|

Pacific Coast Models'

1/32 scale

Macchi C.200

Saetta

by

Ian Robertson

|

|

|

Macchi C.200 |

HyperScale is proudly supported by Squadron.com

Background

The C.200 Saetta was a workhorse for the

Regia Aeronautica throughout WWII, serving in every theater of the war

for Italy until its surrender. In the Mediterranean theater the

Saetta proved an effective adversary for the Hawker Hurricane, P-40,

and early Spitfires. A unique feature of the C.200 and its two well

known successors, the C.202 Folgore and C.205 Veltro, was

the unequal wing length designed to compensate for engine torque

rotation. This innovation enabled pilots to fly the aircraft without

constant control corrections for engine torque. (Aside: It’s also

amusing to show someone, lets say your wife, the unequal wing lengths

and then complain that the model you just bought is really messed up).

Here I present a Pacific Coast Models 1/32 C.200

Saetta in the markings of a fighter from the 364a Squadriglia, 150o

Gruppo Autonomo, 1942. A photograph of the port side of this aircraft

appears on page 42 of Osprey’s “Italian Aces of WWII”, while a photo of

the starboard side can be found on page 35 of “Regia Aeronautica Caccia

& Assalto 1940-1943, Part II” by Waldis and De Bortoli. This latter book

also features a complete color profile of the aircraft.

PCM’s kit – What’s in the Box?

The kit is an excellent example of just how far

short-run kits have come in recent years. The light grey styrene parts,

made by MPM, feature finely recessed panel lines and plenty of detail.

The plastic is a bit softer than what you get in a Tamiya or Hasegawa

kit, but it remains easy to work with. Some large ejection stubs in the

inside surfaces of the fuselage and wings require removal, but this is

not problematic.

The resin parts are excellently crafted, and include a well detailed

cockpit, straightforward engine, and a superb one-piece cowl.

In general, the photoetch parts are reserved for

those places on the model that really benefit from them. For example,

the unique seatbelt/bondage apparatus and the instrument panel. However,

I found the photoetch for the landing gear (apart from the oleo

scissors) fiddly and more than I wanted to deal with. Your mileage may

vary.

Two vacuform canopies are provided in the kit. Ironically, the

particular Saetta I chose to build (the markings were included on the

decal sheet) had an early style canopy that was not included in the kit.

A minor modification was necessary (see below).

The decals were produced by Skymodels and printed by Cartograf. Six

attractive marking options are provided, and they span a wide range of

camouflage styles for the C.200.

Let me start by emphasizing this is an excellent

kit and I thoroughly enjoyed building it. It is a great example of just

how good a limited run kit can be, and how subjects that many doubted

would ever be produced are now getting a chance to shine in 1/48 and

1/32 scale. Of course there is always room for improvement, and it’s

important to realize that this kit is not intended for beginners.

However, it is well within the reach of modelers with moderate

experience, especially those with some experience using resin and

photoetch. This model took me three weeks from start to finish.

Cockpit

Construction begins with the resin cockpit. The

parts are very well detailed and fit together quite well, although the

assembly is not without a few challenges. First, I had difficulty

installing the seat properly because it bumped into a cross bar on the

rear bulkhead. After careful consideration of the instructions to see if

I was assembling the parts incorrectly (I don’t think I was), I opted to

remove the cross bar and re-install it slightly lower to accommodate the

seat. A clear diagram of the completed seat assembly would have been

welcome in the instructions.

Another area of difficulty I had with the cockpit

was determining how far down in the fuselage it should sit. It seemed

obvious at first, but when I positioned the cockpit so that the top of

the rear bulkhead met the spine of the fuselage, the control stick

extended too high. I opted to remove a small section from the middle of

the control stick to adjust its height so that it looked correct within

the cockpit. Again, it’s not quite clear to me where the error occurred.

Despite these difficulties, the cockpit tub looks great when finished

and installed in the fuselage. Unfortunately, in my haste to seal up the

fuselage I forgot to take photos of the completed cockpit.

