|

Classic Airframes' 1/48 Scale

Hawker Sea Hawk FB.5

by

Stephen Naylor

|

|

|

Hawker Sea Hawk FB.5

WN108 ('033') |

Classic

Airframes' 1/48 scale Hawker Sea Hawk is available online from

Squadron

For a look at the contents of

Classic Airframes' 1/48 scale Hawker Sea Hawk,

see the in-box

review elsewhere on HyperScale.

Armstrong Whitworth Sea Hawk FB.5, WN108 ('033'),

was operated by Airwork Services Limited FRU (Fleet Requirements Unit)

from their base at Hurn Airport (now Bournemouth Airport) in Dorset

(UK), from June 1958 to August 1963. Airworks used various marks of Sea

Hawk at Hurn, as well as other types, in order to provide gunnery target

practise and radar calibration for warships of the Royal Navy, during

exercises off the south coast of England.

Sea Hawk FB.5's were basically the FB.3 model

fitted with the uprated Nene 103 engine, a conversion carried out by the

original manufacturer on this FB.3 airframe (#AW6041) in 1955. In this

way, all FB.5's were conversions - there were no production examples.

As soon as I heard that CA was to produce a Sea

Hawk, I knew that the aircraft I would model would be one in the FRU

Hurn 'all-over black' finish (more on this later), but which one?

Whilst there are several Hurn-based examples I would like to have done,

I eventually chose 'WN108', mainly because 'Kits at War' (Dutch Decal)

produced a timely decal sheet featuring the aircraft (their sheet #K4/13

'Royal Navy Postwar'). This avoided the need for me to source

appropriate decals from elsewhere, especially being a black aircraft

requiring white lettering and numbers of the correct size and style. As

a bonus, this aircraft is also preserved at the Ulster Aviation Society

Heritage Centre in Northern Ireland, though the only useful photograph I

have found to date of 'WN108', is the one on page 15 of Warpaint No.29.

Sea Hawk 'WN108' Details

In terms of the subject-specific features or

modifications I undertook on the kit, these were just two comprising;

●

No fins on the under-wing drop tanks (a feature of FRU/Hurn

Sea Hawks)

●

Port drop tank to be fitted with a searchlight (Harley

Light?) in its nose. [This searchlight 'pod' was an aid to target

acquisition by ship-board gunners during exercises, as was the all-over

black finish. Choosing to fit this pod is a bit of 'modeler's license'

on my part, as although this feature is shown on other aircraft of the

time, I have no actual proof of one being fitted to 'WN108'].

Summary

Although they will be mentioned shortly during

the build steps, here is a quick list of the other corrections or

modifications I made to the kit;

●

Opened the canopy (to show off all that excellent

resin/etch).

●

Opened the cannon ports under the nose.

●

Opted for folded wings.

●

Added scissor links to main undercarriage leg oleos.

●

Discarded use of photoetch (PE) Parts 'PE8', 'PE9', 'PE10'

and 'PE14/15'

(the engine intake guides

– see later).

●

Replaced the kit's stubby resin jet pipes with longer

(internally) brass tubing.

●

Added the curiously missing 'tail bumper' to the tail.

Other than the decal sheet mentioned earlier and

my own scratchbuilding efforts, no aftermarket accessories were used,

though I was tempted to replace the ejection seat with something more

detailed. However, given the long gestation of this build and the

'issues' I had (some kit-related, some of my own making), I went with

the kit seat to save time (and my sanity!).

Finally; CA's Sea Hawk FB.3/FGA.6/FGA.50 kit has

already been extensively reviewed elsewhere, so as usual I do not

propose to repeat what has already been said. On the other hand there

are some 'issues' with the kit which will have an influence on the

modeler's 'experience', so I will mention them where appropriate.

Extras

●

Kits At War's (Dutch Decals) 1:48 decal sheet K4/13 'Royal

Navy Postwar' (www.kitsatwar.nl).

