|

Classic Airframes 1/48 scale

De Havilland

Sea Hornet F.Mk.20

by Stephen Naylor

|

|

|

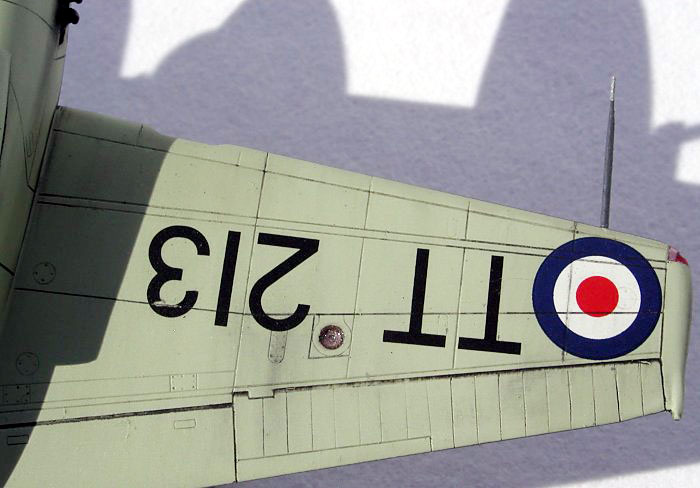

Royal Navy Sea Hornet

F.20 of Airwork FRU, Hurn Airport, Dorset. C1955 |

Classic

Airframes' 1/48 scale Sea Hornet F.Mk.20/21 is available online from Squadron.com

By rights, this model (the first aircraft

I have attempted since my youth) should have been a

Beaufighter. Why? Well although aviation has always been a

keen interest, I eventually took up railway modelling, a hobby which I

still enjoy. More recently though I caught the aircraft 'bug' again

and, after discovering 'HyperScale', set about catching up on

developments in aviation modelling that had occurred in the meantime.

The changes that have taken place are amazing: improved accuracy of

models; greater diversity of subjects; the massive increase in

aftermarket support; limited run kits; multimedia kits; larger scales

are better supported, plus the role of the Internet and publishing in

providing greater information about your chosen subject matter - the

list goes on.

After 'watching' HyperScale for a while, I

decided on a planned campaign for my return to modelling aircraft, in

stark contrast to the random disorder of my earlier days. My main

decisions were:

·

Scale would be 1:48. Mainly because of the display space

available (Piston-engined twins are likely to be the biggest thing I

will be attempting) and also because I think it is a pleasing size to

work in.

·

Subjects chosen would primarily be those with a local

connection here in southern England, but which also fit in with my

specific interests, e.g. WW2 (Allied, especially the Mediterranean

Theatre) to Post-War/Fleet Air Arm/Early Jets. This doesn't rule out

some 'diversions' along the way (my other interests include photo

reconnaissance and flyingboats!), but does give me an overall 'focus'.

So after selling-off the few unmade kits in

various scales, which I had stashed away from years ago, I drew up a

list of subjects/specific aircraft and began gathering information on

them (another favourite pastime). Eventually I began purchasing a few

kits and then made a start on the aforementioned Beaufighter (my

favourite aircraft of WW2). However, with research stalled on the

intended subject (T3316 'M' Pegasus), modelling ground to a

halt. Then Classic Airframes brought out the Sea Hornet F.20, for which

I had got all the information, so the 'Beau' went back in it's

box and the workbench was cleared for action.

Why

'TT213'?

Primarily, because she was operated by the then

local firm of Airwork Limited FRU (Fleet Requirements Unit) at Hurn

Airport (now Bournemouth International) in Dorset, from 1953 until

1955. At this point I should just mention that this was BEFORE I was

born (though only just!).

Two other reasons tipped the balance, firstly she

was an unusual aircraft in that she had also spent time on loan to the

RAAF (1948 to 1951, as A83-1) undertaking some 49 hours of Tropical

trials, and secondly (and decisively), because Hannants produced the

Xtradecals sheet X042-48, which contains markings for 'TT213'. Of

course the DH103 is a also a beautiful aircraft, from the zenith of the

piston-engined design era - who needs any other reason?

Classic

Airframes' 1/48 scale Hornet

|

Classic Airframes' RAF Hornet F.1/F.3 and RN Sea

Hornet F.20/NF.21 kits have already been extensively reviewed, both here

on HyperScale and elsewhere, so I do not propose to repeat what has been

said already. However, what I will do is describe my experience of the

kit and the modifications I carried out.

