|

Building the 1/72

Amodel Tu-160

"Dealin' Blackjack"

by "Bondo" Phil Brandt

|

|

|

Tupolev Tu-160 Blackjack |

HyperScale is proudly supported by Squadron

Background

At first glance, the

Tupolev Tu-160 “Blackjack” and Rockwell B-1"Bone” would seem to have

strikingly similar outlines. Moreover, the longstanding Soviet reverse

engineering of Western aviation technology certainly lends credence to

such a line of reasoning. Noted Russian aviation author, Yefim Gordon,

argues that, given the requirements and role of these two weapon

systems, it entirely believable that the basic configuration of both

might turn out independently to strongly resemble each other.

The “Bone” long suffered financial indignities of developmental

penny-pinching, actually dying on President Jimmy Carter’s watch, only

to be given CPR and revived by the Reagan administration. Conversely,

according to Gordon, the Blackjack program basked in the financial

largesse of an aggressively managed Soviet defense community, developing

into a much larger, significantly more powerful, faster, longer-ranging,

more weapon-diverse, bird.

With the breakup of the Soviet Union serious money problems did

eventually catch up with the Blackjack fleet; today’s aircraft are not

maintained at desirable standards, and aircrews are hard-pressed to stay

current, especially with regards to air refueling. Meanwhile, the B-1

fleet is very busily operating in the Middle East conflict.

The Kit

Per my earlier review in

Hyperscale, the Amodel “elves” in the Ukraine have excelled in taking

the lead in limited production, mixed media kitting of large Soviet

aircraft. That is, main airframe components (fuselages, wings and,

sometimes, tails) are done in hand-laid epoxy glass, while the remaining

components are in injected plastic. In theory this is a clever solution

to ease construction. In practice, however, meshing the two mediums is

not a walk in the park, by any means, and requires the obligatory use of

CA glue. Further, the nature of laying up and impregnating fiberglass

layers invites ill fitting joints between plastic and glass. Plus, the

cast-in engraving of the epoxy-glass sections is on the aggressive side,

and often has discontinuities in the depth of panel lines, a

characteristic difficult to fix.

So, there I was with a 50% complete, righteous-buck ($205) Blackjack

when the significantly lower priced Trumpeter Tu-160 hit the market

about a year later. The execution quality of the all-injected CHICOM

release simply blows away the earlier Amodel. Although this curmudgeon

is on record as frequently bowing to the forward march of model

production science, willingly trashing a started kit when an obviously

superior release of same hits the street, $205 was a strong inducement

to “dance with the one that brung ya”, and I pressed on, even though

also buying the new Trumpeter kit.

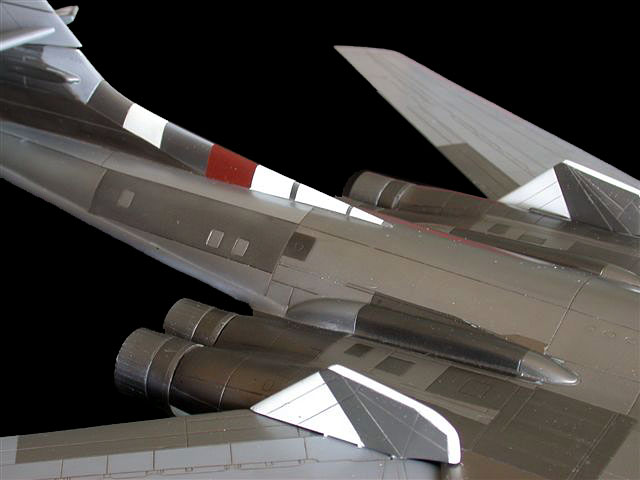

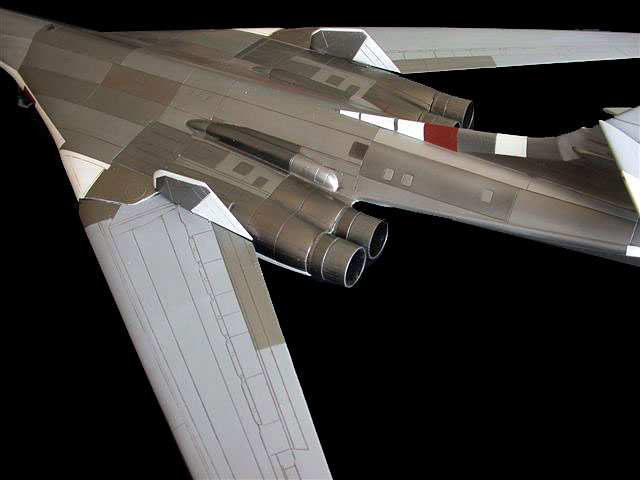

The relative roughness of

the Amodel kit needed a color scheme which would help to camouflage the

many surface discrepancies, and I didn’t feel that solid white, as the

operational fleet is painted, was it. While reading the Yefim Gordon

book (“Tupolev Tu-160 Blackjack”, Red Star Vol. 9, Midland Publishing) I

was struck by the series of color pix showing “29 Grey”, a

pre-production demo bird, in flight and on the ground at a Russian air

show. The entire airframe surface is a crazy-quilt of dirty, variegated

metal panels, white fiberglass/composite fairings, gray wings and

vertical fin. Perfect! And, since the Amodel kit had no flap/slat

options, I’d do it with wings fully swept, leaving the Trumpeter kit to

be finished in all-over operational white, wings full forward, slats and

flaps deployed.

