|

Fiat G.50bis Freccia

by Werner Scheibling

|

|

|

Fiat G 50bis

Serie V, MM. 5945,

20° Gruppo Autonomo C.T., 352a Squadriglia,

Martuba (Libya), June 1941 |

HyperScale is proudly supported by

Squadron.com

Italian Classic's full resin kit with additional

white metal and photo-etch parts is one of three options (next to

Hasegawa/Secter's injection-molded and Pacific Coast Models' mixed media

kit) available to those who want to build a Fiat G 50 in 1/48 scale.

Apart from being the most expensive, it is

unfortunately also the trickiest kit to build. It kept me busy for

nearly one and a half years nonstop.

If you calculate how much the average modeller

might spend on mainstream kits in that time, it's not such a bad deal

after all (does that sound a bit like an excuse?)

While talking about costs I should also mention

that it is almost essential to have access to the 'Ali d'Italia'

reference book on the Fiat G 50. This is where I found all the necessary

plans and information to figure out how the parts go together. The kit's

instructions are photocopies of hand-drawn sketches and are not very

helpful, to say the least.

Other 'musts' while tackling this kit are a

reliable electric tool with various milling and grinding bits, a razor

saw and - if possible - a set of calipers or a pair of dividers for

essential measuring.

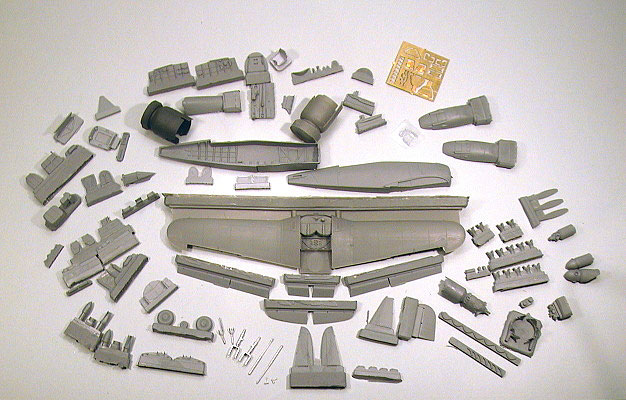

In an extremely sturdy cardboard box you'll find 150 resin, white metal

and photo-etch parts, tightly packed in several zip-lock bags. In

amongst this multitude are two types of cowlings (smooth or with rocker

cover bulges), two different gun-bay covers (small or large bulges),

both kinds of spinners (small or sand proof), both kinds of carburettor

air intakes (open or with sand filter) and finally underwing racks plus

bombs. In this way the kit allows you to build virtually any possible G

50bis/AS configuration.

The resin casting in my kit was unfortunately a bit

on the disappointing side – there were quite a few unnecessary casting

imperfections that needed hours of clean-up, and some nasty trapped air

bubbles where I least wanted them.

The material on the other hand is of very good

quality – strong, elastic and very break resistant. This makes the work

with very delicate parts, like the paper-thin landing gear covers, much

less nerve-wracking.

All important internal fuselage parts are represented, even a petrol

tank under the cockpit floor and several bulkheads that will disappear

forever in the fuselage unless you decide to build a museum style

cutaway model.

As the kit does not include a decal sheet it is necessary to find a

suitable after market set. I went for the 'Sky Models' sheet, printed by

'Cartograf', as it is readily available and of highest quality.

Sequence

The best way to build this very complex resin kit

is to break up the project into independent sub-assemblies which should

finally be joined together after they have been completely finished -

including painting and weathering.

I chose the following order:

-

cockpit

-

fuselage/wing/tailplane

-

engine/cowling

-

airbrushing and

decalling

-

undercarriage

-

final detail parts

(propeller, pitot and venturi tubes, aileron mass balances and trim

tab actuators.)

If I had decided to show my model with a detachable

gun bay cover (the parts are there and I was strongly tempted!) this

would have led to a further complex sub-assembly.

The decision to put all these nice resin parts into

the spares box was not an easy one. After hours of measuring with

calipers and dry fitting, I came to the conclusion that it would be next

to impossible to cut and assemble the involved parts so precisely that

the resulting panel lines wouldn't stand out embarrassingly.

Leaving the gun bay cover off permanently would

have ruined the G 50's typical silhouette - the hump between cowling and

windshield being the type's giveaway recognition feature.

