|

A-Model's 1/72 scale

Tuploev Tu-128

Fiddler

by Jim Rotramel

|

|

|

Tuploev Tu-128 Fiddler |

HyperScale is proudly supported by Squadron

Well, Sports fans, somebody has to go first, and I just couldn’t resist

taking on A-Models Fiddler kit. Hopefully, what I learned will help your

build go a bit smoother. I would put the “ease” of building this monster

somewhere between the Testors B-2 and a Mach II kit (Yikes!).

Remember kids, this is a

limited run kit (and a very ambitious one at that!). I’m NOT

complaining, just letting you know that if you demand Tamiyagawa fit,

you’re going to be severely disappointed!

I never dreamed I would have an opportunity to build this Cold War

interceptor, and am overjoyed that this kit is as good as it is.

First Impressions This was

an enormous aircraft—a fighter as big as a B-58 Hustler! I suppose it’s

because of the limitations of the A-Model molding equipment, but the kit

has many more pieces than you would expect from Monogram or Hasegawa. For

instance, the nose wheel well has separate pieces for the top and each

side, each exhaust has five pieces, each main gear bogie has 17 pieces

(!), etc. There is a fair amount of flash, especially around the smaller

parts, but nothing unmanageable. I’m going to generally follow the

instruction sheet sequence in this review.

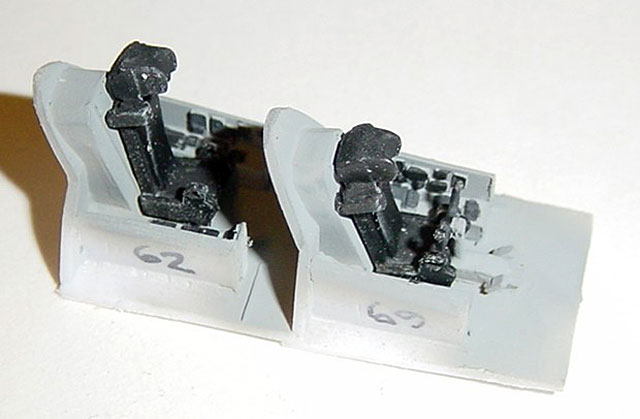

Cockpit (Steps 1, 2, & 4)

The cockpits are nicely detailed for 1/72, but unless you plan on cutting

apart the single piece canopy to open the them, virtually none of it will

be visible once the kit is built. I did note that parts 68 and 69 (the

front cockpit sidewalls) are reversed on the instruction sheet. Other

nits: 1) The ejection seats are too narrow. 2) The control yoke (part 73)

on mine had been pulled from the mold too quickly and was slightly

deformed. 3) The rudder pedals/control column base (part 72), if assembled

using its locating pin, will be off-center (just delete the locating pin)

and you’ll probably want to drill a hole in its top to insert the control

column into.

Aside from the nits, it all fit together well and the assembly fits well

into the top front fuselage (part 104). To prevent sanding dust from

creeping into the cockpit after the canopy was installed, I cut a 17mm

diameter half disk to close off the front of the interior and sealed the

whole cockpit assembly into the fuselage with a seam of superglue along

the edges.

Landing Gear (Steps 3 & 9)

As you can see from the photos, I built my Fiddler “gear up” (as I do all

1/72nd kits), but here are some observations. As previously mentioned,

there are a LOT of parts to the landing gear assemblies and the very

delicate parts have a fair amount of flash on them, so cleaning up for

assembly will require some care. Overall, I think you can build this “gear

down” without undue difficulty. The one thing you’ll want to change is the

nose gear installation. It is designed to be installed in the nose well

and then into the fuselage nose section as it is assembled. If you’re half

the ham-fist I am, this WILL be broken during subsequent assembly!

