|

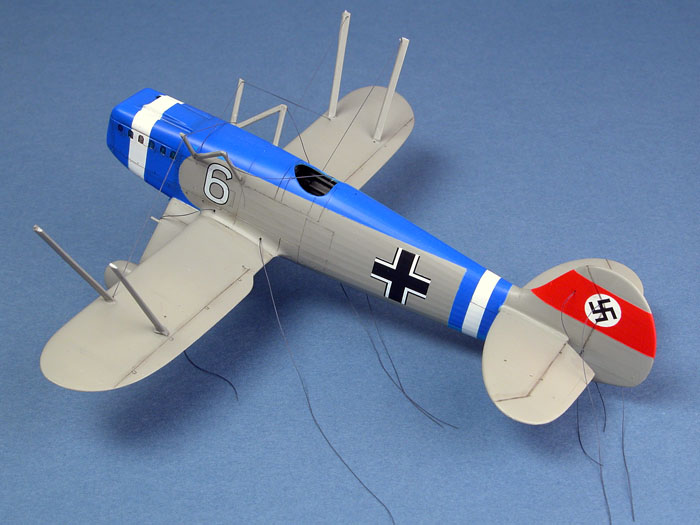

Classic Airframes' 1/48

scale

Heinkel He 51 B-1

by Brett Green

|

|

|

Heinkel He 51

2./JG 135, Bad Aibling, Germany, September 1936 |

HyperScale is proudly supported by Squadron

I needed an early Luftwaffe fighter model in a pre-war

scheme for a future project with a fast-looming deadline. Apart from my Bf 109 V4 in Spanish Civil War markings, I did not

have anything answering the description in my collection of built

models.

At a local Sydney hobby shop, I found a dusty box that

might fit the bill - Classic Airframes' 1/48 scale Heinkel He 51. I

handed over a very reasonable AUD$30.00 and rushed home to see what I

had pulled out of the lucky dip.

Classic Airframes released their Heinkel He 51 in 1996.

The standard of these early limited run kits could be variable, and I

was a little uneasy about what might await me. My anxiety was heightened

because I had never built a biplane, at least not during my adult

modelling career - maybe an Airfix Sopwith Camel in the 1960s.

Upon opening the box I was pleasantly surprised to find

a model with excellent fabric texture, thin wing and tailplane trailing

edges and a few resin and phot-etched enhancements. My $30 seemed to be

well spent.

The kit betrayed its early origins by its thick sprue attachments and

flash surrounding smaller parts. First, all the plastic parts were

removed from the sprues with a side cutter and cleaned up with a sharp

hobby knife and sanding sticks. This took less than a half hour, spent

with the family in front of the television (earning brownie points while

modelling - priceless).

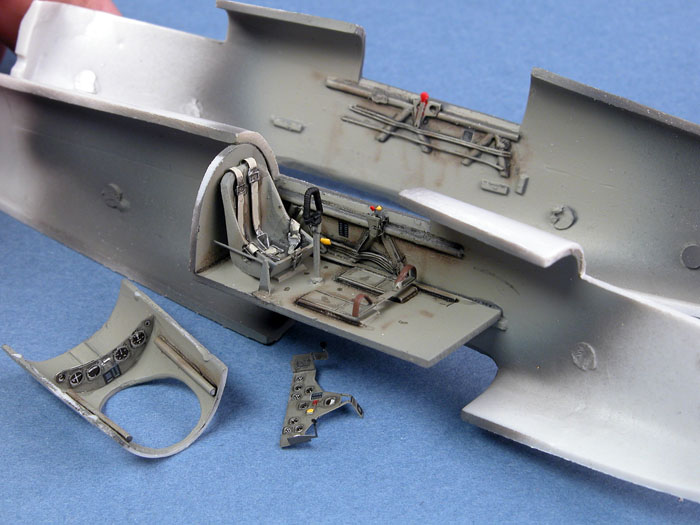

The cockpit was simple but adequately detailed. Basic parts were

supplied in styrene, supplemented with photo-etched instrument panels,

rudder bar, quadrants and harnesses, and a nice resin control column. I

added some fine electrical wire to the lower sidewalls, and structural

detail (plastic strip) to the upper sidewalls. The only other

improvement was to sand down the sides of the pilot's seat, which looked

a bit too thick.

Click the

thumbnails below to view larger images:

The

cockpit paint job commenced with a coat of Tamiya Flat Black followed by

Gunze RLM 02 Grey. The 02 colour was misted in several thin coats onto

the parts at a high angle, leaving natural shadow areas in black.

