|

AMT's 1/48 scale

P-40K-5 Warhawk

by Tom Dungan

|

|

|

Curtiss P-40K Warhawk |

HyperScale is proudly supported by

Squadron.com

How Decisions Get

Made

After doing a number of builds

specifically for this or that contest, I really wanted to work on

something relatively easy, without pressure. If you are like me,

sometimes the stash of kits waiting to be built becomes so large that I

am afflicted with “Project Selection Paralysis.” Thinking it might be a

good chance to involve my wife in my hobby, I enlisted her help to

resolve the impasse.

“What would you like to see me put together this time?” I asked,

dragging her to the closet to view the stack of boxes.

“How about this one?” my wife asked, pulling out a 1/48 Classic

Airframes ‘Walrus.’

Not exactly the “something relatively easy” I was looking for.

“Er….how about we pick something else,” I gulped.

“Well if you don’t want me to pick, then why did you pull me in here?”

“Come on….just please pick something else.”

After a few more moments (and comments muttered under her breath), she

pulled out the AMT P-40K kit.

“Do this one. I like the rabbit on it,” she said, referring to the

pilot’s personal insignia depicted on the box art.

Rabbits are to my wife what aircraft are to me, so this seemed like a

perfect match of interests. Building the P-40K would be “without

pressure,” because I don’t really care all that much about the aircraft,

other than it looks cool. Accuracy, I thought, would be distinctly

secondary. As a bonus, the kit looked like “something relatively easy.”

We’ll see how that worked out in a moment.

“And no buying aftermarket,” she added. “I don’t want you buying a bunch

of stuff for a plane that isn’t one of your favorites.”

The gauntlet had been thrown, and it seemed like a good chance to show

that I could beat Advanced Modeler’s Syndrome (AMS).

“The Name’s Nollmeyer….”

The AMT kit contains only one decal

option – for Major Ed Hollmeyer of the 26th FS (51st FG), based in China

during 1943/44. Since this kit was being done because of Hollmeyer’s

rabbit, that was no bad thing.

A web search uncovered that this fellow’s real name was almost certainly

Edward M. Nollmeyer, not Hollmeyer. Two books, 1 decal sheet, and the

internet said Nollmeyer, while another decal sheet and the kit said

Hollmeyer. Majority rules – and if the internet says so, it must be

true..

As an additional resource, I borrowed a Squadron P-40 Walk-Around

reference book to add to the Histoire & Collections profile book I

already owned. Strangely, I could not find a single photo of the entire

aircraft, but certainly there must be one somewhere. Figuring I’d find

that photo about two weeks after finishing the kit, I forged ahead.

Background

I’ll spare you all the background

information, since this aircraft needs no introduction. Likewise, the

AMT series of P-40 kits has been reviewed in numerous articles, so I

won’t go into much detail except to provide a refresher.

The AMT P-40K kit features fine recessed detail, but is basically their

generic P-40 kit with a new sprue featuring parts for the larger tail on

the –K. Unfortunately, this is the only –K specific item included in the

kit, which resulted in a number of details needing to be scratchbuilt or

refined, as we will see. The plastic is soft and workable, which was a

good thing for this project. My particular example had a lot of flash on

some of the smaller parts.

Construction and

Compulsion

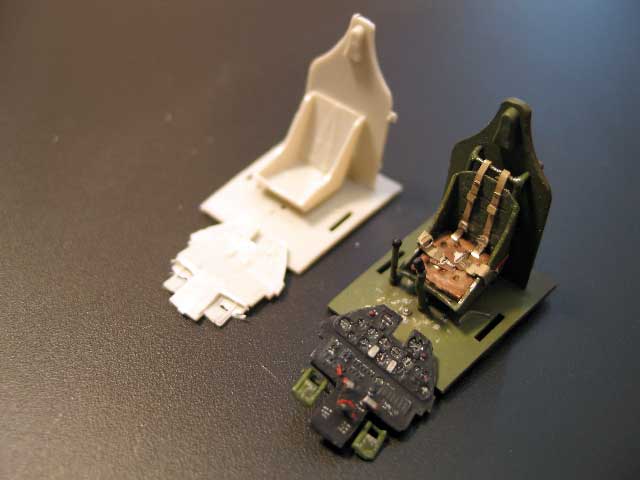

The cockpit provided has decent sidewall

detail and instrument panel, but the pilot’s seat and its mount really

needed some work. My thoughts turned to aftermarket solutions, but with

the gauntlet thrown down, I decided to work with what the kit provided.

