|

Focke-Wulf

Fw 190C-0 (V13)

by

Floyd S. Werner Jr.

|

|

|

Focke-Wulf Fw 190C-0

(V13) |

R.V. Resin Kit

#4802

HyperScale is proudly supported by

Squadron.com

Finding historical information in English

on this prototype was difficult.

The Focke-Wulf Fw 190 was a great fighter but its ultimate performance

potential was limited by its non-supercharged engine. Above 20,000 feet

the aircraft was decidedly non-maneuverable and the engine performance

fell off rapidly. The Fw 190C was a projected high altitude aircraft.

To address the performance problem the Fw

190C-0 was re-engined with the DB603A inline engine. The V13 was the

first prototype designed for the high altitude mission.

Even though marginally successful, by

1944 the project had been cancelled due to technical problems and

opposition to use of the DB 603. The DB603 was needed for other

aircraft, such as the Me-210/410 and the Do-335.

R.V. Resin's

1/48 Scale Fw 190C-0 (V13)

|

R.V. Resin kit contains some beautiful

cast resin in a caramel color with some beautiful surface detail. A fret

of photo etch parts is included for the oil coolers, seatbelts, and

cockpit coaming. The landing gear is cast in white metal. A single

one-piece clear canopy is crystal clear. Decals for this particular

aircraft include all the national markings. The instructions are not

very helpful. There are parts included in the kit that are not shown on

the instructions.

The resin has a fine sheen of mold release agent on all the parts. There

are some bubbles and mold imperfections, but the beautiful rivets and

panel lines are absolutely exquisite.

Before I began, I washed the entire model

with a Dawn dish detergent and warm water to remove the mold release

agent. Once that was done it was time to test fit the major parts. I

flat sanded the fuselage halves and wing halves. This proved that the

major subassemblies fit very well, but when test fit together there was

going to be some filling. The wing to fuselage join was a little off and

the wings had no dihedral. These would be relatively easy to fixes

though.

Fuselage

The fuselage, once flat sanded, fit

beautifully.

I have a procedure that I do with all my

kits, resin or plastic, and that is to apply a bead of superglue to the

seam. I just find this as a way to save time in the construction. Think

about it, you are going to sand it anyhow. Why sand and then find a

pesky seam when you can eliminate it on the first sanding? Less sanding

means less detail lost and the seam will be perfectly filled the first

time.

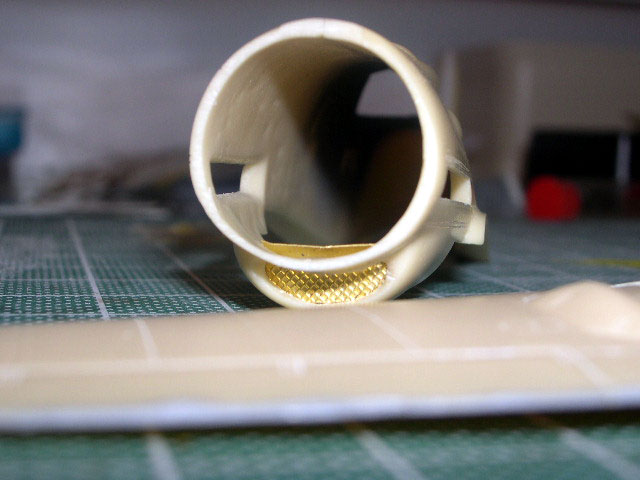

I added the photo etched oil cooler to

the inlet. I had to deepen the mounting area with a couple of swipes of

an #11 blade. There is another oil cooler that is oval in shape but the

instructions don’t show you were it goes. I used it after the wings were

attached. Once cleaned up, a coat of RLM 66 was applied to the interior

and the cockpit tub.

Cockpit Cockpit

Assembly of the cockpit tub was easy and

just like any other plastic kit. The seatbelts were bent to the seat and

then painted Polly-S Dirty White.

A coat of Model Master RLM 66 was applied

to the cockpit, followed by a wash of black and a dry brush of RLM 02.

Some detail was added with a silver

pencil. The instruments were given a drop of Krystal Klear.

The whole assembly was inserted through

the belly and secured with superglue.