Streaks of grime were sprayed from my Aztek A470 airbrush using a thin

mix of Black and Red Brown. This was followed by a pinpoint wash of

Tamiya Semi-Gloss Black paint applied to the edges of framework and

panels to add further depth to these structural features. Next, details

such as straps, knobs and buckles were picked out with acrylic paints

and a fine brush. Chipping was simulated here and there with a

well-sharpened 2B pencil, and spots of oil and dirt with thinned black

acrylic paint. The

cockpit paint job commenced with a coat of Tamiya Flat Black followed by

Gunze RLM 02 Grey. The 02 colour was misted in several thin coats onto

the parts at a high angle, leaving natural shadow areas in black.

Streaks of grime were sprayed from my Aztek A470 airbrush using a thin

mix of Black and Red Brown. This was followed by a pinpoint wash of

Tamiya Semi-Gloss Black paint applied to the edges of framework and

panels to add further depth to these structural features. Next, details

such as straps, knobs and buckles were picked out with acrylic paints

and a fine brush. Chipping was simulated here and there with a

well-sharpened 2B pencil, and spots of oil and dirt with thinned black

acrylic paint.

I also applied cockpit placards to the sidewalls and instrument panels

from a Reheat decal sheet. The whole cockpit finally received a coat of

Polly Scale Flat.

Test fitting the fuselage halves revealed that the top

of the rear cockpit bulkhead was marginally too wide. A whisker was

sanded off the top edge of the bulkhead to achieve a perfect fit. This

is probably the easiest fitting Classic Airframes cockpit I have

installed, presumably due to the absence of resin parts.

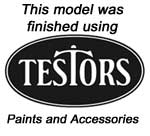

Before I glued the fuselage halves together, I decided

to plan for the tailplanes, which did not have any locating tabs to mate

with the fuselage. First, I tacked the horizontal tailplanes on to the

rear fuselage with a couple of spots of superglue, then drilled holes

into the mating surfaces of the tailplanes from the inside of the

fuselage. I then snapped off the tailplanes, sanded the mating surfaces

and installed short lengths of brass rod as locating pins. This method

ensures perfect alignment between the tailplanes and the fuselage.

You can use the same method for wings without locating

tabs too. I have used a similar technique for years, but I would like to

thank Lee Coll for sharing the suggesting the simple but rather brilliant additional step of supergluing the parts to the fuselage before drilling the locating

holes.

Construction from this point forward was fast and easy.

The fuselage halves aligned nicely. They were clamped together then

Tamiya Extra Thin Liquid Cement was flowed along the join lines. The

wing roots needed some trimming before the full-span lower wing was

glued in place, but fit was then perfect. The brass pins in the

horizontal tailplanes worked like a charm - gap free and precisely

aligned.

The only part that did not fit well was the radiator

housing, but a few minutes trimming and sanding fixed that problem.

The spatted undercarriage legs were drilled and pinned

to reinforce attachment to the fuselage at the top, and the wheel

fairings at the bottom. Reinforcement pins were also installed in the

interplane struts and the tail skid.

Click the

thumbnails below to view larger images:

|

|

|

|

Fit and alignment of the tailplanes was perfect after the installation of brass pins

|

|

|

|

Overall fit of the airframe was surprisingly good for an older limited run kit

|

|

|

|

Gear leg spats were reinforced with brass pins

|

|

|

|

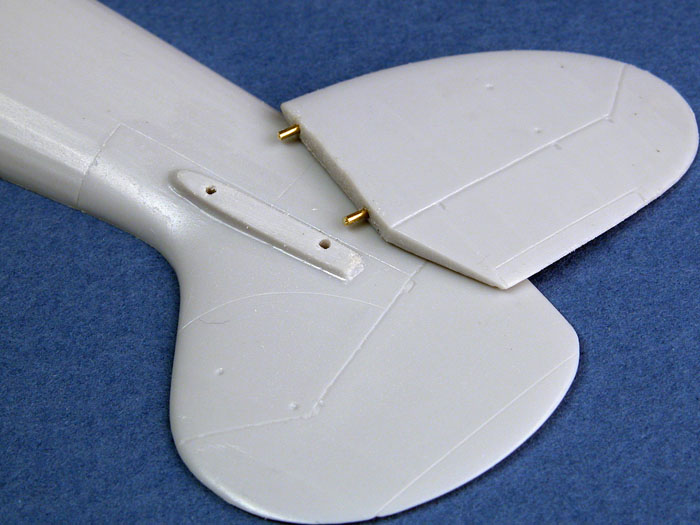

Detail was added to the fuselage face. Ventilation slots were drilled out and fasteners were punched from styrene sheet

|

|

|

Detail was added to the fuselage face. In photos, there

appear to be four raised shapes along the upper cowl join line. Four

small circles were fabricated using my punch and die set. These were

glued in place. Two diagonal ventilation slots were also cut into the

front of the fuselage.

