|

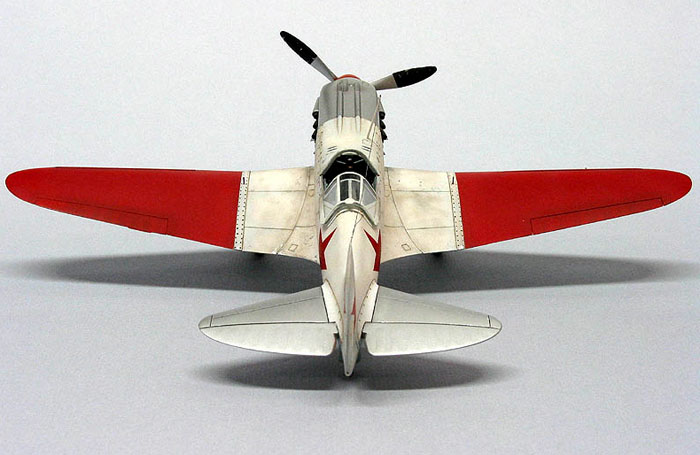

MiG-3

by

Tony

Bell

|

|

MiG-3 |

ICM's 1/48 scale

MiG-3 is available online from Squadron.com

In early 1939 the Voyenno Vozdushnyye Sily, (VVS – the Soviet

Air Force) issued a requirement for a high altitude strategic interceptor, which

the Polikarpov design bureau was assigned to develop. Polikarpov fell out of

favour with Stalin however, and the new MiG design bureau headed by Artem

Ivanovich Mikoyan and Mikhail Iosifevich Gurevich was given the task instead.

The resultant I-200 was a small fighter built around the powerful but heavy

AM-35A engine. The aircraft was very fast (651 kph) but extremely difficult to

fly because of poor longitudinal (pitch) stability due to the short rear

fuselage. In spite of handling problems and short range, the I-200 was ordered

into production as the MiG-1.

The MiG-3 was a result of an attempt to rectify the MiG-1’s range and stability

shortcomings. Stability was improved by increasing the wing dihedral and

lengthening the nose to move the centre of gravity forward. The aerodynamics

were cleaned up, and pilot’s armour and an additional fuel tank added. These

changes improved the flight characteristics from “extremely difficult” to merely

“difficult”.

The MiG-3 was produced starting in late 1940, and constituted close to 90% of

the modern VVS fighter force at the time of Operation Barbarossa in June 1941.

The air war over the eastern front was more tactical than strategic in nature,

with most combat taking place at altitudes of 5000m or below. With an engine

optimized for performance at an altitude of 6000m, it quickly became apparent

that the MiG-3 was outclassed by the Luftwaffe opposition at lower altitudes. In

the first half of 1942 it was withdrawn from the front line to serve in air

defence squadrons for the remainder of the war.

The MiG-3’s AM-35A engine was produced in the same factory as its closely

related cousin, the AM-38 which powered the Ilyushin IL-2 Sturmovik. Stalin had

declared that the Sturmovik was “as important for the Red Army as air and bread”

and production of the AM-35A was discontinued in favour of the AM-38. Although a

MiG-3 fitted with an AM-38 exhibited improved performance, the AM-38 was

reserved exclusively for the IL-2. Production of the MiG-3 ceased in December

1941.

The ICM MiG-3 comes packed in a flimsy, end opening box (grrrrr!).

The kit consists of five sprues in light grey styrene and one clear. The clear

parts are quite transparent, if not a little on the thick side, and the grey

plastic parts have a fine pebbly texture and nicely engraved panel lines,

although the fabric texture on the control surfaces is way overdone. The parts

also sport a heavy coating of mould release grease, necessitating a good scrub

with dish detergent and an old toothbrush. The kit includes a very complete

looking AM-35A engine which is a separate model in its own right.

Some of the thicker parts exhibit sink marks, most notably the propeller blades,

main wheels and horizontal stabilisers. The decals are very thin and matt, not

unlike Italeri kit decals. They suck, frankly. They are translucent and

delicate, and broke into pieces as soon as I tried to shift them from the

backing paper. As far as marking options go, the kit that I bought was the

boxing which only includes markings for VVS ace and Hero of the Soviet Union

Nikolay Krasnov. The other release of this kit includes markings for 10 aircraft

in a variety of different winter and summer schemes.

The MiG-3 is not a simple aircraft, with numerous scoops, intakes, lumps and

bumps. The parts breakdown is likewise complicated, but necessary to avoid

compromising detail.

Given the complicated nature of the kit, it would be wise to

follow the instructions which would have you start construction with the engine.