Getting Underway

In describing this build, I will follow the kit's

instruction sheet sequence and parts numbering, though this is not

necessarily the order in which I proceeded. Although I realise this is

not as convenient for those without access to these instructions, I

think it will still work with a bit of explanation along the way, and

perhaps be of more use to other modelers faced with the open box of

parts.

STEP 1

(Instrument Panels)

One of the delights of the kit for me, was the

depiction of the main and front quarter instrument panels. After

dipping the clear acetate instruments sheet in Johnson's 'Klear' floor

polish, and allowing to dry, I sprayed the rear face of it with white

automotive primer (as per the instructions), so that the dials, etc,

would show up better. The faces of the panel etches (Parts 'PE1', 'PE2'

and 'PE3') were then sprayed with black automotive primer, followed by

dry-brushing with white enamel paint to pick out the highlights and

added a few lamps picked out with a fine brush in appropriate colours.

These latter parts were then secured in place over the appropriate areas

of the aforementioned instruments acetate with superglue. Once trimmed

out of the acetate, three beautiful panels resulted, the best I have yet

seen on a model. Strange therefore, that some subsequent CA kit

offerings (Meteor NF and Canberras for example), only have simple

moulded-plastic instrument panels. However, moving on...

STEP 2

(Cockpit Wall Instruments)

No problems here. Resin pieces 'R13' – 'R16' fit

fine and similarly benefit from dry-brush work and detailing (check your

references).

STEP 3 (The Cockpit)

One of the 'problem areas' with this kit is

squeezing that resin cockpit tub (Part 'R1') into the fuselage.

As indicated in most reviews, a considerable

amount of material had to be removed from not only the sides, but

particularly the base, of the main cockpit tub resin casting. In fact,

the floor of mine ended up so thin, that it actually separated from the

base! Despite all this fitting and sanding however, I was still not

really able to get the two fuselage halves (split horizontally) to meet

properly. This ultimately led to some filling and sanding of the mating

seams, with consequent loss of panel line detail, requiring re-scribing

later. That said, the the side panel detail of the cockpit tub is good

and shows up well once painted (lightened black) and picked out in

appropriate colours (references again).

The gyro gunsight (Part 'R3')

and its 'film' reflector glass (I only fitted one of the two required -

my eyesight is not what it was!) was painted and left to be fitted after

final painting, as was the joystick and ejection seat (Part 'R2'). On

the subject of the seat; it passes muster but the perfectionists amongst

you will probably want to replace it with a more-detailed aftermarket

specimen. For simplicity's sake I chose to use the kit seat, though

fitting the PE parts was fiddly. In the end, the retractable knee guard

etch (Part 'PE13') broke off once too often for my patience, so I

discarded it.

STEP 4

(Lower Fuselage Internals)

No problems here. The resin main wheel wells

('R7') and intake duct housings ('R5' and 'R6') are superbly moulded and

fit with little other attention. Do not forget the required weight in

the nose (10g + suggested: see later for further problems I had in this

regard), otherwise you will end up with a 'tail-sitter'.

STEP 5

(Closing the Main Fuselage Halves)

For me, this was an area where I undertook some

technical modifications, partly to correct a problem, and partly to

enable a more secure assembly. Obviously this was my decision and I'm

sure others will do things differently, but anyway here goes...

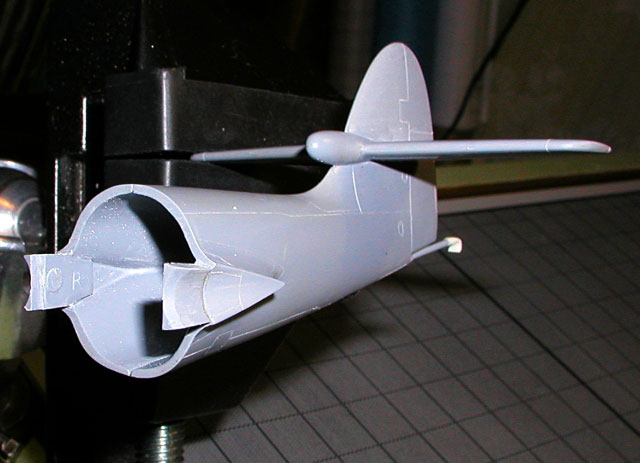

The kit instructions require that the jet exhaust

pipe mounts (Parts 'A8' and 'A27'), which form part of the aircraft's

two jet pipe 'pen-nib fairings', are fixed in place between the fuselage

halves (after some fitting and fettling) and then the tail assembly is

butted on to the rear of the closed fuselage halves in the next step. I

was not happy about this method for a couple of reasons.