Wings

The wing assembly begins with the landing

gear well. It is a two-part affair. The wheel wells sit into the lower

wing and are sandwiched with the top wing. It is essential that you

check the fit prior to gluing the well. Ensure that the well is centered

fore and aft, as well as, left and right. The wings fit beautifully and

glue together with no problem. I used my normal bead of superglue again.

General Assembly

Now that the two major subassemblies were

done it was time to join them. Here is where the first issue with the

kit came. The wings had no dihedral and the portion that fits under the

fuselage in the front and back was straight while the fuselage was

angled up. What to do? First thing I did was get a good join at the

front, apply superglue and let dry completely. Then I taped the back

portion so that it was fairly close. The wings roots were flush with the

fuselage so to get some dihedral I needed some room. I slowly and

carefully scraped the wing and fuselage, while still joined, from front

to back, ensuring that the amount of resin removed is equal, both front

to back, as well as, from each side. The wings were then bent carefully

and held in place with some tape.

Once that was done now came the hard

part. I used an embossing heat gun (a hair dryer would work). Moving it

continuously and working from the center out. Let the heat build slowly

so that the resin doesn’t melt or crack. The heating will eventually set

the dihedral. Now that everything was bent correctly, it is time to glue

everything tight. The whole process took about 30 minutes. Nothing that

any modeler couldn’t do. A little filler at the front and in the back

and everything was fine.

OK, now we are starting to see the airplane take shape. The tail planes

are thin and have no mounting lugs. I drilled holes for hypodermic

needles and mounted the tail.

Flat sanding cleaned up the nose cooler. I cleaned up all the small

parts. I had to fill some holes in the exhaust stacks and the landing

gear doors. The model was now ready to paint. I rewashed the whole model

with Dawn dish washing liquid and a toothbrush. I let it dry and then I

used some Sylvan Resin-Prep. This ensured that all the oils were

removed. I attached the white metal landing gear using five-minute

epoxy. The epoxy allows you time to manoeuvre the landing gear to get it

aligned.

Primer

The model was given an initial coat of

Alclad Grey Primer. Mistakes (oh yes I make them all the time) were

cleaned up and some pinholes were filled with 3M Blue Acryl. The whole

model was sanded lightly and using a pin the rivets that I sanded off

were replaced. Then the aircraft was painted again with the primer. The

process was repeated three times. If done correctly the surface

imperfections I mentioned disappear but the rivet detail stays. Once

happy it was off to the paint booth.

Paint

The V13 was not a flamboyant aircraft. It

was painted overall RLM 02. Using my Tamiya airbrush, I pre-shaded the

panel lines with RLM 66. For this project I decided to use Model Master

Enamel RLM 02. I like to use enamels on resin just in case the surface

prep wasn’t perfect. Enamels bite more than acrylic and doesn’t peel up

as easily. Once the paint was on I lightened the paint with some flat

white and thinned it some more. Then I selectively painted small spots

on the whole aircraft. Then I added some more white and painted the

fabric control surfaces. This breaks up the monotone color.

Decals

Now that everything was RLM 02 it was

time to decal. A coat of Future prepped the surface for decals. The

decals are ever so slightly out of register, but not to where it is

noticeable. They laid down well, but a word of caution. Once the decals

are placed they are done moving. HERE IS A TIP: Use some saliva instead

of water on the model. The saliva allows you to slide the decal a little

to position it. Once the decals were set in place I used some SolvaSet.

The decals were very thin and looked great once dry. I attached the

exhaust stacks after painting them with Model Master Burnt Metal

Metalizer. The stacks were weathered with Burnt Sienna and orange

pastels. Before you seal the nose section, add the oval radiator panel

on top of the wheel well. It seemed like a natural place to put it. The

instructions don’t show where it goes, but putting it here prevents you

from being able to see through the model. Attach the nose radiator after

painting it with Model Master Titanium then attach the nose to the

model. The wheels were added at this time. They had some bubbles but

they cleaned up easily. If you wanted to you could use True Detail

wheels.

The prop blades had some pin holes but a

little filler and they cleaned up nicely. The blades were pinned to the

spinner and the assembly was given a coat of Model Master Black Green.

This is the only “flair” to the camouflage.

