|

Tamiya's 1/48 scale Fw

190A-8/R2

Bodenplatte

Sturmbock

by Brett Green

|

|

|

Focke-Wulf Fw 190A-8/R2 |

Tamiya's 1/48 scale Focke-Wulf Fw 190A-8/R2 is available online from Squadron

Tamiya released the first of their 1/48 scale Focke-Wulf

Fw 190 kits in the mid 1990s. These two kits - a Fw 190A-3 and an F-8 -

were very easy to build and well detailed, but they were not perfect.

The main problems were undersized undercarriage legs and main wheels.

This resulted in a somewhat squat appearance when compared to the Dragon

Wurgers that had been released some years earlier.

Even so, Tamiya's kit established a loyal following due

to its the sheer buildability when compared to the trickier to assemble,

but more accurate, Dragon offering.

The only Tamiya Wurger that I had previously

built was a sole Fw 190F-8 back in 1999. The speed and ease of assembly

was impressive, to say the least.

In late 2005 Tamiya released a new variation on the

theme - a 1/48 scale Focke-Wulf Fw 190A-8 / A-8/R2 kit.

What's in the Box?

I was curious to see how Tamiya would approach the

changes to their basic moulds in order to deliver the tough-looking,

heavily armed and sturdily armoured Stormbock variant.

At first glance, Tamiya's 1/48 scale Focke-Wulf Fw

190A-8/R2 looks very similar to the earlier Fw 190F-8 kit. Indeed, the

main sprues hold the same parts, including redundant weapons unique to

the F-8.

The biggest difference is the inclusion of a new sprue

with a broad-bladed propeller, new wing cannon covers and shell ejector

inserts, and other details specific to the A-8. I believe that the

Sturmbock used the same VDM propeller blades as the Fw 190D-9. Tamiya

already offers a D-9 kit and its propeller blades, while not perfect,

are not too bad. The prop blades supplied with this new kit are totally

new mouldings, and they are not an improvement. The new propeller

assembly is too small in diameter, and the profile looks peculiar.

Examining the wings also reveals some tooling changes.

Most notably, there are now cutouts on the bottom of the wing to

accommodate a selection of different inserts depending on the variant

being built.

Click the

thumbnails below to view larger images:

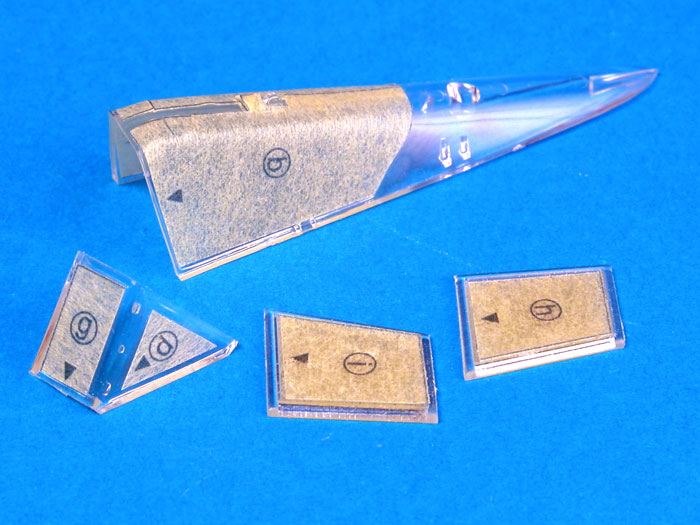

This new kit includes revised clear parts. In addition

to the standard and blown hoods, Tamiya has supplied the canopy armoured

side panels. These include an accurately raised frame, and are very

nicely done. Only one style of windscreen is included though (some

Sturmbocks were fitted with appliqué armoured glass panels on the

side of the windscreen too).

Also new is a canopy masking sheet. This is a very nice

touch, but the individual masks are not die-cut. You do have to cut the

shapes out yourself.

The final multimedia element is a self-adhesive vinyl

(?) sheet with the fuselage armour plates. Lines dividing the individual

plates and fasteners are recessed into the material but, once again, the

modeller must cut them out with a sharp knife.

The kit parts most complained about from the earlier

releases - wheels, undercarriage legs and slightly bulbous gun cowl -

are unchanged.