Exhaust Nozzles (Step 5)

This

was the most curious part of the kit for me. While the rest of the kit

seems accurate, the nozzles don’t resemble ANY of the photographs I have

of the Fiddler. (BTW, Linden Hill has some very helpful photos on their

web-site.) My first hint came when I tried to assemble parts 27 and 31,

found they had the same diameter and asked, “Why did they do that?” Then I

began looking at photos and discovered that what was in the kit bore

absolutely no resemblance to the real thing. What I ended up doing (and

this is much easier than it sounds) is making my own. I bought 1/2” and

5/8” diameter brass tubing; cut two 3/4” segments of the former and two

1/16” segments of the latter using my trusty Dremel with its Emery wheel

attachment (AND eye protection!). I then superglued strips of plasticard

on the outside of the long tubes, fit the rings over those assemblies

about one width back, then cut off the short part of the strips at the

exhaust end of the nozzle and glued on the kit’s turbine faces. It only

took about an hour to do both and I think they look pretty good (at least

they look something like the real thing!). This

was the most curious part of the kit for me. While the rest of the kit

seems accurate, the nozzles don’t resemble ANY of the photographs I have

of the Fiddler. (BTW, Linden Hill has some very helpful photos on their

web-site.) My first hint came when I tried to assemble parts 27 and 31,

found they had the same diameter and asked, “Why did they do that?” Then I

began looking at photos and discovered that what was in the kit bore

absolutely no resemblance to the real thing. What I ended up doing (and

this is much easier than it sounds) is making my own. I bought 1/2” and

5/8” diameter brass tubing; cut two 3/4” segments of the former and two

1/16” segments of the latter using my trusty Dremel with its Emery wheel

attachment (AND eye protection!). I then superglued strips of plasticard

on the outside of the long tubes, fit the rings over those assemblies

about one width back, then cut off the short part of the strips at the

exhaust end of the nozzle and glued on the kit’s turbine faces. It only

took about an hour to do both and I think they look pretty good (at least

they look something like the real thing!).

Wings (Steps 6 & 7 & 12)

What is it with kit manufactures these days? They seem obsessed with

individual control surfaces. I remember them going through that phase back

in the 1960s and thought they had outgrown it. I guess everything old is

new again. I would be happy with thin trailing edges—but things are what

they are.

You need to remember to install the carry-through box (part 21) between

the right wing upper and lower halves (parts 6 & 17) and then assemble the

left wing upper and lower halves (parts 7 & 16) around it to form the

complete wing. I found that the end of the lower wing halves needed to be

thinned a bit to eliminate a “step” between the upper and lower parts. One

thing that annoyed me was that while they provided separate flaps, there

was no indication of how to pose them in a lowered position (if desired).

Also, they don’t fit very well. The instructions show the flaps (parts 8 &

12) and ailerons (parts 9 & 13) being installed from behind the

wings—you’ll actually be fitting them from the top or bottom as that is

the only way the hinges and slots align. The inboard flaps won’t fit

without some thinning of their forward bottom “tongues”. Also, on one

side, the bullet hinge fairing on my kit’s lower wing could have used some

filing on the side that is hidden after assembly to improve the fit of its

inboard flap. On the right side, I found it necessary to add a thin strip

of plasticard to the landing gear pod’s inboard flap fairing to eliminate

a gap when the flap was fitted. The other side fit fine.

I added the wheel pods here and was glad I did. These are the poorest

fitting parts of the kit. They are too narrow at the rear and require

substantial filling on both sides. If I was building it “gear down”, I

would have assembled the landing gear making sure they fit into the

locating holes on the top wing (Parts 6 & 7), then glued the lower pod

pieces to the wing and after all the filling and sanding was finished,

insert the gear later.

Fuselage I (Steps 4, 8 & 10)

Before assembling the upper and lower front fuselages, you’re instructed

to drill out holes for the landing lights (parts 109). The clear pieces

themselves are physically small, difficult to make round because of flash,

and too large in scale. I took a “that looks about right” (TLAR) approach,

drilling out holes that looked about the right size, gluing the clear

pieces on the inside, inserting small rhinestones into the holes from the

outside, filling them with superglue or clear epoxy, and later sanding

them flush.

On my kit, the top front fuselage half was slightly wider than the bottom

half. The bottom half has a tongue at the back to “help” when fitting it

to the lower back fuselage (Part 1) and wing assembly. If used, it will

prevent the lower front and back halves from mating flush. I cut mine off.

What you WILL want to do is cut a 1 x 3/4” piece of THICK plasticard and

insert it the 1-inch dimension between the top and bottom front fuselage

halves from the back to spread them so they will mate flush with the

assembled aft fuselage.