Another coat of Future sealed everything. Allowed to dry overnight, a

coat of Model Master Acrylic Flat prepped the model for weathering. A

wash of Burnt Umber Artist Oil in the panel lines brings out the

definition. Once it was dry I applied a dry brush of white artist oils

over the entire surface of the kit, paying particular attention to the

fuselage spine and wings. Silver pencil was used sparingly on the wing

root and wing leading edge to simulate chipping.

The only two photos I could find of the V13 showed it after some testing

and the exhausts stains were quite noticeable so I wanted to simulate

this. I started out with highly thinned Tamiya Flat Earth beginning at

the exhaust stacks. As I moved aft I pulled the airbrush away from the

model. This gives the effect of thinning and expanding exhaust. Next

empty the airbrush but don’t clean it out. Add some Flat Black and more

thinner and repeat the process staying more towards the center of the

exhaust streak. Finally, add just a little bit of brown pastel

immediately aft of the exhausts and drag it back through the exhaust.

Now another coat of Flat seals all the pastels.

Before you can attach the canopy you have to bend the anti-glare panel.

This is actually fairly easy, but I had to think about how it would

mount. I came to the conclusion that the two pieces that are obviously

to be used for mounting would be bent so the panel sat on the edge of

the canopy sill and not down inside the cockpit. Once that was done a

coat of primer and flat black and it was almost time to celebrate.

The only thing left was the canopy. You only get one so, of course, I

screwed it up bad. I would have liked to have had a second canopy. The

clear parts are crystal clear and the plastic is thick. While trying to

remove the canopy I slipped and scribed a huge gash in the side panel.

Luckily, I wanted to pose the canopy open anyway and the Tamiya canopy

fit well. I cleaned up the kit front windscreen and as I anticipated

there was a large opening at the front. I used white glue and then some

putty to fair it in. Overall the look is very good. As I said just a

touch of glue will hold the Tamiya canopy in place. I’m sure I could

have gotten a replacement canopy from the importer or a Falcon set or

even the Squadron one. It is just a typical Fw 190 “flat” canopy. I used

Black Magic canopy masks and painted it all RLM 66 followed by RLM 02.

The canopy masks worked like a champ, even on the kit front canopy. I

touched up the paint around the canopy where I had to fill.

Some white glue and Tamiya clear red and green formed the wing tip

lights. The addition of an antenna and the model was complete.

As this was my first R.V. Resin kit, I

was overall impressed with the surface detail, even though some of it

had to vanish with the sanding and be replaced. All the “problems” I

encountered (poor instructions, bubbles, pin holes, warps, and surface

blemishes) are typical of all the resin kits I’ve ever built and are

easily fixed. Even with the problems the total time spent on building

this kit was no more than a “normal” plastic kit.

I recommend this kit to an experienced modeler or a plastic modeler

looking for a challenge. It is a relatively easy build but not a Tamiya

or Hasegawa but definitely buildable. This unique aircraft is not

available in any other scale or media that I’m aware of. It offers a

unique look to a classic fighter and even with the plain paint scheme it

looks quite nice.

As a bonus, if you need replacement parts the kit seems to be based on

the Tamiya offerings so if you screw up, like I did on the canopy, you

can just use the parts in the plastic kit.

I can only hope that when R.V. finishes the Fw 190 prototypes they will

tackle the Bf-109 prototypes. I’d be forced to buy the complete range of

those, but based on my experience with their Focke-Wulf series, I

purchased an R.V. Resin Ta-152C-0 V7. That should say something about

the quality of the kit.

References

and Acknoweledgements

|

-

Model Art #8-Focke-Wulf Fw 190D &

Ta-152

-

Focke-Wulf Ta-152- Der Weg zum

Hohenjager, Ditmar Hermann, Aviatic Verlag, 1998, ISBN 3-925505-44-X

(I think this is available in English now)

-

Focke-Wulf Jagdflugzeug, Peter Rodeike,

ISBN 3-923 457-44-8

Thanks goes to Dave Cooper, US importer

of R.V. Resin, for the review copy. The kit is USD$50.00 plus shipping

and handling, and can be ordered directly at

http://resin-plane-kits.com/

or by email at Airplane104@aol.com

.

Click on the thumbnails

below to view larger images:

Model, Images and Text Copyright ©

2003 by Floyd S. Werner Jr.

Page Created 20 March, 2004

Last Updated 20 March, 2004

Back to

HyperScale Main Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search