However, having read several reviews of the kit I opted to avoid any potential

fit issues I the construction of the nose and omit the engine. For me,

construction therefore started with, you guessed it, the cockpit.

The Cockpit

The kit cockpit is quite nice, featuring a separate tubular

structure and good detail. As nice as the kit cockpit is, the Cutting Edge resin

replacement cockpit is truly marvellous. The Cutting Edge cockpit consists of 13

pieces in their typical tough medium grey resin plus a printed acetate sheet for

the instrument dials. The armoured seat has moulded on cushions and Sutton style

harness.

Vintage aircraft interior colours seem to be a perpetual point of debate between

modellers, and VVS aircraft interiors are probably the worst. Some research over

at the VVS modelling website (http://vvs.hobbyvista.com/) indicated that some

MiG-3 interiors were likely painted the same colour as the aircraft underside.

Good enough for me.

After the resin parts were carefully removed from their pour stubs, they were

painted overall Testors enamel Russian Underside Blue, with the seat cushions

painted Testors Leather and various other details picked out with black, silver

and leather. The whole cockpit was given a “wash” that consists of a mixture of

Polly Scale flat, India ink and water. It was then drybrushed with light grey

artists’ oils and some paint chipping and general scuffing added with a “steel”

coloured Prismacolor pencil.

Click the thumbnails below to view

larger images:

The Cutting Edge instrument panel is particularly nice. The builder is given the

option of painting the dials and their raised detail, or the back of the panel

can be sanded away to expose the instrument holes so that the acetate gauges can

be used. I chose the latter option.

Some careful trimming, filing and dry fitting was necessary to get the resin

components to fit properly inside the fuselage, with particular attention being

paid to the radio shelf behind the pilot’s seat. The completed cockpit was set

aside and not glued into the fuselage until later.

The Fuselage

Oh boy. Okay, so how many parts do most kits need to represent

the fuselage of a single engine fighter? Two? Three? Four? Well on this kit it’s

nine, and that’s not including the rudder!

Apart from the two main fuselage halves, there are two upper and one lower

engine cowling pieces, split along panel lines. I found that these pieces had

somewhat soft edges, which would look inconsistent with the rest of the panel

lines which are quite crisp. How to fix this? I couldn’t sand the edges sharp,

as that would remove material and degrade the fit of the parts, which was

actually quite good. Instead I brushed a bead of Gunze Mr. Surfacer 500 along

the outside edges of all the cowling pieces, let it dry, brushed some more and

repeated until a sufficiently thick ridge if Mr. Surfacer had built up. I then

carefully sanded the excess Mr. Surfacer with 800 grit wet & dry sandpaper,

leaving nice sharp edges. The next order of business was to eliminate the pebbly

surface texture of the cowling, as I wanted to paint it in natural metal. An

airbrushed coat of Mr. Surfacer 1000 and a rub down with 1500 grit sandpaper

took care of that, although it was tricky work sanding in and around all of the

intakes, troughs, scoops and other surface features.

There are numerous fasteners moulded into the fuselage in the vicinity of the

cockpit that were not as well defined as I would have liked. Since they were

already fairly deep, drilling them out further wasn’t an option, so I elected to

re-do them entirely. So, I filled each one (about 70 of ‘em) with Mr. Surfacer,

sanded them smooth and then drilled each one clean trough with a No. 76 drill

bit.

Now came the tedious part. I stretched about a gazillion pieces of sprue over a

candle, and cut pieces such that one end was thicker than the No. 76 hole, and

the other end thinner. I inserted the thin end of a piece of stretched sprue

into each hole from the outside and gently pulled it through without forcing it

until it was too thick to fit. I then cut the sprue flush with the fuselage

using a sharp new X-acto blade. Finally I pulled it through a tiny bit more

until it was slightly recessed, brushed some liquid cement from the inside and

trimmed away the excess.

At this point the cockpit parts were attached to the fuselage with five minute

epoxy to allow sufficient time to line everything up. The engine panels were

attached by brushing liquid cement from the inside so as to avoid melting the

nice sharp panel lines I spent so much effort on. Next up were the wing root

pieces which required considerable and repeated trimming and test fitting before

they were attached with liquid cement, again applied from the inside. In the

end, no filler was used on the fuselage which speaks well for ICM’s engineering,

given the complex nature of the assembly.

Disaster Strikes

It happens to all of us. Please tell me it does. Carefully cut

windscreen off of sprue. Clean up windscreen part. Admire handiwork. Fumble part

and drop on floor. Push chair back to look for part. Cringe at crunching sound

as part is crushed under chair castor.

