|

Hasegawa + Rutman 1/32 scale

Focke-Wulf Fw

190D-13

by

Ian Robertson

|

|

|

Focke-Wulf Fw

190D-13

Yellow 10 |

Hasegawa's

1/32 scale Focke-Wulf Fw 190D-9

is available online from Squadron.com

“Yellow 10” is a rare Focke-Wulf Fw.190D-13 that ended its wartime

career in Flensburg, Germany, where it was surrendered to the RAF. Prior

to its surrender the aircraft was the personal mount of Major Franz Götz,

Geschwader Kommodore of JG26. To many, “Yellow 10” is known only for its

striking and unusual late-war camouflage scheme. However, this aircraft

has a remarkable history that extends from late war Germany to its

current home at the Museum of Flight in Seattle. “Yellow 10’s” journey,

at least through its discovery in Germany, recovery in Atlanta, and

restoration and display at the Champlin Fighter Museum in Arizona,

before relocating to Seattle, is thoroughly documented in the book

“Yellow 10: The story of the ultra-rare Fw.190D-13” by Jerry Crandall

(2000, Eagle Editions). Excellent wartime and restoration photographs

are included in the book, along with color artwork by Tom Tullis. The

book was an invaluable resource for me while building my model.

The Focke-Wulf Fw190D-13

The D-13 variant of the Fw.190D (Dora) series differed externally

from the far more numerous D-9 in the following respects: redesigned

upper cowling in front of the windscreen, wider engine cowl with larger

supercharger intake, VS 9 paddle-bladed wooden prop, and a single

ejection port for the engine-mounted MG 151 20 mm cannon that fired

through the spinner. A number of other minor refinements dealing with

the position of access panels were also present on the D-13.

Although the D-13 is unmistakably a Dora, the deviations from the D-9

require a moderately ambitious conversion project. Luckily, Jerry Rutman

(J. Rutman Products) has produced a high-quality and well thought out

conversion set for Hasegawa’s new-tool 1/32 Fw.190D-9. While the

conversion is not for beginners, those with moderate modeling experience

and experience working with resin should find it straight forward.

The Shopping List

-

Hasegawa 1/32 Fw.190D-9 (new tool)

-

J.Rutman Fw.190D-13 conversion (resin

parts)

-

includes fuselage halves, gun

hood in front of windscreen, spinner, prop blades, rear wheel

well bulkhead, and lower wing center section with single

ejection port. No instructions, but the conversion steps are

obvious.

-

MDC main wheels (treadless) and tail

wheel

-

MDC seat belts and buckles

-

Cutting Edge resin seat

-

Eagle Parts Fw.190D radiator cowling

(#43-32)

-

EagleCals decals #32-59

The first step in the project was to wash and clean up the flash on

the resin parts. The fuselage halves were very well cast and needed only

a minor amount of cleanup around the wing roots and cockpit. The

supercharger intake, upper cowl, and prop blades suffered from numerous

pock-marks that required filling and sanding. This task was time

consuming but not difficult. The amount of time spent on the

supercharger intake increased considerably when I decided to hollow the

intake out with a Dremel motor tool. (Note that a mask was worn at all

times while preparing resin parts.)

Because the Rutman conversion is designed to replace specific parts

of the Hasegawa kit (i.e., no surgery to the kit is required, except on

the prop blades), construction proceeded more-or-less as shown in the

Hasegawa instructions. However, before starting construction it was

necessary to dry fit the resin fuselage.

Gluing the fuselage halves together is a major step in the conversion.

Great care is needed to ensure proper fit and alignment of the wings and

tail to the forward fuselage. Therefore, I jumped ahead in the Hasegawa

instructions and completed the wing assembly so that it could be used

effectively in dry fitting to the fuselage.

The flaps on the wings were positioned up for pragmatic reasons.

According to Jerry Crandall, “Yellow 10’s” flaps were made from wood and

therefore the internal ribbing on the kit’s flaps is incorrect for this

particular aircraft. Solution - flaps up.

Now back to the fuselage halves. Careful dry fitting was essential for

proper wing and tail attachment. Although the resin fuselage halves were

well cast, it was still necessary to sand the inside surfaces to ensure

proper fuselage width and a continuous gluing surface for the parts.