Cockpit

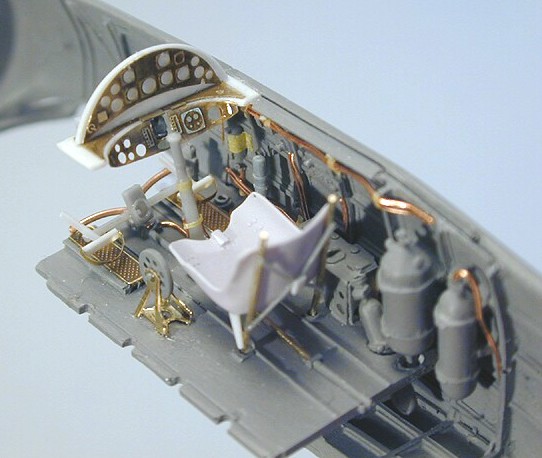

The inner fuselage side panels had to be cleaned up

before I could add all the necessary plumbing from copper wire in

various widths (0,1 - 0,3 mm). The castings of the four compressed air

and oxygen bottles behind the pilot's seat were bad and it took a whole

evening of creative sanding to achieve a halfway round appearance. I

painted these items a neutral metal colour as I could not find any

reference on their original colouring (if there ever was any). The real

G 50 needed all this compressed air for its pneumatic engine starter and

wheel brakes.

Click the thumbnails below to view larger

images:

Other parts like seat support frame, control

column, rudder pedal bar, instrument panel lights and various levers

were built from scratch.

The intricately curved and angled instrument panel

was created using Eduard's early PE set for the Hasegawa/Secter kit and

thin styrene sheet.

The pilot's safety harness is a generic item from

RCR's excellent PE set.

Fuselage/Wing/Tailplane

The casting of all involved parts is generally rich

in detail, but unfortunately very vague concerning precise dimensions.

It's not always completely clear where the part ends and the casting

block starts.

With lots of dry fitting and measuring against the

excellent scale plans in the 'Ali d'Italia' book I came up with the

following assembly sequence:

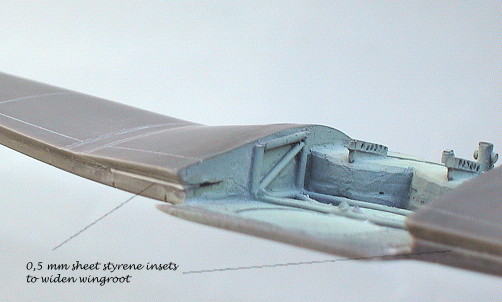

First the width of the fuselage has to be defined

via measurements taken from the one part wing (wing root to wing root),

from the front and rear upper fuselage deckings and from the tail cone.

Then the width of the cockpit floor has to be adjusted accordingly. As

you can see in the photos I had to insert slivers of sheet styrene along

the front bulkhead (which also serves as an attachment point for the

engine and should therefore be very sturdy), along the seam of the lower

fuselage and around the rear fuselage decking to make everything fit

properly.

Before both upper fuselage deckings can be

installed, it is vital to mark, on both fuselage halves, where the

pilot's small entrance doors will later go. These markings define the

position of front and rear fuselage decking and not vice versa!

Otherwise you might find out that the model is nearly finished and the

gap you left for the doors is too wide or too narrow...

The addition of tail cone, vertical and horizontal

tail surfaces completed the basic fuselage sub-assembly.

I reinforced the attachment areas of vertical and horizontal tail

surfaces and all movable flying surfaces with stubs of brass wire, to

make sure I could handle the assembled model safely.

To the best of my knowledge, the one piece wing with separate flaps and

ailerons started its career as a replacement part ('corrected wing') for

the Hasegawa/Secter kit.

This is unfortunately the reason for one of the

kit's major assembly problems. It is also the only part that has raised

panel lines, which I removed and re-engraved. The two oil-cooler air

intakes are depicted as elliptical openings, whereas they should be

round. As one of the openings was badly miscast, I decided to drill them

both out and add the three-piece shutters from little styrene strips.

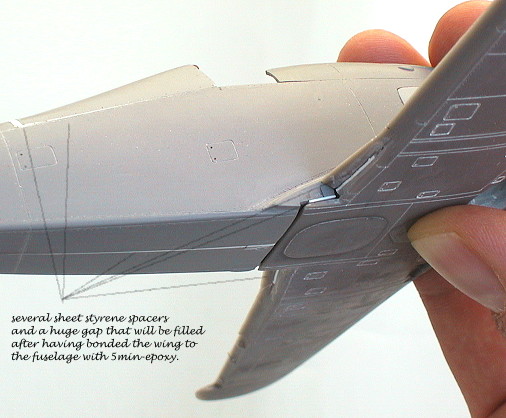

When I dryfitted the completed fuselage against the

wing I noticed to my horror that the rear section of the one piece wing

was nearly one millimetre shallower than the fuselage at that point,

resulting in either a matching lower fuselage or upper wing root

connection – but not both at the same time. I guess this is an

inheritance of the wing's earlier life as a replacement part for the

Hasegawa/Secter kit. But that certainly doesn't give you any comfort

while trying to build this resin kit. I wondered many times, also during

later stages, whether the master maker had actually ever tried to

assemble his own creation.