So, I broke the windscreen in two. I emailed ICM and they charge money for a

replacement part (it was my own stupid mistake after all), so I decided to fix

it myself. First I glued the part back together with liquid cement and then

sanded polished the seam so that the surface was glass smooth. The crack was

still highly visible, so the clear portion had to be replaced. I made a mould

out of RTV rubber and cast a copy in resin which was sanded and polished to

remove the frames. This was used as a master to vacuform a new windscreen from

sheet butyrate. The clear portion of the kit part was carefully cut away and the

vacuformed replacement trimmed to fit and attached with Future. It actually

looks better than the original, but next time I’ll be more careful…

The rear portion of the canopy was attached with liquid cement after the

requisite trimming and dry fitting.

Wings and Control Surfaces

The wings, like the fuselage, are more complicated than average,

the lower portion consisting of a centre section and separate outer panels. The

upper wings are fairly conventional one piece affairs. Once more, test fitting

is the order of the day as the tops of the landing gear wells interfered with

the wing root, and the radiator recess interfered with the cockpit floor. After

removing sufficient material from these areas, a good fit was achieved and

ultimately only a little bit of filler was required between the inner and outer

lower wing pieces. In order to avoid sanding, a small amount of epoxy putty was

worked into the seam and the excess wiped away with a damp cotton swab.

The wing tip lights were carved away and replaced with chunks of clear Plexiglas

which were filed to shape, sanded, polished and painted with Tamiya clear red

and green. The fit of the landing light cover was poor, so a replacement piece

was dug out of the spared box (from the Monogram Marauder, I think), carved to

shape, installed with superglue, filed, sanded and polished to blend it in with

the rest of the wing.

The ailerons, elevators and rudder all suffer from a grossly overdone fabric

effect which I sanded off until it was next to invisible. I used a razor saw to

cut notches in the leading edge of the rudder to portray the hinges, and added a

small formation light from clear stretched sprue inserted into a hole drilled

just below the trim tab. The horizontal stabilisers fit very well, requiring no

filler.

Because the landing gear was to be the same colour as the rest of the

undersides, they were attached before painting. The attachment of the main gear

legs was very weak looking, with only a shallow recess in the top wing. Before

attaching the legs, I drilled a hole through the top wing at the gear attachment

points from underneath. The gear were then glued on with liquid cement,

carefully aligning them front to back and side to side. After they had dried I

drilled down through the hole in the top wing into the gear legs and inserted a

length of steel sewing pin to strengthen the gear. The hole was then filled in

with superglue and sanded smooth.

Landing gear indicator pins were added to each wing from steel wire inserted

into holes drilled in the appropriate locations.

Fiddly Bits

I had obtained the Part photoetch set for the MiG-3, but only

ended up using about a third of it on the model. The photoetch set includes

parts for the cockpit (which redundant w.r.t. the Cutting Edge set) a set of

frighteningly impressive flaps (which I was too chicken to use), plus other

exterior bits. The parts I did use included the wheel hubs, radiator and outlet

door and landing gear doors. The wheel hubs were dished slightly by placing them

on a thick pad of paper towel and pressing a pencil eraser into the center.

The prop suffered from prominent sink marks near the base of the blades. These

were filled with successive layers of superglue set up with accelerator. The

prop blades were filed and sanded to reduce their thickness to something closer

to scale. The spinner was missing a panel line, so this was scribed by holding

the spinner on a flat surface and turning it against the tip of a No. 24 X-acto

blade held at the appropriate height between the pages of a book.

|

Painting, Weathering

and Decals |

I masked off the canopy with Tamiya tape which was trimmed in

place, using the well defined frames to guide a new No. 11 blade. No caffeine

for a few hours prior to attempting this exercise. The nose and stabilizers were

also masked off and the model pre-shaded by airbrushing dark grey along the

panel lines. The white (Tamiya) was airbrushed next, well thinned and applied in

thin coats to allpw the pre-shading to just barely peek through.

Blu-Tak was used to mask the demarcation line and the undersides were painted

Testors enamel “Russian Underside Blue”. This is actually a post war colour, and

even though Polly Scale produces a Great Patriotic War shade of underside blue,

it is much too garish for my tastes. I simply couldn’t bring myself to use this

more “accurate” colour for fear that my red, white, blue and silver model would

end up looking more like an Easter egg than a deadly instrument of war.

Anyway, instead of thinning the paint with mineral spirits or lacquer thinner, I

used “automotive paint reducer”. This is actually a lacquer thinner, but is

considerably less volatile (i.e. “hot”) than the regular stuff. It allows the

paint to flow nicely, adheres well and dries hard with a slight sheen.