I wanted to build this kit specifically to be

photographed in flight. In the past I have attempted a few different

methods for simulating flight. I have used a hair dryer to spin the

propeller, installed photo-etched "Prop-Blur", and even attempted to add

a blurred propeller in Photoshop. All these methods work in a fashion,

but they all have their disadvantages too.

This time I decided to install a small electric motor.

In 2002, Tamiya re-released their Fw 190A-3 kit with a tiny motor to

spin the propeller. Comparison of the two kits suggested that I could

install the motor in the new Fw 190A-8/R2 with only minor modifications.

First, though, I assembled and painted the cockpit,

engine, wheel bay and the remaining interior parts. Most of the parts

were pre-painted and weathered while they were still on the sprue. I did

not spend a lot of time detailing the cockpit as the canopy would be

closed, and the seated pilot would hide much of the detail anyway.

Click the

thumbnails below to view larger images:

The pilot was painted with a combination of Tamiya and

Vallejo acrylics, followed by a selective oil wash.

Next, the fuselage armour was cut out of the

self-adhesive vinyl sheet. I used a steel rule and a new blade in my

hobby knife for this task. I was concerned about how well this material

would stick to the kit plastic, but they settled very well. However, I

did not cut off the small bumps under the windscreen before applying the

armour pieces. The result was a noticeable lump under the thin material.

I managed to lift the edge of the armour, slice the lump off the

fuselage, and relay the vinyl without any loss of adhesion.

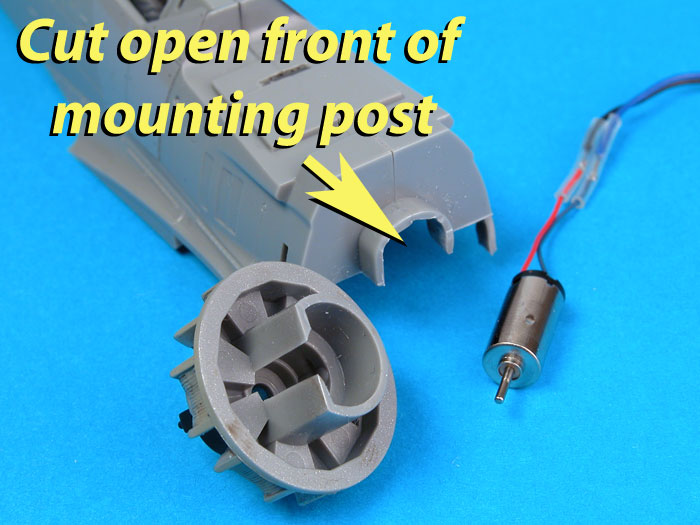

The front of the engine mounting post was cut open in

preparation for installation of the electric motor. The image below

shows how much plastic I cut out of this area.

A hole must also be cut into the bottom of the wing to

feed out the electrical wire for the battery.

I applied a spot of super glue to each side of the

little motor, and slid it into the rear of the plastic engine part.

Click the

thumbnails below to view larger images:

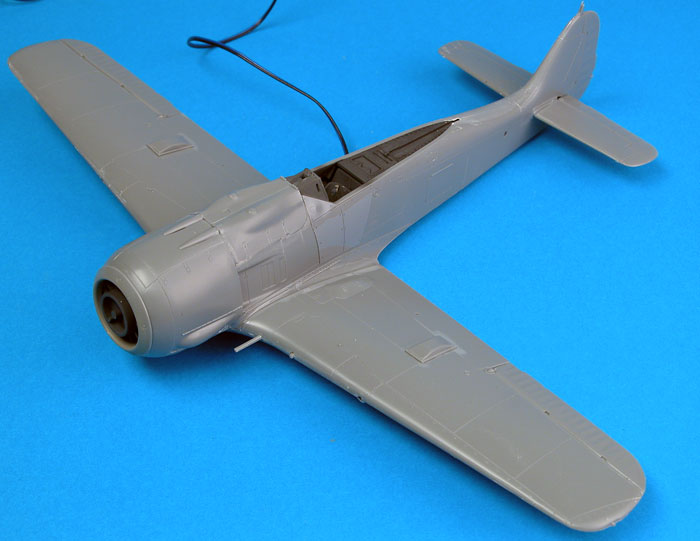

In common with the Focke-Wulf Fw 190F-8 that I built

back in 1999, the balance of construction was almost embarrassingly

fast.

