|

This is part two of a three part posting on my U-2S

"Senior Span/Spur" project. It has only taken two years

to get to this point. Sorry for the delay...

In part one I discussed a brief history of the U-2, a

description of the Testors / Italeri kits, and

the building of the fuselage on my U-2S model. In this

part I will discuss the completion of the fuselage,

construction of the wings, and attachment of the wings

to the fuselage.

Follow these links to get to the other parts of this

posting.

| |

Part

One: |

Aircraft History, Model Kit

Description, and Fuselage Interior Construction |

I left off in the last part with the fuselage having

just been assembled. That completed the work on the

inside of the fuselage. Now, there are lots of tings to

do on the outside of the fuselage.

Before installing the wheel bay unit into the

fuselage, I had cut the fuselage sides to open up the

engine intake areas. Into these openings, I could now

install the rear engine intake duct pieces. First, I

painted them following the instruction sheet directions.

The inner walls are colored with a color closely

resembling Israeli Pale Gray-Green (F.S.34242). I used

this color from the old Floquil Military Colors

line. Then, I gently pushed them into place inside the

engin eintake openings on either side of the fuselage.

The pieces are keyed to fit only one way. Scribing on

the pieces tells which piece goes on which side.

The fuselage update set completely replaces the

forward intake pieces in the kit with seamless one-piece

resin engine intakes. I painted the inside of the

intakes in the same Israeli Pale Gray-Green that I used

on the inner duct pieces, then I attached them to the

sides of the fuselage. They do not fit as well as I

would have hoped. Shrinkage in the resin causes htem to

be a bit small. I fixed this by applying a backing piece

of 0.015" sheet styrene on the sides that go against the

fuselage. This pushed the intake pieces out enough to

remove the step in the surface where the intakes meet

the fuselage.

When I constructed the the original intake master

pieces, I used the actual kit pieces as a starting

point. The result is that the new resin intake pieces

still have some of the original fit issues of the kit

pieces. I needed to fill voids on the top and bottom of

the pieces to achieve a flush surface with the fuselage.

I also needed to file down the mounting areas on the

fuselage sides because the intake pieces were too far

away from the fuselage (based on reference images).

The oil cooler louver details on the outside of the

intakes was another sticky point for me. My original

masters did not include these details. Considering the

nature of the louvers (being mostly flush), I considered

using a decal to represent them. As such, I only scribed

in the outline of the outer panel. The master pattern

maker at Meteor decided to help me and cut in the

louvers with some high-tech router milling machine.

Unfortunately, this person did not consult enough

references to get the louvers right (IMHO). They are too

big, too deep, and look more like grills than louvers

(IMHO). They are vast improvements on the louvers molded

on the kit intake pieces to be sure, but I wanted to

tone them down for my model.

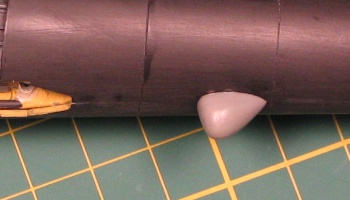

Corrected Intake Louver

|

I decided the only real way to do this was to start

over. I took a bunch of super glue and filled in the

louvers. Sanding this smooth, I re-scribed the panel

lines around the louvers. Next I measured and lightly

scribed the placement of the louvers and their

individual blades. Using a new X-Acto blade, I

scraped the lines so as to create the louver blades. It

took most of one night and a couple re-paintings with

primer to get to the point where I happier with the

louvers. The final version is seen in the picture to the

right contrasted with the louver as provided in the

Cutting Edge resin set.

My version of these

louvers is still not perfect. As they are hand carved,

there are some irregularities. They also are missing the

tabs on the louver blades that give the impression of

braces. But, I like my version better as they are much

less "in your face" on the finished model. When looking

at real U-2 aircraft, these louvers are mosty invisible

unless the lighting is just perfect to light up the

louver blades.

After working out the fit and permanently attaching

the intake pieces, I was very pleased with the view

looking in from the front of the engine intake. It is

not completely accurate (being a bit too shallow in

depth), but you would be hard pressed to see this on the

final model sitting on a display table.