Firstly, as the parts ('A8' and 'A27') form part

of the 'pen-nib fairing', the majority of which is actually ed onto the

tail halves (parts 'C1' and 'C2'), it is therefore important that they

line up correctly with the latter, rather than just fitting them to the

main fuselage and then having to accept the resultant alignment the kit

sequence gives you. Secondly, I was also not that happy (from a visual

perspective) with how short the actual resin jet pipe 'cans' were (Parts

'R9' x 2).

To solve that, I substituted two of my own jet

pipes made from suitable thin-walled brass tube and placed a couple of

mounts for them (ex-1/72 Airfix Lancaster wheel centers I think, from

the scrap box), inside the lower fuselage half in order to fit the pipes

to them, after final assembly. These scrap 'mounts' also have the

advantage of stopping the pipes from disappearing completely inside the

body when you do come to fit them! Fitting the pipes later also allowed

me to paint them, and the natural metal finish (NMF) 'pen-nib fairings',

as separate items later, rather than as an assembly. Note, that if you

do use the CA-supplied resin jet pipes, there is a problem in that the

location 'pips' moulded on parts 'A8' and 'A27', which determine where

the supplied jet pipe 'cans' ('R9') are positioned, are actually cast

too far aft anyway (in reality, the ends of the jet pipes barely emerge

from the rear of the outer part of the fuselage fairing).

So if you are still with me, the upshot of all

this is that I actually fitted parts 'A8' and 'A27' (having first

removed those location 'pips') to the assembled tail in Step 6, and

offered that sub-assembly up to the dry-assembled fuselage halves, so

that I could get the tail/'pen-nib fairing' spot-on before closing the

fuselage permanently. More on that in Step 6.

The fit problems at the cockpit end have already

been mentioned, so what else? Well the only other problem (for me) is

with the intake duct splitter plates (Parts 'PE8', 'PE9' and 'PE10') and

their respective 'top plates' (Parts 'PE14' and 'PE15'). The problem,

is that the kit shows them as being fitted flush with the leading edge

of the intakes, 'ala' DH Vampire. In fact, these actually curved

(rather than straight) guide vanes are in reality much further back (and

staggered aft) inside the intake ducts and can therefore hardly be

seen. This is especially true in the case of my model, as the insides

of the ducts were going to be black anyway. As a result, I left all

this PE out completely, though I did still fit the boundary layer

splitter plates (Parts 'PE11' and 'PE12') next to the fuselage here,

back in Step 4.

STEP 6

(Tail Assembly)

See Step 5 above for how and why I did things

slightly differently here. One or two things are worth mentioning

though. The main thing, is that despite my best efforts, and in keeping

with the experience of many other modelers at this point, I failed to

get a good match between the cross-sectional profile of the tail

sub-assembly (split vertically) and that of the main fuselage (split

horizontally), at this important butt joint. Not sure if it was all my

fault or partly the shape of the kit's moulding, but in the end I again

had to resort to a fair bit of filling/sanding/re-scribing around this

joint after assembly, to restore its smooth aerodynamic shape. Remember

also to fit something appropriately shaped to the underside of the tail,

to represent the rubber 'bumper' seen in this location (for some reason,

CA left this feature off this kit's tail, but did provide it on the

'Mk.101' version).