With the cockpit, engine and wheel wells pre-painted,

assembling the fuselage, the multi-part cowl, wings and tailplanes took

less than three hours. This included the time required to remove parts

from the sprues and clean them up. Quite remarkable.

I only encountered one minor alignment issue during

construction. Test fitting suggested that there might be a tiny gap at

the wing root, so I installed a spreader bar (simply a length of plastic

cut from the kit sprue) between the fuselage halves.

Note the lump

under the windscreen beneath the vinyl armour sheet. The armour was

later lifted and the lump sliced off.

During the course of construction I noticed a few other

minor engineering modifications to the original kit parts, including a

new undercut at the front of the gun cowl to accommodate the gun trough

inserts.

The kit propeller was replaced with a part raided from

Tamiya's Fw 190D-9.

I managed to break off one of the 20mm cannon barrels

that are moulded to the wing, so I cut off the other one too and

replaced them with brass tube.

Not a spot of putty was required on the entire airframe.

Yellow

is always tricky. Yellow

is always tricky.

I often have trouble getting yellow paint to cover

properly. I also find that acrylic yellows take a long time to dry and

are very prone to fingerprints and damage even weeks after application.

This time I decided to try to avoid these problems. I started with a

coat of white primer on the lower cowl. This was lightly sanded and

polished before spraying a coat of Tamiya Spray TS-34 "Camel Yellow" on

the area. I decanted a quantity of this gloss yellow paint from the can

into a disposable container and applied the paint using my Aztek

airbrush. This acrylic lacquer still needed two coats over the white

primer, but it dried fast and coped well with subsequent handling.

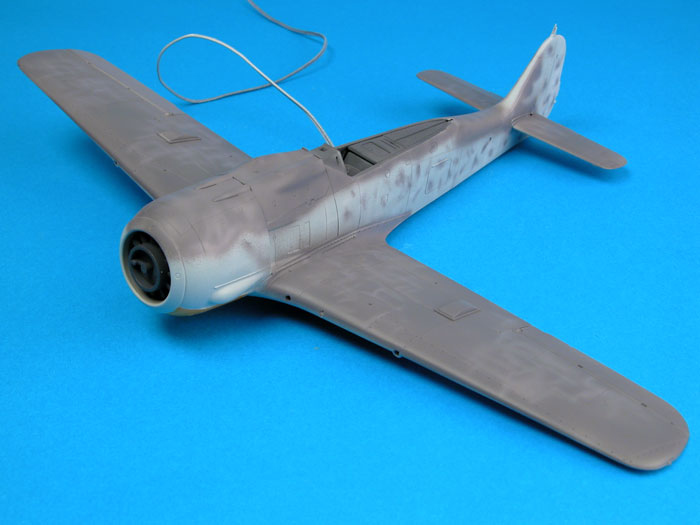

My Sturmbock was one of three Luftwaffe models

that I was painting in the same session. To save time, I sprayed all

three models with an overall base coat of Tamiya AS-5 Light Blue

(Luftwaffe) straight from the can. By the time I had finished spraying

the first light coat on the last model, the first was ready for its next

(and final) coat of the colour.

I applied a random mottle over the lower surfaces and

fuselage sides using Gunze acrylic H417, RLM 76. This noticeably paler

shade delivered a pleasingly uneven finish - the first stage of

weathering.

Next, Polly Scale RLM 75 was applied to the top of the

wings, tailplanes and fuselage spine with the Testor Aztek airbrush

fitted with the fine tan coloured tip. A first-pass mottle of RLM 75 was

also sprayed onto the fuselage sides and fin. Similar to the treatment

of the RLM 76, a paler shade of RLM 75 was mixed. Small, random streaks

were sprayed over the base colour.

Click the

thumbnails below to view larger images:

This was followed by a disruptive coat

of RLM 74. I used a mix of Gunze acrylic RLM 74 with a few spots of dark

green.

A mask was cut out of a self-adhesive

Post-It Note to assist painting the grey area behind the fuselage cross.