In the end I performed a deep and wide horizontal

cut with a cutting disc into the back of the wing and jammed slivers of

sheet styrene into the gap to widen the wing (see photo). Now the wing

had the right depth to follow the fuselage contours perfectly.

Ailerons and flaps were attached with stubs of brass wire that fitted

into pre-drilled holes. I used five-minute-epoxy throughout for these

connections.

To give the lowered flaps an authentic sit it is

necessary to keep the following in mind: In reality the flaps moved

slightly down on hinges (visible from underneath) while they rotated

downwards. This resulted in a visible gap between the wing's upper

trailing edge and the flaps.

Click the thumbnails below to view

larger images:

Engine / Cowling

Again all the necessary resin parts are there to

build a very detailed and complete Fiat A74 RC38 14-cylinder radial

(even with carburettor and magnetos if desired).

The only items needed to be added by the modeller

are OHV push-rods, which have to be cut to length from suitable round

material. I used 0,4 mm copper wire for that job.

Other scratch built items that I decided to add

were single oil feed lines that run from the reduction gear case to each

individual front row cylinder head, intake tubes and ignition harness.

All parts, especially the cylinders, have to be

exactly measured, filed to length and aligned to make sure the

peripheral parts fit to the cylinders and the assembled engine fits into

the cowling.

Click the thumbnails below to view larger

images:

In my case this was the late style cowling with

bulges. After removing the massive casting block that engulfs both the

in- and outside of the cowl ring I modelled open cowl flaps from 'Dymo'-tape

to expose at least a tiny bit of the engine's rear.

The completely finished model engine was carefully

centered and aligned inside the cowling with the help of a template and

3 little slivers of styrene sheet, tightly fitted between cowling and

cylinder heads. This exact position was secured with some drops of

five-minute-epoxy and left to harden thoroughly.

The engine/cowling assembly was joined to the

airframe after both airbrushing and decaling were completely finished. I

was surprised about the perfect fit, something I had no longer expected.

A generous amount of five-minute-epoxy assured a durable connection.

Airbrushing and Decaling

The Serie V of G 50bis built by Fiat's own

Aeritalia factory in Turin sported the standard three-tone upper

camouflage colours of Verde Mimetico 3 (camo green) and Marrone Mimetico

2 (camo red-brown) over a base coat of Giallo Mimetico 3 (camo yellow) –

this time not in spots, but in alternating diagonal stripes along the

fuselage and in ragged patches on the horizontal flying surfaces.

The undersurfaces were painted Grigio Mimetico (camo

grey).

The camouflage shades are my own slightly darkened

mixes from the range of LIFECOLOR 'Regia Aeronautica' acrylics. I prefer

to work with LIFECOLOR matt acrylics, as they flow incredibly fine and

evenly from my IWATA HP-BS airbrush and do not tend to clog the nozzle

too quickly. I found out that the trick is to keep the paint rather

thick and turn the air pressure up to 15-18 bar (~ 22-28 psi) – rather

the opposite of what is generally recommended for detail work.

First I sketched the intricate camouflage pattern

on photocopied scale planes, using the variety of published b/w photos

of '352-4' as a guide. These sketches were a great help airbrushing the

camo pattern free-hand later.

For the first time I tried Johnson's Klear (the

British version of Johnson's Future) as a gloss undercoat for decaling.

A test shot on a piece of LIFECOLOR-ed scrap went well so I got the Fiat

out. When the liquid touched the readily camouflaged model it curled up

into round droplets and wouldn't straighten out. After a few seconds a

milky white residue started to show. I immediately held the affected

area under running water to get rid of the mess before the Klear had any

time to cure. In the end I used PollyScale Semi-Gloss Clear with great

results, as all the other years before.

The decals went on beautifully without a trace of

silvering. Even the tiny Matricola Militare serial (MM. 5945), whose

digits had to be cut singly from the excellent 'Sky Models' sheet,

presented no problem.

Everything was sealed with a coat of PollyScale

Flat Clear.