Inner Engine Intake Pieces |

Outer Engine Intake Pieces |

View from the Front |

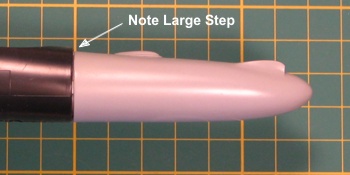

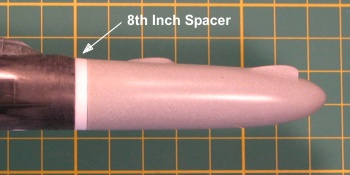

With the intakes

attached, I started test fitting the ASARS II nose.

There is a slight shrinkage when resin cures. To my

dismay, I found the nose was smaller in diameter than

the kit fuselage -- so much for expecting a "drop in

fit" with the nose. Rather than increasing the diameter

of the resin ASARS nose piece (which would have

necessitated some elaborate putty work to blend the

expansion into the rest of the nose), I chose to try to

reduce the diameter of the kit fuselage.

Helping me in this pursuit, I had someone in the UK

send me an e-mail telling me his ideas that the

Cutting Edge ASARS nose seemed to be too short based

on his investigations. I decided to take a much more

detailed look at the part using some side-view images to

measure the details of the nose. Bottom line, yes, the

nose is too short by somewhere between four and ten

scale inches. Also, the ADF fairing on the top is out of

place by a small amount and molded too large.

The ADF issues are hard to see without a tape

measure, so I ignored these, but the length of the nose

was noticeable to me, so I decided to fix it. I added a

1/8" adapter to the rear of the nose to lengthen it by a

scale six inches. This extention acted as an adapter and

gave me the chance to start to enlarge the nose diameter

to better meet the size of the kit fuselage. I then

filed down the forward 1/8" of the fuselage to reduce

its diameter to meet the size of the nose piece.

Fortuneately, the thickness of the fuselage pieces is

sufficient so as to allow this thinning without breaking

through.

Effectively, this process slightly decreased the

cross-section of the fuselage, nominally increased the

forward fuselage taper, and lengthened the nose, but it

made everything meet up without having to blend a lot of

putty on the nose itself. I glued the nose into place

and addressed the seams where it met the reduced

diameter fuselage. There are a couple small blisters on

each side of the fuselage just behind the nose joint

that seem to only be on ASARS equipped aircraft. I

whipped up the blister shapes using some strip styrene

and attached them in place.

The Fit of the ASARS Nose

Before Fixing It |

The Fit of the ASARS Nose

After Fixing It |

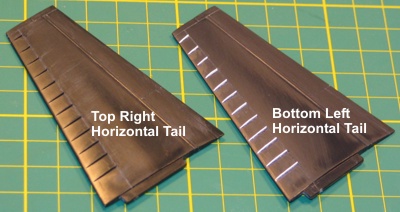

The Italeri

horizontal tails have some fine ribs molded onto the

upper leading edges. After some investigation, I found

these only pertain to early-built aircraft (serial

numbers 68-10329 thru 68-10340). The ribs are stiffeners

to solve a flutter issue when the super pods were added

to the wings. Later-built aircraft (serial numbers

80-1063 thru 80-1099), do not have these ribs. To solve

the flutter issue, the later airframes had the interior

structure beefed up when they were constructed.

If building a model of an early-built aircraft, leave

the kit-provided ribs on the tails. If building a model

of a later-built aircraft, remove the ribs. Here is the

problem, though -- the ribs should be on both the top

and bottom of the tails. The kit only has them on

the top.

Horizontal Tail Ribs

|

The original aircraft I saw at the Andrews AFB air show

was a later-built aircraft without the ribs on the

horizontal tails. However, I really liked the look of

the ribs on the kit tail and decided to change the tail

number on my model to be an early-built aircraft with

the ribs. This meant I had to scratch-build the ribs on

the lower sides of the tails. I did this with 0.010" by

0.030" strip styrene. I rough-cut the taper into the

strip, tacked it to the tail, chopped it to the right

length, and permanently glued the rib. My results are

show here to the right.

For any modelers

considereing whether they need these ribbed tails, for

what it is worth, I learned from looking over a U-2

aircraft attrition table that most all the early U-2R

airframes have been lost for one reason or another. Most

any U-2 seen today is a later-built aircraft that will

not have the reinforcing ribs on the horizontal tails.

All the ER-2 aircraft flown by NASA and the two-seat

U-2R/S aircraft are also later-built aircraft without

the ribs.

To help other modelers wanting ribbed horizontal

tails, I provided my modified tail pieces to Meteor

Productions. The recently released U-2 horizontal tails

correction set is made from my masters. I actually used

Cutting Edge pieces on my model, here, not

modified kit pieces.

