|

Tamiya's 1/48 scale

Gloster Meteor F.Mk.3

by

Wolf Buddee

|

|

|

Gloster Meteor F.Mk.3 |

Tamiya's

1/48 scale Meteor F.Mk.3 is available online from

Squadron

Tamiya's 1/ 1/48 Gloster

Meteor F.3 kit was built using Hi-Tech's resin detail set and Eduard's

photo-etch set designed for Tamiya's Meteor F.1 kit.

Fellow Hyperscalers Derek Pennington and Steve Long graciously provided

me with reference drawings and photos and I would like to acknowledge

and thank both these gentlemen for their kind assistance.

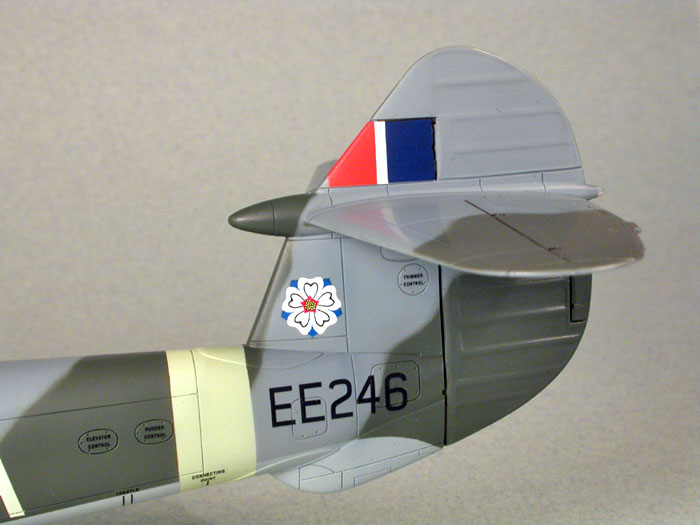

My Meteor is finished as EE246/YQ-A, a No.616 Squadron F Mk 3 Meteor

based in Lubeck Germany, 1945.

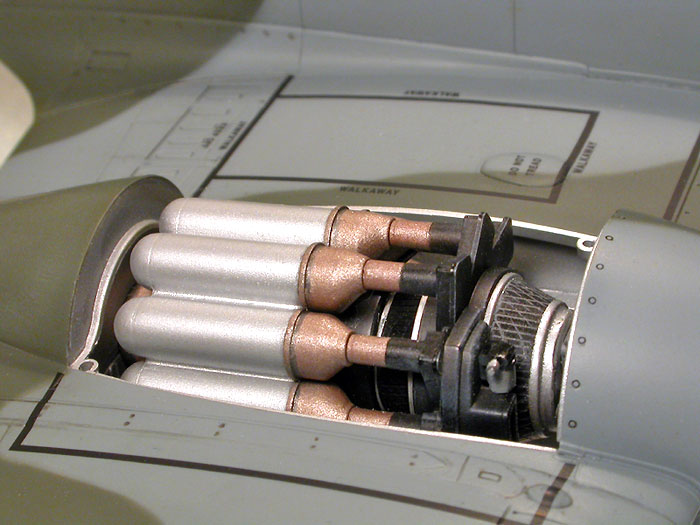

Assembly started with

elongating the troughs behind the open gun ports inside the fuselage

halves and gluing in small lengths of Minimecca metal tubing to

represent the gun blast tubes.

The interior nose sections

of the fuselage were then sprayed with MM British Interior Green and the

fuselage halves were glued together. I then added the wing root pieces

to the fuselage. I had read that getting a good fit between the wing

roots and the upper wing sections was tricky so I took extra care here

by dry-fitting everything repeatedly before committing the parts to

glue. I now added the upper wing halves to the one piece lower wing and

epoxyed the kit supplied ballast ( which prevents the model from

becoming a tail sitter) in place on the lower wing. The wing assembly

was now glued to the fuselage. The extra work done in dry-fitting the

assemblies paid off with an almost perfect fit. The only area that

required any real filler was at the rear section of the lower wing to

fuselage join which I filled with CA and sanded smooth.

The front engine nacelles

were then added to the wings and any small gaps were filled with Mr.

Surfacer 500. Excess Mr Surfacer was removed with a Q-Tip soaked in

Isopropyl alcohol. The horizontal tailplanes were glued in place, the

ventral drop tank added, and Eduard's photo-etch parts for the wheel

wells were glued on to the otherwise featureless walls. This more or

less completed the fuselage.

A final note here: I was to learn later that the droptank was never

fitted to a Mk 3 Meteor. It was not used until the introduction of the

Mk 4.