Other pointers are: don't do as I did and fit the

tailplane (Parts 'A3/A4') to the tail sub-assembly early on, to 'make

some progress'. Wait until AFTER the tail is actually assembled to the

fuselage, so you can sight back over the top of the fuselage and get the

tailplane parallel with the wing (or wing stubs if opting for folded

wings). I couldn't wait however, and although the tailplane seemed

square when I fitted it to the tail assembly there is, even now, still a

slight tilt towards Starboard after I assembled the tail unit to the

fuselage. Whilst this 'tilt' may be mostly of my own making, it might

also be because once assembled the tail itself seems, for some reason,

not to be quite vertical with respect to the fuselage?

Just one final don't here. Don't fit the

arrestor hook now; wait until just before final painting - the resin

hook-end on mine broke off three times(!). Luckily 'The Carpet Monster'

failed to get it!

STEP 7

(Wing Assembly - Deployed)

Not followed - see Step 8.

STEP 8 (Wing Assembly - Folded)

The wings were no problem really. Getting the PE

on the hinge end of the wing halves to stick with superglue was fun

(Parts 'PE16' and 'PE17'), and they needed some trimming to match the

wing profile. Though the resin parts (Parts 'R17' and 'R18') fitted

reasonably well to their respective points in the fuselage, one of the

paradoxes of this method of providing the wing-fold, is that the PE on

the ends of the folded wings is very good (but will not really be seen),

whilst the resin parts on the fuselage (which are more prominent) do not

really represent this area too well at all.

As is my preference, I also fabricated clear

plastic wingtip lights port and starboard, drilled-out and filled with

red or green food colourant as appropriate.

In lieu of suitable microtubing, I substituted a cut-off dressmaking pin

for the kit's pitot tube on the port wingtip.

The wing sub-assemblies were painted and decaled

separately, then assembled to the fuselage using a card jig I designed

with CAD on the computer, to provide symmetry and support whilst the

glue set.

Click on the thumbnails

below to view larger images:

STEP 9

(Nose Wheel Assembly)

No real problems here. With care, you can leave

the wheel ('R10') off until later and squeeze it between the forks of

the nosewheel oleo ('A16' and 'A25') after assembly and painting. The

only other improvement, was to beef-up the PE arrestor wire guard

('PE5') with some superglue gel, once fitted, and then sand it to a

shape more like the forging it represents.

STEP

10 (Main Wheel Assembly)

Again, this is all pretty much straightforward.

To help assembly of the main undercarriage (Parts 'A13'/'A29',

'A18'/A24' and 'A20'/'A22'), I drilled a fine hole into the fuselage end

of each gear actuator ('A18'/A24') and also into the corresponding

location points for that actuator in the resin main wheel wells ('R7').

This was done, so that a short piece of fine wire could be glued into

the end of each actuator, both to assist with location during final

assembly and to help with undercarriage strength. Although a small

detail, I also added the missing scissor link to each mainwheel leg,

sourced from the scrap box (removed from ex-1/72 Airfix RA-5C Vigilante

undercarriage units I think) though in truth, they can hardly be seen on

the finished model.

One other thing to watch in Step 10, is that the

kit's instruction sheet shows the resin catapult strop hook ('R12'), as

being fitted in a position aft of the rear gunbay access doors. In

reality, this hook is mounted just forward of the chainlink/shell

ejector chute access panels (you will see a small rectangular engraved

panel area for it, at the correct location). On the prototype, this

hook was retractable, though my reference photograph and many others,

show that in practice it was usually left in the deployed position.

Finally here; the shell ejector chute parts ('A19' and 'A23') need their

upper ends attended to, in order to get a good fit against (and the

slight outward angle from) the fuselage.

STEP 11 (Underwing Stores and Doors, Etc)

As mentioned earlier, I fitted the two drop tanks

('B5'/'B6' + 'B7'/'B8') to the two inner stores pylons ('A21' x 2),

having first modified the tanks to FRU specifications.