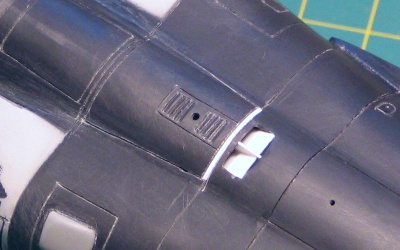

The vertical tail on the U-2 is sort-of unique,

especially in the way it handles trimming the aircraft.

Instead of (or in addition to?) standard trim tabs on

the horizontal tails, the entire unit formed by the

vertical and horizontal tails is one solid item that is

pivoted inside the fuselage to accomplish trimming the

aircraft. The thin white or silver line on the leading

lower vertical tail is one scuff zone for this unit when

it pivots.

Another scuff zone exists all along the lower edge of

the vertical tail where the tail slides in and out of

the rear fuselage. This scuff zone is black though,

instead of the white or silver found at the leading

edge, so it is easy to miss on a casual look, but it is

there. A glove fairing at the base of the rudder that

produces a small step in the surface is part of this

scuff area. I wanted to include this fairing on my model

and added it using some 0.010" sheet styrene.

Vertical Tail Scuff-Zone |

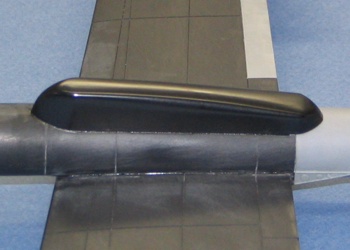

Senior Span/Spur Dorsal

Antenna Unit |

The next thing I worked

on was the bulbous Senior Span/Spur dorsal antenna.

Comparing the Cutting Edge pieces to the recent

Italeri U-2S pieces, I found I liked the

Italeri antenna pod better, but I preferred the

Cutting Edge antenna pylon. I cleaned up the

Cutting Edge antenna pylon pieces and attached the

piece for the large cooling intake found on the left

side of the antenna pylon. Then, I assembled the

Italeri antenna pod and hacked it off of its pylon.

After cleaning up the seams, I attached it to the

Cutting Edge antenna pylon. I attached the unit to

the fuselage with brass wire pins to make sure it was

secure.

Choosing to use the Cutting Edge dorsal

antenna pylon opened a can of worms for me. The pylon

has recessed scribing while the Italeri kit has

raised. I hate when all the components of a model do not

match on this detail. I toyed briefly with the thought

of adding raised scribing to the Cutting Edge

piece, but decided against it. Instead, I broke out my

scribing tools and rescribed the rest of the model to

match the recessed lines of the Cutting Edge

piece. Since the majority of the lines are just long

straight runs, this was not as difficult as it can be on

some other aircraft.

At this point, I was down to minor things on the

fusleage. I added mounting plates and drilled holes for

the anti-collision beacon lights that are provided in

the Cutting Edge fuselage update set. I would add

the lights after I was done painting.

Spine Exhaust Port

|

The kit has several molded-in louvers on the upper

fuselage. These are way over-done, represented as deep

depressions with some molded ribbing. I took a moment to

fill most of them in with super glue and sand them

smooth. The louvers molded over the wing roots are only

applicable to U-2R aircraft with the J75 engine. The

aircraft lost these louvers when they were upgraded to

the U-2S standard and received a TF118 engine. Since it

was a U-2S that I was building, I just filled these and

left them go.

The louver on the

aircraft spine, just ahead of the Senior Span/Spur

antenna pylon, is not a louver at all on the real

aircraft. It is an open exhaust vent for the hot air

exiting the air conditioning unit behind the cockpit. I

drilled this vent open and added some sheet styrene to

create the angled forward slope of the vent. In front of

this exhaust are a couple louvers that bracket the

location of the upper communications blade antenna. I

used an X-acto knife to scrape thes in like I did

for the louvers on the sides of the engine intakes.

Under the forward and rear fusleage, there are two

data link antennae bulges on the U-2. Over time, these

antennae have varied in shape and size. Sometimes they

are not even installed. Looking at reference pictures, I

determined that the aircraft I was building used the

more common types of these data link antennae. The

needed bulges are provided in the Cutting Edge

fuselage update set. I cleaned them up and attached them

to the fuselage.

