The

Junkers Ju 88C-4 was a night fighter based on the A-5 with the new,

longer wing and some other differences from the A-4 based C-6, which

succeeded it after less than 100 C-4 were built. The C-4 was produced

between late 1941 and early 1942.

I decided to paint my model black as I had bought a decal set from Peter

Roberts of PD Models, very thin and accurate decals. R4+KL, which

suffered a landing accident in Catania, Italy, in August 1942 was the

individual I chose as the subject of my model.

Italeri's 1/72 scale Ju 88C-6 in the box

This kit was released in the early nineties and was a giant leap

compared to the earlier kits of the Ju 88. The only competitor is the

AMT C and G version which was released a year or so later, but I prefer

the Italeri kit because of the thin raised panel lines that can easily

be removed. The AMT kit has engraved panel lines that I find too large

for this scale, but apart from that the kit is as good as Italeriís, and

the landing gear and interior is much better.

To convert the Italeri C-6 to a C-4 this was done:

∑

The asymmetric cowling on the engine lower side was completely removed

as the Jumo 211 G or F didnít have the extra air cooler the C-6ís Jumo

211 J had

∑

Italeri Ju 188 propeller blades were used as they are more narrow and

thin (metal vs. wooden propeller blades) than the kit propellers

∑

The C-4 did not have a balanced rudder, so the upper part of the rudder

was made shorter

The C-4 also had weaker landing gear than the C-6, but the Italeri gear

is thin enough to represent that!

Fuselage and Cockpit

Before

assembly all panel lines were removed, and new lines not crossing the

fuselage joint were scribed with a Bare Metal scriber.

Click the

thumbnails below to view images full-sized:

The

fuselage halves were then mated using liquid cement, and the cockpit

interior was completed almost stock, painted dark gray and dry brushed

in a lighter shade, only seat belts in lead foil and ReHeat belt buckles

were added. Now was the time to scribe the missing panel lines. Here the

new rudder contour can also be seen.

The Falcon

canopy was measured and the razor saw was put into action, removing

plastic both in front of and behind the cockpit. One problem with the

Falcon canopy is that it was designed for the much wider Revell C-6

fuselage.

With the

excess plastic gone I used plastic card to build the frame on which the

canopy would rest, a recess was made on the port and starboard using

plastic strips 0,3 x 0,2 mm to get a better surface to glue the canopy

to. As it is virtually impossible to sand down the plastic in the canopy

it was necessary to use putty for the final blend with the fuselage

front and rear. The images below show the interior and a dry fit.

Click the

thumbnails below to view images full-sized:

The

ventral gondola is clear and fit quite well, the rear part was left off

as it would be in the down position with a ladder, and the windows were

masked. The hatch actually looks different on the C-4 but not so much

that it matters. As the hatch would be down the inner surface of the

gondola had to be painted matte black too, and the windows were also

masked.

The blind

landing antenna FuBL2 was located inside a cover painted like the

aircraft and not ďbareĒ like in the kit, this was made from sprue and

glued far back on the lower rear fuselage.

Wings and engines

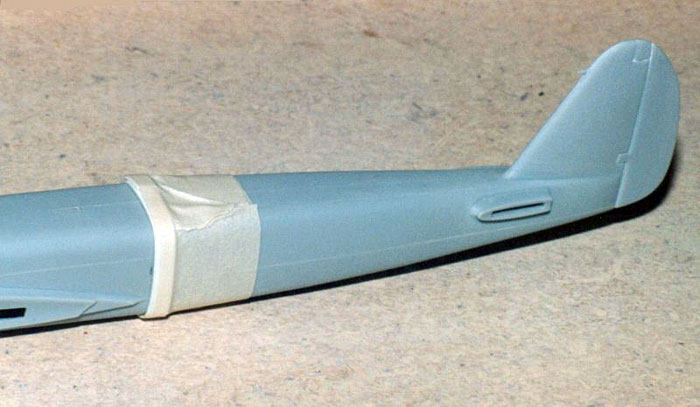

The

already scribed upper and lower wing halves were sanded flat on the

mating edges, and the trailing edge was made much thinner as it tends to

be much too thick if nothing is done. I use liquid glue for the wings

and Iím very careful to get the wings straight. Sometimes even drooping

a little at the tip to simulate heavy, fuel-filled wings, but not so on

this Ju 88.

The wings

have a dihedral of 13 mm in this scale, and to strengthen the

fuselage-wing joint I usually bend a piece of brass tube or piano wire

and insert it through the fuselage. The wings may have to be prepared

for this depending of how thick the tube or wire is, and this calls for

careful dry fitting.