Panel lines were accentuated with various shades of

dark brown pastel dust. Certain areas, like wheel wells and the yellow

cowling were additionally treated with light washes of 'burnt umber' oil

paint.

After several days of drying the model got one more final layer of flat

clear.

Undercarriage

To cut a long story short: The kit's white metal

parts, with the exception of the wheel forks, had to go straight into

the dustbin. The material is so soft, that the tail wheel couldn't

possibly carry the resin kit's weight. The parts themselves were so

shabbily cast, that I couldn't think of a single method to achieve

straight u/c legs with a round circumference from them.

So, I constructed new legs from styrene rod with a

brass wire core and attached the heavily reworked wheel forks with

five-minute-epoxy. This assembly was completed with the complex landing

gear covers, which are partly kit (resin, photo-etch) or scratchbuilt

items made from styrene sheet.

Click the thumbnails below to view larger

images:

The tail wheel fork was hand carved from an old

Tamiya Corsair part, attached to a brass wire strut.

All wheels are original 'Italian Classic' parts.

Final Details

Two rather complex pitot tubes had to be

constructed from styrene sheet and rod plus 0,2 mm copper wire - these

are not provided with the kit.

As this aeroplane wasn't equipped with a radio set,

I didn't have to worry about aerial wires - which was nice.

Finally, the proud pilot is from Mike Good's classic set 'Two Italian

Pilots WW II', which he did for Jaguar Models quite a few years ago.

Figures in that scale can't be sculpted more realistically than this

one!

Resources

-

'Italian Classic'

1/48 resin kit #006, Fiat G 50 Serie VII bis/AS

-

'RCR Models' 1/48

PE set #S16, Fibbie E Cinture Regia Aeronautica (Regia Aeronautica

buckles and belts)

-

'Eduard' 1/48 PE

set #48-032, Fiat G 50 for Secter kit

-

'Sky Models' 1/48

decal sheet # 48-026, Fiat G 50

Not really essential, but much better than the kit

parts, if you should come across them:

-

'Falcon Clear–Vax

Canopies' 1/48 scale set No. 37, WWII fighters pt.2, Fiat G 50

standard canopy (for Secter/Hasegawa kit) (o.o.p.)

-

'Aires' 1/48

resin/PE set #4009, Browning M2 .50cal (only resin barrels used)

Bibliography

-

'Ali d'Italia'

No.6, Fiat G 50, by Piero Vergnano,

La Bancarella Aeronautica, Torino / Giorgio Apostolo Editore, Milano

-

'Ali e Colori'

No.3, Fiat G 50 – I Colori Del Fiat G 50, Macchine-Piloti-Storie,

by Paolo Waldis, Marino De Bortoli, Angelo Brioschi

La Bancarella Aeronautica, Torino / Giorgio Apostolo Editore, Milan

-

'Profile

Publications' No.188, The Fiat G.50, by Gianni Cattaneo

'Dimensione Cielo', Immagini A1, Caccia Assalto, by Emilio Brotzu

and Gherardo Cosolo, Edizioni Bizzarri, Roma, 1972

(These interesting series of photo publications have recently been

re-published by

Aviolibri - IBN Editore - Instituto Bibliographico Napoleone, Roma

and show rare photos of Fiat CR.32+G 50, Breda Ba.65+88.

-

'Scale Aviation

Modeller International', Vol.7 No.2, Feb. 2001, Fiat G.50 'Freccia'

by Richard Caruana

-

Wings of Italy -

The Italian Airforce in Original WW II Colour Pictures,

by Gregory Alegi and Baldassare Catalanotto, Giorgio Apostolo

Editore, Milano,

ISBN: 88-87261-01-6

-

Colori & Insegne

Regia Aeronautica Caccia & Assalto 1940 -43, Parte I /

Camouflage and Markings of the Regia Aeronautica, Fighter and Ground

Attack Units 1940-43 Part One, by Paolo Waldis, Marino De Bortoli

and Angelo Brioschi,

La Bancarella Aeronautica, Torino / Giorgio Apostolo Editore, Milano

Click the thumbnails below to view larger

images:

Italian Aces of World War

2

Aircraft of the Aces 34 |

|

|

|

|

Author: Giorgio Apostolo

Illustrator: Richard Caruana

US Price: $19.95

UK Price: £12.99

Publisher:

Osprey Publishing

Publish Date:

November 25, 2000

Details: 96 pages; ISBN: 1841760781 |

|

|

Model, Images and Text Copyright ©

2004 by Werner Scheibling

Page Created 13 August, 2004

Last Updated

15 August, 2004

Back to

HyperScale Main Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search