Forward Data Link Antenna

Bulge |

Rear Data Link Antenna Bulge |

The last thing I

addressed on the fuselage was to drill a bunch of

locator holes in the lower center fuselage. These holes

would be the locators for the antennae farm found on the

bottom of Senior Spear aircraft. The Cutting Edge

Senior Span/Spur/Spear update set and the Italeri

"Senior Span" kit both provide all these antennae as

well as instructions on where they all go.

With the fuselage mostly assembled, it was time to

turn my attentions to the wings. Many pictures of parked

U-2 aircraft show the wing flaps being down, although

the one I saw at the Andrews AFB air show had its wing

flaps up. This left me with a quandary -- do I drop the

flaps or not? I decided to have the flaps dropped.

Besides the look of the model with its flaps down, this

would also give me a chance to correct some fit issues

on the wings. There is a substantial seam on the wing

top that cuts straight through the flaps. Replacing the

wing flaps removes this wing seam when the kit's wing

flaps are cut off.

I used the Cutting Edge U-2R/S / TR-1 Wing

Correction set. Having created the masters for this set,

there were no surprises in its usage. Not only does the

set provide dropped wing flaps, it also provides

replacement super pod tail cones, corrected antenna

fairings, and properly sized ailerons along with some

other minor details.

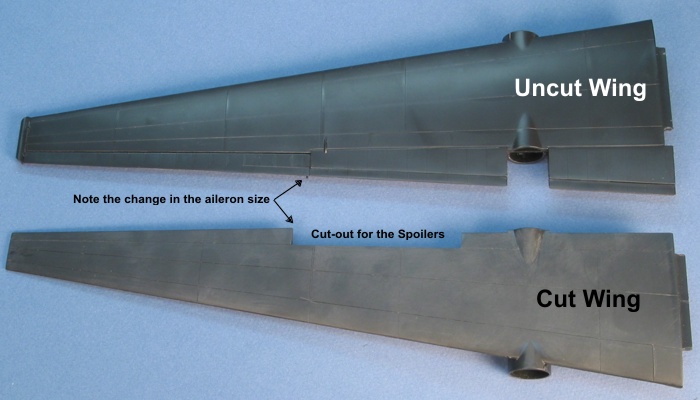

I started by cutting the wing flaps and ailerons off

of the kit wings. I then measured the distances

carefully to where various items should be located and

further cut the wings to make these details line up

correctly. The exact measurements are outlined in the

Cutting Edge instructions.

Cut and Uncut Wings |

Before I assembled the

wings and started attaching the correction set pieces to

the wing, I took time to re-scribe the wings to engraved

scribing. As it was all just long straight runs, this

was done easily with a metal ruller and an X-acto #11

blade drawn backwards over the wing surface. A few of

the kit scribed lines are located in the wrong place, so

I also took time to measure out the corrected locations

and scribe the lines. Most notable amoung the incorrct

lines are the wing fold lines. They should be 70 inches

from the wing tip. Italeri molded them about a

scale foot (a quarter inch) too far inboard.

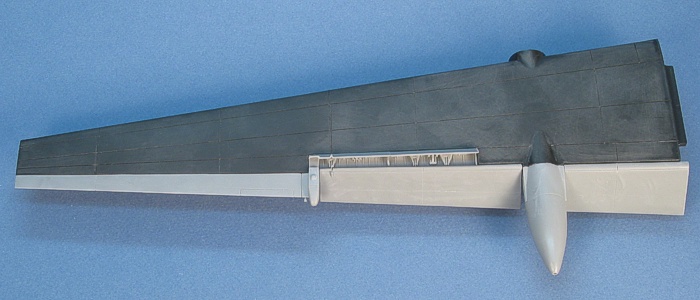

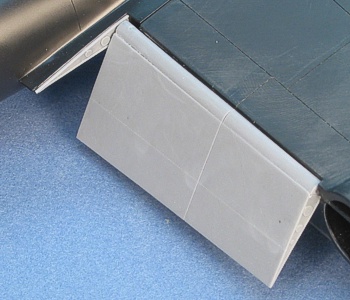

Assuming the wings are cut correctly, the resin

pieces attached to the wing easily. I missed by a little

on one of the spoiler wells and had to add a strip of

styrene to fill a gap that I created by accident. The

instructions say "measure twice, cut once", but I always

get too excited to take time to be that thorough. I

permanently attached the super pod tail cones, spoiler

wells, System 20 and GPS fairings, and the ailerons. I

left the wing flaps loose until after doing some

painting. With the mounting tabs on the flaps, they hold

themselves into place quite well, so I could get the

look of the wings without committing glue to the flaps.