The spinner and outer wing panels were painted Tamiya flat red and over sprayed

in a random pattern with a heavily thinned faded red colour. To avoid the wings

taking on a pinkish hue, the faded red colour was mixed from Tamiya red, white

and yellow. The Soviet stars were painted on using masks cut from frisket

masking film.

I unmasked the nose and stabilizers, and masked off the rest of the model to

paint the silver. The NMF on the nose is Alclad II “White Aluminum” which was

misted onto the unprimed plastic (gasp!). The key here was to apply the first

few coats very lightly so that they dry almost instantly and never have the

chance to craze the plastic. Risky, but it saves time if you do it right. While

the airbrush was loaded with the Alclad, the prop blades were also sprayed. The

back 2/3rds of the blades were painted acrylic dark grey and chipped with a

toothpick before the paint set up.

Weathering consisted of a Windsor and Newton burnt umber oil wash in the panel

lines and paint chipping done with Humbrol silver No. 11 and a 0000 brush.

Because the outer wings and the rear fuselage were wood, I made sure I applied

chipping only to those areas that were actually metal on the real aircraft.

General grubbiness was added with ground up chalk pastels (this was before I

discovered MiG Pigments), applied dry and manipulated with a damp cotton swab.

The engine exhausts were painted black and weathered with several shades of

ground brown chalk pastels, and the exhaust stains airbrushed on with a

brown/black colour mixed from Tamiya paints and thinned 90% with rubbing

alcohol.

The tail numbers and the little serial on the nose are the only decals on the

model, and these came from Aeromaster sheet number 48-313, "MiG-3's Early

Warriors Pt. I". Local applications of Future prevented silvering, and Polly

Scale clear flat was airbrushed after the decals and Future had dried.

I sanded flat spots on the tires and painted them Aeromaster

acrylic tire black, while the hubs were painted underside blue and glued on. The

tail wheel was painted in a similar manner and glued in place.

The pitot probe provided in the kit was set aside in favour of one made from a

short piece of stainless steel tubing. The tube was cut to length with a Dremel

tool, which was also used to round off the tip to make it look more aerodynamic.

The antenna mast was attached with superglue and the aerial was made from nylon

invisible mending thread painted Humbrol Metal Cote steel. The insulators were

made from sections of stretched Evergreen styrene tube. To make the insulators,

I heated the tube over a candle and stretched it thin, after which I cut the

insulators to length with a new X-acto blade. These were then carefully threaded

onto the antenna which was then superglued into anchor holes drilled into the

tail with a No. 80 bit. After tightening the antenna up with hot air from a

paint stripping gun, the insulators were fixed in place with a small amount of

Future brushed on.

Ain’t it always the way? More information turns up after the

completion of a model, and there are several minor (or major) things wrong. So,

based on the photograph of the specific aircraft modelled, the following

potential inaccuracies are noted:

-

The spinner wasn’t red, but

rather a darker colour, probably green or even black.

-

The outer wing panels may in

fact be green as opposed to red although to my eye, the tonal value of the

wing is very similar to the Soviet stars.

-

The tail number wasn’t black,

but rather was red, again based on the comparison to the Soviet stars.

-

The nose and stabilizers may

have been some colour other than silver, based on the absence of specular

reflections (as opposed to Black 12 in the background).

-

No radio is visible behind the

pilot’s seat, in spite of the presence of the antennas.

-

There were no leading edge

slats.

For a very thorough analysis of this particular aircraft, I

refer the reader to the web page

http://mig3.sovietwarplanes.com/mig3/howred.html on Massimo Tessitori’s

excellent dedicated MiG-3 web site.

At the end of the day I’m not too concerned. Had I known I’d have done it a bit

differently, but hindsight is always 20/20.

This was a fun kit to build. It was difficult enough to

challenge some basic skills that were in real danger of becoming rusty, but it

was good enough to do so without becoming frustrating. It is a cool subject that

really stands out on the shelf next to all the P-47’s and Bf-109’s.

Click the thumbnails below to view

larger images:

Soviet Aces of World War 2

Modelling Manuals 17 |

|

|

|

|

Author: Hugh Morgan

Illustrator: John Weal

US Price: $17.95

UK Price: £12.99

Publisher:

Osprey Publishing

Publish Date:

October 15, 1997

Details: 96 pages; ISBN: 1855326329 |

|

|

Model, Images and

Article Copyright © 2004 by Tony Bell

Page Created 23 December 2001

Last updated 10 December 2004

Back to HyperScale Main Page

Back to Features Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search