|

Tamiya's 1/48 scale

Heinkel He 162A

by Tony Bell

|

|

|

Heinkel He 162A |

Tamiya's 1/48 scale Heinkel He 162A-2 is available online

from Squadron.com

I am a slow builder, no denying it.

Between the demands of my family, work and my other hobbies, the best I

can usually manage is three to four months for a straight forward, out

of the box build. Anything more involved can take much, much longer.

Just ask me about my Marauder. No wait! On second thought, don’t – it’ll

just depress me.

OK, so here’s the situation: Due to work related obligations I’m on call

and can’t venture more than an hour’s drive from the office. My wife is

taking the kids up to a friend’s cottage in the Muskokas and I’m stuck

at home all by my lonesome for the weekend. Time for a little self pity?

No! Time some serious modelling! Yay!

What to do? I could get back to work on my long term P-80 project which

seems to have stalled completely, or I could go for an ultra-quick OOB

build and see just how much can be accomplished in two and a half days

of intense, concentrated modelling. The former would be the responsible

thing to do, whereas the latter more satisfying. But this is a hobby and

satisfying trumps responsible any day, so a speed build it is.

Now to choose a kit. A recent release Tamigawa Wunderkit is just

the thing, with no need for any aftermarket stuff or scratchbuilt

details in order to get an acceptable result. I have the Hasegawa P-40E

in the stash, but the fiddly fuselage parts breakdown will be too

time-consuming to do properly. Yet another Tamiya P-47 or P-51? Erm, no

thanks, I’ve already done those to death. Oooh, I know, the new Tamiya

He-162! It’s small and simple and the paint schemes are dead easy. Plus,

it should just about fall together, engineering-wise.

On your marks, get set, GO!

Getting Started

After going over the instructions and doing a paint inventory to

ensure I had all the right colours in stock, I sat down on Friday night

with my various cutting and abrading implements to remove and clean up

all of the parts that go between the fuselage halves. Lately I’ve

abandoned my side cutters and X-acto for removing parts from the trees

in favour of my razor saw. Yes, I now saw my parts off the sprues. While

it may sound more time consuming, it actually pays off in cleanup time,

as one can cut the attachment stubs almost perfectly flush with the

parts.

Starting

with the cockpit parts, I pre-shaded things with Tamiya semi-gloss black

and then sprayed XF-63 for the RLM66 dark grey. I added a few drops of

Future to the XF-63 to cut the chalkiness. Starting

with the cockpit parts, I pre-shaded things with Tamiya semi-gloss black

and then sprayed XF-63 for the RLM66 dark grey. I added a few drops of

Future to the XF-63 to cut the chalkiness.

I concocted a mixture of Polly Scale semi-gloss, India ink and water

to use as a wash, and once that was dry, I sprayed Polly Scale flat and

drybrushed everything with a medium grey mixed from Citadel acrylics.

Normally I would have drybrushed with artists’ oils, but they take at

least 48 hours to cure properly, so acrylics were the order of the day.

Citadel acrylics were also used to pick out the details on the side

consoles and cockpit walls. There is a little clear piece that attaches

to the nose wheel well, presumably so the pilot could tell if the gear

was down. This was fixed in place with a little bit of Future floor wax.

The instrument panel features blank gauge faces and a nice colourful

decal, which fit perfectly. By flooding the panel with Gunze Mr. Mark

Softener and carefully aligning the decal, I was able to get it to

conform perfectly. After allowing it to dry for an hour, I sprayed it

with Polly Scale Flat and applied a small dab of five minute epoxy to

each gauge face for the glass. The IP is an absolute gem, and I can’t

see how any aftermarket resin or photoetch panel could offer any form of

improvement.

One thing I strive to do with each build is to stretch my skills a

little bit by attempting something new, and this time it was the look of

leather. Like a lot of folks, I have been eagerly following Klaus H’s

progress on his amazing 1/32 Revell He-162. One of the many things that

has struck me about his build is the utterly convincing leather cushions

on his ejection seat. I shamelessly copied his technique, and all credit

must go to him. First off, I painted the seat cushions Model Master

Acryl “Wood”, which is a nice yellowish tan colour. MM Acryl doesn’t

brush paint for crap, so the headrest had to be masked off with Blu-Tak

and airbrushed. The back rest is a separate piece, so no masking was

needed for it. Once the wood colour had dried, I placed a few dabs of

Citadel “Chaos” black, “Blood” red and “Scorched” brown onto a film

canister lid. With a fine brush and some soapy water, I applied several

thin, uneven, watery coats of various shades of brown ranging from

red-brown to almost black, allowing each coat to dry before moving on to

the next. The result was a subtle leathery patina which I finished off

with a clear coat of 50/50 Polly Scale semi-gloss and flat applied with

a brush. The seat was finished off with some light scratching and

scuffing using a Prismacolor Silver pencil.