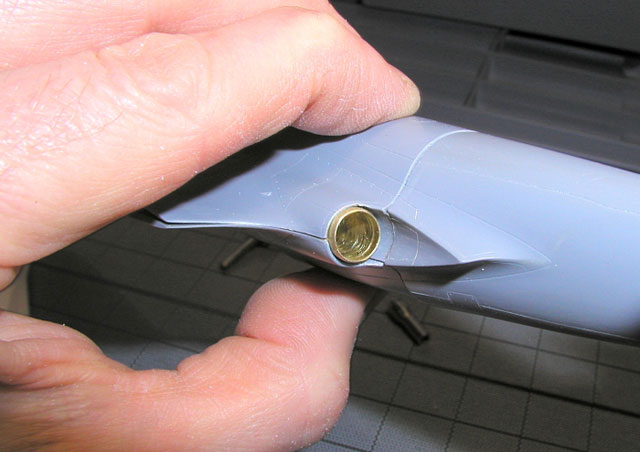

Initially, this involves removing the rear fins

on each tank (a standard FRU Sea Hawk feature). Additionally, on this

aircraft, the Port drop tank was then further modified by having its

nose cut back and replaced with a glazed searchlight (Harley Light?).

The light unit was made from a scrap rear rocket motor (chromed plastic)

from an old 'Zero-X' toy from my childhood - remember that? (the toy,

not my childhood!). To finish it, a large-headed dressmaking pin

represented the bulb.

The searchlight's glazed nose/lens was made by

'heat-smashing' some clear plastic sheet over the end of the resin radar

nose left over from CA's NF.21 Sea Hornet kit. Once cut out from the

sheet, this glazing was then attached to the tank with white wood glue.

I had no drawings for these tank modifications, I just roughly scaled it

from the reference photos I had to hand.

Everything else at this stage went together OK,

though I obviously didn't need the second set of stores pylons ('A21'),

one under each folded wing, for this aircraft.

Click on the thumbnails

below to view larger images:

STEP

12 (Canopy and Other Details)

This final step on the instruction sheet, mainly

covers the fitting of the cockpit canopy ('C1').

What should have been the most difficult part of

this (separating the canopy into two halves to allow the sliding section

to be displayed open) was, in the end, the easiest. Merely a simply

operation with a razor saw, followed by sanding and polishing to cleanup

the cut faces. Once the front (fixed) canopy section had been painted

internally, it was secured to the nose with superglue (using the sliding

canopy section as a guide) and any resulting gaps between it and the

fuselage filled and rubbed down. The sliding section of the canopy was

masked and painted separately, then secured to the fuselage with white

wood glue on final assembly.

Step 12 also covers the fitting of one of the

many antennas (i.e. 'PE7') - though other antennas are expected to be

fitted in preceding steps. In my case, I elected not to use any of the

PE antennas from the kit's fret. This is firstly because I don't think

that PE is necessarily a good representation of these things (my

thoughts are, 'just because you can etch something, does not mean you

should'. Secondly, most of these antenna are better left off until

after final painting and finishing anyway. Normally, I use fine wire or

bristles from a brush for the wire-type antennas and shaped Evergreen

strip for the blade-type UHF antennas (e.g. the one in the centre of the

roundel, under the starboard wingtip). There is a good reference

diagram covering all possible antenna 'fits' to Sea Hawks, on page 30 of

the '4+' book (see the reference list at the end).

The usual filling and sanding was undertaken and

once cleaned up, the cockpit area and glazing was masked off, as were

the wing-tip navigation lights and the tip of the pitot tube (that metal

pin), on the separate wing assemblies. Parts such as the main

undercarriage and nosewheel oleo assemblies, the wheels, undercarriage

doors, sliding canopy and the pair of jet pipes were left off to be

painted and weathered separately and assembled later.

So, on to the painting. Should be simple - its

just black isn't it? Well the exterior of the airframe is, but what

about the wheel wells, undercarriage and wing-folds? The kit

instructions are silent with regards the wing-fold area but as usual,

suggest that the wheel wells and the inside of the undercarriage doors

should/could either be aluminium or the same colour as the underside of

the aircraft.