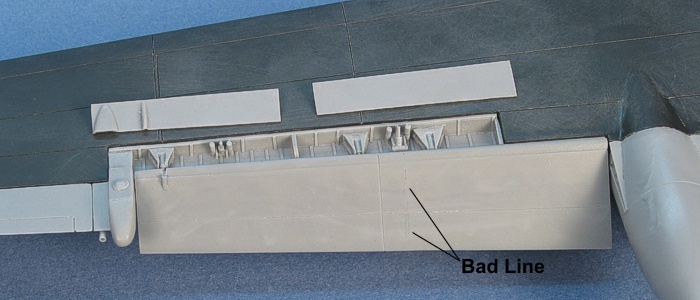

There is one quick fix to make on the resin wing

pieces. When I made the masters, I accidentally scribed

some bad lines on the outboard flaps. I thought I had

sufficiently filled in the bad lines, but in the resin

pieces you can still see the hint of them. Note the

pointer in the one image below and remove all traces of

the line being pointed to in the pictures. The same line

is present on both sides of both outboard flaps.

Sorry...

Wing Flaps Installed |

Wing Correction Detail |

Flap Angle Detail

|

Next, I turned my attention to work on the super pods.

In the "Sky Patrol" kit, the super pods are simple tubes

with rounded cones that fit on the front and rear of

each wing-mounted center section. There are no bulges or

antennae provided. In the "Senior Span" kit, the nose

cones of the super pods are modified to incorporate the

flattened sides of the Senior Ruby installation and the

canoe fairing for the left super pod is included for the

Senior Spear installation.

Wanting to have my model

outfitted with both Senior Spear and Senior Ruby

(collectively referred to as Senior Glass), I built up

the Senior Ruby nose cones for the super pods and

attached them to the wings, orientating the flat spots

at a slight angle down from facing straight out to the

sides. I studied all the pictures I could find and

decided to use the Italeri kit canoe fairing

under the left super pod. I am not convinced that its

shape is any better or worse than the Cutting Edge

equivalent piece, it is just different. The selling

feature for me was that the kit canoe fairing fit better

onto the super pod.

Senior Ruby Super Pod Nose |

Senior Spear Super Pod Canoe |

Then, I addressed the

seams where the super pod nose cones are attached. With

a little pre-work to flatten out the mating surfaces,

the cones mounted with only a small seam. I filled this

and sanded it smooth. Then, I turned right around and

scribed a panel line right where the seam line had been.

I continued on to scribe lines around the super pods

based on the diagram in the Cutting Edge Senior

Spear/Span instructions. With the scribing done, I

located and drilled holes along the pod centerlines to

mount the Senior Spear blade antennae.

The last details I added to the super pods where a

series of small intake vents along the outside of each

pod. These are provided in the Cutting Edge wing

correction set. There are three intakes on the left pod

and two on the right. Shrouded in shadows under the

wings, I did not even know these intakes existed before

I started researching to create the wing correct set

masters. Some pictures I got from a source on the

Internet highlighted them to me. Knowing about them, I

was then able to find them in my own pictures, too. It

is amazing how long you can look at some pictures and

not see some details.

The wingtip skids from the kit are fine. I cut these

from their sprue and attached them on the wingtips. The

ECM pods that attach to the skids are also pretty much

fine right out of the kit. I did add some laminated

sheet styrene to their end plates with punched out holes

to represent the round center antenna points, then

attached the pods to the skids. I also filed off the

solid kit navigation lights and drilled holes to mount

Cutting Edge clear red/green lenses from the

generic Cutting Edge navigation light sets.

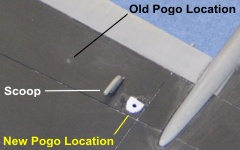

With the wingtips done, I moved to the undersides of

the wings. First thing here is to change the location of

the pogo leg mounting holes. Italeri molds the

holes too far inboard. They stay within the same

scribing panel, but move outboard to the outer edge of

the panel. Picturtes show what looks like a reinforcing

plate where the pogo legs attach, so I built this up

using 0.005" sheet styrene. Then I drilled the mounting

holes for the pogos.

The final additions to the wings were the fuel cell

pressurization intakes. These small scoops are found in

the lower middle of the wings, just inboard of the

attachment points for the pogo legs. These are also

provded in the Cutting Edge wing correction set.

