|

Extratech's 1/72 scale

M4 Sherman

by Glen Porter

|

|

|

M4 Sherman |

Extratech's 1/72 scale M4 Sherman is available online from Squadron.com for

USD$6.46

images by Brett Green

Until Extratech got in on the act, there were only

about five 1/72 Shermans on the market. Some were good and some were

not. The only M4 was by Hatt and was quite accurate but being aimed at

War-gamers, was not very detailed.

Extratech's 1/72 scale M4 in the box

On opening the Extratech box,

[kit No EXM72035] I was impressed with the amount of detail in it,

including ďlink and length tracksĒ, but some of the sprues are straight

from the M10/achilles kit, which means there are a lot of parts not

used.

On closer inspection, you will

find that the detail is a little bit soft though still quite good and

most of the parts need some clean up. For-instance, the road wheels have

a prominent seam around the centre, which will need to be filed off.

There appears to be a problem with the kit instructions, as there is a

note in the box, which says to ignore the numbers and work off the

diagrams only. Unfortunately some of the diagrams are a bit vague on the

placement of some parts, so be warned.

The decals, as usual for Eduard/Extratech, look very nice and offer four

alternatives - two British, one US and one Canadian. However, one of the

British vehicles, ďShaggy DogĒ is not an M4 but an M4A2. Right hull,

wrong engine deck. The Canadian offering may also be an M4A2 but I donít

have a photo and if they got one wrong they may have got two wrong.

However, I like the Canadian scheme the most so, right or wrong, thatís

the one I was going to do.

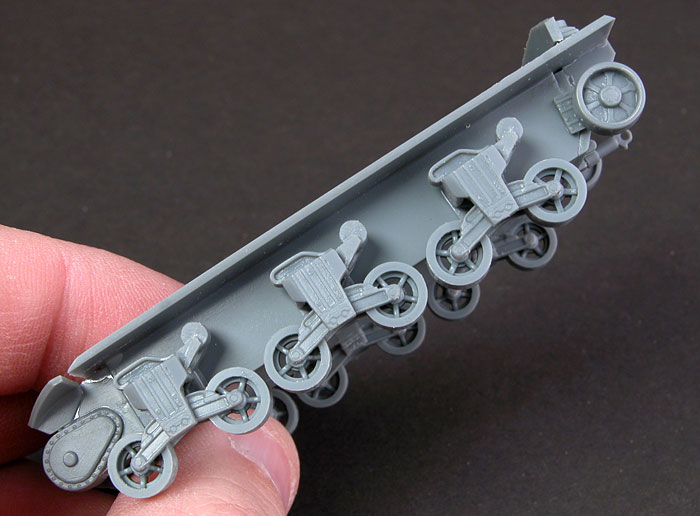

The first job is to assemble the

six bogies, including the road wheels, which are made up from eight

parts each so thereís a lot of cleaning up to be done right at the

start. Caution!. Make sure all of the road wheels are aligned when you

glue the bogies on to the lower hull; otherwise the tracks wonít fit

properly. You get a choice of three transmission covers [nose pieces]

and the instructions tell you to use the three-piece one. The other two

are for later models. This is made up from five parts, the main section,

two bolt flanges and the two bulges that go on the outer edges. Again,

the instructions are a bit vague about which way round these four small

parts go on. I would advise fitting the main part to the lower hull

first, then work out the others. Next, the lower hull rear is fitted.

Leave the exhausts, air-filters and tow coupling till later.

