|

1/48 scale

Grand Phoenix kitbash

Fairey Firefly FR.5

by Mike Prince

|

|

|

Fairey Firefly FR.5 |

HyperScale is proudly supported by Squadron.com

The Fairey Firefly was originally designed as a two seat naval

fighter to meet specifications issued by the British Admiralty in June

1940. Ultimately, this aircraft evolved into a true multi-role aircraft,

with various marks performing roles as diverse as fighter /

reconnaissance, night fighter, anti-shipping and anti-submarine warfare,

dual control trainer and, in later years, target tug.

The first Fireflies reached squadron service with the Royal Navy in late

1943 and were operational in time to participate in attacks on the

Tirpitz in Norwegian waters in July 1944. By late 1944 Fireflies were

operating with the British Pacific fleet.

Australian Service

In 1948 HMAS Sydney was commissioned into the Royal Australian Navy

(RAN), followed thereafter by HMAS Vengeance (on loan from the United

Kingdom) then HMAS Melbourne in 1955. Sydney’s Air Group initially

consisted of Hawker Sea Furies and Fairey Firefly FR5s, the individual

squadrons embarking in Sydney in 1949 following workup in the UK.

Ultimately, the RAN took delivery of 108 Fireflies, including two FR4s,

37 FR5s and 69 AS6s.

In October 1951 Sydney deployed to Korea to relieve HMS Glory with 805

and 808 Squadrons embarked, both equipped with Sea Furies, along with

817 Squadron equipped with Firefly FR5s. These FR5s were transferred

from other RAN squadrons as the cannon armament of this version was

considered to make it more suitable for operations over Korea than the

AS6s with which 817 Squadron had previously been equipped. Roles

performed by the Fireflies included spotting for naval bombardments,

dive-bombing of rail targets, bridges and other transport

infrastructure, attacks against troop concentrations and armed

reconnaissance. A number of aircraft were lost or damaged by enemy

ground fire, whilst the hazards of operating from a small escort carrier

also took their toll. Operations continued until 31 January 1952.

Attrition replacements were drawn from Royal Navy stocks both during the

deployment and during the return passage to Australia. Following a

subsequent deployment to the UK and return via the United States, Sydney

conducted a second deployment to Korea from November 1953 to June 1954,

this time contributing to enforcement of the truce signed between North

and South Korea in July 1953. No combat flying was undertaken during

this second Korean deployment.

With the arrival in Australia of Melbourne with a Carrier Air Group

consisting of DeHavilland Sea Venoms and Fairey Gannets in late 1955,

both the Furies and Fireflies became obsolete. Between 1957 and 1959 the

vast majority of Fireflies were retired from service, though a number

soldiered on as target tugs until the mid 1960s.

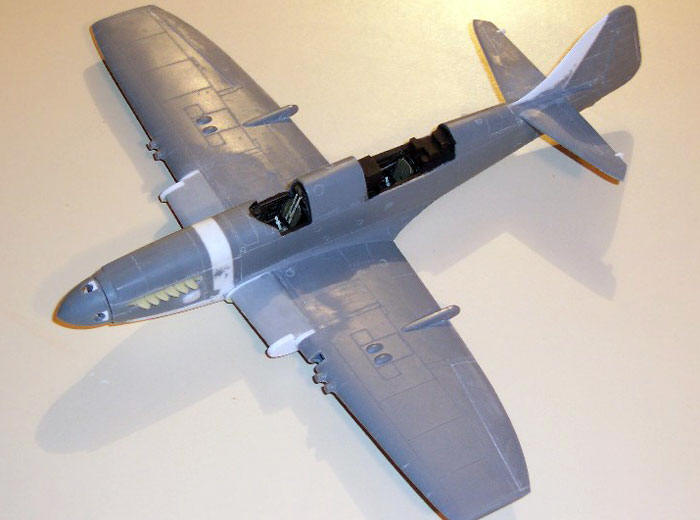

The Kit

I have long wanted to build to models of the aircraft operated by the

RAN, preferably in 1/48 scale. A few years ago Grand Phoenix released an

excellent model of the Firefly Mk1, however, with its beard type

radiator, shorter fuselage, three bladed propeller and lack of radar and

fuel pods on the wings, it was not entirely suitable. Whilst rumours of

a kit of a later mark abounded, no injection moulded kit of a more

suitable version has appeared to date. Therefore, it was time to

undertake some relatively serious kit-bashing to convert a Mk1 into an

FR5 as used by Sydney in Korea. As no conversion kit was available, this

was undertaken using sheet styrene, parts from the spares box, and a

degree of lateral thinking. Whilst this conversion might initially

appear complex, once a solution had been identified for each discrete

step, there was nothing that was ultimately too difficult.

