|

1/48 scale

scratchbuilt Halibag

Handley Page

Halifax

Part One

by

Philip Robson

|

|

|

Handley Page

Halifax under construction |

HyperScale is proudly supported by

Squadron.com

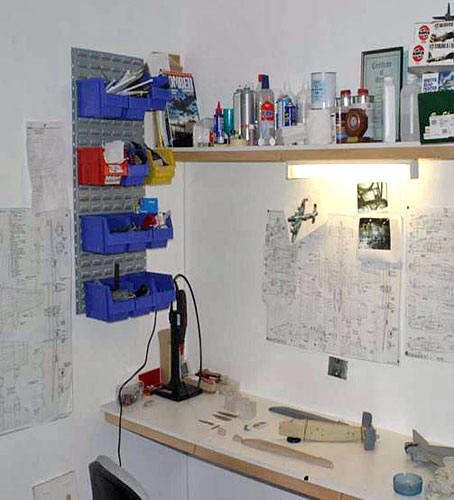

This is my workshop, simple but efficient. Funny how much stuff you

end up needing. What were empty shelves and surfaces all of a sudden are

full.

This would be my return to model making after a break of about six

years, so what subject? kit? or maybe scratchbuild. My thoughts were

leading me in a Whitley direction when the Halifax became my preference.

The path was set, plans (MAP) were purchased, the internet scoured for

pictures.

Early fuselage construction commenced with making the patterns for

what was originally going to be a kit.

Two side profiles were cut out of 1.5 mm plastic. Provision was made

for two spars each for the tail and wings .On a 'contiboard' building

board the fuselage sections were attached and the gaps between filled

with balsa superglued in. The two sides were then roughly sanded and the

two sides mated together using brass tubing in the spar locations. Brass

tube enables you to engineer the pieces so that they always register.

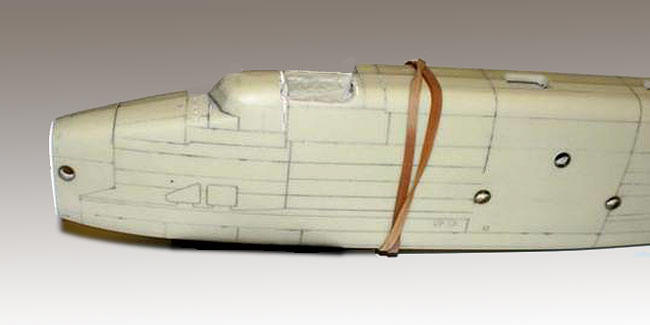

The rough sanded blanks were then filled with pollyfiller and sanded

again. Once happy with the shape (oh yes just wait) the blanks were

wiped over with casting resin which gives a lovely surface to work down

to a finish. Once sanded and primed the area around the canopy was not

right. If the shape is not right when you come to mark all the framing

positions they will not fit. The whole area was cut out and redone.

Eventually I did it by cutting out the individual FLAT panes of the

canopy and fixing them into their correct spacial position, then filling

and sanding to get the curved panes and transitions. Once happy the

blanks were converted into solid resin pieces using a silicone mould

(£80 in rubber and it leaked all over the kitchen).

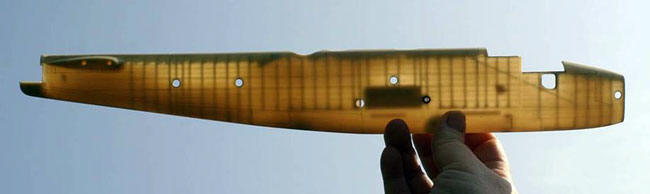

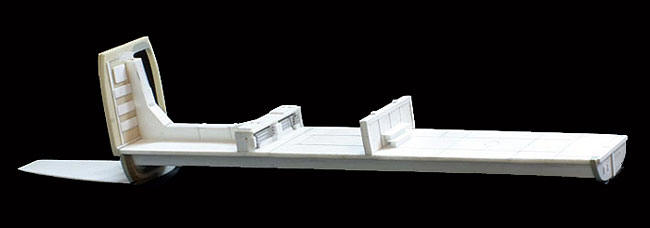

After many weeks of work we arrive at the point shown below. The

exterior has been scribed and the enormous process of grinding out the

inside of the shells begun. How I ended up doing it this way I don't

recall but it was certainly satisfying to turn the blanks into beautiful

complex pieces. Go get you motor tool and grind a little bit of resin.

Now imagine grinding away a piece bigger then a bag of sugar. The Hoover

was my constant companion. All windows were lined with brass to give a

sharp edge. Some consideration should be given to the amount of handling

they would take over the coming years (I seem to work quite slowly).

When you scribe on the panel lines is when you find out how well you

have got the shape. Thankfully most areas were fine. Before the halves

were ground out they were fixed together and moulds taken of the nose

and canopy areas. These would be used to form the transparencies.

