|

Building Collect-Aire's 1/48

scale

Sukhoi Su-24M

“Fencer D”

by Phil "Bondo" Brandt

|

|

|

Sukhoi Su-24M “Fencer D” |

HyperScale is proudly supported by

Squadron.com

The Sukhoi Su-24

(NATO “Fencer D”), affectionately known by aircrews as "The Suitcase," was

born in the mid-Sixties amid the alarm caused in Soviet planning circles

by introduction in the West of the General Dynamics F-111 "Aardvark".

The Soviet Union

had no equivalent airframe with the Vark's unique capabilities: low level

speed, terrain following radar, long unrefuelled range and significant

weapons carriage ability.

The Fencer's long

development was a quantum jump for the Soviet aircraft industry and, as in

the case of the F-111, a difficult one. But, the Fencer's difficult

early years eventually led--again, as in the Vark's case--to a relatively

stable maturation phase; the Fencer has soldiered on through the

Afghanistan debacle of the Eighties into the New Millennium.

Collect-Aire's

1/48 Scale Fencer D

|

Initial Assessment

With many past

Collect-Aire releases, the good and the not-so-good often battle to a

Mexican standoff, and the Fencer is no exception. This one was done by LF

in the Czech Republic and, as such, exhibits clean, smooth molding, very

little warpage and petite, sharp engraving that rivals the best injected.

Unfortunately, the very nice looking parts in-the-box suffer from variable

resin shrinkage which significantly affects major component alignment, and

resin pinholes (not bubbles).

Wings

The wings have

caused the Difficult Kit Division of Bondo Industries the most grief and

indecision. The problem centers around the fact that the folks doing the

master decided not to create movable wings (as opposed to the design

philosophy of the much more inexpensive Monogram and Academy F-111s) but

to leave it to the kit builder to permanently set the desired wingsweep

angle and to cut the outer wings at an appropriate location to mate

properly with the solid “gloves” (inner wing segment).

This scheme would

have been OK but for the unfortunate cross sectional enlargement of the

outer wing at the wing/glove interface. This enlarged section makes the

outer wing exactly the same thickness as the glove, which ain't the way

these 'switchblades' work! They really do slide between thin structural

layers of the glove, and there simply isn't any extra thickness left in

the Collect-Aire resin gloves. What to do…what to do?

Plan A

Although this

scheme was eventually shelved in favor of working with the original

Collect-Aire wing parts, I’ll go into the procedure anyhow because it is

workable. Bondo ambled out to the plastic kit “junkyard" and examined

the Zhengdefu ripoff of the Academy F-111 kit. Wonder of wonders; the

Vark gloves and wings were essentially the same shape and size (just have

to trim 1/4 inch of wingtip) as the Fencer's! The only changes needed to

adapt the injected gloves and wings to the C-A resin fuselage were to thin

the cross sections of both wings and gloves by about 1/16 inch on the ol'

sanding plate — the pivot pins/bosses also had to be trimmed--and to saw

off a small aft portion of the Vark glove to match the Fencer planform. I

even planned to adapt the interlocking Academy "gears" so that the

wingsweep would be synchronized. To pull off this synchronizing trick and

provide clearance for the gears required some delicate, yet

industrial-strength Dremmeling of the inside top half of the fuselage--we

Vark troops call it the "over-the-wing fairing." And, we haven't even

mentioned the rescribing of all the F-111 parts to match zee Russkiy

panels or adding the irregularly shaped pivot pin covers which stand

proud of the upper and lower glove surface! Although all the milling of

the fuselage top has made it very thin for such a large section, there's

a relatively thick, wide resin spine that laminates right over the

thinned area. Mebbe it's a lotta practice bleeding, but since Bondo's an

old Vark 'crew dog,' he really cared that the wingsweep appear realistic.

An added advantage of this route would have been lightness and increased

rigidity of the injected wing/glove halves. But it wasn’t to be. After

actually creating both wings, I rethought the whole deal and opted,

instead, to work with the labor-intensive Collect-Aire wings.