The piano

wire is glued using epoxy glue, and for the wing/body joint I use liquid

cement. The airframe is then put in a ďjigĒ using paint jars or

something similar in height, so the dihedral can be adjusted to the

final, perfect look. Itís also very important that the fin is absolutely

vertical, and sometimes mild force must be used in this operation, but

with good preparation of the wings that will not be necessary. With the

airframe in the jig, the stabilizers were glued using liquid cement and

fixed with paint jars and strips of plastic card to the absolutely

horizontal position of the Ju 88.

Over to

the engines which had the lower side cowlings modified with plastic card

and putty.

This was

almost ten years ago and I had not heard of Milliput or epoxy putty yet,

so the cowling modification got some really large sink marks (this was

after painting the airplane black the first time!).

The

Italeri wheel wells are not so good, I think they donít look like the

real Ju 88 does, and the fit between the engine and the wheel well is

not good. There are other drawbacks in this area which I will mention

later. The well interiors were painted slightly darker than RLM02 as I

wanted the contrast to the black exterior not be too significant.

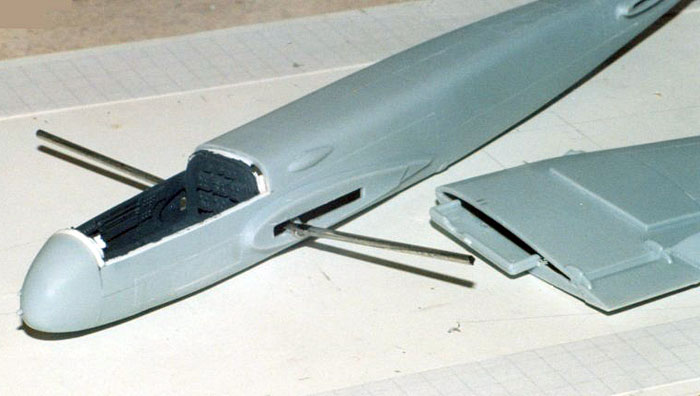

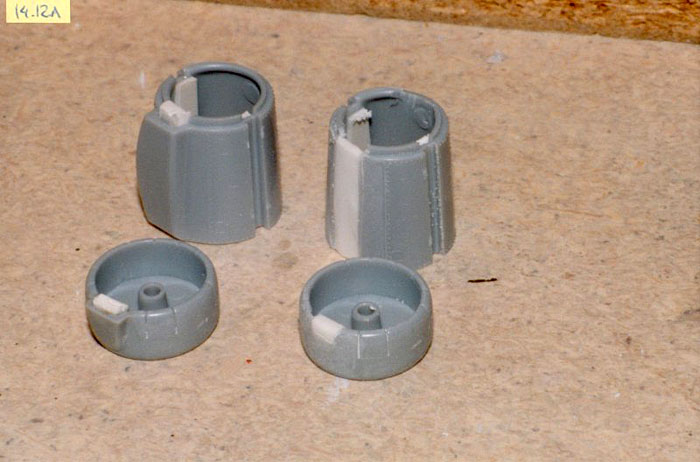

The

propeller hubs were drilled out and piano rods of 1/16Ē was glued in

position. On the front annular radiator a piece of suitable sized brass

tube was inserted and fixed with CA glue. This can be done before or

after the engine is in place, but itís easier before as the tube needs a

support on the back side of the engine. By doing this I get a strong

propeller shaft, it is centered (if done correctly) and still

detachable.

With

engines and exhausts in place, now it was time to fix the canopy with

epoxy glue, after a thorough polish on the inside, using tape to secure

it while the epoxy is hardening.

Click the

thumbnails below to view images full-sized:

The canopy

was masked with ordinary masking tape and liquid Microscale Micro Mask.

I prefer

the gloss enamels, as they give a hard, glossy surface for the decals,

usually Xtracolor as they are easier to paint and have a very prolific

range of hues. The only drawback is drying time, which forces me to wait

at least overnight before applying decals or the next masking tape. I

have an old double action spray gun and spray 2-4 thin layers, I use

ordinary cellulose thinners and mix roughly 60/40% paint/thinner. For

masking I prefer Tamiya tape as it is thin and does not leave any

residue of adhesive, but sometimes ordinary masking tape is used. Larger

areas I cover with paper or plastic film from the kitchen!

For this

Ju 88 I mixed the black with 10 % white to get a more realistic color.

The decals

from PD Models went on without problems and as mentioned they were thin

and of a very high quality, the wing crosses were from mixed Superscale

sets. All crosses have a fine wash of black to tone the white color

down, and the white fuselage band is completely over painted except on

the top, all of this like the real aircraft.

The canopy

frames were cut from black painted decal film and looks convincing to

me.

To get the

final touch I use Future in thin layers on the whole aircraft, and

sanding each layer with wet paper on the decals. I repeat the procedure

with painting and sanding until all traces of decal film is gone.

