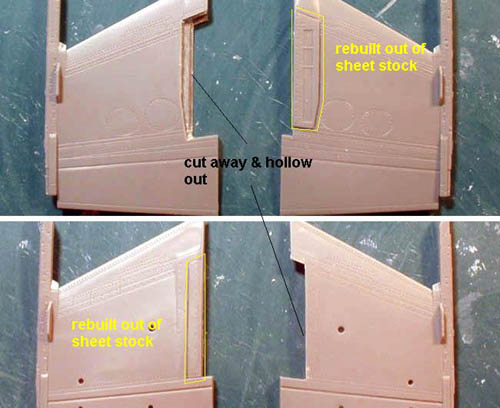

While the wing breaks roughly at the wing fold, it really isn’t possible

to pose them folded without some work still. To start, a section of the

outer wing will need careful removal and the displaced area rebuilt;

namely the upper panel that folds up and a small strip on the bottom.

The wing fold mechanism consisted of just strip styrene of styrene

wrapped around a styrene rod.

Click the thumbnails below

to view larger images:

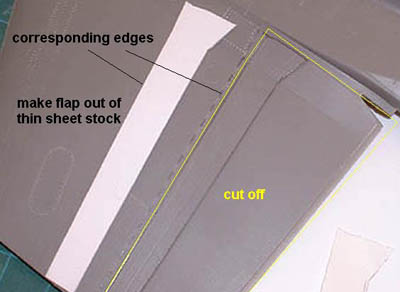

As the F/A-18 Hornets typically park with fully deployed trailing edge

flaps due to bleeding of hydraulic pressure upon shutdown, I’ve elected

to drop them on the model. The Hornets are equipped with single-slotted

Fowler flap which is a bit more involved to modify. The flaps were first

cut from the wings; the top piece removed along with the panel just fore

of it, the latter of which was replaced with a scratch built item. The

removed flap was then filled and profiled to a proper airfoil.

The flap hinges were modified corresponding to the new flap position,

and an actuating rod inboard the flap was built to support the assembly.

Overall alignment was done at this point to ensure symmetry between the

two wings. Note that there should be a very fine slot between the flap

and the wing as featured on Fowler flaps.

Click the thumbnails below

to view larger images:

A small cut out should be made on the aft inboard corner to clear the

fuselage missile station. The fuselage corresponding to the flap was

also filled in and built up with appropriate surface details. Similarly,

the fuselage contours adjacent to the leading edge flap was slightly off

and was built up and the correct surface detail rescribed.

Click the thumbnails below

to view larger images:

Lastly, the wingtip launchers were slightly modified for a more

accurate representation. The Super Hornet uses three different types of

wingtip launchers distinguishable by their respective physical

differences. By observation, it seemed Revell had crossed between the

details so a ~3.3mm insert was added just aft of the wingtip formation

lights to alleviate this issue.

Click the thumbnails below

to view larger images:

Empennage

The horizontal stabilizers were attached via a carry-through member

inserted into the aft fuselage. This design allowed very rigid and

positive attachments than most other kits concerning stabilator.

However, make certain you do NOT try and attach these before they’re on

permanently, otherwise you’ll mostly likely break something trying to

remove it . . . uh, like I did.

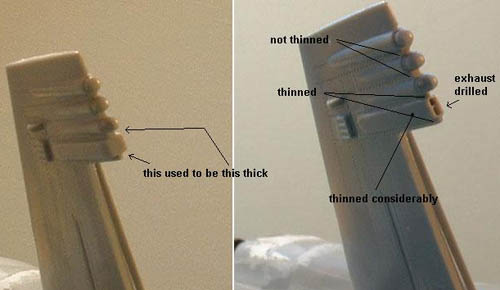

The vertical stabs were an enigma. They were molded with strange, thick

beveled leading and trailing edges that needed removal and lost details

replaced. More annoying was the stab base reinforcement bulge, which was

wrong and needed quite a bit of re-profiling on both inside and outside.

The general fuselage contour in this area was also off enough that the

removed rudder would not deflect due to interferences with the fuselage.

Consequently, the vertical stab base, rudder and fuselage contours were

also reshaped. Lastly, the upper trailing edges exhaust ports were

thinned down and drilled out.

Click the thumbnails below

to view larger images:

Aft Fuselage

The Revell exhausts were too small and short internally, ending at

where the finger braces meet the fuselage, a by-product of the

horizontal stab carry-thru member. I elected to resort to heat-and-smash

covers once again as a fix would have been quite involved. Also note

that the exhaust feathers should have a slight clockwise-twist while

Revell had them straight. As well, the finger braces should follow the

fuselage contours while Revell had them along the feathers.

The arresting hook and faring were molded in a single piece, so they

were removed and separately improved upon. The hook was refined both at

the base and the tip, and the faring also received minor detailing.

