|

Anigrand's 1/72 scale

Douglas D-558-1

Skystreak

|

|

|

Douglas D-558-1 Skystreak |

or, Train guys don’t know

how to cut plastic!

by Bill Dye

HyperScale is proudly supported by Squadron

I never built a resin kit before. Vacuforms were

challenging enough. Horror stories of grinding diamond hard surfaces;

sagging landing gear struts and air bubbles the size of walnuts came to

mind. But then somewhere I found out about Anigrand. They are making

1/72nd scale resin model airplanes many of which, of course,

I had already purchased the vacuform version years ago – except for the

Rainbow. That one I just plunked down some bucks for the vac version,

plus extra parts, only to find out that these guys have a resin version

out for, true, just a tad more money, but hey, it’s resin. Oh well, I’ll

save my money for the Martin Sea Master; that one I don’t have yet.

The kits Anigrand produce are, for me, like gifts

from above (trumpets here). Some of their subjects I remember seeing in

magazines when I was little but I never saw a kit of them; not even a

vac – at least none that I knew of. They have stuff like the four

engine tilt wing airplane, the four engine ducted fan looking thing and

even a Mixmaster, Sky Lancer and of course the XF-84H

Thunderscreech because I just finished the vac kit; shoot me now!

So, I took the plunge and, being a sucker for

prototypes and the unusual, I bought the Skystreak, the Cutlass, the

XB-46 and the Sky Lancer. When they arrived only 2 weeks later I opened

the package that would be a stamp collectors dream and found there were

only two boxes. What gives? I ordered four kits. I opened the XB-46

and the Sky Lancer boxes and found that they had taken the contents out

of the other two smaller kits, neatly folded the boxes and put them

inside. Pretty clever!

I looked at the Skystreak and thought, ‘It’s a tube

with wings; should be the easiest to build . . . . I think I’ll do that

one first.’ I bought a book about building resin models1 and

after realizing that plastic glue was not for these kits, I grabbed my

trusty epoxy and super glue and dug in. But wait . . the real aircraft

blurb:

Historical Background

“The Douglas Skystreak (D-558-1

or D-558-I) was designed in 1945 by the Douglas Aircraft Company for the

U.S. Navy Bureau of Aeronautics, in conjunction with the National

Advisory Committee for Aeronautics (NACA). The Skystreaks were turbojet

powered aircraft that took off from the ground under their own power and

had straight wings and tails.

Conceived in 1945, the D-558-I

Skystreak was among the early transonic research airplanes like X-1,

X-4, X-5, and XF-92A. Three of the single-seat, straight-wing aircraft

flew in a joint program involving the National Advisory Committee for

Aeronautics (NACA), the Navy-Marine Corps, and the Douglas Aircraft Co.

from 1947 to 1953. In the process, the Skystreaks set several world

speed records. All three D-558-1 Skystreaks were powered by Allison

J35-A-11 turbojet engines producing 5,000 pounds-force (22 kN) of

thrust.”2

Anigrand's Skystreak in the box

Well it’s pretty basic, a tube fuselage in halves

with nice wings and horizontal stabilizers. It was so nice not

having to scrape the trailing edges of the flying surfaces as one does

for vac kits. To pick up a wing and have thin trailing edges right

there . . already done! I realized just how much of a drag vac trailing

edges are for me. These were quite nice.

The little bits – gears, doors, cockpit, etc. –

were nice; not very much flash on any of the parts and very delicate

looking – at least compared to what I’m used to, and since I broke a

gear door hinge strut trying to get it cleaned up.

I particularly enjoyed the fact that molded into

the wings and fuselage were the wheel wells with detail! WOW I’m not

used to that! The holes for the gears protruded through the top surface

of the wings but a dab of putty and it was gone. The cockpit was sparse

but that didn’t bother me since I wanted to build the all metal canopy

version. . . well, the whole canopy wasn’t metal . . I mean ‘cuz

if it were all metal then the guy couldn’t see out . . . . it’s

the almost all metal one with the teeny weenie windows that I

wanted to do.