Summary of conversion

-

Fuselage: Lengthened 8mm using

plastic sheet between windscreen and firewall. Wing fold braces

added to rear fuselage. Various bulges and vents added to upper and

side cowl panels.

-

Lower cowl: “Beard” type radiator

removed, new carburettor intake and lower cowl built up using

plastic sheet. Revised cowl panel lines scribed.

-

Spinner: Kit spinner re-profiled from

rounded to pointed and converted from three bladed to four bladed

arrangement. Backplate modified to match.

-

Propeller blades: Scratch built from

8 Academy Spitfire Mk XIV blades.

-

Wing radiators: Scratch built from

sheet plastic, sections from discarded wings and brass wire.

-

Wings: Wing tips clipped, landing and

navigation lights cut out and replaced with clear lenses, landing

light from scrap, (wing spar built to compensate for sections

removed to accommodate new radiators). Rockets from spares box.

-

Fin: Straight leading edge removed

and replaced with extended leading edge and fillet. Actuating rod

added to rudder trim tab.

-

Tailplane: Elevators separated,

balance horns altered from 45º

to fore / aft alignment.

-

Front cockpit: OOB except for

gunsight from spares box and windscreen replaced from clear sheet.

Canopy runners added.

-

Rear cockpit: OOB except for canopy

cut open, with open sections replaced from clear sheet.

-

Markings: Roundels and parts of

aircraft serials from Eagle Strike “Sea Fury Pt 1”, black and white

side numbers from Aussie Decals (generic), remainder of serials hand

painted.

Fuselage (1)

The fuselage was initially built as per the kit instructions, though

the resin exhausts were left out as they were at risk of being damaged

when conversion of the nose was undertaken later. The resin components

for the two cockpits were painted extremely dark grey (almost black) and

dry brushed with a lighter grey and silver. The two small levers either

side of the pilot’s seat were replaced with wire, the etched seat belts

were painted and installed, and the instrument panel assembled then

fitted. Dry fitting showed that only a little thinning of the completed

cockpits was necessary, after which the two fuselage halves were joined

and the aft cockpit glued in, though the forward cockpit was left loose.

Before addressing the changes to be made to the fuselage the fuselage

and forward cockpit were then put aside while the internal structure of

the wing was addressed.

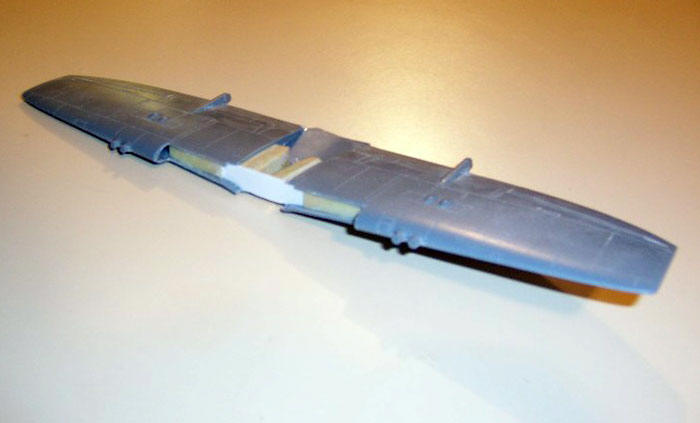

Wings (1)

Having completed the fuselage more or less as per the kit

instructions so far, the first stage of building the wings was

undertaken. First up, the mating surfaces of the upper and lower wing

halves were sanded smooth. The tops of the resin wheel wells were

thinned to allow the upper and lower wing surfaces to mate, then once

correct, the wheel wells were glued to the lower surface.