Repeated dry fits were made until I was convinced that the wings and

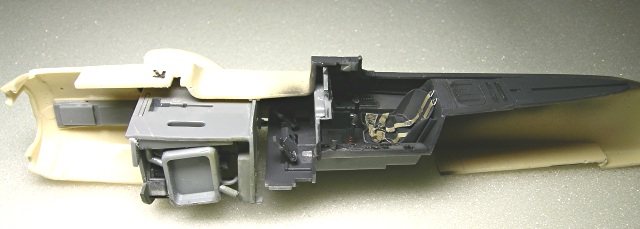

tail would fit seamlessly. In the photograph below, the cream-colored

parts are resin whereas the grey parts are styrene.

Once I felt comfortable the fuselage halves would fit together

properly, I turned to the cockpit. I replaced the kit seat with one from

Cutting Edge, and I added etched brass belts and buckles from MDC. Guide

rails on each side of the seat back were made from Evergreen styrene.

The cockpit was painted RLM 66 using Polly Scale acrylic, although in

the photo it appears overly dark owing to the poor light conditions.

Proper insertion the cockpit and engine plug required careful dry

fitting and some minor adjustments. Remember that the resin fuselage

halves are thicker than the kit’s styrene parts, so some thinning is

required for the cockpit and engine plug to fit properly. I opted to

thin the width of the cockpit floor rather than the fuselage side walls.

The same was true for the engine plug.

The resin conversion includes a rear firewall for the engine plug;

however, I opted to retain the kit’s original part for ease of assembly.

The part isn’t readily visible on the completed model anyway.

Before gluing the fuselage halves together, don’t forget to add the

wells for the exhausts. Note that because the resin fuselage is thicker

that the kit parts, the exhaust wells sit a little deeper than they

should. Reducing the depth of each well before attaching it to the

interior of the fuselage is the best option. I learned this lesson the

hard way when my MDC exhausts nearly disappeared into the uncorrected

wells. However, the kit exhausts fit satisfactorily in the uncorrected

wells, so ultimately I used them.

Once the fuselage halves were glued together (with CA glue) I returned

to the cockpit area to make a small but noticeable correction. As in the

Hasegawa kit, the placement of the gun sight is incorrect in the Rutman

conversion because it interrupts the padding that extends across the

front of the coaming above the instrument panel. Therefore, I

repositioned the gun sight further forward and added a strip of styrene

rod to fill the gap in the padding.

I chose to display the cowl flaps open as this is how they appear in

the photographs of “Yellow 10” taken at the end of the war (see pg 21 in

Jerry Crandall’s book). One point of interest – one of the cowl flaps on

the starboard side of the Hasegawa part is molded shut, consistent with

numerous photos of D-9s, including a photo on pg 77 of Jerry’s book.

However, the photos of “Yellow 10” clearly show this flap open. While

I’m not certain of the significance of this discrepancy, I chose to

modify the kit part so my model would be consistent with the photos of

“Yellow 10”.

Attaching the tail and wings was easy given the careful dry fitting

that preceded. The small insert between the wheel wells fit perfectly as

well. At this point main construction was complete and the model was

ready for painting.

Painting

of the outer surfaces began by spraying the model with Mr. Surfacer

1000. The wheel wells (RLM 02), cockpit, and engine face were masked

prior to the application of the primer. Once the primer was dry I

polished the model with a Micromesh sanding cloth. Painting

of the outer surfaces began by spraying the model with Mr. Surfacer

1000. The wheel wells (RLM 02), cockpit, and engine face were masked

prior to the application of the primer. Once the primer was dry I

polished the model with a Micromesh sanding cloth.

I then painted and masked the JG26 Reich defense bands on the rear

fuselage. Note that the white and black bands were unequal in width and

not parallel.

I preshaded the model with black paint and then polished it again.

Alclad II aluminum metalizer was sprayed on the wing roots. The

metalizer in this area would later be exposed to simulate scuffed paint.

Click on the thumbnails

below to view larger images:

The underside of “Yellow 10’s” wings were natural metal with RLM 75

on the leading edge and RLM 76 on the ailerons. I used Alclad II for the

metal surfaces and weathered it slightly with washes of thinned Tamiya

black acrylic. The natural metal surfaces were then masked for

application for RLM 75 and 76 using Polly Scale acrylics.

The fuselage was painted RLM 76. Afterward, the upper fuselage and

wings were painted RLM 75, as described in the painting guide for

“Yellow 10” on the back cover of Jerry Crandall’s book.

The remainder of the painting was an exercise in free

expression.…almost. In truth, I followed Tom Tullis’ artwork as closely

as possible, although it often became an exercise in artistic expression

trying to spray the complex pattern freehand. In the end I feel that I

fairly represented the look of “Yellow 10”, at least as interpreted by

Tom Tullis.