It was while checking over the completed fuselage assembly that I

dropped the model. Inspection revealed that the rear extreme of the

bullet fairing on the tail had squashed flat. I repaired it by trimming

off the damaged section of the fairing and gluing on a small piece of

clear sprue which I sanded and polished to form the taillight.

I also cut out the wingtip lights and fashioned new ones from a set of

CMK clear green and red resin lights. These were glued in to place,

sanded, polished, and then removed for installation after painting.

Before final installation I gave them a brushed on coat of future for a

high gloss finish.

A final note here: I was to learn later that the droptank was never

fitted to a Mk 3 Meteor. It was not used until the introduction of the

Mk 4.

Cockpit

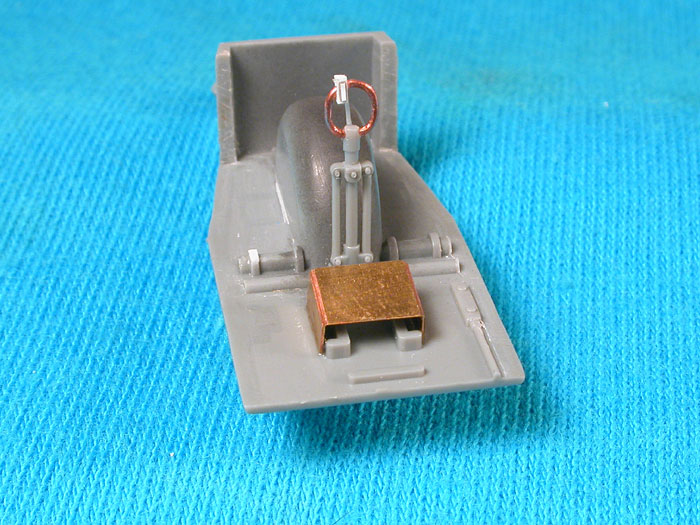

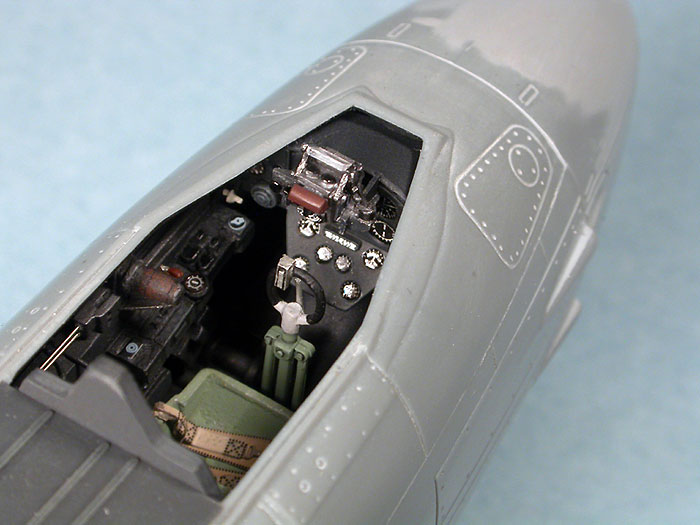

The kit cockpit is

oversimplified in my opinion and adding the beautiful Hi-Tech resin set

made a huge improvement. It appears very accurate when compared to

photos in the Meteor Pilot's Handbook.

I began by cleaning up all

the resin cockpit parts and removing the necessary details from the kit

cockpit. Looking at the pics in the instructions, I guessed that the "Q"

style seat harness fitted through the rear cockpit bulkhead and extended

back in much the same way as in a Spitfire. I drilled out a slot within

the molded detail on the rear bulkhead to accommodate Eduards prepainted

photoetched seat harness. I also noticed from pictures that the control

column spade grip was the wrong shape so the grip portion of the column

was removed. I drilled a hole through the top of the column and

fashioned a new grip from copper wire and added a brake control lever

and gun firing button from plastic.

It was at this point that I realized, to do the cockpit justice, I

needed more info. After a lot of fruitless internet surfing I broke down

and bought the Modelers Datafile book on building the Meteor. This is a

excellent book and I would highly recommend it to anyone building a

Meteor. It revealed that the hole I had drilled in the rear bulkhead for

the seat harness wasn't supposed to be there. The shoulder belts draped

over a small round bar on the rear bulkhead and were secured somewhere

behind the seat. I filled the hole in the bulkhead from behind, removed

the molded on bar and added a new bar from fine stiff wire. Hi-Tech's

resin seat was used with Eduard's photo-etched mount. I painted the main

cockpit with Aeromaster's RLM 66 Blackgrey darkened with a little flat

black. Details were then painted according to the color drawings and

pics in the Datafile book. When I went to paint the port cockpit

sidewall, I noticed that the throttle detail had somehow broken off.