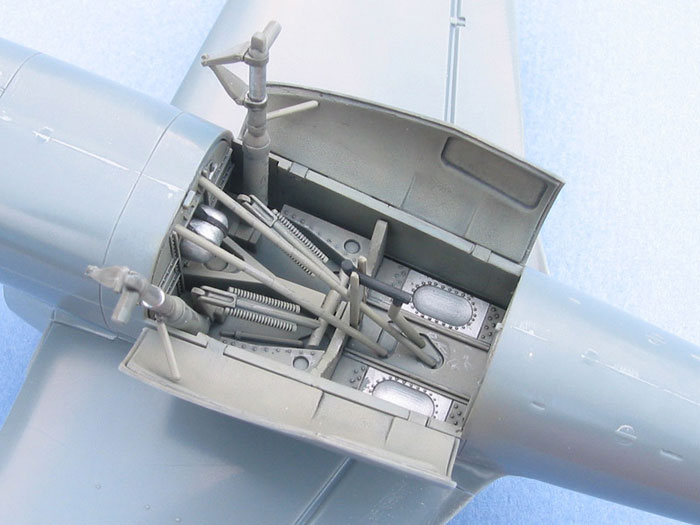

Moving on to the wheel wells, I dry fitted the front and rear bulkheads

and then glued all the rods, springs, beams, etc and gear legs to the

roof , whereupon I popped the bulkheads off and sprayed everything with

Gunze RLM02. Various detail bits were brush painted with Citadels, a

wash of ink and Polly Scale was applied and the whole thing sealed with

a flat coat. The gear well looks very busy and complicated, and the only

addition that I might want to make would be some brake lines, were I to

stray from my out-of-the-box course (but I didn’t).

Assembly

My efforts so far had taken me until early Saturday evening. In less

than 24 hours I was ready to close up the fuselage. A new record! Take

that, Jack Bauer!

I snapped the main gear well bulkheads on without any glue and attached

the whole assembly, along with the cockpit bits to one half of the

fuselage. I left the seat off, as it can be inserted later when the

model is complete. Holding the fuselage halves together, I ran liquid

cement along the seams to join them. Immediately afterwards I brushed

some Gunze Mr. Surfacer along the seams and set the fuselage aside. I

turned to the wings and tail next, which went together perfectly. There

is a tiny bit if play in the stabilizers, so some care is required to

ensure that they are square. At this point I decided it was a good time

to turn in and let everything dry over night.

The next morning, after a mug of tea and a bowl of Cheerios, I broke out

the sandpaper and smoothed out the seams on the fuselage and wings,

using a Staedtler Mars plastic eraser as a miniature sanding block, and

taking care to preserve the stall strip on the inboard leading edge of

the wings.

Next I assembled the engine. I decided not to go with the open engine

panels as I want to eventually detail the engine with wire & stuff and

display it next to the finished model on the stand provided with the

kit. The intake and exhaust trunks require some careful filling and

sanding on the insides to eliminate the seams. The seams were filled

with Mr. Surfacer 500 and sanded with a rolled up piece of 600 grit. I

followed this with an airbrushed coat of Mr. Surfacer 1000 and some more

sanding with rolled up 3600 and 4000 Micromesh cloths. I then sprayed

them with Alclad, Aluminum for the intake and Steel for the exhaust. The

engine pod was the one thing that fit less than perfectly. When

assembled as per the instructions, it rests about 1/32” too far aft. I

left off the polycaps and enlarged the holes in the pod to allow it to

sit properly. I stuffed little blobs of Blu-Tak into the polycap wells,

which served to hold the engine in place.

The canopy bits are exceptionally clear and distortion free, which is

all the more impressive considering their compound curvature. Although

they don’t need it for clarity’s sake, I nonetheless gave them a dip in

Future as protection against painting mishaps. For the windscreen, I

stuck a piece of tape to the forward inside edge to act as a handle,

whereas the rear portion has a nice handy tab between the hinges at the

back. I filled a film canister with Future and held the parts with

tweezers as I dipped them in and slowly extracted them, all the while

looking for any little bits of flerm that might mar the finish.

After the Future had cured with the help of Mr. Microwave Oven, I

carefully painted the little circular port in the canopy with a thin,

soapy wash of Citadel black and dabbed away the dried excess with a

tightly folded damp paper towel. I then masked the canopies with Tamiya

tape, applying oversized pieces and trimming them very carefully with a

brand new X-acto blade whilst holding the pieces up to a bright light. I

sprayed the frames gloss black and then masked the frames off before

attaching the windscreen with liquid glue. The aft portion was fitted in

place without any cement and taped to the forward bit to keep it in

place while I painted the rest of the model.

The other clear piece is the Revi gun sight, which has a seam running

right up the middle of the reflector glass. If this weren’t to be an

IPMS rules OOB build then I would have simply lopped off the glass and

replaced it with a clear piece of sheet styrene. As it was, I scraped

the seam with a knife, sanded it with 1500 grit, brushed it with Future

and painted the edges with thinned Gunze clear green. I painted the body

of the sight dark grey and attached it with superglue to the instrument

hood.