The seat mounting was fabricated from brass rod and styrene strip, using

Squadron walk-Around reference photos. The seat itself needed to be

re-sculpted and downsized, and I also added some recessed detail in the

seat back with a Dremel tool. A seat cushion was fabricated from

Milliput, and seat belts came from an Eduard WWII US Belt set (I know, I

know, it’s aftermarket, but I already had them and they seemed so very

necessary!)

Various levers and control thingies for the sidewalls and instrument

panel were added using scraps of metal, and some basic “plumbing” from

fuse wire. The rudder pedals were partially rebuilt using rod &

rearrangement of the kit parts. With detail painting, I realized that an

aftermarket cockpit wasn’t really needed after all. You can see how it

all turned out vs. the original parts in the accompanying photos.

This assembly was set aside to focus on what I anticipated would be the

most difficult aspect of the kit – fuselage and tail assembly.

The original P-40F (?) tail must be cut from each fuselage half. Chain

drilling along the indicated panel line was performed, and the

irreversible cut made.

The tail halves were offered up to the

cut fuselage for a session of dry fitting and sanding. Once satisfied

with the alignment, I reinforced the fuselage with styrene “tabs” to

facilitate locating and bonding of the tail unit. Each tail half was

separately glued to each fuselage half, and then the complete fuselage

halves were joined. Despite all the pre-work, there were still some

areas that were not properly blended between the fuselage and tail –

filler and sanding would be needed.

Of particular concern was the area where the new big tail faired into

the top of the fuselage. Again, despite all the dry fitting and

pre-work, this fairing didn’t blend well. On my example, this seemed to

be a limitation of the way the plastic fairing tapered to a point (or

rather failed to!) Milliput was used to reshape the fairing and fill the

gaps, although the reshaping probably distorted some of the original

outline and profile.

I

wasted some time drilling out the kit exhausts and congratulating myself

on a job well done, then realized that the “curved tube”-style kit

exhausts are wrong for the –K. I pulled some spare “fishtail” exhausts

from a Spitfire kit and used those instead – close enough. The Dremel

tool seen in the photos was then used to drill out the fishtail exhaust

– the first use for this particular strangely-shaped item in the

toolbox. I

wasted some time drilling out the kit exhausts and congratulating myself

on a job well done, then realized that the “curved tube”-style kit

exhausts are wrong for the –K. I pulled some spare “fishtail” exhausts

from a Spitfire kit and used those instead – close enough. The Dremel

tool seen in the photos was then used to drill out the fishtail exhaust

– the first use for this particular strangely-shaped item in the

toolbox.

At this point I realized that I was backsliding into a full-blown case

of AMS (as you no doubt already have, dear Reader). Sleepless nights

were spent agonizing over whether to just slap the rest of the kit

together as originally intended, or to continue down the path of

improvement and accuracy. Meetings at work were spent daydreaming of how

to rebuild those over-simplified wheel wells. I was losing the battle.

With no AMS support group at hand, the die was cast, and it was on to

the wheel wells. These were boxed in with sheet styrene drilled with

lightening holes. Plumbing was added per photos in the Walk-Around

(these Walk-Arounds are really a big part of the problem, aren’t they?).

Fortunately the P-40 is a fairly simple beast in this area.

Now everything was ready for airframe assembly, which was completed with

reasonable success. A lot of dry fitting of wings and fuselage saved

some effort here.

As the kit’s detail parts were added, so other details were added to

them in turn:

-

Tail surfaces were separated and

dropped, but flaps were not, as I couldn’t find any photos of

airworthy P-40K’s with dropped flaps

-

Cooling flap actuators were made from

rod and scrap metal bits

-

The kit’s gun barrels and shrouds

were cut off and new shrouds installed using brass tube (more on

this later).