From research and photos, I know that Hurn's

Fleet Requirements Unit (FRU) received their Sea Hawks from the Fleet

Air Arm in their last service scheme and then repainted themselves in

black. However, that then raises the question; what scheme was 'WN108'

in when received by the FRU in 1958? Barring any exceptional

circumstances, the underside options are clearly either 'Sky' (more

likely?) or White (less likely?). Even if I knew that (and I do not),

the next point is whether the FRU would have left the wheel wells and

insides of the undercarraige doors as delivered (for simplicity's sake)

or would they have gone to the trouble of repainting them? From a

maintenance point of view, I cannot imagine that black for these areas

is a good idea, but I could be wrong of course. To add to the

complexity, my only photo of 'WN108' shows that this aircraft had (as

with some other, but not all, FRU black-finished machines) a black

nosewheel strut/oleo. Of course, this photo and many others of Sea

Hawks does not show the main undercarraige clearly, making it difficult

for the modeler to confirm whether they too were painted black. This

problem is compounded by the fact that on an aircraft with such a short

undercarriage, this area is often in dark shadow. In the end, I decided

that I would go with black undercarriage legs and aluminium/silver for

the wheel wells and hubs, as well as the inside of undercarriage

doors. For the wing-fold, I decided on black, partly because the few

(b/w) reference photos of black Sea Hawks with folded wings I have, seem

not to show a light colour (aluminum or 'Sky'?) in this area, and partly

because black tends to hide the relatively poor representation of the

wing-fold joint on the fuselage.

Having thus, finally, decided the colour scheme,

the interior of the wheel wells, the inside of the undercarriage doors,

the wheel centres, the ejector seat, the interior and exterior of the

masked canopy and the wheel hubs all received a spray coat of cellulose

automotive Silver primer from a 'rattle can'. With the exception of the

ejector seat and the canopy, all then received a very dilute wash of

black enamel paint to accentuate the detail. The wheel wells were then

masked off using damp tissue and the model, plus the wings, the exterior

of the undercarriage doors, the undercarriage assemblies, the ejector

seat and the exterior of the sliding canopy, were then sprayed with a

coat of cellulose automotive Grey primer, also from a 'rattle can',

followed by a top coat of Humbrol Matt Black. Once dry, these areas

received a couple of light coats of Johnson's 'Klear', prior to

decaling.

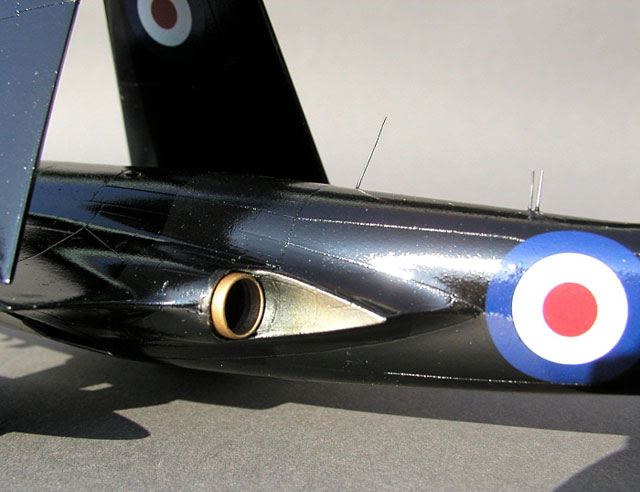

Using the 'Klear'-coated black finish as a base,

I separately masked off the engine exhaust 'pen-nib fairings' and,

together with the painted exhausts themselves, sprayed them with Alclad

II 'Polished Aluminum'. Afterwards, I tried Tamiya acrylic 'Clear Blue'

('X-23') and 'Clear Orange' ('X-26') on these areas to simulate heat

discolouration of the stainless steel, but without a great deal of

success - need more practice. Perhaps on my next project I'll give

Bare Metal Foil a try and see what happens.