Fuselage

I put enough weight in the nose to counter balance

a bowling team with balls, so to speak. I added the control panel

(habit), put in the intake splitter and glued the halves together.

I filled the too deep and too wide for my taste

panel lines with TAMIA putty and/or Mr. Surfacer. But that was after I

tried superglue. Yikes! The resin is soft and it was a job trying to

sand the super glue without marring the resin even after only about an

hour and a half of drying. The super glue wasn’t even at that ‘hard as

a diamond’ state yet. First resin lesson for me: don’t use super

glue to fill panel lines.

Let’s see, very small cockpit with teeny weenie

windows. What to do? Solution: gloss black interior, put canopy on and

hope Plastic Model proctologists with flashlights and magnifiers don’t

peer in and see what’s not going on in there.

Click the thumbnails below

to view larger images:

The Tail

But wait. A reference photograph I had3

was taken exactly from the side looking right down the wing centerline.

Something was wrong with the tail. I looked at the model kit tail and

then the photo and then the kit tail and then the photo. I held a

fuselage half with the kit tail propped up against the photo. Hmmmm.

The kit tail looked kind a like a DC-6 tail. Not only that, but the

slot for the horizontal stabilizers had a couple of degrees of

incidence. Was it too far aft? Nope. Too far forward? Nope. Was it just

me? Maybe, but I didn’t think so.

The photograph of the real a/c showed that the tail

had a more pronounced ‘hook’ in the leading edge and the horizontal

stabs were at zero degrees incidence. I debated. I don’t fix things

that I have to measure to see if they’re out a whack. But this . . .

this, to me, was out a whack. So, I decided to make a new tail. I

measured the thickness at the base and it was not quite 0.10 inches

thick.

I went to a train shop because they sold plastic

sheet and I wanted to see if they had an N scale box car I wanted – oh,

sorry, wrong hobby. I found some .080” white plastic; close enough.

The guy at the counter, who always wants to know ‘Why are you doing it

that way?’, and, oh by the way, ‘you can do it better my

way,’ says, “Oh man this stuff is really tough to cut, you have to use a

jig saw; you sure you want plastic that thick?”

I was tired of being polite. I was a tad . .

‘pointed’. I mean, I had a bad day – with the tail out of whack and all

and, oh yeah, work stuff too, so I said, “No, it’s not tough to cut and

yes I need it that thick.”

“So, how do you think you’re going to cut it?” as

he looked down his nose.

“With an X-Acto knife.”

“Yeah, right. (snicker) How many cuts do you have

to make? 30? You’ll go through a lot of blades!”

“Nope, one dull blade, one cut; one firm snap,” I

said.

“Yeah, sure; well, good luck.”

“Won’t need luck, just an Xacto knife.”

He looked at me like I was nuts. I paid my $4.90

for a hunk of plastic and when I got home I took out one of my normally

dull knives and make one pass and snapped the plastic. I did it again

in another direction and just like that I had a small rectangle of .080

plastic in my hand.

I smiled. It’s these little things in life that

can be so rewarding sometimes.

,dye%20640.jpg)

I made the pattern for the new tail by photocopying

the magazine photo. I changed the copier magnification until the

fuselage length was the same length as the model. Shhh, I smuggled a

fuselage half into work and used the fancy-schmancy machine that can

enlarge or reduce copy. Like I said, this photo was a perfect side shot

and even if there was some photo distortion, it would be closer than the

kit DC-6 tail.

I had to transfer the photo of the correctly shaped

tail to the white plastic. As Agent 86 Maxwell Smart would say, “Well

Chief, I transferred the pattern to the white plastic using the ol’ –

‘rub a pencil on the back of the pattern then put the pattern on the

plastic and trace over it with a pencil’ – trick.” I broke out the

trusty dull Xacto and made cuts about a 16th of an inch all

around in case it didn’t snap cleanly. . . . . . “Would you believe

3/32nds plus an armored car?” Sorry, I’ll get out from under the ‘cone

of silence’. It did; snap OK I mean. I sanded the pattern of the new

tail with my 80 grit vacuform dry sanding matt to finalize the shape and

to taper the thickness toward the tip. It was finished by sanding with

wet 400 then 600 paper. I scribed the rudder and then added some plate

like thingies copied from the kit tail using 0.015” thick plastic. I

transferred some bumps that I cut off of the kit tail onto the new tail

in the same spots. (The little bumps were tiny fairings for the counter

weights for the elevators and rudder).