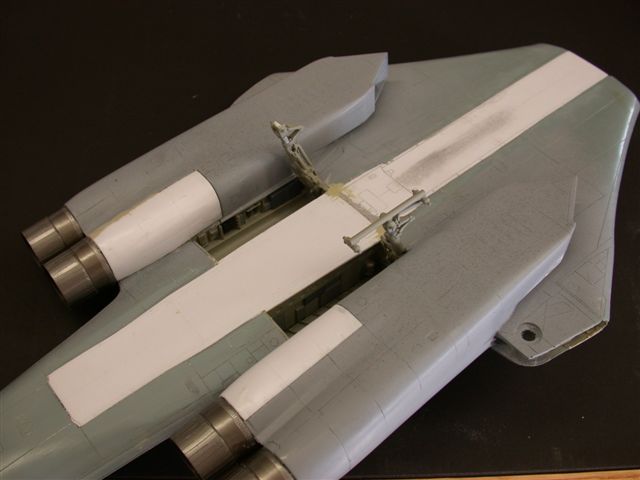

When doing an Amodel kit,

one has to expect many fit problems and soft plastic, and this builder

was not disappointed. Then there’s the razor sawing removal of the thin

epoxy glass covering of the wheel wells, etc. and the Dremmeling of

epoxy glass join areas to accept the injected components in reasonable

fashion; lotsa fun, but just another day at the Bondo Industries

Difficult Kit Division office! The multipiece injected maingear wells

were especially difficult to assemble in such a manner as to fit into

the rock hard fuselage. And, we won’t even talk about the surgery that

was required to install the ill-fitting wing pivots late in the game,

after everything had been painted...

Click the

thumbnails below to view larger images:

The gear struts are also

multipiece, complex units, but both struts sweep aft; their strength and

mounting scheme leaves something to be desired. After finally resting

the completed airframe on its gear, both main units folded in about

thirty minutes and had to be completely cleaned off and remounted with

copious CA and Zap. With the wings full aft and the large flying

surfaces installed, the model was very tail heavy. I dropped numerous

pieces of lead sinkers into the laser window just aft of the radome

following with drops of CA to fuse the stuff together.

You’ll note that the aft aircrew ejection seat blow-away hatches–the

four aircrew members enter the bird from underneath the fuselage, behind

the nose gear–have been cut out to allow viewing the interior. Openings

for two small aircrew windows on the forward fuselage sides were marked

by Amodel, but it’s up to the modeler to cut ‘em out and fit injected

clear panes.

The engine pods/compressor faces also were not easy, and required much

filling and sanding. OK, OK, don’t hit me again, I’ll level with ya;

EVERYTHING needed filling and sanding!

Because a significant amount of oil-based wash would be used to simulate

the considerable grime covering the real thing, I used lacquer products

exclusively: Alclad II, of course, in at least five shades (some custom

mixed), and gray and white Tamiya primer in spraycans. The pigment of

these great lacquer primers is so fine and the spray pattern so even

that often no sanding is required. I wet sanded anyhow, up through 8000

grit (MicroMesh), and the semi-gloss Tamiya took on a pure gloss.

The same Tamiya primers

were used as topcoats for the wings, vertical fin, slabs, engine pods

and simulated composite structures.

There were some bonding

problems (masking media lifted all paint coats) between the Alclad/primer/epoxy

glass, but they were in very small, tight areas; the wet sanding hadn’t

reached into ‘em enough to create proper “tooth”. Decalling was a

no-brainer since Grey 29 sports only a single red star on each side of

the fin.

This modeler can now

afford to look back with gladness and relief that I stuck with this beeg,

trying sucker, and I still look forward to future innovations and daring

subjects tackled by the Ukrainians.

In any event, the Amodel

folks are usually the first–-often the only ones--to market these

“Amonster” subjects, and, therefore, usually sell out their limited,

albeit less-refined runs before Trumpeter hits the streets with

significantly improved, all-injected versions. It’s the old

“one-in-the-hand-equals two.....” gamble; sometimes this curmudgeon is

lucky and, well, you get the picture.....

Click the

thumbnails below to view larger images:

Model, Images and Text Copyright ©

2006 by Phil Brandt

Page Created 17 May, 2006

Last Updated

16 May, 2006

Back to

HyperScale Main Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search