|

Detailing the

Airfix 1/72 scale

Henschel Hs 123B

by Glenn Irvine

|

|

|

Henschel Hs 123B |

Airfix's

1/72 scale Henschel Hs 123 is available online from Squadron

The Henschel 123 was a 1930’s design that was

relegated to second line duties fairly early in its life due to advances

in aeronautical design, but as history would show, was later to achieve

much greater success in its field due to its basic and rugged design

than it’s much more modern replacements which struggled when the

conditions were too harsh for their finicky design.

The Russian front during the extremes of climate

change is no place for wimps or finicky highly strung engineering

designs. Unfortunately the German war machine was filled with such

‘wunder weapons’ and as impressive as they were to the rest of the

world, they had not factored in the extremes of the environments they

would be asked to operate in. This blinkered approach would eventually

be part of the great undoing of the Third Reich’s vast war machine.

To give an example of the simplest of problems that

happened in winter in Russia was the problem of finding the round would

not fit in the chamber of your rifle due to such extreme contraction of

the metal in the cold and the very fine machining tolerances commonly

used by the German manufacturing industry. The Russian machinery on the

other hand was a lot cruder, but, it did continue to function even under

the most extreme of climatic conditions.

The Henschel was an example of the latter and as

such was able to function when a lot of the other war machinery would

not. It was basic in design and thus, easy to maintain, easy to fly and

much loved by its pilots. The aircraft soldiered on until there were

none left. At one point an attempt was made to put it back into

production, such was it’s effectiveness, unfortunately this was not

possible as the jigs had been destroyed long before as more modern

machinery succeeded it.

The Kit - Airfix 1/72 scale Hs 123B-2

This was one of Airfix’s early bagged release kits,

and I remember building it for the first time in the early 70’s. As a

kit it is typical of the time, fairly basic components, crude detail by

today’s standards and not particularly accurate. Unfortunately it is the

only game in town. It represents an early A series airframe with the

fabric wing and the later headrest fairing as found on the B series.

Preparation

I wanted to build the B series which had the wing

fully skinned in metal so I had to do a lot of sanding first.

Fortunately there is a lot of excess plastic built into the kit. The

first thing I did was attack the flying surfaces with a small bastard

file to bring the wing back to something approaching an aerofoil shape

then finish of with successive grades of sanding stick. After this, the

entire airframe was rescribed using the plans in the Wydawnicto book as

my primary reference with extra detail added after detailed examination

of available photographs.