The next few steps were then developed to ensure that the relationship

of the wings to the fuselage would be maintained once the leading edges

of the wings and the lower front fuselage were removed a little further

down the track.

To maintain the dihedral already moulded into the kit’s lower wing, a

main wing spar was fashioned from sheet styrene and fitted to the

forward faces of the wheel wells where it would later be enclosed and

hidden. Next, the upper and lower wing surfaces were taped together and

the depth of this spar, and the thickness of the resin on the base of

the forward cockpit, were both repeatedly filed and dry fitted until the

wings fitted the fuselage correctly.

Following this, the leading edges of the wings were cut away from 2mm

inboard of the wing fold lines. On the lower surface care needed to be

taken not to interfere with the resin wheel wells and the new wing spar

on the forward face. The lower fuselage area immediately ahead of the

wheel wells was also removed where the kit’s wing was shaped to fit the

aft end of the beard radiator. Finally, the upper and lower wing skins

were glued together and, once set, the wing tips removed approximately

4mm outboard of the outer end of the ailerons. This excess was then

filled and filed to shape to represent the clipped wingtips of the later

marks of the Firefly. Concurrently, the opportunity was taken to thin

the trailing edges then re-scribe any lost detail. At this point, the

focus of work returned to the forward fuselage.

Fuselage (2)

The forward cockpit was permanently fitted in the fuselage at this

stage. Next, the nose was separated from the fuselage using a razor saw

to cut vertically mid way between the two vertical panel lines

immediately behind the engine exhausts. The lower cowling was also

removed; cutting along what would eventually be the new panel line

dividing the new lower cowl from the side panels. It should be noted

that this panel line lies further down the fuselage than on the Mk 1,

the panel line ending mid way down the wing radiator openings rather

than above the wing as on the earlier version. Side views of the

aircraft show this quite clearly once the difference has been

identified.

A 38cm stretch was included on versions of the Firefly following the Mk1

to counteract the additional weight of equipment fitted to the

observer’s cockpit. The fuselage was therefore extended 8mm using sheet

styrene glued inside the fuselage to provide some structure, with a

second 8mm wide strip wrapped around the outside to fill the resultant

gap. Once this strip was faired in and the panel lines replaced, the

kit’s resin exhausts were then fitted through the new opening in the

lower cowl. The prominent flame dampers over the exhausts were left off

as these were not fitted to all aircraft, and seemed to be rarely fitted

to FR5s.

Finally, the leading edge of the fin was removed, then the fin extended

forward using sheet styrene to reflect the curved leading edge and large

fillet that characterised Fireflies from the FR4 onward.

Wings (2)

Having extended the fuselage the wings were then fitted to the

fuselage with the primary mating surfaces being the wing upper surfaces

to the wing fillets, and the wing spar to the base of the resin cockpit.

Nose

The lower cowling of the nose was blanked off using a single layer of

sheet styrene to form a base for further construction. To this was added

a new carburettor intake below the spinner, resulting in an intake about

3mm deep. The remainder of the lower cowl was then built up using

successive layers of sheet styrene, extending in a smooth curve all the

way back to the wheel wells. Once complete this was carved, filed and

sanded to shape, with a coating of CA glue used as filler to ensure that

the edges of each layer would not be visible once the model was painted.

Finally, the inner ends of the wing radiator housings were shaped from

two layers of sheet styrene and glued to the sides of the nose ahead of

the cut down wings. These were cut so that they extended forward until

mid way between the two vertical panel lines immediately behind the

exhausts, and created a blunt airfoil shape extending forward from the

existing upper and lower wing surfaces.