-

Kit canopy was replaced with a

Squadron vacuform item (I already had it in hand, honest), although

the fuselage windows were left in the original clear plastic because

the vacs were too hard to trim to fit flush with the fuselage.

Painting and

Deliberating

Now

it was time to think about colors and markings. Normally, I do quite a

bit of research before beginning a project, but since I didn’t care

about this P-40... Now

it was time to think about colors and markings. Normally, I do quite a

bit of research before beginning a project, but since I didn’t care

about this P-40...

Unfortunately, the Squadron Walk-Around

book again bedeviled me, as it contained a profile of the aircraft from

the AMT kit, but in an overall Olive Drab on Neutral Gray scheme instead

of the two-tone topside in the kit’s instructions. Which was right?

Inquiring minds had to know!

After an internet and book search, it seemed that the Walk-Around was

the outlier in describing this specific aircraft, and Far East-based

P-40K’s generally, as OD/NG. The general scuttlebutt sounded like

P-40N’s were universally OD in the CBI, but not necessarily –K’s.

Further, it seemed likely that the CBI camouflage would have been a

British or British-equivalent green sprayed over existing olive drab,

rather than spraying a second dark earth color. At least that was my

interpretation of the few sources I checked.

The Histoire & Collections P-40 book includes a COLOR photo on page 43

allegedly showing Nollmeyer’s P-40K, although there are no details

visible that support that specific identity. You would think that the

photographer might have bothered to include the rabbit art in the photo

to clear things up for us, but they just don’t make it easy, do they?

This photo clearly shows a faded drab & medium-ish green application

with hard edges.

Taking stock of the available markings,

it was obvious that the kit’s decals were not up to snuff – with a funky

blue color used for national insignia, and fuzzy, unconvincing unit nose

art. Fortunately, I had other options, as by luck I had these same

markings on TWO other decal sheets. Now, I know what you’re saying: “Uh,

didn’t you say you didn’t really care about the P-40?” Well, that’s

true, but I’m still a sucker for a nice paint scheme and colorful

markings, so I have a few in stored in a box.

Superscale has produced two versions of these markings. One would think

this is the result of improved research and access to information, but

perhaps not. The original sheet (#48-18) shows a two-tone upper camo

with the Stars & Bars outlined in red. The newer sheet (#48-635) shows

solid OD on neutral gray with plain Stars & Bars. Lingering doubts over

the color scheme crept in, but I forged ahead, using the decals from

48-635 on the color scheme from 48-18.

With the Histoire & Collections color photo in hand, I mixed up some

homebrewed colors using the Modelmaster Enamels range, using a Field

Drab/Faded Olive Drab mix, and a Euro Dark Green/Medium Field Green mix.

Unfortunately, I didn’t write the specific mix down, and when it came

time to make some more for touch-up work, I never could get it back

exactly right – so always write down your custom mixtures!

I pre-shaded all the panel lines with black paint, and proceeded to

build up layers of the colors, starting with Neutral Grey on the

undersides, then working up to the OD mix for the topside. Once the OD

was dry, I used Maskol to paint on a mask. This was my first time using

this stuff for hard-edged camo demarcation, and I thought it was darned

near the best thing since sliced bread. Once the green color was sprayed

and dry, I just rubbed off the Maskol. At the end of each color step, I

added a bit of white and tan to the mix and sprayed a bit in the center

of each panel to give a more faded look. Lastly, the yellow fuselage and

nose stripes were painted in a tricky masking session.

Gloss coat was applied, followed by the decals, and then another

protective layer of gloss. A wash of thin burnt umber acrylic was

painted into most panel lines and quickly wiped away. Dull coating was

followed by addition of fluid stains using Tamiya Smoke.

Details and Detours

After so much back-and-forth on paint, it

seemed like I was in the home stretch as I began to attach all the

detail bits.