I left the radome off until the rest of the fuselage/wing assembly was

completed.

Fit the wing to the aft fuselage. I trimmed the fuselage fillets for the

inboard flaps, which were about 1/8 inch too long, but in retrospect, this

may not have been the best thing to do. What you might want to think about

before you glue the wing and lower fuselage together is trimming the

fillets so that theystart flush with the fuselage and fair smoothly into

the flap trailing edge.

I next glued the front fuselage assembly to the bottom aft fuselage (Part

1) and wing assembly. Once satisfied with the alignment, I set that

assembly aside to dry and harden overnight.

Inlet Ducts (Step 10)

The

inlet spikes (parts 29 & 30) don’t fit cleanly to the fuselage, but be

careful when filling and sanding the resulting gaps as the flat inlet ramp

is very thin and can inadvertently be sanded in the process. The inlet

ducts (parts 18 & 19) and compressor faces (parts 22) should be assembled

as a unit and allowed to dry before you start to manhandle them. Before

installing them, grind away the exposed lip around the edge of the

compressor faces. The assembly then fits (sort of) to the front fuselage,

but filling and sanding along the entire inlet assembly will be required

to make these suckers seamless! Lacking definitive information on what

color the Fiddler intake ducts were, I looked at available photos of other

Soviet aircraft from that era and ended up making a mix of Metalizer Burnt

Metal and Brass. In any event, by the time everything is assembled, very

little of the ducts will be visible. I wasted a lot of time on this. My

recommendation is to forget about in inlet ducts as they are difficult to

see even with a flashlight after the model is assembled and save the

compressor faces for some other project.

Fuselage II (Step 10)

To

get the top rear fuselage (Part 2) to fit over the compressor faces will

require cutting a notch in each side to compensate for the thickness of

the plastic. (See my final comment in the previous paragraph). Women and

young children should be cleared from earshot while you fit the top rear

fuselage to the front fuselage/wing/lower fuselage assembly! In the end I

had to trim a bit (1/2 mm or so) from the back of the top front fuselage

(Part 104) to get it to mate with the front of the top rear fuselage (Part

2). While most of the fuselage/wing assembly lined up pretty well, the aft

vertical tab of the right wing stuck out so far that I had to carve it

down before it fit well enough to even begin to think about sanding the

rest of the panel lines off the sides of the fuselage! As you can see,

quite a bit of filling and sanding was required to eliminate the seams

between the parts.

Inlets (Step 10)

Once I

had the fuselage/wing assembly all glued together, I felt I was over the

hump and it would all be downhill from there on. Wrong. Then I added the

inlets (Parts 32 & 33). The one on the right side fit fine. The inlets

mate to the flat part of the inlets (parts 29 & 30), all four fuselage

segments and fit around the upper and lower wing halves. The right one fit

fine. But the left one… In the end, I cut off the tongue that wrapped

around the wing root, added about 1/16 shim to fill the gap between the

inlet and upper wing and used plasticard and filler to take care of the

lower fairing of the inlet into the lower fuselage/wing. After all the

sweating and cursing was over, the inlets looked acceptable, but not quite

symmetrical as to the mating of the upper inlet to the top fuselage. As

noted above, I wasted a lot of time working on the inlet ducting. My

recommendation to you is to basically forget the ducts. Assemble the

inlets (Parts 29/33 and 30/32) and then fit them to the fuselage/wing

assembly, concentrating on the fit between the inlets and front fuselage.

This may not work any better than what I did, but it might.

Tail Plane (Step 11)

Not

much to report here, except that for my money Parts 42 & 35 are the left

tail and 43 & 35 are the right tail, opposite of what is on the

instructions, unless they were designed to produce negative lift. Both

parts 42 & 43 have a somewhat irregular “wavy” shape on one side that

required more filling and sanding, as you can see from the Mr. Surfacer

stains on the accompanying photos. Also, the front rod on the tailplanes

will need to be trimmed way back to make them fit.

Nose Radome (Step 4)

I

delayed adding the radome, but there is no reason you really need to. I

was disappointed to discover that there is a small, but significant step

between the radome and fuselage. I used several applications of Mr.

Surfacer (as you can see from the photos) to overcome this. I probably

should have used a layer of putty first.