Hi-Tech's resin was very hard and brittle and some of the pieces were

too small to glue back together. I wound up rebuilding the throttle

assembly with bits of plastic, a piece of brass from a photoetch fret,

lots of CA, filing, sanding, and rescribing. The rudder pedals were

removed from the resin foot troughs and replaced with Eduard's

photo-etched pedals. I also added a missing hydraulic pump handle to the

floor.

I decided to use the kit instrument panel with a few modifications. I

removed most of the raised detail on the left side of the panel and

replaced the flaps indicator with a photo-etched item from an Airwaves

set. A new DR compass indicator was made using a Re-Heat instrument

decal and a Waldron instrument bezel. The undercarriage lever was

scratchbuilt and added. On the right side of the instrument panel, the

fuel gauges were added, again using Re-Heat instrument decals and

Waldron bezels. The oxygen regulator panel was added by cutting it from

Eduard's photo-etched instrument panel and detailing it with an

instrument decal and a small photo-etched knob. The yellow hood jettison

handle was added above the fuel contents gauges.The main instrument

panel was finished using the kit supplied instrument decals.These were

punched out individually with my Waldron punch and die set. Each

instrument was finished off with a small drop of Future floor polish to

replicate the glass faces.

Click the thumbnails below to view larger

images:

I should mention, that the

instrument panel, is still missing 3 instruments. Eduard does a Mk 3

photo-etch set which includes the correct instrument panel. I found this

out later but I probably wouldn't have purchased another photo-etce set

just for the panel.

The gunsight supplied in the kit is awful so I ordered a replacement

from Cutting Edge and installed their Mk-9 Acemaker gunsight. While not

completely accurate for this application it is a close representation of

the gunsight used on the Meteor Mk 3. Only a crashpad and the glass

reflector were added to the sight.

With the painting

completed, the cockpit was assembled with Ca and test fitted in to the

fuselage. The fit was perfect. The cockpit was placed within the

fuselage without glue and the upper fuselage section was glued on

securing the cockpit firmly in place. The reason for not gluing the

cockpit assembly was that the nose wheel doors glued in to holes formed

by the bottom of the cockpit tub. Having a little play here assured I

wouldn't have any alignment problems with the holes when fitting the

doors later. Finally a small coaming was made and glued in place to

close off the area between the instrument panel and canopy windscreen.

The Engines

The engines were built

straight out of the box. The tailpipes were sprayed Testors Metalizer

Burnt Metal and the very front part of the engine painted a dark

metallic gray from Humbrol Metalcote. The rest was painted according to

Tamiya's instructions. Washes were applied using thinned Liquitex Paynes

Grey acrylic paint and all parts were drybrushed with a slightly lighter

shade of the base color.

The front air intakes have

a molded in screen detail which is represented by fine recessed lines

and I gave this a sludge wash made of a mixture of light grey pastel

chalk, dish soap and water. Once dry, any excess sludge was cleaned up

using a slightly dampened paper towel. The recesses are shallow so I had

to repeat the procedure a number of times before I was completely

satisfied.

Tamiya provides the parts to build the engines with the extended exhaust

representative of the first 15 Mk 3 aircraft powered by the Welland 1

W2B/23C engines. What is not mentioned anywhere in the instructions is

that parts are also included to build a Derwent 1 powered aircraft with

the short exhausts and the additional scoops for the engine covers as

found on the 16th and on production Mk 3's. You will have to come up

with your own markings though as I have yet to find a single aftermarket

decal sheet for a Mk 3 Meteor in 1/48 scale.

Landing Gear

The landing gear was built

with very little modification. The kit supplied wheels were replaced

with ones from the Hi-Tech set which were flattened on the bottom, had

very finely engraved tread detail, and over-emphasized wheel bulges. The

bulges were sanded down substantially to keep the tires from looking

grossly underinflated. I added fastener details to the landing gear

struts and retraction arms using my Waldron punch and die set. Eduard

also supply a couple of detail pieces to add to the struts.The strut

assemblies were painted with Testors Metallic Silver decanted from a

spray can and shot through the airbrush. The wheels were then slipped in

to the strut assemblies without glue to finish off the landing gear.

Canopies

The canopy sections were

carefully removed from their sprues and when cleaned up were dipped in

Future. When dry, the fixed sections were masked both inside and out

using Tamiya's masking tape and the inside framework sprayed with the

same RLM 66/flat black mixture I had used for the cockpit. The canopy

sections were then glued to the fuselage using Mirco Kristal Kleer.