Click the thumbnails below

to view larger images:

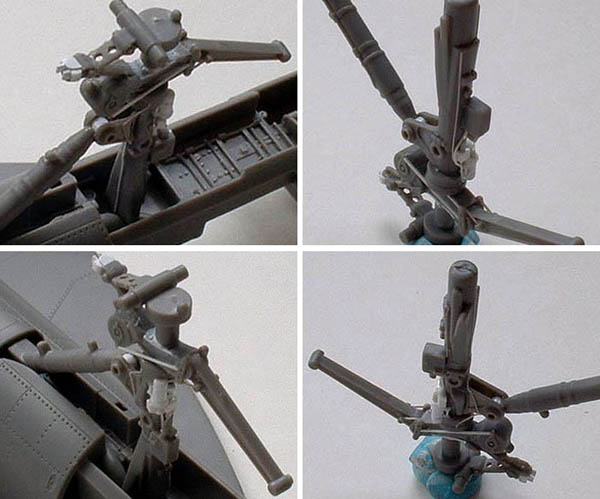

Landing Gear

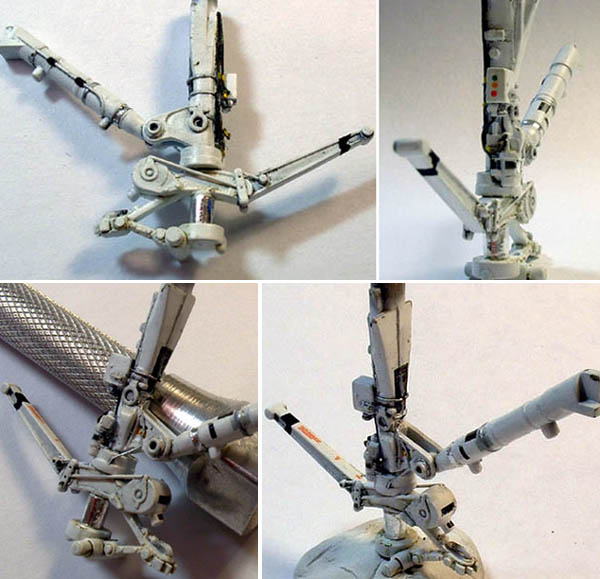

The kit landing gears were generally well done for a

single-piece affair, but lacked the details and finesse of a multi-piece

assembly.

The nose gear strut launch bar linkages were removed and rebuilt, along

with the retraction/main strut elbow which was hollowed out. Holes in

the shock scissors were detailed out and the oleo shortened by a bit to

reduce the nose-high phenomenon. Further detailing included misc. wires

and bottles from styrene rods and sprue. Improving the main gear struts

was a bit more involved, the chief of which was the drilling out and

modifying the solid knee joint. The shock struts were replaced with

brass tubing as the kit items were poorly molded on a diagonal.

Additional hydraulic wires, tie-downs, and other items complete the

detailing.

Attention was given to the nose wheels, which were a little too squared

and the thread details piled up like mini stepped pyramids. The threads

were sanded down and the tires rounded off at the corners and around the

rims. Thread details were not replaced because, well, I can’t scribe

threads if my life depended on it.

Click the thumbnails below

to view larger images:

The struts were painted with Tamiya gloss white and weathered with

artist’s oil paints prior to flat coating. The oleos were covered with

bare metal foil, and the various wires and pipes painted appropriately.

Decals were a mix of kit supplied placards and scrap bin scavenged.

The gear bays didn’t come out as nice as I had hoped, given the

relatively soft and overly busy molded-on details. Do take note that the

red trim on the gear doors have specific patterns, especially the MLG

doors.

Click the thumbnails below

to view larger images:

Stuff That Hangs

The GBU-16 and JDAM were from Hasegawa’s weapon set. The USN

anti-fire coating was reproduced by scrubbing with toothbrush over the

plastic surface softened with liquid cement, being careful to achieve a

very subtle effect. The GBU-16 had the forward and aft (retracted) fins

replaced and the seeker head hollowed and lowered. Both bombs were also

detailed with a few other paraphernalia. Decals were once again a

combination of weapon set’s and those from the scrap bin.

Click the thumbnails below

to view larger images:

The AIM-120 was taken from Hasegawa’s 1/48 F-16C kit, and was further

refined with new surface details, new fins, cable conduit and exhaust

details. The forward fins were sprayed with a slightly metallic colour

before the edges were masked off and the centre painted flat black.

Decals came from Twobob’s AIM-120/AGM-88 sheet, which went on

beautifully but required minor trimming and adjustments for proper

alignment. The AIM-120C pylon needed modification to better represent

the actual launcher.

Click the thumbnails below

to view larger images:

The empty outer pylon was detailed with scratch built mechanisms on the

lower surface. Sway braces on the empty fuselage station were also

reshaped a little. The inboard wing pylons were left off and the

associated mounting holes filled, rescribed, and an attachment eyehook

built just before the flaps.

Click the thumbnails below

to view larger images:

Someone pointed out to me that the kit centre fuel tank may be

somewhat too low as apparent by its relative height to the bottom intake

lip. After a bit of Mk.1 eyeball gauging, I removed just under half the

pylon height which allowed a more appropriate height for the tank. Note

that the leading and trailing edges of the pylon were flat and were duly

sharpened.

Click the thumbnails below

to view larger images:

A significant amount of modification was needed on the AN/ASQ-228

ATFLIR pod and its fuselage adaptor. I’m not sure what Revell had as

references but certainly was not the ATFLIR. Much time was spent trying

to reshape the adaptor and the adjacent fuselage to achieve an

acceptable contour, as well the form the surface panel line details of

the pod itself.

Click the thumbnails below

to view larger images:

End of Part Two

Model, Images and Text by Copyright ©

2006 by John Chung

Page Created 06 March, 2006

Last Updated

06 March, 2006

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search