The fuselage mottle on the real

aircraft was quite messy, suggesting several oversprays and repairs. I

tried to reproduce this look by randomly overspraying the heavy fuselage

mottle with RLM 76 Light Blue, then restoring some of the mottling with

RLM 74 and RLM 75.

With the basic camouflage in place, it

was time to attend to the detail parts. I cut the canopy masks out of

the kit-supplied sheet. Fit was good, and the masks adhered well to the

plastic. I did get a little "bleeding" of paint under the masks at the

top of the canopy where there is a compound curve. Next time I will

burnish the masks down with a toothpick to avoid this problem.

Tamiya supplies two styles of mask for

the sides of the windscreen. The smaller masks presumably represent the

armoured glass. This actually works quite well as an illusion. Another

nice touch is that masks are supplied for both the inside and the

outside of the armoured glass panels.

The panel behind each side of the

engine cowling was masked and sprayed with a 50/50 mix of Tamiya XF-1

Flat Black and XF-63 German Grey. The spinner and propeller blades were

painted RLM 70 using Polly Scale acrylics.

The airframe now received an overall

coat of Polly Scale Gloss in preparation for the decals.

Markings

I was planning to finish my Sturmbock in the

markings of Oskar Bosch, according to a photograph in the excellent

Hikoki book, "Bodeplatte - The Luftwaffe's Last Hope". I could not find

any after market decals with these markings, so I resorted to an old

Aeromaster sheet with black Luftwaffe numbers. The "4"s on this sheet

did not quite conform to the photograph, so I modified them slightly by

slicing a small amount off the diagonal of the digits.

Tamiya decals were used for the balance of the

markings. The kit decal sheet is great, with five marking options

for JG 3 and JG 300. I have heard complaints that Tamiya decals are

thick, but these markings conformed well to panel lines and the

surrounding film virtually disappeared under a coat of Flat Clear.

Finishing Touches

Some additional weathering was applied after the

decals had set. I sprayed a very thin mix of Flat Black and Red

Brown along panel lines and camouflage demarcation. I have

described and

demonstrated this post-shading technique on two recent "Testor's

ScaleWorkshop" videos.

The final step of weathering was a thin wash of Raw

Umber oil paint flowed into panel lines.

The paint job was sealed with a coat of Polly Scale

Flat acrylic, then smaller details such as the 20mm gun barrels,

canopy, DF loop, Morane mast and propeller assembly were attached.

The stubby 30mm cannon barrels provided in the kit have hollowed-out

muzzles - very nice!

The kit pitot tube was replaced with a filament from

an industrial light bulb.

E-Z Line was used for the aerial wire. This elastic

material is easy to work with and, being elastic, is more resistant

to handling than nylon thread. Isolators were built up from tiny

spots of Micro Krystal Kleer.

I took the in-flight photos before attaching the

landing gear and drop tank.

A breather tube was inserted in the front of the drop

tank from fine brass tube, then the drop tank was painted and weathered.

Although they are undersized, I used the kit

undercarriage legs and main wheels. Replacements for both these items

are available (gear legs from either Wurger Mechanic or Airwaves, and

wheels from Eagle Editions). Next time I will use the replacements for a

comparison.

Tamiya's 1/48 scale Focke-Wulf Fw 190A-8 / A-8/R2 kit is

not perfect. In fact, this release seems to have introduced at least one

new error (the propeller assembly) and corrected none of the problems of

the original kits.

Even so, it makes a very attractive model when

completed, and I can forgive these relatively minor problems and easily

addressable problems when I consider just how well the kit goes

together.

Construction is sheer joy.

Photography

The hangar and construction photos were taken with a Nikon

Coolpix 5700 digital

camera and optimized in Photoshop CS.

The model was photographed on a cardboard base against a photo of a

German hangar. The cardboard base was given a snowy appearance by

sprinkling the surface with baking soda.

The in-flight photo was taken with a Nikon D70 digital

camera against a plain grey background with the model's motor connected

to a AA battery. The aircraft image was merged with a photo of a cloudy

sky in Photoshop CS.

Finally, the images were cropped, resized to 700 pixels in

width, and saved as .jpg files for posting on HyperScale.

Model,

Images & Text Copyright © 2006 by

Brett Green

Page Created 13 February, 2006

Last Updated

21 February, 2007

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search