I was concerned about the alignment of the long exhaust

stacks. References show that the pipes were sometimes linked by a metal

rod. I temporarily secured the individual stacks to the outlets in the

engine cowling using Blu-Tack, then glued a length of brass rod to the

row of exhausts using thick super glue. This thick glue is a reasonable

depiction of the welding.

These assembled exhausts were used as a template for the

second set.

With the basic airframe assembled - sans upper wing -

holes were drilled in preparation for subsequent rigging.

Painting is easy to describe, but was time consuming in

execution.

First, the model received a base coat of RLM 63 overall.

I used a 50/50 mix of Gunze H70 RLM 02 and H332 Light Aircraft Grey for

this shade. The result was a light grey colour with a hint of green.

Now came the masking of the national markings on the

fin, the fuselage deck and the rear tail band. The mask for the

crescent-shaped demarcation of the engine cowling was cut from 4cm wide

"Kamoi" tape (marketed by Tamiya) using an Olfa circle cutter. A

combination of Kamoi and narrower Tamiya tape was used for the rest of

the masking.

A coat of White Primer was laid down to provide a

smooth, pale base for the bright (and temperamental) colours to follow.

Pure White was then sprayed in the general areas of the fuselage bands

and the circle for the Hakenkreuz.

The next step was to mask the white circle on the fin

and the two white fuselage bands. With this done, Tamiya spray colours

were decanted into containers and sprayed from my Aztek A470 airbrush. I

wanted a robust, fast drying gloss finish and Tamiya's spray lacquers

offer these qualities. The price is a noxious cloud of vapours, so a

filter mask is essential while spraying. Tamiya TS-49 Bright Red was

used for the RLM 23 of the national markings, while a 50/50 mix of TS-44

Brilliant Blue and TS-23 Light Blue was my interpretation of RLM 24.

Click the

thumbnails below to view larger images:

I was quite pleased with the results when the model

emerged from its paper cocoon.

I was inspired to reproduce this colourful scheme after

reading about the Luftwaffe pre-war marking system in Volume Two of Ken

Merrick's excellent "Luftwaffe Camouflage and Markings" series from

Classic Publications, and finding

Bob Pearson's

"History in Illustration" web page on the Heinkel He 51.

The paint job was sealed with a couple of thin coats of

Future floor polish.

Decals came from various sources - national markings

from a Cutting Edge sheet and from Classic Airframes' Bf 109 B kit, with

the "White 6" coming from a Tally Ho generic Luftwaffe code sheet. Most

of the decals behaved well, but the number on the port side silvered

after the flat coat was applied.

Weathering was kept to a minimum, as I am sure that

these aircraft would have been maintained in excellent condition. The

main emphasis was on control surface hinge lines, which each received a

thin line of a dirty black-brown. Cowling and cockpit panels received

even more restrained treatment. A few translucent chord-wise streaks

were added to the top wing. The final weathering step was a very thin

wash of Tamiya Semi-Gloss Black applied to the major panel and hinge

lines with a fine brush.

Click the

thumbnails below to view larger images:

|

|

|

|

Decals were sourced from various miscellaneous sheets. Numbers came from a generic "Tally Ho" Luftwaffe codes sheet

|

|

|

|

The front struts were held in place with Blu-Tack while the top wing was positioned.

|

|

|

|

Once I was satisfied with the position of the wing in relation to the front struts, they were glued in place.

|

|

|

With painting and weathering complete, it was time to

face my greatest fear - aligning the struts and the top wing.

First I temporarily positioned the forward main struts

on the bottom wing with blobs of Blu-Tack. I held the top wing in

approximately its correct position, and adjusted the top of the struts

to fit into my pre-drilled holes in the bottom surface of the top wing.

When I was satisfied with the alignment, I applied a bead of super glue

to the base of both struts using a fine piece of wire as the applicator.

Next, I lined up the rear struts directly behind the front struts and

glued them in place. Once again, I test-fitted the top wing. This time,

it seemed that the rear struts were slightly too tall so I trimmed them

to a more appropriate height while they were still glued in place.