Plan B

The solid resin

Collect-Aire gloves were carefully sliced into upper and lower halves with

a razor saw, and a filler sheet of plastic sandwiched in between. The

outer mating surface of each glove was painstakingly Dremmeled so that the

outer wings would nest inside, with only a thin layer of resin covering

the joint….just like the real thing. Rather than have the wings full

forward, the wingsweep was set at forty-five degrees, which lends an

offsetting sleekness to the boxiness of the “Suitcase’s” fuselage.

Included wing

fences are of the square-edge profile, seen only on the cammo’ed MK, or

export, version (Iran, Iraq, etc.). To make proper -24M fences, the

forward and aft fence top corners were rounded off and the whole fence

tapered to a relative knife edge at the top. The fit of these fences with

the wing was not good, so putty and some very careful sanding were

required to blend in to the wing leading edge.

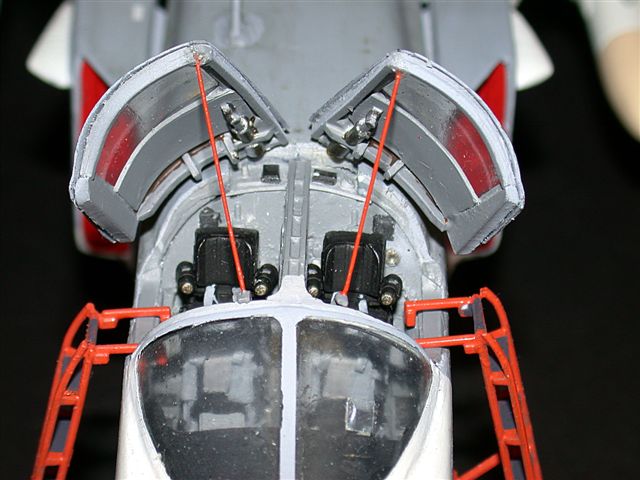

Cockpit and Canopies

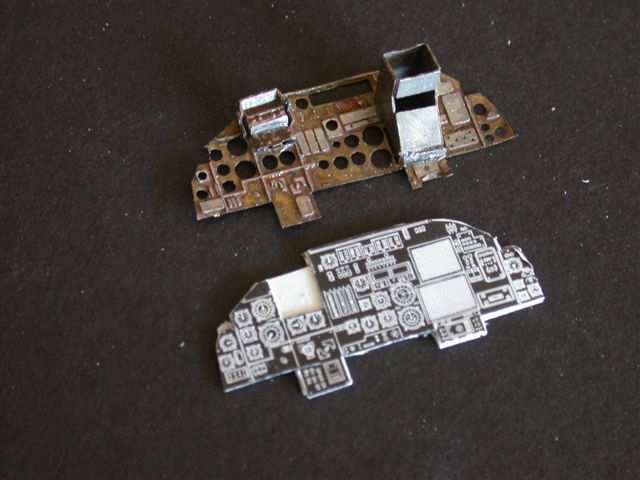

Most of the Collect-Aire photoetch panels were used, with some added

sidewall boxes. No throttles were included, so they were scratchbuilt, as

was a right console radar tracking handle. A thin piece of clear plastic

sheet was sandwiched between the PE instrument panel and the included

printed instruments. These instruments, although helpful, are way removed

from Eduard’s latest and greatest. Each kit instrument was printed with a

hokey white ring which I inked over with a fine Koh-i-Noor pen.

Although the Collect-Aire KM-36 seats are not bad, I substiututed KMC ones

which are much “busier” and have very nice harnesses, etc. molded in. An

avionics shelf under the canopy raising mechanism was scratchbuilt, as was

the top of the longitudinal cockpit divider “wall”. The aft edge of the

windscreen was thickened for realism with plastic strip, and another strip

was glued down the inside of the center divider.