Construction

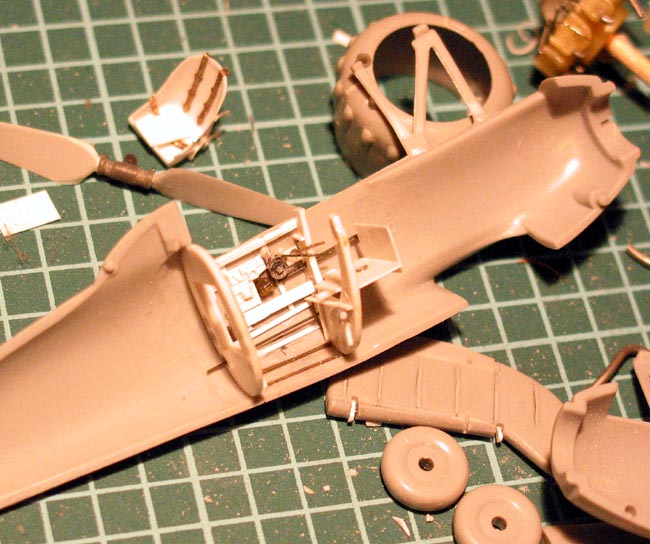

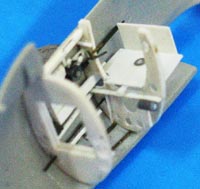

The fuselage came in for some extra detailing and

accurizing as well. The cockpit was entirely scratchbuilt using drawings

and photos as reference. Some of these drawings came from Modeldad,

thanks! , also reference was made to the 1/48 resin set in the AML kit,

photos of these are found in one of Hyperscales reviews. The fuselage

was thinned down to paper thin with my Dremel and bulkheads and

stringers were fabricated. The seat was plunge formed out of a coffee

sipper lid! These are great for those little plunge form jobs like this

as they have a stiffening rim which gives you something to hold it with

and to support the softened plastic while you plunge your master into

it. I use a small candle to apply heat. They are made from about 8-10

thou sheet so are perfect for this sort of work and, best of all, they

are free!!

The instrument panel, side consoles, throttle

quadrant, radio boxes and oxygen regulator and bottle was built up using

sheet styrene and stretched sprue, plus the odd leftover etched metal

part as lever handles with white glue as the knobs. Seat belts were

etched metal from an Airwaves set for the shoulder harnesses and foil,

tape and wire for the lap belts.

The

rudder pedals were plunge moulded and drilled to represent the early

style pedals that were in use at the time the Henschel was built. The

control column was built up from strip and wire and includes the brake

lever and the gun firing button. The oxygen hose was from fine wound

guitar string. The side access doors were cut out and masters made to

plunge mould new ones of the correct shape, padding was added from fine

lead wire. This was also added to the forward cockpit edge either side

of the gunsight. The

rudder pedals were plunge moulded and drilled to represent the early

style pedals that were in use at the time the Henschel was built. The

control column was built up from strip and wire and includes the brake

lever and the gun firing button. The oxygen hose was from fine wound

guitar string. The side access doors were cut out and masters made to

plunge mould new ones of the correct shape, padding was added from fine

lead wire. This was also added to the forward cockpit edge either side

of the gunsight.

Now

for the main fuselage, for a start, the headrest fairing had to be

reshaped and shortened and a new headrest pad made from plastic sheet,

the forward fuselage was circular in cross section and this was

incorrect as the cowling complete with exhausts would not fit. So, after

analysis of photos it was found that the fuselage was actually oval in

cross section and this allowed the exhausts to fit. The upper gun

decking was attended to at this point too, as it was very crude and

required the gun ventilation louvers to be entirely redone out of 5 thou

card embossed with louvers of the appropriate size. These panels were

then fitted to areas that were slightly recessed with my Dremel. After

gluing they were blended in with filler. The upper gun decking did not

match the curvature of the lower forward fuselage at this point and was

blended in with super glue. Provision was made to fit gun barrels later

so stops were glued in just aft of the gun openings. New reversed vent

scoops were made and glued in place behind the louvers. Now

for the main fuselage, for a start, the headrest fairing had to be

reshaped and shortened and a new headrest pad made from plastic sheet,

the forward fuselage was circular in cross section and this was

incorrect as the cowling complete with exhausts would not fit. So, after

analysis of photos it was found that the fuselage was actually oval in

cross section and this allowed the exhausts to fit. The upper gun

decking was attended to at this point too, as it was very crude and

required the gun ventilation louvers to be entirely redone out of 5 thou

card embossed with louvers of the appropriate size. These panels were

then fitted to areas that were slightly recessed with my Dremel. After

gluing they were blended in with filler. The upper gun decking did not

match the curvature of the lower forward fuselage at this point and was

blended in with super glue. Provision was made to fit gun barrels later

so stops were glued in just aft of the gun openings. New reversed vent

scoops were made and glued in place behind the louvers.

The large engine cooling louvers on either side of

the forward fuselage were cut in and shaped as they were gone completely

after reshaping the forward fuselage, not that they were there in the

first place, at least not properly.

