|

Sukhoi Su-27

Flanker B

Zhuravlik

by Ingo Degenhardt

|

|

|

Sukhoi Su-27 Flanker B |

images

by Lutz Degenhardt

HyperScale is proudly supported by Squadron

I think this well-known heavy Russian fighter does not need any

detailed introduction.

About 400-500 Su-27 are believed to have been delivered to the

Russian Air Forces. Over the years severe financial problems reduced the

number of serviceable aircraft drastically and the others begin to show

their age – for example faded paint is a common sight and even bald

tires can be seen on some Flankers.

Of course it still forms the fighter backbone of Air Forces such as

Russia or the Ukraine. Foreign users include China, Vietnam, Ethiopia

and India. The Flanker’s impressive appearance is not only made up by

the aircraft’s sheer size but also by it’s elegant lines.

Quite a lot of aftermarket items were used on this model.

I started with the Cutting Edge cockpit tub that was sprayed

Xtracolor X629 Russian interior blue/green and was given some

drybrushing and the appropriate detail painting. To make it fit between

the upper and lower fuselage halves a good amount of material has to be

removed as well from the tub’s bottom as also from the inside of the

front wheel well. The CE cockpit fits nicely into the upper fuselage.

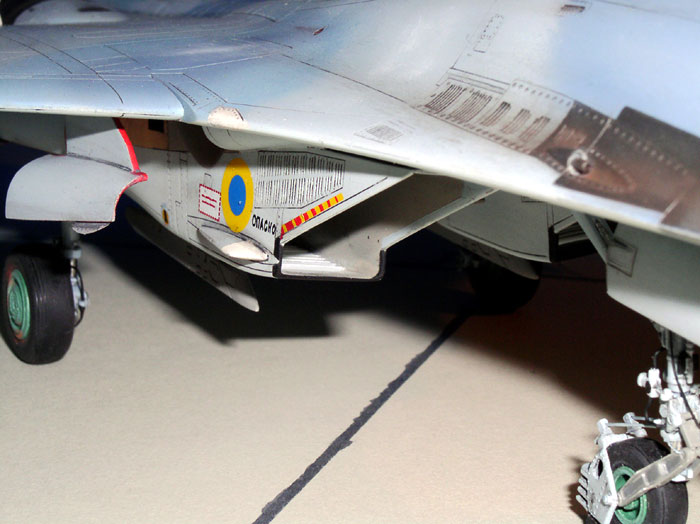

Next step was the correction of the main wheel wells on the lower

fuselage half. The top walls of the wells have a straight edge that

covers part of the wheel well so no wheel could retract into it. The

intake duct outsides have a correct rounded cutout and by simply

dry-fitting the intakes into place, this can be used as a template to

draw a line where the wall has to be cut out. Some filling and sanding

here becomes necessary later when the intakes are glued on.

Test fitting showed a very poor fit of the upper/lower fuselage

halves and the air intake ducts as well. Lots of work to be expected

here. I decided to start with the intakes by cementing their halves

together, filling the ejector pin marks on the inside and sanding them

smooth. They were now painted gloss light grey with the front edges in

light blue (underside colour).

The FOD-screens (etched metal, kit-contained) were fitted in the

raised position. The square opening in the bottom of the intakes

(auxiliary intake slots) were left open for now.

I thought it best to attach the intake ducts to the lower fuselage

half first and then to glue this assembly to the upper half of the

fuselage. The decision was right but it turned out to be hard work

anyway.

First I glued supporting styrene strips to the inside of the engine

trunks in order to force the intake ducts to align with them. Width of

the intakes was also mostly out of shape, so I inserted (not glued) rods

made from sprue and cut to the desired length in order to widen the

intakes where necessary. It took a while to make each intake fit as

desired, but finally I was satisfied and glued them on using

Cyanoacrylate. Only moderate finger pressure here and there was still

necessary. After everything had dried thoroughly, the sprue rods were

removed (using the ‘rear exit’, as the FOD-screens blocked the other

way). The styrene alignment strips then were carefully cut and/or broken

off, too. (an exciting moment) Fortunately the ducts stayed in place,

although with a remarkable tension in some places I think. The strips

had to be removed because they occupied the position where the

compressor front parts had to go. These were attached next, adding some

further strength to the whole assembly.

Next step were the fuselage halves – another challenge as their fit

is also only very poor.

Again, I used styrene strips on both parts to align the seams as good

as possible. Especially to the left and right of the engines and on the

forward fuselage. Cementing the big parts together was done in several

steps: tail boom first, then the rear section to the wing trailing

edges, the wings themselves, LERX and finally forward fuselage.

Attaching the radome completed the construction of the basic fuselage.