For some reason Murphy's

Law would plague me throughout this part of the build and a couple of

times, due to sheer frustration, the model came very close to becoming a

wallflower.

I started by preshading the panel lines with flat black. Next I sprayed

the fuselage tail band with MM Sky, and when dry the band was masked and

the underside was painted MM Medium Sea Grey straight from the bottle.

Next, the bottom was masked off and I started painting the topside with

MM Ocean Grey. Not having this color in my collection of model paints, I

bought a new bottle of MM Ocean Grey and as I began spraying, I couldn't

help but notice that the paint had a decidedly green cast to it. I was

convinced that Ocean Grey should have a bluish tint so I sought advise

from fellow Hyperscalers. After various different suggestions I decided

to buy another bottle in hope that maybe I had gotten either a bad mix

or a mislabeled bottle. No such luck. In the end I made my own Ocean

Grey by mixing MM German Uniform Feldgrau and MM Medium Sea Grey. The

resulting color came very close to my references. I honestly couldn't

tell you what percentage of each color I used but it looked much better.

After spraying the Ocean Grey I made masks from regular lined paper

using the camouflage pattern provided by Tamiya as a guide. These paper

masks were attached to the model with small rolls of masking tape

positioned just inside the edge of the mask. I used MM RAF Dark Green

and carefully sprayed the green pattern. For the most part this worked

very well and I had a nice tight feathered edge between the two

camouflage colors. In a few places I had a bit too much overspray and I

had to touch things up a bit.

Finally it was time to

unmask the bottom. In the process I managed to pull off a few small

patches of paint. This was easy to fix but to my surprise, I found that

there wasn't enough contrast between the Medium Sea Grey and my mix of

Ocean Grey. The Medium Sea Grey straight from the bottle now appeared

too dark. Photos showed a definite contrast between the 2 colors so I

lightened up the Medium Sea Grey with some white, masked off the top and

resprayed the bottom again. This time it looked much better but now

pulling off the masks removed some of the paint from the leading edges

of both the wings. AAARGGGHH! After more masking and repainting both

topside colors along the damaged leading edges, everything looked good.

I clear coated the entire

model with Testor's Metalizer Sealer which dries quite quickly and hard

as a rock. To my dismay it dried, yellowing in patches. I had used this

sealer many times before and had never run in to this problem so I

assumed it was my doing. After further masking and repainting of certain

areas of both greys, (the green looked unaffected), I carefully

resprayed the sealer, and it happened again. After much wailing and

gnashing of teeth, I again repainted the affected areas but this time I

tried Polly S Clear Gloss. It was the first time I had used this brand

of acrylic paint but I was very happy with the results. I could finally

get on with my favorite part of the build, the Decaling and weathering.

I started by applying the upper wing roundels from Aeromaster. I used my

usual Miro-Set/Sol method of applying the decals.The upper roundels were

two part decals, the red center being separate. When I applied the red

center, it looked almost orange on the model. So much so that I removed

it and placed it back on the wet backing paper. Comparing the color of

the dull red center with a half dozen other decal sheets I had, I

reapplied the red center and decided to just let it dry and see how it

looked. In the end it looked fine and I carried on.The tail fin flash

applied with no problems and I moved on to the fuselage roundels and

codes.

I applied the first part

of the right fuselage roundel which included the yellow outer ring and

the white center. While this dried I added the code letters which came

from Xtra-decal and these laid down beautifully. Next I added the blue

portion of the roundel after the first part had fully dried and then

quickly added the red center and left them to dry. I wasn't at all

surprised to see them wrinkle up but I was very surprised to see them

bubble up badly and no amount of coaxing, prodding, setting solution, or

just leaving them alone would get them to settle down. I had never

experienced this before with Aeromaster decals. When dry it looked so

horrible, I decided to remove the decal and try again, but the damaged

decal wouldn't budge. Not even pulling on it with masking tape! I wound

up using a 3200 grit polishing cloth and I literally sanded and polished

the blue and red decal off. I reapplied the blue section of the roundel

using one from another sheet and the same thing happened. I was

beginning to think I was being cursed by some nasty modeling deity. Off

it came again, using the 3200 grit polishing cloth. This time, thinking

I had nothing to loose, I used a roundel from a Watermark decal sheet

and to my surprise, with a little persuasion, the decal laid down

beautifully. Initially the decal looked thick but once on the model and

dry, it looked great. When adding the fuselage roundel to the left side

I experienced the same horrible wrinkling and while trying to persuade

the decal to lay flat, I smudged it beyond repair. Out came the

polishing cloth again. Giving the Aeromaster roundels one more try, the

next decal worked perfectly. I still haven't figured out why I had so

many problems, none of which I'd experienced before.