Now itís

time for a wash of white spirit and oil color. I use a mix of black,

brown and umber and depending on the color of the aircraft I mix the

wash darker or lighter. The wash is applied generously with a brush and

is wiped off with a dry cloth after a while just like the flowing air

would dry oil stains, i.e. from the nose to the tail. It can even be

almost completely cleaned from the aircraft with a moist cloth, but

donít rub too hard or some paint will come off too! The wash can be done

over and over until you are satisfied.

The wash

is sealed with more Future, this time mixed with Tamiya Flat Base to get

a matte surface for the dry pastels. With a coarse sand paper I produce

a pastel dust that can be applied where dirt is needed, e.g. along panel

lines or where rain water is running vertically on parked aircraft. A

fine brush is used and the dust adheres well to the matte Future. With

an eraser it can be removed and done over again!

Itís very

important to remember that dirt is not spread uniformly on an aircraft;

there is much more on the underside where oil and dirty water is

collecting, along panels edges that are often removed and where the

surface is exposed to exhausts.

When

everything is as I like, I use Future and Flat Base to seal the pastels.

This time I mix Flat Base to get the right shine, and after that I

remove the cockpit canopy masking and cross my fingers the canopy was

thoroughly masked!

The

landing gear was painted light gray and a thin wash was applied with a

sharp brush. With the right amount of white spirit the wash creeps into

every corner and one small drop is enough. Fuse wire was used for the

hydraulic tube.

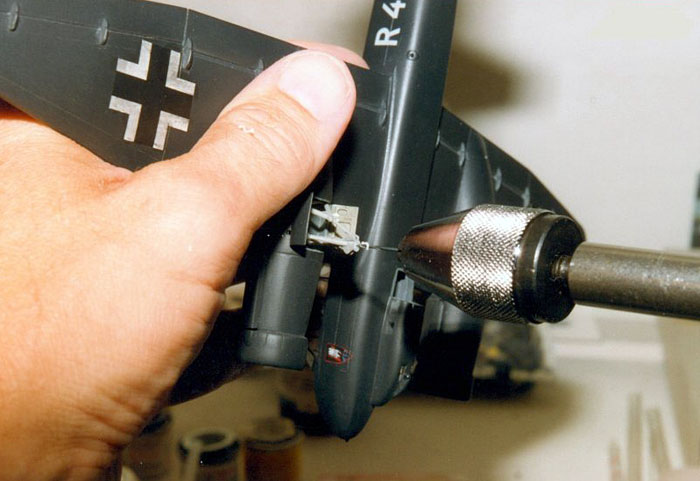

The main

gear and struts were glued with liquid cement, and care was taken to get

the main gear at the right angle. I succeeded, but when I glued the

wheel well doors in place with cyano acrylate, the too small gondola

became obvious! The main landing gear looked far too long, even though

it wasnít when I measured it! I think the gondolas are 1,5 mm too low in

profile, and the wheel well doors are 1 mm too narrow, and in this scale

itís obvious! Below is an image of the already finished main gear leg

before shortening.

What to

do? Some surgical work was necessary, the main gear was cut just below

where the strut connects and 2 mm was cut off each gear. A 0,8 mm drill

was used to make small holes in the main gear upper and lower parts and

two piano wire pieces were cut and with patience and CA and probably

some luck the operation was successful!

Even

though my C-4 sits too low it looks much better than before!

The

propeller blades were painted black green RLM70 and the spinner black as

the airframe.

I did one

mistake in providing the ventral gondola hatch in the rear with a

machine gun like the A-model usually carried, but as the C-4 variant had

two forward firing 20 mm MG FF in the gondola there was probably no room

for the person who should fire this weapon!

This C-4

had one rear firing MG15 of 7,92 mm in the cockpit, for this I used a

thin brass tube. The main forward armament was the fixed trio of MG 15

and one MG FF in the nose.

Even though the Italeri is the model I prefer, this does not mean it is

perfect. On the contrary, it took a lot of putty in the fuselage and the

wing-body joint to make them decent, and maybe the under wing wheel well

gondolas should be replaced. Fortunately, now Czech Six have resin parts

for this.

I must say black paint makes a model almost invisible! Details are

difficult to see, the wash is only noticeable in some angles and I

really donít see all the hours I put into this model!

References

The Squadron/signal Ju 88 in action part 2 covers

most of the important aspects of the Ju 88 night fighter versions, but

for purists there are lots of heavier literature.

I have three Japanese books with an immense

amount of information, not easily read though!

Click the

thumbnails below to view images full-sized.

Click the "Back" arrow on your browser to return to this page.

German Night Fighter Aces

of World War 2

Aircraft of the Aces 20 |

|

|

|

|

Author: Jerry Scutts

Illustrator: John Weal

US Price: $19.95

UK Price: £12.99

Publisher:

Osprey Publishing

Publish Date:

June 5, 1998

Details: 96 pages; ISBN: 1855327147 |

|

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search