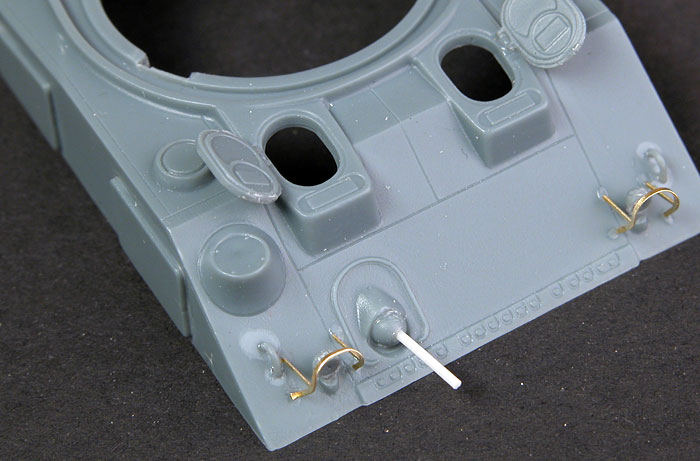

A major problem arises now. There is no positive position for the drive

wheel and return wheel mounts. I would advice again, if you canít work

it out your self, ask some one or look at a similar model. To get it

wrong will cause problems later when you fit the tracks. At this point I

test fitted the upper hull and found that it did not want to go on to

well but a bit of filing around the inside of the glacis plate and it

fitted fine. I didnít glue it on though as I want put figures in it

later. Everything that goes on the upper hull is small and fiddly and

can be hard to clean up, such as head lights, tail lights, lifting rings

and the like, but persistence and a good magnifier help. Iím told that

most M4s in Italy had the extra armour so I fitted that along with the

driver hatches and engine intake cover.

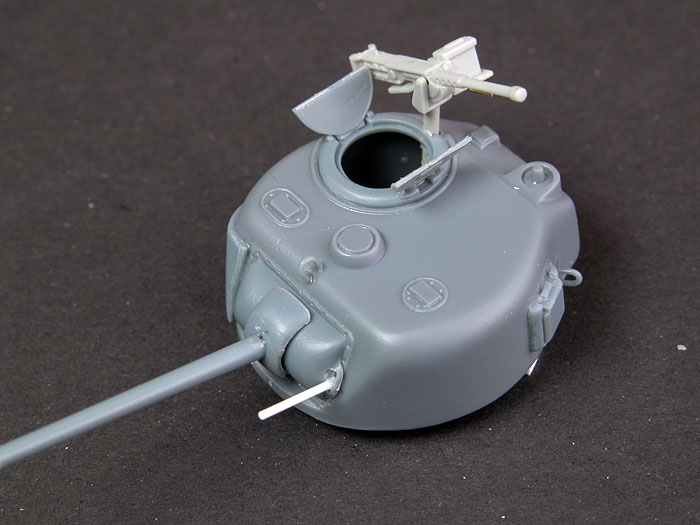

The next item of concern is the two-piece turret. The problem is, it

doesnít have anything to hold it on to the upper hull. This means you

glue it on or it drops off every time you invert the model. After

assembling the turret, including the gun mount, I scratch built a device

to hold it on to the hull while allowing it to rotate. With the turret

upside-down I glued two pieces of shallow channel to the turret roof

vertically, and to the inside of the turret ring on opposite sides,

extending about two millimetres above the ring. Then another piece of

the same channel was glued across the first two with a length of about

two to three millimetres longer than the inside diameter of the aperture

in the upper hull. Then two small slots were cut in the lower hull

turret ring to allow this horizontal channel to pass through when the

turret was placed on top. By turning the turret left or right it would

not drop off.

Extratech does not supply a coaxial machine gun for the turret. As far

as I know, all Shermanís had them. A slot was cut in the fixed mantlet,

a hole drilled in it and a piece of plastic rod was glued in as a gun

barrel.

Next, all the small bits were

glued on the three sub-assemblies including the PE light guards. A few

small problems here: the exhaust outlets donít look anything like the

drawings on the instructions and I would suggest you use the numbers to

identify the correct part. The hull machine gun barrel was too short so

after the ball mount was glued on and dried the barrel was cut off and

replaced with plastic rod.

Click the thumbnails below to view larger

images:

The return wheels, when dry

fitted to the model, were too close to the side of the hull and didnít

align with the other wheels. The existing axle was cut off, a hole

drilled and a short length of rod glued in which stepped the wheels out

a bit. The drive wheels were not fitted yet but I assembled them. Make

sure the teeth on either side line up or other wise you will again have

trouble when fitting the tracks. More on this later.