One week later…

After the initial flurry of activity, once more life got in the way

of modelling (I never confuse the two), and it wasn’t until the next

weekend that I was able to resume my “speed build”. I temporarily

attached the engine pod (sans intake and exhaust) and wiped the model

down with alcohol to remove finger oils and suchlike. I then pre-shaded

the panel lines by airbrushing them with Tamiya semi-gloss black thinned

80% with pure rubbing alcohol.

The RLM76 was a 50/50 mixture of Tamiya XF-23 Light Blue and X-2 White,

with a dash of XF-66 Light Grey to de-saturate the colour a bit. The

RLM82 Lichtgrun is XF-5 Green, again with a dash of XF-66, while the

RLM83 Dunkelgrun is XF-61 lightened with a bit of white. All the colours

were thinned about 60% with rubbing alcohol and Future, and sprayed on

in light coats, allowing the pre-shading to show through just slightly.

I applied the paints in order from light to dark, masking between

colours with Tamiya tape.

Next was a coat of Future as a prelude to the decals. The kit decals are

a big improvement over Tamiya’s previous efforts, appearing to be quite

a bit thinner than before, albeit still not nearly as thin as the better

aftermarket brands. Colour density was very good, but the registration

was a bit off, with a sliver of white showing at one end of the red

arrows. They went on well too, responding quickly to Gunze Mr. Mark

Softener and spot applications of Solvaset for the panel lines. After

the decals had dried I sealed them in with another coat of Future.

Although these decals are thinner than usual for Tamiya, they’re still

thicker than I’d like so I gently rubbed them down with a 3600 grit

Micromesh cloth after the Future had hardened to blend the edges in

further.

Next up was the panel line wash. I mixed a greyish-brown schmutz colour

from Citadel acrylics and thinned it with distilled water and a good

healthy glob of liquid dish detergent. I used a medium-fine brush to

apply the wash to all the panel lines and then wiped away the excess

with a damp paper towel once the wash had dried. The dish soap reduces

the ability of the paint to adhere to the surface, making it much easier

to clean up.

I then mixed up a similar schmutz colour from Tamiya paints and thinned

it about 90% with rubbing alcohol. I airbrushed the decals to blend them

in and tone them down and sprayed it along the panel lines for a bit of

post-shading. I also did some random streaks on the fuselage and wings

and then took some of the RLM76 light blue, thinned it likewise and

toned down the shading, as well as adding some more streaks to the

wings. Once everything was to my liking, I sealed it all in with an

airbrushed coat of Polly Scale flat, thinned with distilled water.

Brain Fade

Ah yes, the brain fade. No project is ever complete without one.

After flat-coating the model it was now time to remove the canopy masks,

an activity I always enjoy. Off came the masks and as I was admiring my

handiwork something struck me as being not quite right. I was unable to

put my finger on it right away, but after a few moments it struck me: I

had put the gun sight on backwards! Thankfully both the canopy and

engine pod were only temporarily attached allowing me to manoeuvre my

micro-chisel in there and pop the gun sight loose. Superglue and

tweezers got it back on again.

A relatively minor brain fart to be sure, but it would have been pretty

embarrassing not to have noticed it until someone pointed it out to me

at the local contest…

Fiddly Bits

There is an annoying ejector pin mark on the nose gear oleo strut

which I filled with superglue and sanded smooth. The main gear doors had

some pin marks which were also filled with superglue and scraped smooth

with a micro-chisel. I sanded flat spots on the wheels and painted the

hubs semi-gloss black. I stuck each wheel on a toothpick and brush

painted the tires with a dark brownish grey mixed from Citadels. I then

dusted each tire with MiG “European Dust” pigment and airbrushed

straight mineral spirits to fix the pigment in place. With my pinkie, I

smeared MiG “Black Smoke” around the circumference of the treads to

darken them. The fit of the wheels on the main gear legs was so tight

that they could be press fit in place without any glue. The cannon

barrels and pitot probe were brush painted Humbrol Metalcote steel

(wonderful stuff) and buffed with a soft cloth.

I left the hinged part of the canopy unattached so that it can be posed

either open or closed. Nor did I glue the engine pod on, instead leaving

it attached with Blu-Tak in the event that I ever complete the exposed

engine (Ha! As if!).

Although I never had any illusions that I might complete a model in

one weekend, I still achieved a new personal best by finishing this

one in less than three weeks. It is a testament to the outstanding fit

and engineering of this kit that, although I finished quickly, I never

had to rush things or cut corners.

A lot of folks questioned Mr. Tamiya’s latest choice of subject matter,

given that the Trimaster/Dragon/DML kit is perfectly adequate. I for one

however, would probably never have built this particular aircraft had

Tamiya not released it. I’m glad they did.

Click the thumbnails below to view larger images:

Model, Images and Text

Copyright © 2006 by

Tony Bell

Page Created 01 August, 2006

Last Updated

21 February, 2007

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search