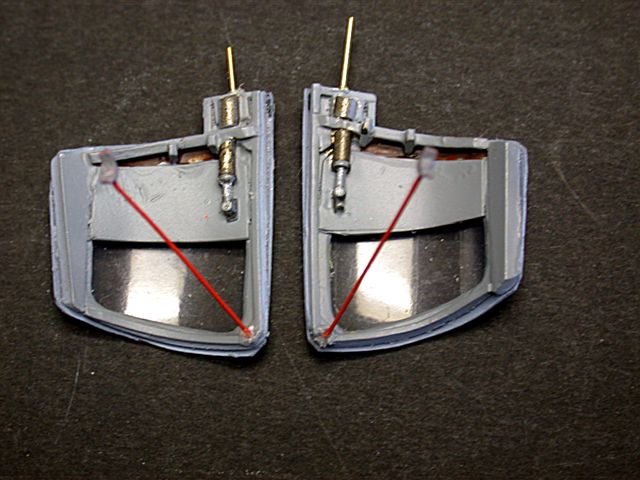

In the interest

of even more cockpit busi-ness, I elected to pose the unique split

canopies open in their flower petal configuration. This required

significant thickening of those thin, vacuformed pieces. I used the spare

canopy set as a female mold for two laminations of plastic sheet. Window

cutouts and scratchbuilt interior surface detailing.

Fuselage

Now is where fit

problems really surface. The radome aft cross section was fully 1/32” too

large as compared to the mating cross section of the forward fuselage.

Instead of industrial strength grinding and sanding of the radome, or

significant puttying of the forward fuselage, I chose to cut (razor saw)

deep vertical and horizontal kerfs in the radome, then gluing and clamping

down to squeeze the part in both dimensions; it works! The bottom area of

the separate afterburner empennage casting is oversize, also, and this

time I chose to grind it down to mate with the aft fuselage. The long,

flat resin fuselage “spine” didn’t mate properly (too low) with the

forward fuselage section, so I (again) sandwiched in plastic sheet for the

whole length of the spine, all the way aft under the vertical fin.

Afterburner

assemblies from the Academy Flanker were substituted for the simple, much

too shallow kit ones, and the divider area between the burner cans, absent

in the kit, was scratchbuilt. For balance, model railroad lead sheet was

rolled and then glued into the forward fuselage; sure glad the landing

gear is cast metal!

The kit didn’t

seem to allow for the distinctive anhedral of the wings, and the

wing/fuselage joint seemed under designed for those relatively heavy

parts, so I custom-bent a 1/8” diameter brass rod and glued it (somewhat

like the modeler’s version of a “carry-through box” ) to the inside of the

fuselage top or, as we in the Vark community call it, the “over-wing

fairing.” The laborious sanding required by ill-fitting parts naturally

obliterated much delicate scribing, and lotsa rescribing was required to

duplicate the complex lines. 3/32” brass rod was also run through the

empennage to create a strong mounting point for the large, movable slabs.

Gear wells were

devoid of any detail, so both maingear ones were lined with ribbed plastic

sheet. The nosegear well is too small for any detail to be seen. And,

while I’m at it, the PE maingear doors are much too thin to be realistic,

so an outer panel was made from plastic sheet and laminated to the PE.

Thicker, scratchbuilt plastic ventral strakes were also substituted for

the kit PE ones.

The PE seals, or

fairings, into which the wing trailing edges slide when they’re swept aft

were too small and difficult to integrate with the fuselage. I

scratchbuilt new ones using very thin (.005”) sheet which could actually

be pressed in to duplicate the softness of the real thing. BTW, in the

Vark these flexible fairings are actually inflated to properly seal the

wing/fuselage interface.

Ancillary Fuselage

Parts

There were many,

many tiny resin and metal detail blisters, cooling air intakes, ECM

antennas, pylon components, etc., all in small unmarked plastic baggies,

with no numerical references in the exploded parts diagrams. To really

make things worse, my kit was missing a significant number of 'em. Lou

Maglio, the Collect-Aire honcho, quickly sent me the missing parts, with

the exception of two. Because of time constraints the still-missing ones

were duplicated in resin using the other, present, item of each pair as

masters. The large sweptback antenna on top the fuselage, just aft of the

cockpit, was scratchbuilt.

Weapons

I chose to use

the included AS-11 "Kilter" and AS-14 "Kedge" missiles. The included PE

fins and pylon sway braces add to the detail, but it's my opinion that the

PE weapon fins are actually too thin. I used thicker plastic sheet

instead. The “TV” nose of the “Kedge” was created by using kitbashed

fronts of 1/32 Mavericks from the Trumpeter A-10. The “Kilters’ are

carried on the inboard pylons, but the fins wouldn’t clear the wing under

surfaces, so I added a missile launch pylon from the Monogram F-18.

