|

Classic

Airframes'

1/48 scale

Hawker Sea Hawk

Mk.101 and FGA.6

by Ingo Degenhardt

|

|

|

Hawker Sea Hawk Mk.101

|

images

by Lutz Degenhardt

Classic

Airframes' 1/48 scale Hawker Sea Hawk may be ordered online from

Squadron

Initially I did not intend to build two Sea Hawks but only a Mk 101

as in service with the German Marineflieger during the early

1960’s.

Classic Airframes offers two Sea Hawk kits for the different versions

that can be build. So I ordered the kit for the Mk. 100/101.

Opening the box reveals 3 sprues of injection moulded parts, 20 pale

yellow resin parts, one fret of etched metal parts, a large decal sheet

and of course the instructions.

Construction in general looks rather simple and I started with

cleaning the major resin parts such as cockpit tub, main gear well

interior and air intakes. Some dry-fitting looked very promising and

indeed the fit of all these parts is excellent. My personal favourite

part of this model is the large resin block for the main whell well

interior – well detailed, flaw-free and a snap-fit into the lower

fuselage half. Just make sure about front and rear of this part.

Some attention must be paid to removing the excess resin because

otherwise the top and bottom front fuselage halves will not fit

together. As an example, the cockpit floor on my model was paper-thin

after I finally sanded off enough resin to make it fit. When all the

surplus resin is out of the way the front fuselage halves are glued

together. They do not fit very well.

To help them align a little better I glued small discs made from sheet

plastic along the inside of the joints on both parts. You just have to

make sure the upper and lower discs do not interfere with each other.

This measure improves things here a good deal, but there is enough

filling, sanding and rescribing left when the front fuselage has been

glued together.

Not quite so for the left and right half of the rear fuselage – although

no location pins are provided, these parts can be glued together without

any problems. I just used a few of my “alignment-discs” here.

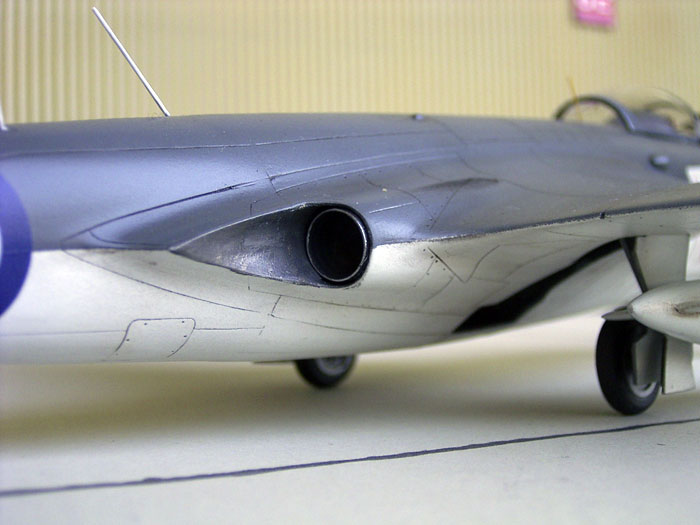

Attaching the parts A 8/27 (base for engine nozzles/blast shields) needs

some filing and sanding according to the instructions before glueing

them into the front hull, but their fit was quite good without much

extra work. The jet nozzles are to be installed at this stage also.

Connecting front and rear fuselage is nearly a butt-joint and fit ist

rather poor. Only limited success this time trying to equal the

cross-sections of this joint in the described way. Quite a lot of filler

was used here, followed by intensive sanding and of course rescribing.

Most difficult thing here is to smoothen the connection of A 8/27 and

the rear halves of the blast shield moulded to the rear fuselage halves

as there is very limited space for filling and sanding.

When that was done I installed the completed horizontal stabilizers.

Their fit is very good and needed no filling or sanding at all.

Click the thumbnails below

to view larger images:

Next I drilled out the flat nose and carefully sanded it

into an oval shape with rounded edges. The gun ports were also drilled

out because they are moulded much too shallow. I did not install any gun

barrels as I could not make them out on any photograph. They seem to be

too far inside the fuselage.

Canopy and windshield are moulded as a one-piece clear injection part.

The fit of this part is not that good so I carefully separated

windshield and canopy by cutting them with a sharp hobby knife. The

windshield installation needs some filling and sanding to make it fit

but this is much easier than to make the closed cockpit fit. Besides

there now is a nice view into the cockpit when the canopy is displayed

open.

The last parts to be glued onto the fuselage are the catapult hook and

the spent cartridges ejectors. The hook must be positioned further

forward than stated in the instructions due to my drawings and the two

protruding ejectors must be reworked because they are angled too far

outwards when glued on as they are. Seen from the front their angle is

nearly exactly vertical downwards.