Preparation, as with most things I do, involves

producing a plan and following it. This is especially important for me,

as the time I have free for modelling is often limited and I may have

to put a model to one side for days (sometimes weeks) at a time. By and

large, this plan will follow the kit's printed assembly sequence and

also use it's part number references. Modifications required are also

highlighted, together with any aftermarket parts or other variations.

The use of such a plan also allows me to tick off each phase of assembly

or variation as it is completed; handy when picking up the model again

after a hiatus.

Rather than ramble on, describing the build

'blow-by-blow', I will just give a summary of the assembly sequence.

Firstly though, I will outline the final form of the model I wanted.

The aircraft was to be shown on the ground with a view to incorporating

it into a diorama at some point (possibly about to be serviced, refueled

or towed). As such I decided to leave the cockpit canopy closed (thus

no pilot required), have the rudder and tailwheel shown offset to Port

(as if the aircraft had been swung round to the resting position, before

switching off) and leave the wings un-folded (although I understand from

a local ex-Airwork employee that they would have been folded on landing,

before the aircraft was towed away and parked in the hangar.

[Note: my local 'source' also told me that at

that time, Airwork's aircraft 'tug' was a Ferguson TE20 tractor ('Little

Grey Fergie') with an improvised tow bar. At present, the nearest kit I

can think of to model this, would be the 'O'-scale/1:43 whitemetal kit

by Langley Models].

Anyway, enough of this, on to the assembly.

Pre-Assembly

·

Opened-out the opposing camera windows in the fuselage

halves (A1 & A2).

[I over-did this

initially, so I used stock plastic tubing to 'sleeve' the hole size down

again, before reaming it out carefully to the correct size.

Coincidentally, fixing this insert so that it ended up recessed

slightly below the fuselage surface, has produced quite a good effect I

think. Just goes to show how sometimes a mistake can lead to an

unexpected outcome].

Main Assembly

·

Modified the tailwheel halves (A22 and A23) to represent

the anti-shimmy type wheel actually fitted to DH Hornets (similar to

that used on the Mosquito).

·

Modified and repositioned the tailwheel oleo (R17) to

Port.

·

Cockpit - added scratchbuilt cylindrical radio aerial

(behind headrest) and the angled tubular brace fitted to the rear of the

armoured seat back (strengthening for deck landings?). Also added one

of Eduard's coloured etched seatbelts (#49-007 'RAF Late') to the seat.

[I ignored the

(surprising?) lack of a cockpit gunsight in the kit, as TT213 didn't

undertake live firing whilst with Airwork at Hurn (canons were retained

though, to maintain the aircraft's CofG). Anyway, I used the excuse

that such a delicate and superfluous piece of equipment, would probably

have been removed and stored].

After painting the

cockpit and fuselage interior (lightened matt black), dry-brushing to

bring out the detail and assembling the fuselage halves;

·

Opened up the four, shell ejector chutes.

[However, I ignored

the instruction to cut the lower nose and insert the section R5 (having

the 20mm gun port troughs). This was because my local source told me

that as TT213 was used to provide a radar/gunnery practice target (i.e.

never firing it's own guns), these ports were always covered and doped

over and then painted to match the aircraft's own colour scheme].

·

Added appropriate holes for the Gun Camera Port (upper

front of nose) and Cockpit Fresh Air Intake (lower front of nose).

·

After dipping the cockpit canopy in 'Future' (thanks

Swanny), I drew the black framing lines on the inside using a

draughtsman's (Rotoring) pen, before assembling it to the fuselage.

·

Removed the rudder elements from the fin parts (B5 and B6)

and reassembled to show the rudder set slightly to Port.

[On this occasion

however, I chickened-out of doing the same to the elevators, despite the

fact that my reference photo of TT213 showed them slightly drooped -

what can I say].

·

Scribed the wing-fold panel lines, and add appropriate

‘lumps’ to represent the two (upper surface) wing-fold hinges.

·

Added the Port and Starboard Wing-tip Navigation Lights

(using clear plastic, drilled-out and filled with appropriate Red and

Green food colouring before assembly, then sanded back, polished and

re-scribed any lost panel lines).

·

Drilled out the landing light lens hole, then fitted the

wings.

·

Added the Zeus fastener detail to the rear of the

propeller spinner rims.

·

Assembled the tie-down/towing eye brackets (Parts R14) on

the main undercarriage oleos in the vertical plane (not

horizontally, as incorrectly shown in the kit instructions).