Super Pod Vents |

Wingtip |

Fuel Cell Pressurization Scoop |

With all these wing

modifications complete, it was time to rent a gymnasium

to hold the fully constructed model. Thus, I started the

process to attach the wings to the fuselage.

As I was dry fitting the wings to the fuselage, I

came to the realization that the wing joint was going to

be a weak point in the model. And, the lowered wing

flaps had decreased the size of the mounting area for

the wings. There is more than twelve inches of wing

hanging off each side of the fuselage. Those long wings

have relatively small mounting areas with their locating

tabs being rather short (in comparison to the overall

length of the wings). Even if I did manage to firmly

attach the wings to the fuselage, the weight of the

wings hanging on the model could potentially split open

the upper fuselage seam. I decided I wanted to add a

length of brass tube as a wing spar to add strength to

this joint. This would also help to align the wings for

attaching them and keep them aligned after they were

attached.

Wing Spar Modification |

Fuselage with Wing Spar |

To start the process, I

measured and cut away a center portion of the wing

locator tab on each wing. I then drilled an appropriate

sized hole (1/8th inch)

in the wing inner edge at the place where I had removed

the locator tab section. It was important that these

holes in the wings would line up with each other so the

spar would fit straight across from one wing to the

other.

With the wings modified, I then measured the fuselage

to locate the correct positions of the holes to pass the

wing spar though. Drilling more holes in these locations

on the fuselage set up the whole assembly to be

completed. I measured the brass tube to determine how

far into each wing I needed the spar to go, then cut it

to the determined length (5 inches). This provided about

an inch and one half of spar sticking into each wing.

That seemed enough to me. After making sure the spar was

level in the fuselage and that the wings fit as I

wanted, I super glued it in place on the fuselage. I

then slipped the wings on for a final check. With

everything lining up the way I wanted, I glued the wings

to the fuselage.

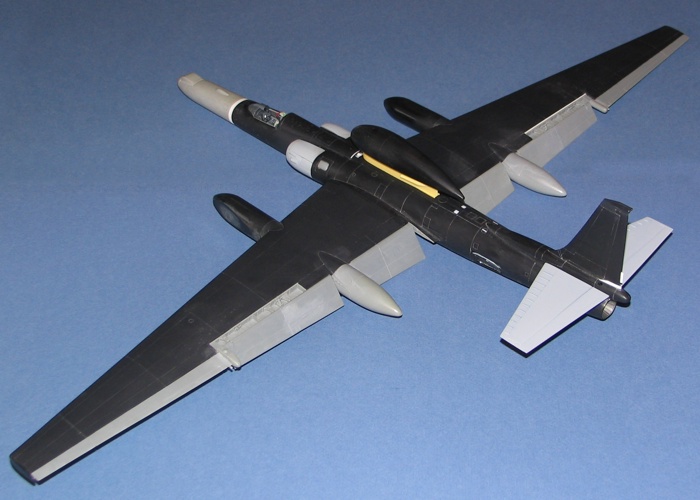

I reworked and modified many more places on the model

than I thought I would at the beginning of the project.

The picture below shows the model just before I painted

it. With the black plastic of the original kit, all the

modifications in white plastic and gray/beige resin

stand out quite well.

Assembled Model Before

Painting |

This completed the

airframe construction. Time for painting. As the

descriptions have gone on here long enough, I decided to

break here and have the painting and finishing of the

kit be a third part in my U-2S "Senior Span/Spur"

project postings.

(Newest to Oldest)

-

U-2R/S Walk Around

by David W Aungst

On-Line HyperScale Reference, 2003

-

U-2: The Second

Generation by Chris Pocock

World Airpower Journal, Volume 28, AirTime

Publishing, 1997

-

Dragon Lady by

Ted Carlson / Toyokazu Matsuzaki

Koku-Fan Magazine, Volume 1996-04, Bunrin-Do

Company, Limited, 1996

-

Recce Tech by

Paul F Crickmore

Osprey Color Series, Osprey Aerospace Publishing,

1989

-

U-2 Spyplane in

Action by Larry Davis

, Squadron In Action #86, Squadron Publishing,

1988/2002

-

Lockheed U-2R/TR-1

by Jay Miller

AeroFax MiniGraph #28, AeroFax, Inc., 1988

-

Lockheed U-2

by Jay Miller

AeroFax AeroGraph #3, AeroFax, Inc., 1983

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search