Although only land-based, it was not unusual to see

German Sea Hawks parked with the wings folded to save space. I built the

outer wings as sub-assemblies to glue them on later in the folded

position. A resin insert closes the wing cross-profile on the fixed part

of the wing while an etched-metal part is used for the outer wing. Both

can be attached without further problems. Parts A 7/26 can be used to

adjust the outer wing profile. I did a little extra detailing on the

resin part later.

So much for the construction – well, almost... later on I discovered two

things about the model that were wrong. The first is the angle of the

windscreen. While fitting it onto the fuselage, I didn’t pay enough

(none) attention to it’s correct attitude. I was satisfied when I had it

properly glued on, filled the gaps and sanded it smooth. What I didn’t

notice then but is most apparent once perceived is the angle of the

windscreen’s rear framing – it is much too steep, nearly exactly

vertical. No chance to correct it now.

The second mistake I discovered while flipping idly through Warpaint No.

29 and looking at the many photographs: The model’s jet exhaust pipes,

installed as per instructions, protrude a good deal from their fuselage

housing. Not so with the real thing. They are visible but end where the

surrounding panels end. This can be easily corrected, provided it is

noticed in time, i.e. before installation. Again no chance to alter it

now.

This was the moment I first thought briefly about making a second Sea

Hawk without these mistakes.

Paint

There is only one paint scheme to choose from for the

kit’s decal options – BS 640 Extra Dark Sea Gray over BS 210 Sky.

I started as usual (cockpit and wheel wells already covered) with a base

coat of flat light grey to reveal any building issues that might still

need some additional work; often not easily noticable without this base

coat. And there were some of those. A little bit of work with some fine

grit wet & dry dealt with that and the model was ready for Xtracolor X 5

and X7

X7 Sky was first – sprayed on aircraft undersides, sides, vertical

tailplane, gear doors and struts. Xtracolors have a quite long drying

time, but nearly always spray very nice and –most important to me- are

gloss paints.

Masking the undersides for this camouflage scheme is not that easy as it

is not a straight ‘waist’ line as on the later scheme with white

undersides but has some curved lines in front of the windshield as well

as on the wing leading edge and the fuselage rear. I used Tamiya masking

tape for the job.

Extra Dark Sea Gray sprays fine too and after removal of the masking

tape the paint scheme is ready for weathering. After a two days drying

time a wash with diluted enamel (brown for the undersides, black for the

upper surfaces) was applied directly onto the XTRA-color. The wash of

course thins the paint but almost never down to the base coat or even

the plastic. Precondition is that the paint has been given enough drying

time.

Decals

As mentioned I used the decals for a Mk 101 of MFG 2

from the early 1960’s. The second choice for this kit is an Indian Navy

Seahawk. Surplus German Sea Hawks were sold to India when the

Marineflieger transitioned to the F-104 in the mid-sixties.

The decals are printed by Microscale and are very good. No problems

here. I used Superscale Micro Set and Sol as usual. When dry, all excess

decal glue was wiped off with a damp tissue and then I checked the

markings for any Silvering that might have occurred. There was only very

little of that and these few air bubbles were pierced with a needle. A

tiny drop of Sol then was applied and pressed into the fine hole with a

brush. Sol then displaces the trapped air.

I repeated the wash on the panel lines running through the larger

decals, wiped it off and now it is time for the clear coat.

I used Humbrol Satin Cote for this because I considered a semi-gloss

finish to be the best compromise between the factory gloss coat of the

real aircraft and weathering and scale effect on the model’s side.

A little further weathering was done with pastel chalk powder to

resemble stains for example from the guns or – often very prominent on

real Sea Hawks- the cartridge starter port on the left upper fuselage

behind the cockpit. Few oil stains were simulated by wiping thinned flat

black from covers, etc. in the direction of the airflow. In general,

this Sea Hawk received only very moderate weathering.

I like the Sea Hawk, I like the Classic Airframes model – and I gnawed

on the mistakes I made. So I ordered CA’s second offer, the kit for the

FGA.6/Mk.50/FB.3 as an on-the-spot decision. This time I chose a RN

aircraft with the later style camouflage scheme from No. 806 Squadron

“Ace of Diamonds”.

Construction methods in general remained unchanged except of course

avoiding my mistakes regarding the windshield and engine nozzle

installation. I am satisfied now with these areas. The wings were now

unfolded, which is of course less detail to take care of but fit is an

issue here. Again, the parts A 7/26 are helpful in order to align inner

and outer wing cross sections. I closed the gap completely with

Cyanoacrylate glue and rescribed the wing folding line afterwards.

In both cases a little bit more ordnance than the two drop tanks would

have been nice; in case of the Mk 101 an EKCO 38b Radar-pod or some

rockets with launchers for the FGA.6.

Source

Warpaint No. 29 Hawker Sea Hawk

Model and Text Copyright © 2005 by

Ingo Degenhardt

Images Copyright © 2005 by Lutz Degenhardt

Page Created 14 December, 2005

Last Updated

13 December, 2005

Back to

HyperScale Main Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search