Click the thumbnails below

to view larger images:

Final Assembly

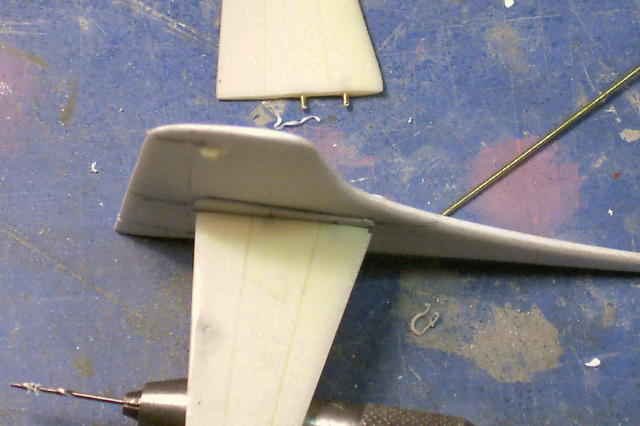

For each flying surface I drilled small holes into

each root chord (poke with a pin or something where you want the drill

bit centerline to be so the bit doesn’t wander) and inserted brass wire

pins. (See photos.) These pins really gave the wing and tail joints

strength. Without these I’m sure the thin little horizontals would snap

off if you just breathed on them.

I carefully cut out the nice canopy by lightly

scoring it with an X-acto and then again and again until it started to

give. I sanded the bottom of it until it was smooth and then dry fit

it. Holy cow! It fit!

I marked the outline of the canopy on the fuselage

with a pencil and then painted everything that would be on the inside of

the canopy gloss black so the flashlight guys wouldn’t see the yellow

plastic inside. I dunked the canopy in Future, let it dry for a few

hours under a paper cup to keep kitty hairs off of it and attached it

with superglue. Some Mr. Surfacer was added around the joint and then

scotch tape covered the teeny weenie windows.

Ready for primer.

First I sprayed the clear canopy gloss black,

plugged the wheel wells and intake with wet paper towel fragments and

later hosed the entire model with a very light coat of Testors Model

Master Acryl gloss white (I thought I’d give these a try . . not too

bad). As usual I found lots of ‘gotta fix its’ so I sanded some more.

Another coat of white, then another, finally it looked OK. The next

night, I misted on a coat of red. I tried Signal red, but it looked too

orange so I went back to D&J Hobby in Campbell, CA and with Al’s help I

bought some Model Master Acryl ‘Guards’ red. It matched the photos

better (I know, I know, photo color changes with type of film etc. etc.,

but I only know the airplane from the photos so I pretended they were

gospel.) I added another coat, and another and then the final coat.

WOW! Is that bright red or what!

Oh yeah, before you put on the red; if you have to

sand a small spot on the white paint and think the red will cover it . .

. it won’t. Well, OK, I admit, I was too lazy to set up the air brush

with white again just to paint another coat of white in that one

itsy bitsy wee little spot . . . ‘the red should cover it’. It didn’t.

After the first few coats of red I had to go back and hose on some

white and then more red. Trust me on this one: The entire model must

be flaw free white before you put on the red. Another thing,

once you see it white, you’ll want to buy another kit to do the white

version. Get your wallet ready! This airplane looks great in white too.