What followed was a lot of filling, sanding and rescribing until this

large ‘sub-assembly’ was ready for further construction. The ‘barn-door’

airbrake was fitted in the closed position and also sanded and it’s

outlines rescribed where necessary.

The two vertical fins each have a small air intake at the base of

their leading edges. On the model, both are of the same size and shape.

On the real thing, the intake on the right is apparently smaller than

the one on the left. So I cut off the moulded-on intake from the

assembled fin an made a new one from Tamiya epoxy putty – filed, filled,

sanded to shape and drilled out. The left intake was given a more

accurate rounded appearance both on the in- and outside.

After installing the vertical fins, wing flaps, ventral fins and a

few other parts the model was ready for painting.

As usual, the landing gear was build as sub-assemblies. These already

fine kit parts received some further detailing such as brake pipes,

electrical wiring and drilled-out landing lights with Krystal Klear-windows

over a silver inside. The struts supporting the front wheel’s debris

guard were replaced with thin wire and the rubber tires were treated

with fine wet&dry to remove the sidewall lettering, the rubber shine and

some of the tread to resemble rather old and worn tires.

Another sub-assembly were the tailplanes – originally designed to be

attached straight and level. These were modified a bit by cutting off a

small slice of plastic where they meet the ledge of the vertical fins,

so they could be attached in a trailing edge-down position, more likely

for a parked Flanker.

May be not so likely my choice to show the auxiliary intakes (bottom

of air intake ducts) in the open position. (venetian blind style) Eduard

provides the etched parts for this but it is a little bit tricky to

attach all the small metal strips to their diagonal slots in the parts

on the left and right side of the opening as they need to have the exact

length to fit in properly.

I choose to equip the Su-27 with the wing tip-mounted ‘Sorbytsia’ ECM-pods

included in CE’s cockpit detail set. Each one is made of two parts –

front and rear half. They look quite good but lack all detail. First I

reinforced the assembly of the two by drilling holes into each half and

inserting a piece of plastic rod as a bigger kind of location pin before

they were glued together, filled and sanded. Detailing included two

cable ducts (or what they are) on top and bottom of the pods, a mounting

rail for the wingtip and a thin square plate for the outside and forward

portion. On these the position lights are located – made from a tiny

elliptical drop of half-dried Krystal Klear painted Clear red and blue.

Work on the cockpit and the canopy, both pre- and post painting,

included the following:

The upper fuselage opening for the instrument panel had to be

enlarged to accommodate the CE instrument panel. It’s cover also comes

from CE. The attached cover gets in the way when trying to fit the

windshield, so the inside of the windshield frame was cut back

accordingly. Canopy and windshield both have prominent moulding seams on

top over their whole length. These were first scraped off with a sharp

knife, then sanded with 1200 wet&dry. The resulting blind areas were

polished using a chrome polish. For the finishing touch the clear parts

were dipped into Future and set aside to dry.

The rear parts of the cockpit behind the CE ejection seat come from

Neomega, while the cockpit sills, Canopy inner framing and lock-pins for

the canopy are Airwaves parts – as well as the various AOA-vanes,

odd-rod and crossbow antennas.

The only kit part in the cockpit is the control stick which I

considered being superior to the ones made by CE and Neomega, it only

needs to be shortened a bit at the base.

To complete the list of additional parts – the burner cans come from

CE too, very fine resin cans in the fully open position.

Painting

I prefer to use Xtracolor for my paintjobs and the Flanker is no

exception. X601, 602 & 603 provide the necessary colours for the

‘standard’ Flanker camouflage scheme. All these were lightened

considerably for spraying, but painting started with the areas around

the engines. I prepared them with a coat of Alclad II – Grey Primer &

Microfiller (ALC302) Very light sanding of this basecoat resulted in a

very smooth surface about to receive a thin coat of ALC 113 – Jet

Exhaust. In the photographs this whole area appears a bit darker than it

really is.

The burner cans (not yet attached) were treated the same way and

additionally their front half was sprayed with ALC104 – Pale Burnt

Metal. All the natural metal surfaces were then masked off using Tamiya

masking tape.

Next step was masking the already painted intake insides and the

cockpit. Then the model received a base coat with Humbrol No.1 – Gray

primer. This also was carefully sanded smooth.

Painting/masking sequence after that was as follows:

-

Humbrol Gloss White Radome, fin tips,

‘Sorbytsia’ tips (sub-assembly) and dielectric panel

on right vertical fin.