I placed the interplane struts into the holes drilled

into the fuselage, then test-fitted the top wing for a third time. The

metal pins offered a degree of flexibility, permitting the unglued

interplane assemblies to find their own level under the weight of the

wing.

Now the model was sprayed with its flat coat - Polly

Scale Flat. This acrylic coat dries fast and resists fingerprints. It is

also very reliable in the level of gloss achieved. The first coat

delivers an eggshell finish, almost flat. The second coat is dead flat.

I was satisfied with a single coat for most of the airframe, with a few

bands of "dead flat" on the top of the upper wing.

At this stage I decided to lay the groundwork for the

rigging.

E-Z Line was chosen as the rigging material due to its

elasticity and robustness. Its thickness also looked about right to my

eye. I started by gluing lengths of E-Z Line into some of the

pre-drilled holes in the airframe. My original plan was to complete the

rigging when the top wing was secured, but I thought I would rig a few

lines beforehand on the tailplanes and undercarriage. These early

attempts were time consuming and fiddly, but not especially difficult,

especially with the in-built elasticity of the rigging material. I built

up a rhythm and found myself rigging the entire airframe before

installing the top wing. This was relatively easy thanks to the greater

access afforded without the obstruction of the top wing.

The finishing touches included the windscreen, the

auxiliary fuel tank and the propeller assembly.

The windscreen was cut out of the flat acetate sheet and

folded into shape. A thin bead of Micro Krystal Kleer was brushed along

the bottom lip of the windscreen and it was carefully positioned in

front of the cockpit opening.

Photos of the wooden propeller assembly suggest that the

front face of the blades were sometimes painted silver. I thought it

would be interesting to combine this with a non-reflective black rear

face and 02 Grey on the centre section. I was tempted to "wear down" the

front of the propeller to reveal bare timber, but I thought it was

unlikely that these pristine pre-war birds would be neglected to such a

degree. The propeller was progressively masked and sprayed the four

colours - first RLM 24 Blue, then RLM 02 Grey, then silver and finally

black.

The external fuel tank was assembled and a disc punched

to represent the filler cap. The tank was painted silver and moderately

weathered using a combination of airbrush and paint brush.

The previously assembled exhaust stacks were brush

painted with Testor's non-buffing Burnt Iron Metalizer, and the stubs of

the machine gun barrels received a coat of Gunmetal.

The wheels were brush-painted Flat Black, and received a

dusting of Tamiya pastel chalks.

And now, the moment of truth.

I mixed up a batch of Araldite 5 minute epoxy glue and

applied small dabs to the tops of the interplane struts and the rear

outer struts. I then filled the locating holes for the forward outer

struts in the top wing with super glue. I carefully positioned the wing

over the forward outer struts, and promptly dropped the wing. No damage

done, so I repositioned the wing and lowered it more carefully onto the

forward struts. With the front struts in the locating holes, I gently

tipped the wing back onto the rear struts. I needed to apply a little

extra pressure to get the rigged interplane struts to sit down evenly.

In the end, I balanced a can of Humbrol paint on top of the wing to

maintain the pressure while the glue dried.

The result was a reasonably well aligned wing assembly.

Not perfect, but I was satisfied as a first attempt.

I still had to rig the aerial wires. The photo-etched

mounts on top of the wings were secured with epoxy cement, and E-Z Line

was once again used for the rigging.

Just when I thought that I had finished, I realized that

I had not installed the rear-vision mirror and the boarding ladder. The

ladder was simple enough, but it was tricky to maneuver the tiny

photo-etched mirror into the narrow space between the deck and the top

wing.

Classic Airframes' 1/48 scale Heinkel

He 51 was not quite as scary as I first thought it might be. For a

start, it fitted together quite well.

Rigging and installing the top wing

were also worse in anticipation than execution.

The model went together surprisingly

fast too. I started cutting parts from the sprue last Sunday afternoon,

and I was adding the finishing touches almost exactly one week later

with only a few hours work each day (well, maybe more than a few

hours over this last weekend...)

After seeing how attractive this

colorful specimen looks, I feel like tackling another pre-war Luftwaffe

subject, maybe this time with the Chrome Yellow trim of JG 234.

Anyone out there got a spare Classic

Airframes Arado Ar 68?

Click the thumbnails below to view larger images:

Model,

Images & Text Copyright © 2006 by

Brett Green

Page Created 08 October, 2006

Last Updated

21 February, 2007

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search