Missile Pylons (Step 13)

I

glued all the pylon pieces together before attaching them to the wing. The

outboard pylon/wing fence assemblies (Parts 36 & 37) fit well (finally,

something that did!) with only a little putty required at the leading edge

of the wing. However, the inboard pylons, which are “supposed” to fair

into the front of the landing gear pods, don’t. Quite a bit of grinding

off and test fitting was required to get everything to finally go together

correctly.

Clean Up

I started out

with 150 grit for major shaping, worked down to 600 to get things smoothed

out, finishing up with sanding pads, working down to 12,000 grit.

Then I primed the airframe with Halford’s primer, found a couple of spots

that needed a little more work and then worked from 600 back down to 12,

000 grit one final time.

Missiles (Step 13)

The

AA-5 “Ash” missiles have single piece bodies (Parts 98 & 99), which I

liked. What I wasn’t so keen on was that the separate wings (Parts 101)

weren’t quite as long as the ones molded into the bodies and that the

separate tail fins were of a different size not only from one another but

also the ones molded onto the bodies. Furthermore, they chose to attach

these small pieces to the sprue at the leading edge, so they ended up

being much thicker than they should have been! If you’re feeling really

industrious, you might want to cut your own tail fins out of plasticard.

(If Eduard does a photoetch set for this kit, they might want to think

about including the missile tail fins...) One other thing, the

instructions for locating the decals of what I believe are the proximity

fuzes are completely wrong. On the top and bottom of both missiles an

antenna “stripe” should be located between each set of wings with the

front of the decal about 1 mm behind the front point of the wing. On

either side of the missile, the fuze “stripe” should be in front of the

point of the wing. Also, the front portion of each wing even with the top

and bottom fuze stripes appears to be black (leaving a small (about 1mm

long) white triangle at the front of the wing). Finally, the conical

radome of the radar-guided variants appears to be a dirty white or light

gray.

I finished the model using Alcad II Aluminum and Dark Aluminum and a wash

using Heavenly Hues to bring out some of the surviving panel lines (there

were a few!). The kit decals are nothing to write home about. First off,

they are flat, not good for a natural metal aircraft, so they have to be

gloss-coated. Also, the national insignia are surprisingly bad,

considering that the kit comes from part of the former USSR, being both

too large and with too big of white surround of the stars.

What I found to match up well with both available photos and the kit

instructions (!) were stars from the spare box that were 14 mm from

tip-to-tip. The kit instructions call for the Radome to be dark gray, but

the available photos I’ve found show it to be medium gray (I ended up

using Humbrol 164, which is BS 381C: 638 or 26173).

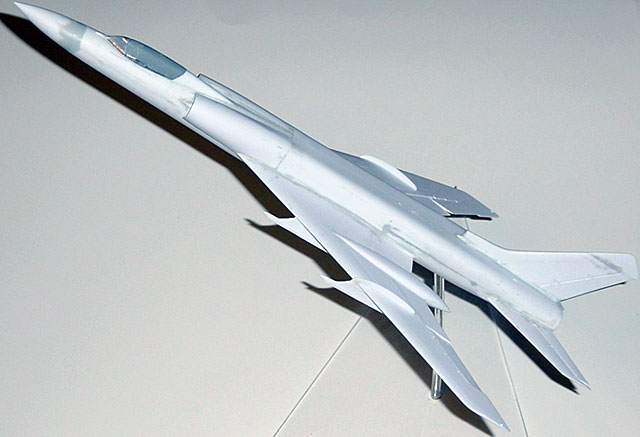

And this is what I do to relax?! Seriously, this may sound like a lot of

carping, but we aren’t likely to see a kit of this aircraft from Tamiya

anytime soon and I am tickled to have one in my collection. It looks like

a Fiddler (I’m not a micrometer kind of guy so will leave that to others)

and despite some obvious shortcomings, makes into a most impressive model.

Now, if A-Model will only do an accurate 1/72 T-22 Backfire C to replace

that clunky old ESCI kit...

Click the thumbnails below to view larger

images:

Model, Images and Text

Copyright © 2004 by

Jim Rotramel

Page Created 11 April, 2004

Last Updated

10 April, 2004

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search