·

Flattened the bottom of the main wheel tyres, remembering

that these wheels are also angled outwards by about 3 degrees (Had to

shorten the main axle stubs slightly as well).

·

Finally; left the propeller assemblies loose, to allow

removal during possible transport/storage of the kit - obviously also

allows the props to be posed in different positions).

The usual filling and sanding was undertaken, but

I could (and should) have done this better (some joint seams still show

in places). Almost unavoidably, this sanding also removed part of the

aircraft's prominent fuselage strengthening band, which I had to replace

using an appropriate strip of paper, attached with liquid cement. Then

the cockpit canopy was masked using 'Magic tape', but only around the

bottom edges (i.e. I didn't bother to mask the individual glazing at

this point). Also masked the wing-tip navigation lights. Parts such as

the undercarriage assemblies, arrestor hook, tailwheel and oleo,

undercarriage doors, propeller/hub assemblies and propeller spinners,

were left off to be painted and weathered separately and assembled

later. I remembered to add the white 'creep mark' to each tyre/wheel

rim, but since completion I have discovered a good photo which shows an

F.20 with pairs of opposing white creep marks (so is this the more usual

practice?).

So, on to the painting. One thing that hasn't

changed since my youth, is my use of enamel paints, mostly Humbrol or

occasionally Revell. For the undercoat, I usually use a can of Holts or

Duplicolour grey or white cellulose primer (a tip originally picked up

from my railway modelling), but on this occasion I used enamel primer

and my Badger airbrush. The area of yellow (Humbrol Matt #24) for the

fuselage band was then sprayed. Once dry, the yellow band was masked

off and the undersurfaces, tail fin, spinners and undercarriage doors

given a couple of coats of Revell 'Sky' (Matt #59). In hindsight, I

hadn't realised how 'Green' this colour is, or at least how green

Revell's version is. In most pictures I have seen of this colour scheme

(EDSG over Sky), the 'Sky' looks more like a mid-grey, so perhaps I

should have lightened it a bit (or is there another 'Sky'?). Anyway,

the undersurfaces and tailfin were masked off next and the upper

surfaces given 2 coats of Humbrol Extra Dark Sea Grey (Matt #123,

lightened with White Matt #34). At this point, the interior of the

wheel wells and inside of the undercarriage doors also received a

brushed coat of Humbrol Silver (#11).

Next, all masking

(except the canopy and navigation lights) was removed, prior to decal

application. Decaling, and particularly weathering, can make or mar a

model, so I had to decide how I would approach this next task

(weathering especially, as although I am used to weathering railway

model buildings, etc, I had never weathered a model aircraft before).

Having looked at HyperScale for some time now, I have seen various

techniques explained and applied but some, although skillfully done, do

not produce results which appeal to me (each to his/her own, as they

say). So eventually, for my first go at weathering an aircraft model, I

decided to adapt Bill Pettyjohn's method, as described in his

Mosquito article in Finescale Modeler magazine (May 2001).

First, the entire model (and the sub-assemblies)

were given a couple of light coats of 'Future', and allowed to dry

thoroughly. Then the appropriate decals from the Xtradecal sheet were

applied, using 'MicrolSol' and 'MicroSet'. These decals went on like a

dream – the first time I have used this method (the last time I decalled

an aircraft, was with water-slide transfers). Next, a second coating of

'Future' went on, to seal the decals and protect them from the next

stages. Weathering came next, using a wash of Winsor & Newton artist's

oils (Ivory Black, Titanium White and a touch of Burnt Sienna, to

produce a grey just darker than the EDSG) thinned with their 'English

Distilled Turpentine'. When dry, this was wiped off (in the direction

of the airflow), firstly with a dry cloth, then using a wrung-out cloth

previously soaked in turpentine. This all went reasonably well, though

some wash repeatedly came completely out of some panel lines (should

have re-scribed, I know). In the end, I turned to the use of a soft

(4B) pencil to infill the missing areas with pencil lead (the excess

being removed with a soft pencil eraser). Pencil lead dust was then

also used to simulate the exhaust stains on the nacelles and the oil

streaks near the undercarriage door hinge lines. Unlike Bill Pettyjohn,

I decided not to try paint chipping as I felt that this aircraft would

have seen relatively little use and also have been pretty well

maintained. So that was about it. The model then got a final coat of

'Future' to seal the weathering, then a finish coat or two of Humbrol

'Satin' (#135).