The appropriate decals from the 'Kits At War'

#K4/13 sheet were then applied, using 'MicrolSol' and 'MicroSet',

seemingly with no problem, followed by a second coating of 'Klear' to

seal them. Some slight silvering has since become apparent, but it is

only visible under close scrutiny and strong lighting (e.g. in digital

photos!). Thinned Humbrol Gloss Varnish provided the airbrushed

finishing coat.

Prior to assembling the undercarraiges to the

airframe, the tyres were picked out in Matt Black and weathered slightly

(dry brushing), remembering also to add the pairs of white 'creep marks'

to each tyre/wheel rim (including the nosewheel). To complete the

model, the various wire and strip antennas were then fitted and the

wings assembled in their final position using the card jig I mentioned

earlier.

Unfortunately, as alluded to earlier on, when the

finished aircraft was placed flat on a level surface, I had still ended

up with a 'tail-sitter' (insert profanities here)! Locations for adding

extra weight were, by now of course, severely limited. In the end, I

had to feed some fishing weight 'shot' into the roof of the nosewheel

bay and pour in some epoxy glue to secure it in place. Although an

unsightly solution, should you happen to pick up the model and examine

it, the Sea Hawk does at least now sit flat on its wheels unaided, but

only just - Phew!

Perhaps one of the most difficult 'post-build'

tasks has been to take some decent photographs. Trying to photograph a

shiny black object has proved to be quite a challenge, whether indoors,

or outdoors, natural or artificial light or flash, automatic or manual

settings! Even now, I am not that happy with the results, but at least

digital photography allows for endless experimentation. Of course, you

do have to bear in mind that gloss black does have a tendency to show up

the slightest flaw on any model and its paint job, especially to the

unforgiving lens of a digital camera (that's my excuse and I am sticking

to it!).

Would I build another Classic Airframes Sea

Hawk? Lets just say its not high on my list of priorities, and I don't

have one in the unbuilt kit 'stash'. Having said that, I am pleased

with the final result and it is the best kit of the 'Hawk' around,

though for me, it was a 'trying' build and there were times when I

thought I would never get it finished. Still, there are also markings

for an all-red FB.3 Sea Hawk of the 1958 'Red Devils' aerobatic team on

that 'Kits At War' decal sheet, so as a former Bond once said, 'never

say never again'...

-

Hawker Sea Hawk; Tony Buttler MRAeS; Warpaint No.29; Hall

Park Books.

-

Hawker Sea Hawk; Michal Ovcacik, Karel Susa, et al; Mark 1

Limited, 2001; 4+ Publication.

-

Hawker Sea Hawk - Type History Database; Derek James;

Aeroplane Monthly; September 2002; p.47 -69

-

Hawker Sea Hawk; Richard J Caruana; Scale Aviation Modeller;

1996?; p.156 -163

-

The Fleet's Hawk; Richard J Caruana?; Modelaid Quarterly,

Issue 3; 1980's?; p.83 - 88

-

The Hawker Sea Hawk; Francis K Mason; Profile Publications;

1966; No.71

-

http://daveg4otu.tripod.com/fru.html This is a webpage

(part of a larger 'Aviation in Hampshire, UK' website) dedicated to

the Airwork Fleet Requirements Unit, listing all the aircraft that

worked at Hurn before the Unit was relocated to Yeovilton in 1972

The photographs were taken with my Olympus

Camedia 4040 Zoom camera on a tripod, mostly using aperture priority

setting (to preserve some depth of field), close/'macro' focusing and

occasionally 'AEL' (exposure lock). The latter was tried in order to

read exposure from a grey card, rather than relying on the automatic

reading from the camera's sensor when pointed at the shiny black model.

The final choice of images were then adjusted, sharpened, cropped and

re-sized using Paint Shop Pro7. Most are indoor shots, lit by up to

three angle-poise lamps fitted with daylight bulbs.

Click on the thumbnails

below to view larger images:

Model, Images and Text Copyright © 2006

by Stephen Naylor

Page Created 12 December, 2006

Last Updated

21 February, 2007

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search