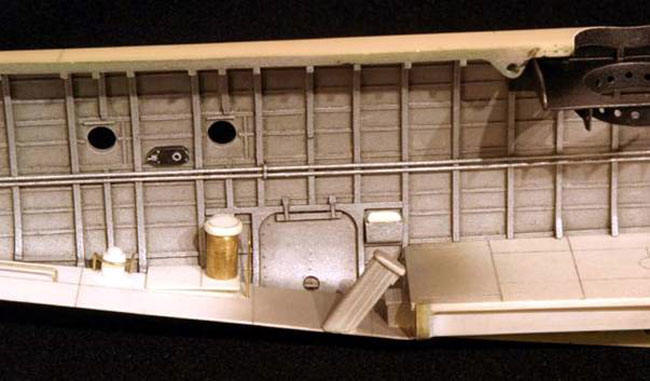

Once sufficiently thin the internal structure was represented with

plastic strip. Thanks Evergreen. Verticals were fitted and then probably

close to 500 horizontals were fitted using liquid poly. For areas under

stress it will not hold strongly enough but for all the small horizontal

pieces it allowed their fine positioning and accurate glue placement

using a fine brush. All the joints were gone over a couple of times. The

main thing achieved now was the positioning of the floor insert which

fits accurately in each of the halves or when together. These parts have

been refitted many hundreds of times as the build has progressed.

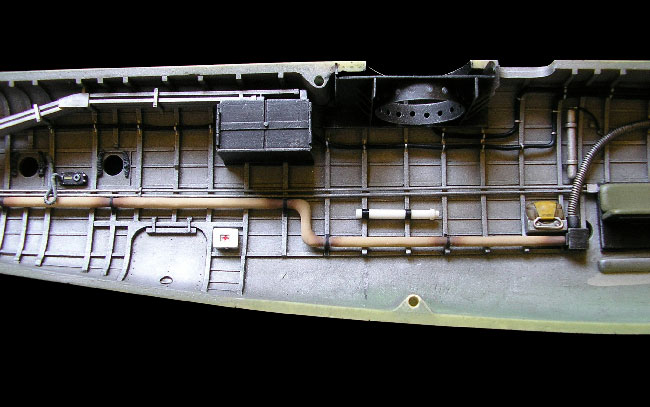

Shown below is the floor insert.

Here is the port fuselage half with the internal structure slowly

coming along. The Pilot's platform and front spar are shown in position.

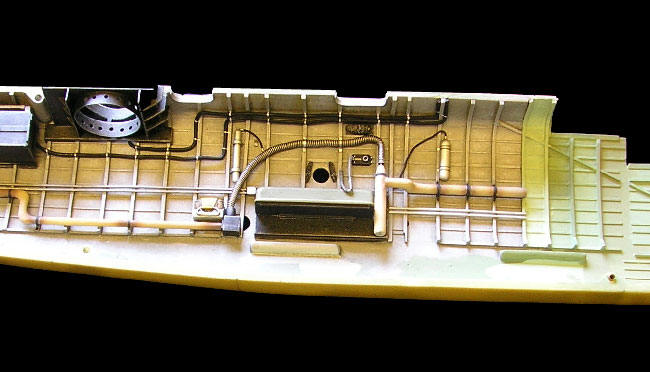

Quite a jump forwards here as the fuselage structure is complete.

Colour? I debated long and hard about this, green or natural metal. The

advice that I took was from those close to the Canadian rebuild of NA377

at Trenton and from those at 57 Rescue a Halifax appreciation site. The

fuselage interiors were painted with Humbrol enamels, a mix of aluminium

and brown as a first coat then a wash of Tamiya smoke (A truly brilliant

product) Next stage was a drybrush to pop out the detail . The turret

mounting was then constructed in plasticard and installed. As a happy

coincidence when about a year later I purchased a Classic Airframes

Defiant the turret fitted EXACTLY in all respects. Either it was luck or

we both independently got it right. Seen below are the control rods back

to the elevators, the flare chute ( since replaced with a more accurate

version), the Elsan, the compass and an oxygen regulator.

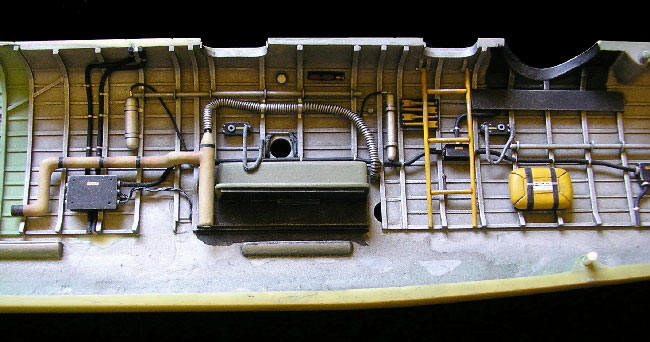

In the next shot the detailing in this area is almost complete.

Additions include the rear turret ammunition racks, a simplified

impression of the wiring, parachute stowage, two hydraulic accumulators,

curtains, oxygen regulator. The brown pipe work connected by the ribbed

tubing is the heating system pipes which were coated with asbestos.

Between the wiring and the ribbed pipe is an oxygen bottle stowage

point. These are a net bag that small personal oxygen bottles were

stowed in. The various shades of green were part of an attempt to get at

the colour I wanted. Looking at a wide range of photos the available

colours all looked too dark or too green. I have made my own mix and it

falls midway between them all. Later additions to this area were 4 photo

flash flares and a strange fitting for which I have no idea of its

purpose.

The other fuselage half contains much the same as the other with the

addition of the escape ladder, life raft, paddles, fire extinguisher, an

interior light and various electrical junction boxes. The paddles I know

realize should be in a bag attached with a lanyard to the life raft.

This brings me pretty much up to date. Next time I will cover more

interior detailing, and the tail planes.

To be continued.

Click on the thumbnails

below to view larger images:

Model, Images and Text Copyright ©

2005 by Philip Robson

Page Created 09 March, 2005

Last Updated

09 March, 2005

Back to

HyperScale Main Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search