Sub-assemblies were also painted, weathered and

finished in much the same way, then assembled to the model. The canopy

masking was then removed and the individual glazing frame members masked

and hand-painted with lightened EDSG. The navigation lights were also

unmasked and given a final brush coat of 'Future'. Glazing of the

oblique camera windows and the landing light lens was achieved using

Humbrol's 'ClearFix' (another first for me). Finally the pitot tube was

added from stretched 'Evergreen' rod and painted, and a paintbrush

bristle provided the whip aerial.

There are always things you would like to do to a

model but can't, either because you don't yet have the information,

because the work involved is beyond you, or perhaps not justified in

terms of the time/effort required. For me, on TT213 these are;

·

Eventually add ventral fuselage identification lamps

(however, the only good underside view I have, is of an FR version of

the F.20 and, as with the Westland Wyvern S.4, I don't at the moment

know which of the three lamps is which colour).

·

Possibly add two vertical camera ports in same location

(shown in the Avia Graphica cutaway mentioned below, but I'm

still not sure if all/any F.20's had these).

·

Fit main undercarriage wheels with 'diamond-pattern' tread

(and bulged) tyres (TT213 and later Hornets had them - aftermarket guys

take note!).

·

Fuselage stencil and propeller decals would have been nice

too, but at normal viewing distances I don't think their absence matters

too much.

Now that she is 'finished', the first question to

ask is, “Is this model the best aircraft kit I have ever built? To

that, I would have to answer, “Yes, absolutely!”

My second question would be, “Could the model

have been better”? No problem, the answer is, “Undoubtedly yes!”

As my first model aircraft kit for over 25 years

(Arrgghhh! - sorry), deciding to tackle a limited-run, low-pressure

injection moulded, multi-media kit, was perhaps asking for trouble.

Luckily I have had experience using plastic, card, resin, whitemetal and

brass in my railway modelling, so it shouldn't have been too traumatic.

Indeed, it was not. In fact I have been impressed by what I have

achieved, even if I do say so myself, and Classic Airframes are to be

congratulated for producing such an excellent kit.

There were problems of course, such as: my liquid

glue of choice (Slaters 'Mepak') not really being as effective on CA's

plastic as I am used to; the tailplanes seem somehow to have acquired

some dihedral that the real thing doesn't have; and I think the

weathering effect I have achieved (my first on an aircraft) is a little

too dirty. Some of the kit parts could be better or need replacing

(e.g. No detail in the u/c bays, some resin parts too small to use

without damage/breaking them, the undercarriage doors too thick/not

detailed inside/difficult to attach), but all in all, I'm quite pleased

with the end result.

So that about covers it and I'll bring these

first ramblings to a close. Hope that some of this has been of interest

or informative, but I mustn't rest on my (1/48th scale)

laurels - now, where did I put that Beaufighter kit?

The Hornet File;

Lewis G Cooper; Air-Britain Publications; 1992; p.25

[Has actual photo

of TT213, albeit whilst with Airwork at St. Davids, Pembrokeshire,

rather than Hurn - thanks to Paul Fontenoy via HyperScale for that]

The De Havilland

Hornet; P J Birtles; Profile Publications; No.174

Sea Hornet

Supreme; Article ('Viewed from the Cockpit') by Captain Eric Brown

CBE DSC AFC RN; Air International magazine; October 1982; p.192 – 199

[Includes an

excellent Avia Graphica cutaway, showing all the salient

details]

The De Havilland

Hornet; Article by Richard Caruana; Scale Aviation Modeller

International magazine; October 2002; p.943 – 951

[Only covers the

RAF's F.1's, PR.2's, F.3's and F.4's though]

The photographs were taken with my Olympus

Camedia 4040Zoom (High Quality setting, i.e. JPEG rather than TIFF) on a

tripod, then cropped, re-sized and sharpened for the web using Paint

Shop Pro7. With the exception of one indoor flash shot, the rest are

all outdoor shots taken on a sunny day.

Finally, many thanks to those on 'HyperScale' for

your encouragement, advice and direct help, as well as those former De

Havilland and Airwork staff, who took the time to respond to my plea for

information on TT213/Airwork Limited in our local newspaper (Bournemouth

Evening Echo).

Click on the thumbnails

below to view larger images:

Model, Text and

Images Copyright 2004 by

Stephen Naylor

Page Created 21 April, 2004

Last Updated 21 April, 2004

Back to

HyperScale Main Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search