Everything was now ready for

painting. The fun part!

I had recently bought the first

four British Army colours from WEM. One of the colours was a bit of a

mystery as I could find no reference for Khaki Drab [ARB 03] but I

assumed that it was British Olive Drab, As the instructions for the

Canadian Sherman specified Olive Drab and Dark Earth, I decided to use

the Khaki Drab. Iíve since noticed that WEM have replaced Khaki Drab

with British Olive Drab so I may have got it right.

All three sub-assemblies were given a base coat of Khaki Drab and left

to dry. Then, using the painting instructions as a guide, I carefully

airbrushed the Dark Earth disruptive pattern. I now think this was

wrong, as I have since heard that British Army Instructions specified a

hard-edged pattern. Ho Hum! On previous Armour kits I have dirtied up

the lower hull after everything else was done. The problem with this is

that it tended to lighten the washes and make the lower hull look a bit

flat so this time I decided to do it as part of the initial colour

coats. To show a bit of wear and tare, I added some Tamiya German Grey

with a fine brush in the appropriate places on the turret and upper

hull.

Another problem is that the road wheels donít have a demarcation between

the rim and tyre. This makes it hard to paint the tyre dark grey. I

didnít worry too much as the whole area was to be coated in dirt anyway.

Weathering

All three sub-assemblies were

now given an all-over black wash.

After drying, the excess was

removed using clean methylated spirits. The fine details were now hand

painted in appropriate colours and attention turned to the tracks.

Tracks used on this particular Sherman were the steal chevron type and

were painted on the sprue. The base colour was RAF Dark Earth followed

by the black wash and then dry-brushed with Flat Aluminium. Gluing six

single track-links to each previously painted and weathered drive wheel

begins assembly. The glue used is Tamiya liquid glue thickened with

clear sprue. Next is the first length of track to the first road wheel.

When this is dry, mount the

drive wheel on the lower hull and rotate till that first length touches

the road wheel. If everything checks out, do the same again only this

time glue the drive wheel on. Continue on around the suspension until

you have completed the track on that side. If the join between two

lengths looks too sharp, place a single link in between to round it out,

but often this will not be necessary.

Because there is no positive

mount point for the drive and return wheels, there may be a slight

variation in the length of track on each side. Thereís not much you can

do about this except be careful and use any spare track links to make up

the difference.

Decals

The decals in this kit are

really very good. Perfect register, very thin carrier film and opaque

colours make these among the best Iíve ever used. The whole model was

given several coats of Tamiya Acrylic Gloss until a nice sheen was

attained. The decals went on with out any problems although I will admit

there was no detail underneath to cause any trouble. A sealing coat of

gloss was then added and then left to dry for several days. Finally, the

model was coated with Model Master Dull Coat and the painting was

finished.

Extratechís 50 cal was not moulded very well so I decided to look else

where for one. I didnít want to pinch one out of the Esci Sherman kits,

as I want to build them later. I found one in the Academy Airfield

Vehicle kit, which looked very good. Itís off the Jeep and with a bit of

modification i.e. under cut handles, drilled out barrel and added

cocking lever, it came up nicely after painting with dark grey, dry

brushing with flat aluminium and brown for the wood handles.

Unfortunately itís got the wrong mount for a Sherman. Just one of the

many inaccuracies on this model. Also, after I had finished painting I

noticed that one of the rear light guards had blown away, never to be

seen again. Oh well, no such thing as a perfect model.

A few observations before I

finish. The model is over-all too dark. Next time I will lighten the

whole paint job before I add any washes. Also, the decals are too stark,

although this may be better if the model was lighter or perhaps I could

try weathering them.

Cheers till next time (and that wonít be long).

Click the thumbnails below to view larger

images:

Model and Text Copyright

© 2004 by Glen Porter

Images Copyright © 2004 by

Brett Green

Page Created 17 December, 2004

Last Updated

16 December, 2004

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search