The included PE

weapon sway braces—adding homebuilt jackscrews would’ve been very

laborious--were replaced by more realistic, three-dimensional ones from

the Monogram E-6B kit. More Monogram sway braces were added to the three

empty under-fuselage pylons. The outer pylons/missiles are anchored to the

wing with brass rod and are removable; same, same with the inboard

missiles, although the fence/pylon assemblies are permanently affixed to

each wing.

Painting,

Markings and Weathering

|

Finish

After much filling

(Blue Acryl) and many primering/wet sanding iterations, all leading edges

and airframe bottom surfaces were shot with multiple coats of PollyScale

Reefer White. Then appropriate areas were masked (luv that Tamiya tape!)

and slightly bluish PollyScale Haze Grey , lightened with Reefer White,

was applied with Bondo Industries’ new Tamiya gravity-feed airbrush.

Masking for the grey was almost as laborious as the above-mentioned resin

fit problems. The outer wing slats are hard masked, but the inner wing

leading edges, vertical fin leading edge, slab leading edges and fuselage

color divider line are “soft-edged.” This was achieved by lifting up the

outer edge of the tape with a knife edge and spraying over the upturned

tape edge. Next, PollyScale gloss clear was applied (at least two coats)

to provide a proper base for the extensive decaling that was to follow.

After the decalling, PollyScale clear flat was lightly applied. This stuff

dries almost instantly, so you don’t have to wait around to see if there

was enough flattening agent to do the job.

Decalling, Markings and Weathering

Collect-Aire

provides a very extensive sheet of markings and stencils. Strangely, the

included sheet appears to be almost an exact duplicate of the older

Cutting Edge offering that was ostensibly produced (years ago) to

accompany their advertised-but-never-released Fencer kit! Bondo went with

the Cutting Edge decals because of the known quality and opacity — he’s

had past troubles in this respect with thin Collect-Aire decals that don’t

underprint vivid colors with a layer of white. I’m confident in saying

that close to one hundred individual decals were laid on, and I spent at

least eight hours just on this task.

Tired of seeing

red Soviet stars, I was impressed with the unusual blue and yellow

national markings on Ukrainian Fencer Ds of the Nineties as seen in a

great World Airpower Journal feature (see references) and with the

weathering opportunities to duplicate the overall VERY dirty Ukraine

airframe exteriors. Apparently there was little financial room in the

post-Soviet breakup budget for wash racks. The multipiece Ukrainian

national roundels and vertical fin badge were taken from the nice Cutting

Edge Flanker sheet.

Weathering was

done with watercolors, and the dead flat PollyScale clear coat provided

the perfect base for the medium, just like watercolor paper! The

“adjusting” of watercolor intensity is, in my opinion, MUCH easier than

with oil washes. There’s no worry about solvent action with the underlying

finish, and, since much of the real airframe staining is done by flowing

liquids, the “staining” can be brushed out, or done over, any number of

times, and seems to these elderly eyes to be more realistic.

Auxiliary Ground Equipment

The thin canopy

braces were scratchbuilt, as were the intake and exhaust FOD covers. The

crew ladders are from old OEZ Su-7 kits and are the same generic design

used on the Fencer and other Evil Empire birds.

This was a

laborious but uplifting project for personnel of the Bondo Industries

Difficult Kits Division. The struggle defines what modeling is to me and

was well worth it.

Now that the

Fencer’s been rolled out, I look forward to the imminent release of same

by Trumpeter! J

I continue to appreciate (and buy!) the wonderfully eclectic Collect-Aire

releases.

1. World

Airpower Journal, Vol. 5, Spring 1991, and Vol. 39, Winter 1999. The

Fencer is the featured cover article in the latter volume and IMO the

primo pictorial reference.

2. Przegiad

Konstrukcji Lotniczych, “Su- 24”, by Jefim Gordon, 2/93, ISSN

1230-2953. This monograph includes a superior centerfold of removable

Fencer line drawings. Many closeup detail pics, some in color.

3. Russian

Falcons, Steven J. Zaloga, Concord Publications, Page 27-31. Nice

color pix.

4. Red Stars

Over Europe, Marcus Fulber, Concord Publications. Color pix (front

cover and pages 10-14). Excellent cockpit

Model, Images and Text Copyright © 2004

by Phil Brandt

Page Created 01 April, 2004

Last Updated

31 March, 2004

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search