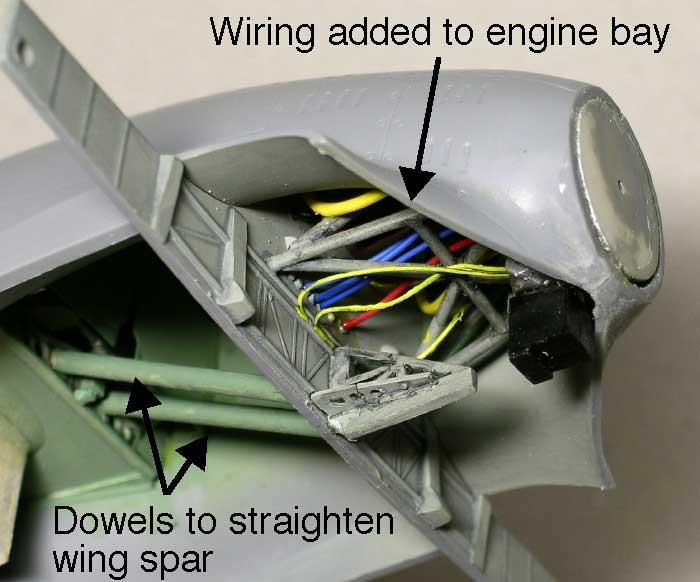

Engine/Undercarriage Bay

The engine/undercarriage bay is an area on the

model that begs for detail in the form of wires and hoses. Following

color photographs in the Aviolibri book “Macchi MC.200 Saetta, Pt 1” by

Maurizio Di Terlizzi (who, incidentally, was responsible for verifying

this kit’s dimensions and accuracy during production), I added the

necessary plumbing to this area. The entire engine/undercarriage bay

assembly was then inserted into the fuselage. The rear bulkhead of the

undercarriage bay, which also serves as the wing spars, bowed slightly

during installation.

To correct this problem, and to avoid later

problems with wing alignment, I wedged two wooden dowels between the

cockpit and the bulkhead to force the bulkhead and wing spars forward

into proper position (see photo).

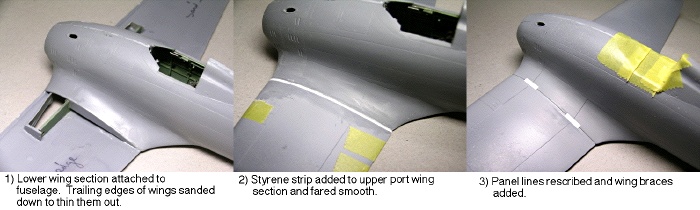

Wings

The lower wing section was attached to the fuselage

as shown in the instructions (panel 1 in photo). When I added the upper

sections of each wing I found the alignment to be fine, but the port

wing was about 1mm too short while the starboard wing fit perfectly. To

adjust the port wing’s length I added a strip of styrene to the edge

where it meets the wing root (panel 2 in photo).

This simple fix solved the length problem and

retained continuity of all the panel lines between the upper and lower

surfaces of the wing. I also sanded off the raised reinforcement strips

on the wing roots (both wings) and replaced them with pieces of sheet

styrene (panel 3 in photo).

Canopy Canopy

At this point I added the vacuform canopy because I

wanted to fare it into the fuselage prior to painting. Some careful

filling and sanding was required, but this effort paid off in the final

result.

Because the aircraft I was modeling had an early

style canopy, it was necessary to add a small flap of clear plastic (not

included with kit) to the rear edge of the canopy frame on each side of

the canopy.

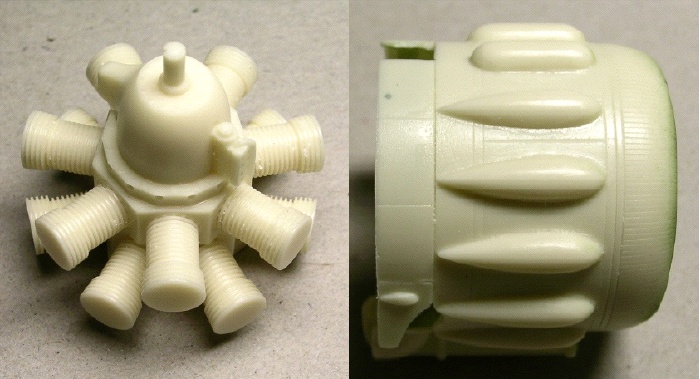

Engine and Cowling

The next major step in construction involved the

engine and its cowl. The resin engine is crisply detailed and easy to

assemble. The heads of the engine cylinders appear simpler in the kit

than in the photos I’ve seen of C.200 engines, but for me they were fine

and indeed may be accurate if different engine configurations were used

on the C.200. I added styrene rods to the front of the cylinders.

Attaching the cowl assembly to the main fuselage is a critical step in

construction because if anything defines the look of the C.200, it’s the

way the engine mounts on the fuselage. Unfortunately there are no

alignment pins to assist in the process. Proceed with caution! I first

attached the cowl to the fuselage loosely with masking tape and then

positioned and glued the machine guns in place. Once the guns were

solidly attached I removed the cowl and then reattached it with 5-minute

epoxy. The machine guns helped me orient the position of the cowl, and

the slow-setting glue allowed me to make last minute adjustments before

the bond became permanent.