For the serial numbers I

cut apart the kit decals until I had the numbers I needed and I applied

these using Mr Mark Softer decal solution. It was the first time I had

used this solution and the Tamiya decals reacted very well to it. The

same went for the data stencils. The large wingwalk decals proved

another challenge but again Mr Mark Softer came to the rescue. My

suggestion when using Mr Mark Softer is to apply the solution only to

the top of the decal and avoid getting it on the paintwork. If not

washed off relatively quick, it seemed to waterstain the paint. This

staining disappeared with a gloss coat and was totally invisible after

the dullcoat.

I used the Watermark

decals for the under wing roundels and they preformed wonderfully again

with Microset and a little prodding with the sharp end of a round

toothpick to get them into the panel lines. I would recommend though,

trimming off as much as possible of the clear carrier film.

The letter "A" on the

nosewheel door was made by cutting up the kit supplied letter "H" decal

and carefully applying the individual elements. I finished off by

applying the wing leading edge decals and a custom printed 616 Squadron

emblem on the tail.

To seal the decals, a

final gloss clearcoat was applied but even though I had wiped the entire

model down first, the clearcoat fish eyed over the large wingwalk decal

on the left wing. When dry, the area was polished out and the gloss coat

reapplied with no further problems.

I now mixed a very thin

wash of Liquitex acrylic paint using a 50/50 mix of Paynes Grey and

Burnt Umber with distilled water and a good dollop of dishwashing

liquid. This mixture was carefully painted in to select panel lines to

indicate some grime but I was very careful to not overdo it as these

planes were kept up with a good measure of "spit and polish".

Finally, the model was

sprayed with Polly S Flat Coat and left to dry.

Finishing Touches

The still unpainted wheel

wells were now masked off and sprayed aluminum. I had left this so late

in the build as I was using the wells as a finger hold to handle the

model. The wells were given a wash of the same mixture used for the

panel lines and finally MIG Pigments European Dust powder was applied to

dirty things up a bit.The powder was also applied to the tires and

sealed with dullcoat. The landing gear assemblies and doors were finally

glued in place.

With all the paintwork done, the masks were removed from the canopy

sections and the sliding canopy section was removed. It had been tacked

in place with Kristal Kleer to aid in masking off the cockpit and now

thin strips of Aeromaster RLM 66 decal material were added along the

front and bottom inside edges to represent the inner canopy framing.

This was easier than trying to mask and spray it. The two lights under

the fuselage had their lenses added after using Bare-Metal Foil for the

reflectors. The lenses were secured in place using Polly Scale Clear

Gloss paint. The same was done for the underwing landing light.

Murphy's Law was not finished and I had to endure one final disaster. I

was getting used to things going a bit sideways but I was unprepared for

what happened next. I was gluing the engines in to their nacelles and I

opted to use Ca glue. I have a very thick Ca and a water thin Ca and to

get something in between I mix both together. I placed a small amount of

the thin Ca in to a plastic lid and was adding the thick stuff when the

thick Ca sort of farted out of the bottle. I saw some of the thin Ca

splash out of the lid but thought nothing of it. After gluing in the

first engine, and making sure everything was aligned properly, I noticed

a small wet spot on one of the wings. When I tried to wipe off the wet

spot, I realized it was solid and I soon discovered that the model was

covered in Ca glue splashes. I wanted to swear but I couldn't. In fact I

was speechless. It had sprayed everywhere including underneath.

Thankfully the canopy remained untouched. After the reality set in I

glued in the second engine and then started to scrape, sand, pick off

and polish off the spots of Ca. In some areas I wound up removing paint

and these areas were resprayed, and carefully sanded to level off the

paint work. Gloss coats were reapplied in these areas and then

dullcoated again. I also had to reapply the panel line washes in the

areas that were repainted.

With repairs complete, I reinstalled the antenna mast I had snapped off

earlier and added the IFF antenna which I made from stretched sprue

sanded to a flat airfoil profile.

After all the trials and tribulations I could hardly believe it was

finally finished. I'm glad I persevered because I now have a beautiful

Meteor to add to my collection as a reward.

Click the thumbnails below to view larger

images:

Images and Text Copyright ©

2005 by Wolf Buddee

Page Created 09 February, 2005

Last Updated

09 February, 2005

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search