The greens applied to the upper surfaces are my own mixtures for RLM 82

and 83. I am not satisfied with most interpretations of RLM 82 (hellgrun)

by paint manufacturers since the color is typically formulated as bright

as a green gummybear. However, White Ensign Models provides formulations

of RLM 82 and 83 that were exactly what I was looking for. Therefore, I

used the colored lids of my WEM paints as paint chips for mixing my own

RLM 82 and 83 using Polly Scale acrylics. (Why, you may ask, did I not

simply use the WEM paints? Honestly, I’ve developed a comfort zone with

Polly Scale acrylic and didn’t want to experiment with a lacquer paint

I’ve never used before. I’ve heard that the WEM paints are superb

though).

My mixture for RLM 83 (dunkelgrun) was 1 part Polly Scale “Pullman

Green” (similar to RAF green) and 1 part Polly Scale RLM 81

(brown-violet). This gave a distinctly brownish green appearance to the

paint. My mixture for RLM 82 (hellgrun) was 1 part Polly Scale RLM 82

and 1 part Polly Scale RLM 83.

The spinner was painted RLM 25. Although the Eaglecals’ decal sheet

provided a spiral decal for the spinner, I believe it was designed for

the shape of the Hasegawa spinner, not the resin replacement. After

several unsuccessful attempts to find a suitable spare decal, I opted to

paint the spinner white, mask the spiral using Tamiya tape, and then

reapply the RLM 25. Note the stains on the rear half of the spinner –

these were caused by fluids leaking through the hole of the propeller

hub for the cannon blast tube. To simulate this effect I masked the

forward part of the spinner and then sprayed highly thinned back paint

across the rear half of the spinner in the direction of air flow.

The prop blades were painted RLM 70 (black green). At the other end of

the aircraft, note the light grey paint on the leading edge of the upper

portion of the tail.

To simulate paint chips at the wing roots, I used fine grain sandpaper

to create surface abrasions and expose small amounts of the Alclad II

aluminum beneath.

Decals

The Eaglecals decals performed flawlessly over a gloss coat of Future

floor wax. Microset and microsol helped the decals conform to the

model’s surfaces. Once the decals were dry I applied a 50/50 mixture of

Polly Scale clear satin and clear flat acrylic.

Adding the Undercarriage

To each landing strut I added brake lines made from wire and thin,

flexible rubber. The oleos were covered with bare metal foil, and the

holes in the oleo scissors were drilled out. I also added some

additional wiring to the radius rod hinges.

An interesting detail of “Yellow 10” is that the starboard tire had a

tread whereas the port tire was smooth. The MDC replacement tires, as

well as the kit tires, were suitable only for the port tire. I simulated

a tread on the starboard tire by scoring the MDC tire with a knife and

then widening the tread with a scribing tool. Note that Eagle Editions

makes a perfectly suitable treaded replacement tire. I had one of these

replacements in my possession, but unfortunately misplaced it at the

time I needed it most. I found it shortly afterward.

Groundwork

A wooden cutting board was used as the base for the model. Celluclay

was used to make the basic ground cover. The celluclay powder was mixed

into a paste with water and white glue, tinted with brown acrylic paint,

and then spread thinly over the cutting board.

Note that the cutting board had previously been treated with several

coats of clear lacquer to prevent warping while the celluclay dried.

While the celluclay was still wet I added pieces of Heki grass mat

(item # 1574 - Wild Grass Savanna), fine sand, and small bits of moss.

Heki Grass is now available in the United States from Scenic Express.

Images of the completed model were taken with a Nikon Coolpix 5400

digital camera outside with a natural background. The “sharpen edges”

tool of Adobe Photoshop was used to restore some of the clarity and

crispness lost during image compression.

I’d like to dedicate this article to my good friend Jerry Crandall,

whose hard work and passion for “Yellow 10” inspired this project. Keep

the wealth of information and interesting Luftwaffe subjects coming

Jerry!

Click on the thumbnails

below to view larger images:

Focke-Wulf Fw 190

Modelling Manuals 20 |

|

|

|

|

US Price: $17.95

UK Price: £12.99

Publisher:

Osprey Publishing

Publish Date:

May 25, 2002

Details: 64 pages; ISBN: 1841762687 |

|

|

Model, Images and Text Copyright ©

2005 by Ian Robertson

Page Created 08 June, 2005

Last Updated 08 June, 2005

Back to HyperScale

Main Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search