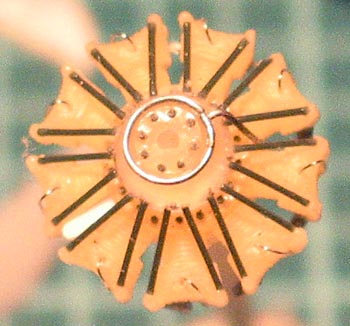

The engine in the kit was a complete waste of time

as supplied from the kit and I had to find a replacement, so, after

looking in my kit stash, I found I had nothing that would work, so, what

does a resourceful modeler do? Why raid a friend’s stash that’s what!!

After looking in Lawrence’s stash I found an engine

from the Hasegawa 1/72 Buffalo which filled the bill nicely. I took this

part home and made a silicone rubber mould of it and cast it in resin

twice.

I

only cast the rear face as the front face had pushrods moulded onto it

and I did not want that as I was going to replace all that with

stretched sprue. So, there I was with two copies which I then sanded

back till they were each half thickness, I then glued them together as

perfectly aligned as I could. Sprue pushrods were added and the ignition

wiring, the reduction gearcasing was turned up on my dremel from some

thick acrylic rod. This had holes drilled to take stretched sprue as

bolt heads and lead wire for the oil pipes and the forward rim of the

casing. This land would later be the location for the cowling bracing

wires so evident in photos of the real aircraft. I also added a shim of

rod on the oil sump painted as the BMW logo which is often very visible

on their radial engines I

only cast the rear face as the front face had pushrods moulded onto it

and I did not want that as I was going to replace all that with

stretched sprue. So, there I was with two copies which I then sanded

back till they were each half thickness, I then glued them together as

perfectly aligned as I could. Sprue pushrods were added and the ignition

wiring, the reduction gearcasing was turned up on my dremel from some

thick acrylic rod. This had holes drilled to take stretched sprue as

bolt heads and lead wire for the oil pipes and the forward rim of the

casing. This land would later be the location for the cowling bracing

wires so evident in photos of the real aircraft. I also added a shim of

rod on the oil sump painted as the BMW logo which is often very visible

on their radial engines

The rear of the engine had the exhaust manifold

constructed from solder of various thicknesses and the exhaust outlets

were made from heat formed rod that had been hollowed out with the

dremel tool. All this would be invisible once the cowling was fitted to

the fuselage but it made me feel better that I had built it as it was

quite a bit stronger and ………just because …OK. To tell you the truth I

had planned to open up one of the forward fuselage panels and the lower

cowl on one side, but could not find enough info on what this area would

have looked like, so did not go ahead with it.

The

propeller was thinned down to more scale like aerofoil thickness and the

hub scratch built from tube, rod and sprue. This was a complete pain as

it broke in the middle of the blades several times as it was so thin,

however MEK to the rescue. I don’t use this stuff all the time, but, it

is good for really quick solid joins with very little excess melting of

the parts. The

propeller was thinned down to more scale like aerofoil thickness and the

hub scratch built from tube, rod and sprue. This was a complete pain as

it broke in the middle of the blades several times as it was so thin,

however MEK to the rescue. I don’t use this stuff all the time, but, it

is good for really quick solid joins with very little excess melting of

the parts.

The cowling was cleaned up and the lower induction

scoop and oil cooler cover was shaped from plastic stock and attached

including the drain tube and starter crank hole. The interior was

thinned down extensively to fit the new engine in and to look more to

scale. The gun blast tubes were made from plastic tubing and thinned

down on the ends; these were fitted to holes drilled in the cowling.

The

cowling joint stiffeners were replicated with strips of stretched sheet

styrene to get extra thin strip and the cowl was scribed. The

cowling joint stiffeners were replicated with strips of stretched sheet

styrene to get extra thin strip and the cowl was scribed.

The tail wheel was scratch built as the kit one was

totally useless, so a wheel was turned up from acrylic rod and a yoke

made from plastic scrap and the leg from wire. The canvas/leather boot

was shaped from plastic scrap and glued in place. The tail wheel drag

strut shroud was also hollowed out and the drag strut made from

stretched sprue. The rear bump stop was built up from scrap plastic

super glued in place. This tail wheel area was misshaped and suffered

from sink marks so was built-up with putty before replacing all the

detail.