It seemed like a good time to insert the brass tube gun barrels into the

brass tube gun shrouds already installed in the wing. After a number of

frustrating attempts trying to get a clean cut of brass tube, I finally

had 6 suitable tubes, and proceeded to slide them into the shrouds. As

you might expect, it’s very difficult to position the tubes with a

consistent, proper length standing proud of the shrouds. This is

definitely something that I should have done BEFORE installing the

shrouds in the wing. One tube stuck out too much and wouldn’t budge – at

least until I pulled it out with pliers. One tube stuck out too little

and wouldn’t pull back out at all. One tube disappeared into the shroud

and was not seen again. Eventually I gave up and cut all the offending

barrels down to the shroud using a cutting wheel. Then I used styrene

rod to create 2mm long barrel openings to glue onto the shrouds. Finally

– gun barrels the hard way.

Next I went to affix the radio antenna mast. “Hmmmm….these profiles show

a loop antenna mounted on a fairing, not a mast!” I should have just

said to heck with it and jammed the mast antenna on with the spirit of

most normal modelers out there. But AMS is a cruel mistress, so out came

the filler and I proceeded to fill the mast hole, then build up a loop

antenna fairing out of Milliput. A loop was fabricated from scrap metal

and rod, and touch-up painting ensued.

It was at this point that I rued not writing down my paint mix, because

I had to remix to do this touch-up job, and it took several tries before

I was happy with a matching result. Then, as I removed the Tamiya

masking tape from around the touch-up area, the starboard national

insignia peeled up with the tape! Arrrrgh! “Relatively easy and without

pressure” was becoming anything but!

The search for a matching decal was dicey, but after rummaging through

several kits, and my box of decals, I found a correctly-sized

replacement Stars & Bars, which went on over the original. More gloss

coat, more waiting.

The landing gear went on without incident. I used True Details P-40

wheels to replace the featureless kit items (Again – I already had

them!). Antenna was made from fine fishing line. Paint chipping was done

with MM aluminum and a fine brush. Pastels were used for gun residue and

exhaust, and a little on some panels.

And it was done.

Was it enjoyable? Well, perhaps not

exactly as I had intended, but I ended up testing and refining some

modeling skills, and I like the end result. So does my wife!

Hopefully you enjoyed a story about a difficult build – I like to hear

about the challenges others face and their mental process for building.

It makes us mere mortals feel better to hear that the “pros” do the same

stupid things, and that somehow we are all together in this battle

against plastic.

I do ask myself why I couldn’t just leave some things well enough alone.

The bounty of information now available in print and on the internet

related to our hobby is both a blessing and a curse. It sets the bar

pretty high for what constitutes an accurate model (and I’m not saying

this P-40K is accurate), and therefore compels the more ana…er…AMS-afflicted

among us to attempt to meet it.

AMS may have won this round, but I’m hoping I have an ace up my sleeve

that will stop the madness. Instead of that Classic Airframes Walrus,

next up is another seaplane: the Revell AG 1/72 Be-6 “Madge.” With only

28 non-transparent parts and no worthwhile detail to speak of, it should

just be a passing weekend of fun without the shadow of AMS.

Or will it?

-

“Curtiss P-40 From 1939 to 1945”,

Planes & Pilots Series, A.Elbeid & D.Laurelut, Histoire &

Collections, 2002 (history, line drawings of all versions, huge

numbers of profiles, some photos)

-

“P-40 Warhawk Walk Around #8”, Lou

Drendel, Squadron/Signal, 1996 (B&W photos, good detail coverage

using photos of restored and wartime aircraft, some profiles)

-

Various internet sources

Click the thumbnails below to view

the images full-sized.

Use your browser's Back Arrow to return to this page:

Modelling the P-40

Hawk 81, Tomahawk, Warhawk and Kittyhawk

Osprey Modelling 15 |

|

|

|

|

Author: Brett Green

US Price: $17.95

UK Price: £12.99

Publisher:

Osprey Publishing

Publish Date:

January 10, 2004

Details: 80 pages; ISBN: 1841768235 |

|

|

Model, Images and Text Copyright ©

2005 by Tom Dungan

Page Created 06 September, 2005

Last Updated 05 September, 2005

Back to

HyperScale Main Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search