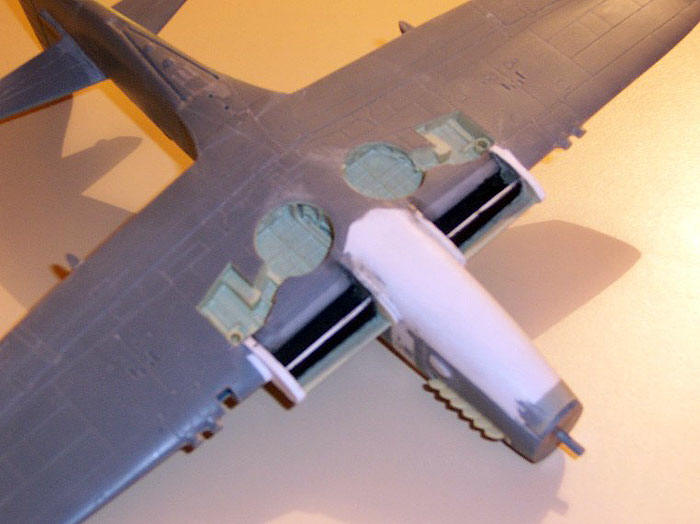

Radiators

The radiator housings were built by shaping and fitting the upper

surfaces, then hanging the internal details off the lower (inner)

surface. This consisted of the outer end of the radiator housing, a

styrene strip running span-wise to represent the front and rear faces of

the radiator, an inner surface for the radiator outlet (attached to the

lower wing skin just ahead of the wheel wells), then the lower skin of

the radiator housing.

The upper and lower radiator skins were cut from the upper and lower

surfaces of wings from the spares box, in this case from an Airfix MkV

Spitfire, as there was potential for sheet styrene curved to the same

shape to warp as a result of handling. The outer ends of the radiator

housings were then faired in, the bracing visible in the radiator inlets

fitted by drilling and inserting brass rod through the lower surface,

then outlet doors made from styrene sheet and fitted.

Propeller and Spinner

Whilst the Mk.1 Firefly had a rather bulbous spinner and a three

bladed propeller, the spinner on later marks was much more pointed,

while the propeller was four bladed, with each blade considerably

broader than the finely tipped blades of the earlier version.

The

spinner was first converted to accept four blades, with two of the

existing three holes for blades filled then reinforced internally, then

three new holes cut and filed to the same shape as the one remaining

original hole. The spinner was then re-profiled from the existing

bulbous shape to something much pointier. The thickness of the plastic

allowed this to be done with a file. Finally, four small pieces of

styrene were glued to the back-plate behind where each propeller blade

was to be later fitted. These were then filed to shape so that when the

spinner and back-plate were joined, the hole for each blade was round

rather than “U” shaped. The

spinner was first converted to accept four blades, with two of the

existing three holes for blades filled then reinforced internally, then

three new holes cut and filed to the same shape as the one remaining

original hole. The spinner was then re-profiled from the existing

bulbous shape to something much pointier. The thickness of the plastic

allowed this to be done with a file. Finally, four small pieces of

styrene were glued to the back-plate behind where each propeller blade

was to be later fitted. These were then filed to shape so that when the

spinner and back-plate were joined, the hole for each blade was round

rather than “U” shaped.

The propeller blades were tackled next. Although my spares box has lots

of propeller blades that rotate to the right, Fireflies were fitted with

a Griffon engine that rotates to the left (as per a late mark Spitfire

or a Typhoon). To solve this I found that I could make a broad enough

and long enough propeller blade by splicing together two blades

discarded from an Academy Mk14 Spitfire kit, using eight blades in total

to make the required four. I think a spare four bladed propeller from a

Typhoon kit would have been much simpler; unfortunately none was

available. Once set, the blades were filed and sanded to shape to match

the references.

Radar Pod and Wing Fuel Tank

Almost all Fireflies from the FR4 onward were operated with a surface

search radar in a pod on the starboard wing, with fuel contained in a

similar pod on the port wing. Photographs taken onboard the Sydney off

Korea indicate only a few FR5s without these fitted. However, around

half my reference photos of restored Fireflies show the aircraft without

them.

The front portions of these were constructed from the “aluminium” drop

tanks of an Accurate Miniatures P51 (the diameter of the “paper” drop

tanks in other kits is too small). All detail was removed and the

diameter reduced slightly at the widest point. The back third of the

drop tank was then cut off and the length extended with sheet styrene to

create a long and streamlined pod. Finally, the top of the pod was cut

to roughly match the shape of the wing’s lower surface. This cut-out was

refined by wrapping the wing in sandpaper (rough side outward), then

sanding back the top of the pod using the wing to define the shape.

