|

Fonderie Miniature's 1/48 scale

Piasecki H21 Shawnee

by Mick Evans

|

|

|

Piasecki H21

Shawnee |

Fonderie

Miniature's 1/48 H.21 Shawnee is available online from Squadron.com

Fonderie Miniatures continues its French flown aircraft

theme with a 1/48 scale Piasecki H21 Shawnee.

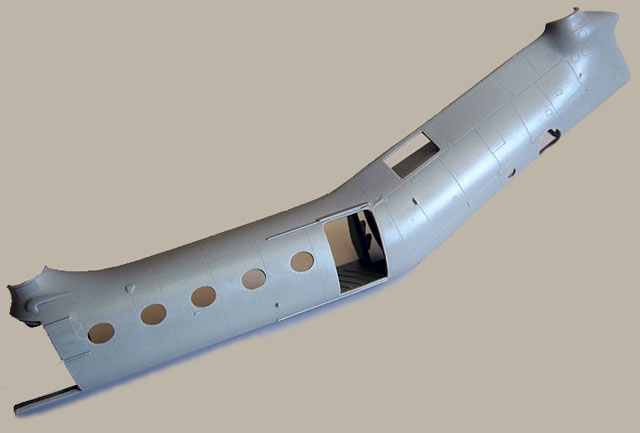

The kit contains 97 moulded plastic styrene parts in a

medium grey colour soft styrene plastic. As usual detail on these parts

is not bad but the panel lines require a light re-scribe to obtain a

consistent level of detail as some lines are not as clearly defined due

to the moulding process.

20 clear parts are provided for the cabin windows. The

main canopy is moulded in the typical vacu-formed style and, as usual,

is not entirely crystal clear, but a quick dip in Future floor polish

improves the clarity.

The resin parts are nicely moulded and add a high level

of detail to the kit. There are 5 resin parts in all.

A major air bubble was evident on one of the main wheels

that required filling. The intermediate gearbox, instrument console,

nose, and main wheels, are all cast and have a very realistic level of

detail to them.

55 cast metal parts are also included. Most of these need

a bit of clean up of flash, and some need some gentle straightening, in

particular the rotor heads. The level of detail is good and under a coat

of paint these parts look great.

For the first time FM has provided an extensive step by step instruction

sheet, with quite good detailed drawings and this is a vast improvement

over previous kits. Mating surfaces need to be heavily sanded, in

particular the trailing edges of all control surfaces to achieve a

realistic thickness. The 2 fuselage halves do not marry up too well in

circumference, but some gentle pressure while gluing should solve the

problem. As with all the previous FM kits that I have built, I am sure

that this is caused by, removing the parts from the mould while they are

still hot. Interior detail provided is good with all the major bulkheads

and cabin floor being provided. 18 webbing seats are provided for the

cabin area, but these need some extensive cleanup.

The decals are clearly printed with the carrier film

being thin. All decals are in register with good colour definition.

Markings are provided for three aircraft:

-

A French Navy aircraft

of Flotile 31F in overall Gloss Dark Sea Blue based in Algeria 1956,

-

A French Armee de Terre

(ALAT) of 25eme Division de Parachutistes in overall Satin Olive

Drab based in Algeria in 1958, and

-

A US Army version in

overall Satin Olive Drab.

The build for the Shawnee commenced with some very extensive cleanup

of all of the mating surfaces of every part and in this kit there are

some parts. The instructions need to be followed meticulously, and if

you are used to looking at exploded diagrams for assembly, then you will

have to get used to reading instruction. There are 6 pages of written

instructions with a few detailed drawings.

Construction started with the sanding of the fuselage halves until the

excess moulded plastic was removed. Next all of the bulkheads and

interior parts were cleaned up and dry fitting began.

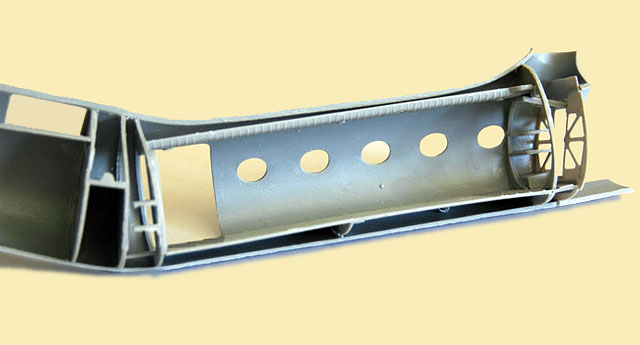

The fuselage walls were thinned down to accept the cabin floor and the 7

bulkheads. This process requires constant thinning and trial fitting

until a snug fit is achieved.

The cabin and gearbox area is quite a complex build, requiring a fair

amount of cleanup work and painting. The detail here is very good but

requires quite a lot of extra work, in particular the passenger seat

webbing.

Once this process is complete, the fuselage assembly is a very easy

assembly process. The cockpit then becomes the next big challenge. The

instructions need to be followed to the letter to ensure that every

thing fits correctly in its right place.

The tail plane assembly is the next area for assembly and both the

horizontal and vertical surfaces need to be thinned down a lot to

achieve the correct thickness at the leading and trailing edges. The

horizontal tail, and vertical fins were added after the cleanup process

and very little filler was required around the fuselage joins.

The next major task was the transparencies. Firstly all parts were cut

out and trimmed and then dipped in Future. The cockpit transparencies

were not an easy fit, which is an understatement. They just donít fit at

all without modification. I had heard of one reviewer giving up at this

point in assembly. On trial fitment of the nose transparencies a 1 cm

gap appears at the top, and any attempt to pull it in forces the sides

to bulge dramatically. The solution was to remove the sliding windows,

then put a relief cut down the panel line below just the sliding

windows, and remove some of the clear panel below. I know that I

sacrificed some accuracy, but at least it now fitted. Removing the

fuselage area below the cockpit floor and then adding a plastic card

replacement after the transparencies are fitted also helps the process.

The sliding window rails then had to be removed from the fuselage sides,

as they did not align with the sliding window cutouts. New rails were

then manufactured and fitted. The canopy frames were all masked and any

seams were filled and sanded. The masking was left on until after the

kit was completely painted. I spent a lot of time blowing all of the

sanding dust out of the fuselage, and a final complete immersion in

water ensured that when the masking was removed no dust adhered to the

inside of the transparencies due to static caused by the tape removal.

The last major project was the rotors. They were a straightforward

construction project that looked very effective when painted.

The kit was finished in XtraColor enamels for the standard Vietnam US

Army scheme of Olive Drab with grey and black rotor blades.

The decals went on very well and snuggled down with a bit of decal

set. The kit was over sprayed with semi gloss before the cabin windows

were fitted with white glue.

The final fit out of the rotors and cabin doors made for an awesome

finish.

The end result was well worth the effort I put in which was approx 35

hours of construction.

Thanks to Squadron for the review kit.

Click on the thumbnails

below to view larger images:

Model, Images and Text Copyright © 2005 by

Mick Evans

Page Created 10 March, 2005

Last Updated

10 March, 2005

Back to

HyperScale Main Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search