I pulled out my reference photos because the

instructions showed the all metal canopy version I wanted to build but

without the Skystreak decal. Hey, I gotta have one with the Skystreak

decal. Sure enough I found a photo in an old yellowed magazine article,3

that I had in my files since Reagan, that showed the teeny weenie window

metal canopy, bright red paint, stars and bars and the Skystreak

decal. Woo-hoo! Life is good! This configuration was to test an

extended exhaust. So, all I had to do was extend the exhaust. Big

deal.

A few days later, decals; but I replaced the stars

and bars with ones from Microscale (OK, Superscale Decals . . the old

Microscale decals) because the decal was situated right over the speed

brakes and the kit decals just didn’t nestle down even with Micro Sol.

The Superscale decals worked fine. Then I put on the Skystreak decal.

That one went on nicely. Uooo cool!

After a few days I applied a Gloss Water Soluble

Varathane clear coat. I thinned the Varathane with ONLY water

(alcohol or any other solvent gets you cottage cheese in the little

paint bowl) about 15 to 20% and misted on the first coat, misted the

second, waited 5 minutes then did another one but a tad thicker and

finally increased thinner to about 30% and gave it another shot. Really

glossy!! It’s thin, so if you get a run you can either swipe it quick

with a Q-tip and hose on some more to level it or wait and hit it with

1,500 wet paper and then polish it out. I’ve done both and it comes out

fine. It’s very forgiving stuff. After awhile you know just when to

stop before it runs. Like anything it takes some practice but it’s very

thin, clear, dries rock hard, is impervious to hot fingers and in

several years has not yellowed. But use the clear coat of your choice at

this point.

The teeny weenie canopy window masking was removed

– hey, look, you can see. . . .ahhhh . . nothing inside. Then

wing pitot probes, (I forgot to predrilled these before I painted, Doh!)

made from 0.20in. Brass rod hand painted with Testors Metalizer Dark

Anodonic Gray and polished with SnJ powder, were attached to the wing

tips. I only punctured my finger once while polishing it – I was

distracted by Star Gate SG-1’s 200th show.

I masked the antiglare panel being very careful not

to get the tape on the ‘Skystreak’ decal. (Hint: Anigrand has extra

decals and clear parts (sold separately). Do your self a favor and

order a second canopy and decal sheet for a couple of bucks.)

It took a couple of tries at paper patterns that

wrap around the exhaust area and when I got one that was close I traced

it onto Bare-metal foil (I like that stuff!) and applied that onto the

exhaust area and trimmed it with a super duper sharp Xacto #11 blade.

The exhaust tube itself was painted with Poly Scale grimy black

(railroad color) and then a little bit of blue and violet Rub & Buff on

the outside. I smeared it with my fingers to mush these colors together

until it looked just kind a cruddy and burnt. I put some brown and gray

chalks (from railroad pastel chalks) on the inside of the exhaust and

glued it in with some Elmer’s glue.

Gears, doors and the bottoms of the wheels were

sanded just a tad. Done. TA-DA!

Even considering that I had to make a new tail. I

STILL think this was a great kit and I’m glad I purchased

a few more subjects from Anigrand. I think I really like these resin

kits! I bought the 4 engine tilt wing, the 4 engine ducted fan thing

and the D-558-2 . . I’m in love!

Lessons learned:

- Fill excessive panel lines on resin kits with

TAMIA putty or Mr. Surfacer but not super glue.

- White under red must be flaw free, i.e.

uniform white.

- Buy an extra canopy and decal set when you

order your Anigrand kits or when you order through your hobby shop.

Bury me with sandpaper!

-

Marmo, Richard; How to Build and Modify Resin Model Aircraft Kits,

Specialty Press, 2002

-

http://en.wikipedia.org/wiki/Douglas_Skystreak

(free)

-

Trimble, Robert L., “Skystreak”, Air Classics, (unknown

date), pp28-32, 91-93.

-

Libis, Scott; Skystreak, Skyrocket, & Stiletto Douglas High-Speed

X-Planes, Specialty Press, 2005.

Click the thumbnails below

to view larger images:

Model, Images and Text by Copyright ©

2006 by Bill Dye

Page Created 18 September, 2006

Last Updated

21 February, 2007

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search