It is up to the modeler’s discretion whether to attach the cowl before

or after major painting. I opted for the latter, but I’m not sure it

makes much of a difference. Adding it before painting lessens the amount

of handling afterward. Something to consider.

Landing Gear

The final major step in construction was the

landing gear. I found the gear covers and associated photoetch fiddly,

and the instructions were vague about the positioning of the covers.

However, with some careful test fitting the landing gear assembly goes

together reasonable well.

In the future I think I will replace the photoetch

for the gear with scratch-built styrene components. I find styrene

easier to work with than photoetch.

Paint

The cockpit was painted in Polly Scale RAF interior

green (a reasonable match for Italian cockpit green) and then treated

with washes and chalk pastels. The seat was painted in Alclad aluminum

and then given a black wash (Tamiya acrylic).

The exterior of the model was primed with Mr. Surfacer 1000 from a

rattle can and then polished lightly with a micromesh sanding cloth. The

fuselage band and tail cross were painted white and masked for the

remainder of the camouflage painting.

I painted the model with a variety of acrylic paints, primarily Polly

Scale acrylic and Model Master acryl. I mixed my own version of Nicciola

Chiarro (hazelnut tan) using the top of a White Ensign Models paint tin

as a color guide. I can’t provide the exact formula (it evolved during

the painting process), but I did use the following colors: Polly Scale

Hazelnut Tan, Polly Scale Israeli Khaki, and Model Master #4 Brown (a

reddish brown color). My mixture is slightly less pinkish than that

shown on the WEM paint lid, but it matched well with other Italian color

chips I have.

Once the Nicciola Chiarro mix had dried I applied the dark green mottles

freehand using Polly Scale Italian Olive darkened with a touch of black.

The underside of the model was painted Polly Scale Italian Light

Blue-grey. Various dark washes were used for weathering.

The cowl ring was painted Alclad copper with a hint of aluminum. This

was followed by a wash of burnt umber/raw sienna, and then a wash of

black. Finally, I applied Polly Scale flat clear with a brush to remove

the shine.

The propeller blades were painted Alclad aluminum of the front and flat

scale black on the back, based on my interpretation of photographs of

the aircraft.

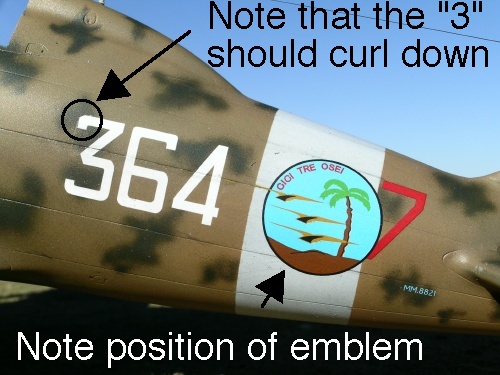

Decals

The decals for this kit worked beautifully. Be

careful with the placement of the until emblem (three birds flying over

the palm tree). Photographs reveal the placement to be slightly

different than that shown in the instructions. Also note that the number

“364” is slightly incorrect in the decals. According to photographs, the

top of the #3 should curve down, whereas on the decal it is straight. I

corrected this error with a scrap piece of white decal on each side.

Photographs suggest that the symbol typically seen

in the center of the tail cross on Italian aircraft was absent in this

aircraft. While it is possible that in the photos the symbol was

bleached out due to overexposure, I was not convinced one way or the

other. I opted to add the symbol on my model.

The antenna wire is stretched sprue and the tension

spring is from a light bulb filament.

Photographs

Images of the completed model were taken outdoors

in natural light with a Nikon Coolpix 5400 digital camera. The “sharpen

edges” tool of Adobe Photoshop was used to restore some of the clarity

and crispness lost during image compression.

Pacific Coast Models has jumped into the fast-growing 1/32 arena with an

outstanding choice of modeling subject in the Macchi C.200 Saetta.

This clunky aircraft oozes character, and the PCM

kit captures the look very well.

For my money this kit is well worth the price given

the generally good fit, detailed resin parts, photoetch, and marking

options. This C.200 definitely won’t be my last in 1/32 scale, and I am

very much looking forward to PCM’s C.202 Folgore and C.205 Veltro down

the line!

Click on the thumbnails

below to view larger images:

Italian Aces of World War

2

Aircraft of the Aces 34 |

|

|

|

|

Author: Giorgio Apostolo

Illustrator: Richard Caruana

US Price: $19.95

UK Price: £12.99

Publisher:

Osprey Publishing

Publish Date:

November 25, 2000

Details: 96 pages; ISBN: 1841760781 |

|

|

Model, Images and Text Copyright ©

2005 by Ian Robertson

Page Created 15 September, 2005

Last Updated 15 September, 2005

Back to HyperScale

Main Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search