-

X602 Light blue Undersides, upper

surfaces camouflage pattern and ‘Sorbytsia’ bodies

-

X603 Blue/Grey Upper surfaces

camouflage pattern

-

X601 Medium Blue Upper surfaces

camouflage pattern

-

Humbrol Flat White Dielectric panels

on LERX, spine, fuselage and intake sides

-

Humbrol Gloss light Grey Front area

of main wheel wells

-

Humbrol 121 Rear part of main gear

wells and front wheel well

-

Model Master Titanium buffing

metalizer Gun blast area (polished)

-

Humbrol Gloss red Inside of wheel

well covers

Weathering

The three camouflage colours were given some spot painting and shaded

panel lines with the original (=darker) paint from their respective cans

to simulate some fading and re-painting. One panel was made as a

pre-painted ‘replacement part’ and so has a sharp edge to the

neighbouring colour. (‘Roof’ of left main gear wheel well)

With all the masking tape removed from the model and a few days drying

time in between, the aircraft received a wash with a heavily diluted

mixture of Flat black and Flat white = Dark grey.

Some oil and grease streaks from thinned black paint were also added.

A special treatment was given to the natural metal areas around the

engines. Streaks, Spots, discolouring and what else happens to these

surfaces were simulated by washes, drybrushing and brush painting in

different colours. The front half of the burner cans was lightly

oversprayed with Revell Metallic Blue.

Some further weathering was done after the decals were already

applied and the model got it’s final coat of Clear Flat. This additional

weathering was made using the powder of pastel chalks in various shades

from White, Tan, Dark and Red Brown to Black. Especially the gun blast

shield, the area behind and again the engine parts were treated with

these brushed on powders.

Decals

I had the HI-Decal Line sheet 48-003 for this model to make it the

‘Blue 06’ of the Ukrainian Air Force, sporting the ‘Eagle & Moon’

insignia.

This sheet also contains a good amount of stenciling data. I started

with the left fuselage side from front to rear (as usual).

I am always a little suspicious with flat decals like these and this

time they were a really bad surprise. I had just applied the first five

or six decals with the support of Microscale Set & Sol (as usual), when

I realised some heavy ‘silvering’ of the decals applied first that now

started to get dry.

I waited for a while and the same thing happened to all the decals

already on the model. There was no cure – the carrier film just would

not stick to the surface (remember: Xtracolor – paints are gloss) These

decals would certainly ruin the model, so I removed them all. I decided

not to use single decal from this sheet and instead ordered Cutting Edge

CED 48-011 as a replacement.

‘Blue 06’ – an aircraft belonging to a Ukrainian Air Defence Regiment

based on the Crimea was also part of this sheet and it was my choice

again.

By the way there are some differences between HI-Decal’s and CE’s

version of the markings for this Su-27. For example, HI-Decal has only

got one ‘Eagle & Moon’ for the left vertical fin, round style Ukrainian

markings for the fins and no roundels for the air intake sides – all

contrary to the CE sheet. I relied on the latter – of course.

Unfortunately, CED 48-011 includes no stencils at all and so I had to

confine myself to the kit-supplied stencils, which are not so very

numerous. Even the air intake warnings had to be painted in this case as

Academy’s choice for markings has the large shark/sharkmouth-decal that

covers the intake sides.

Anyway, the CE decals were a pleasure to work with – very nice.

When the decals all had dried, I wiped off the excess glue and

checked all markings for any silvering, of which there was only very

little. This was dealt with in the usual way by piercing the tiny air

bubble with a needle and putting a small drop of Sol on top. But even

with those very few and minor cases of silvering I contrived to overlook

(as always) one or two to be discovered after the model had already got

it’s final Clear coat of Humbrol Matt Kote.

Afterwards all the remaining sub-assemblies were attached, the cockpit

was completed and the last detail painting was done. Among the last

things I attached were the static dischargers on outer wings, tailplanes

and rudders as well as the metal ‘band’ that runs across the IRST. This

was made from lead foil.

This model has it’s difficulties, especially regarding the poor fit of

the fuselage/intake assembly. But it was fun to build in general and

particularly with all the variety of detail sets used as a mixture.

They were:

-

Eduard 48-150

-

Cutting Edge CEC 48060

-

Cutting Edge CEC 48061

-

Airwaves AC48074

-

Neomega C2

-

Cutting Edge CED 48-011

I had this kit on the shelf for quite a long time, hence this

‘collection’ of additional detail sets. (There is enough left for a

second Flanker).

I did not yet decide about the kit’s missiles. I do not like them

that much. So this Flanker has solely to rely on it’s GSh-301 30mm gun

so far. But there is a detail set for the missiles, isn’t there...?

Sources

and Acknowledgements

|

Model and Text Copyright © 2004 by

Ingo Degenhardt

Images Copyright © 2004 by Lutz Degenhardt

Page Created 25 April, 2004

Last Updated

15 September, 2004

Back to

HyperScale Main Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search