Additional Details

Two bulges on the sides of the engine cowlings were cut from sheet

styrene, shaped, fitted and faired in. A small inlet was fitted on the

top of the engine cowl. Louvres on the lower cowl were cut in and shaped

using a sharp blade. The elevators were separated from the tailplanes,

with the balance horns reshaped so that the extreme tips point directly

forward. The trailing edges were thinned. The coamings of the pilot’s

cockpit were extended upward to include runners for the canopy. The

kit’s gun sight was replaced with a gyroscopic sight from the spares

box, with a small piece of acetate used to model the reflector. The

landing light was cut out, boxed in then built up with scrap plastic,

then covered with clear acetate curved to shape, while the navigation

lights were cut out and replaced with sections of clear sprue that were

later filed to shape and polished. Catapult hooks were fashioned from

scrap plastic and fitted beneath the fuselage just inboard of the

radiators. The pilot’s windscreen was replaced with a scratch built item

from clear sheet, while the rear canopy opened up with the opening

panels then replaced with new items rolled to shape from the same clear

sheet.

The kit’s cannon barrel fairings were replaced with sections of round

sprue, cut to length and sanded to shape, with the protruding barrels

fashioned from brass tube. The mounting panels for the rocket rails were

cut from thin sheet styrene, with the rockets coming from the spares

box. The bomb carriers were shaped from underwing gun pods from an old

Monogram T-6 Texan kit, reduced in both depth and length. A pitot tube

was sourced from the spares box and cut down for fitting under the outer

port wing after painting.

Ultimately, I wanted an RAN aircraft wearing Korean War stripes. This

was easier said than done.

My primary reference only included a profile of FR5 WB377 / 201K as

operated by 817 Squadron from Sydney during the first Korean deployment.

However, this was an attrition replacement borrowed from the Royal Navy.

The profile loosely follows photos available from the Australian War

Memorial that show the aircraft on deck in a damaged state following

Typhoon Ruth on 15 Oct 51. In these photos, the “1” of “201” has been

over-painted by the leading black fuselage stripe, presumably to be

replaced by a white “1” in due course. (Note that Typhoon Ruth occurred

during the first few days of operations.) This would agree with photos

of other aircraft on deck where the side numbers are black on white /

sky and white on black. It also agrees (in part) with photos of the

restored WB518, purportedly in the markings of WB377, though with the

aircraft’s true serial used instead. Further, the profile does not

depict the medium blue spinner denoting aircraft from 817 Squadron, as

shown on the restored WB518 and on the example in the Museum of Flight

at Nowra. On both WB518 and the Nowra example the wing stripes are

further inboard than on the original 1951 photos of WB377 (and all but

one other Firefly photographed during the 1951-52 deployment).

In order to model an RAN aircraft, I chose to depict FR5 WB393 / 204K,

which was downed by ground fire while operating over Korea on 26 October

1951. Fortunately, the pilot made a successful forced landing, albeit

behind enemy lines. After being protected for the remainder of the day

by aircraft from Sydney and Meteors from 77 Squadron RAAF, the crew;

LEUT Neil MacMilland and CPO Phil Hancox, were rescued in fading light

by the USN helicopter embarked on Sydney. I have assumed the aircraft

was in the same common scheme of Extra Dark Sea Grey and Sky with blue

spinner, black and white stripes around the outer wings and aft

fuselage, with the side numbers contrasting the fuselage stripes and

prominent serials beneath the wings that have been partially obliterated

by the stripes. Roundels and parts of aircraft serials came from Eagle

Strike’s “Sea Fury Pt 1” sheet, with the black and white side numbers

from Aussie Decals (generic). Remaining parts of the aircraft serials

were hand painted.

-

Sea Fury, Firefly and Sea Venom in

Australian Service, Stewart Wilson, Aerospace Publications Pty Ltd,

1993

-

Tale of Two Fireflies, Flightpath,

Vol 14 No.2, November 2002 – January 2003

-

The Journey, Aeroplane, Vol 30 No.11,

November 2002

-

ADF-Serials.com

-

Australian War Memorial

Click

the thumbnails below to view larger images:

Model, Images and Text Copyright ©

2005 by Mike Prince

Page Created 30 June, 2005

Last Updated

29 June, 2005

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search