The main wheels were undersized, so spare wheels

from the ‘thou shalt not throw anything kit related away collection’

were put to good use. (no, I don’t know what they came off, they just

measured up to the correct scale size). The main wheel covers had some

sinkmarks and were filled, scribed and extra detailing added, they were

also hollowed out with the ….you guessed it! Dremel tool. The support

struts to the rear of the covers were thinned down to aerofoil shape as

well.

The flying surfaces were all removed and hinge

detail added. At this time Mr Surfacer 500 was brushed on with a 000

brush in fine lines that were tidied up after drying to replicate the

stitching on the fabric covered structure. The ailerons posed a special

problem as they had an unusual shape and no drawing or photograph showed

clearly how the hinges were aligned or how it worked. The underside of

the wing had a 45 Degree angle back to the top surface of the wing which

closely matched the aileron, so there was a large gap between the lower

surface of the wing and the forward edge of the aileron. This design is

consistent with a Friese type aileron but the leading edge of this type

usually has a forward edge on the lower surface further forward than the

top surface. This means that with the hinge placement on the lower

surface of the aileron and level with the top surface joint with the

wing, when the aileron is tipped up a large gap forms between the

ailerons lower forward edge and the lower wing surface and this projects

into the airflow causing drag which helps assist further deflection.

Such seemed not quite the case with the ailerons on

the Henschel. As I couldn’t work out exactly how the whole thing was

designed, I compromised as best I could. – I think it looks OK and I

think I got it nearly right.

I wrote this to illustrate how I went about

detailing this area and the kind of understanding of the mechanical

design sometimes needed to determine the detail required in an area not

sufficiently covered by references.

The interplane struts were thinned down to scale

thickness and the cuffs were simulated with a layer of Mr Surfacer 500

painted on and sanded lightly. The pitot tube was added from fine steel

wire sheathed in stretched tube and faired in with plastic and

superglue. The other struts were thinned down to scale as well, they had

been removed from the fuselage complete and had to be carefully refitted

to the fuselage after fitting the top wing as they were glued to it

first, as were the interplane struts.

When the upper wing was sanded to shape a thinner

section was sanded in the center section as the real aircraft had. I

then had to add a strip of baremetal foil in the centre to simulate the

jointing section in the middle of the wing. Navigation lights were made

from krystal kleer over painted with transparent red and blue/green.

The horizontal tail planes were separated and hinge

detail added. The rear edges were recessed and the trim tab actuators

added. The support struts were added from stretched plastic strut stock

and the joint to the fuselage faired with super glue.

The kicksteps were made from wire, sprue and sheet.

The drop tank was turned up from plastic stock and all connector’s hoses

and the rack were made from wire and plastic. The bomb racks were made

from strip, sheet and wire. The forward braces were a complicated shape

difficult to replicate individually in this scale until I realized that

making a length of ‘stock’ material of a cross section of the same shape

as the aforementioned forward braces, I could, when dry, simply slice

off sections of the correct thickness to replicate each brace and glue

these in place. Amazing what comes to you at 3 in the morning!

The

bombs were junk and I built a new one of accurate size and shape, but

had such fun with the 5 thou fins individually glued in place and

aligned, I decided to cast this bomb in resin and save myself the

stress. The

bombs were junk and I built a new one of accurate size and shape, but

had such fun with the 5 thou fins individually glued in place and

aligned, I decided to cast this bomb in resin and save myself the

stress.

The side pitot tube was made from stretched tube

and fine wire and mounted the very last thing. The aerial was made from

synthetic stretchy transparent material coloured with a permanent

marker, I suspect is knitting elastic or lycra, anyway it is incredibly

fine, very hard to break and stays taut.

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search