|

McDonnell FH-1 Phantom

by

Fotios Rouch

|

|

|

McDonnell FH-1 Phantom |

HyperScale is proudly supported by

Squadron.com

The McDonnell FH-1 Phantom was the first U.S. jet for the Navy and is

important in the role it played in the migration from piston-engine

power to jet propulsion.

It all started in August 1943 when McDonnell and Westinghouse were

commissioned to begin development of a carrier-based fighter jet. The

prototype XFD-1 Phantom first flew on January 1945 (The first XFJ-1 Fury

had its maiden flight on September 1946).

You have to remember that jet engines back then neither produced much

thrust nor would they spool up very fast. So take offs from the short

length of the carrier decks and wave-off situations were very much a

concern! The Phantom made its first takeoff and landing from the USS

Franklin D. Roosevelt in July of 1946. The Navy liked it and deliveries

to fleet squadrons began in July 1947. With the newly acquired Phantom

Fighter Squadron VF-17A became the first carrier based jet fighter

squadron in the world. The first Marine Corps unit that got the FH-1

Phantom was VMF122.

The Phantom served actively until mid 1950. Sixty units were built.

Some Phantoms continued with the reserves until the mid 50s.

McDonnell seemed to have gotten the recipe right because they

continued on with the F2H Banshee, the F3H Demon and the F-4 Phantom II!

Collect-Aire's

1/48 scale FH-1 Phantom

|

I could not have a good US Navy jet collection without the first

operational Navy Jet!

True to form the mainstream injection molding companies have totally

ignored this historically important jet. Collect-Aire came to my rescue

with their full resin kit one more time. The kit comes with a higher

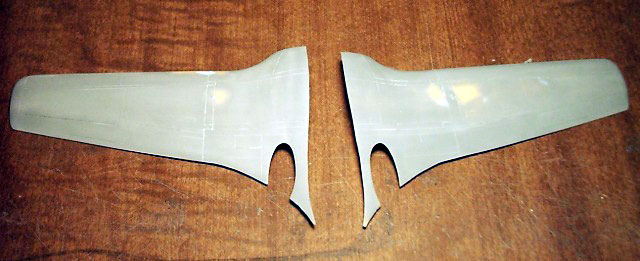

than usual number of parts for such a small jet. This is because the

maker included options such as open gun bay with machine gun assemblies,

top/bottom hollow wings with folding option and deployed flaps.

Click on the thumbnails

below to view larger images:

I was surprised upon opening the box to see so many parts especially

since this Eastern European maker (in the interest of expediency)

usually favors heavy solid resin wings with no flaps down options. All

those parts looked great in the box but what is important to those that

build and do not collect is how all that stuff goes together.

The first thing to do is always wash the resin parts with warm water

and a strong dishwashing or housecleaning detergent. I have been using

409 and a toothbrush with good results. If you do not clean your resin

from the mold release agent your paint will never stick to the model

properly .

Next is the prepping and planning phase.

My kit had plenty of pits and pinholes in its resin. I decided to

complete all the major subassemblies first and then do the resin

corrections. I also decided to pose the kit with its gun bays closed.

This is when I realized that the gun bay covers are quite a bit smaller

that the openings they are supposed to cover.

Click on the thumbnails

below to view larger images:

Once closed they were not conforming to the fuselage curves either. I

was certain that the very thin gun bay covers would not survive the

amount of sanding and filling that would be required. After I glued the

resin covers on the respective fuselage halves I decided to use 2 part

epoxy glue and pour it generously on the inside of the fuselage parts.

This way I reinforced the parts and did not care if I was going to sand

through the gun bay covers as I was trying to re-contour them to be

flush with the fuselage surface. When that was done, I completed the

cockpit and closed up the fuselage. The kit is a tail sitter, you need a

lot of weight up front. I then worked on the wings which I wanted posed

in the open position. Once I had the main surfaces assembled I felt it

was time to address the resin imperfections.

I used again my automotive primer (lacquer based only) and its

thinner. I sprayed the fuselage and wing surfaces with a good thick coat

of this primer. It dries fast. I could then see the potmarks easily

against the dark primer. Additionally the surface got a bit rough due to

the unsanded primer. I took out the 3M Acryl Blue and started applying

thin coats over the potmarks with my trusty tool (my finger). Acryl Blue

sticks great to the dry and rough primer. 3M does not stick as well

straight on the resin.

Mr. Surfacer will not fill the resin pinholes and potmarks unless you

poor it on and then there will still be a sink mark after it dries up. I

wet sanded the Acryl Blue with my Micromark polishing cloths and

polishing sponges. I tried not to go through the primer and reveal the

resin surface underneath. When I would see the Acryl Blue slowly

disappearing under sanding I would get more cautious and slow down. In

the end I ended up with gray primed fuselage full of nice little blue

dots where the resin imperfections were. When all looked good I sprayed

a nice coat of nicely thinned primer and polished it good.

Assembly continued with the usual delays that take place in full

resin kit construction. Some panel lines had to be recreated, some had

to be corrected or added per photos, etc. The cockpit is reasonably good

and close enough to the pictures in the Ginter book. I added only

seatbelts to the seat. The vac canopy really needs a couple of

submersions in Future.

The biggest difficulty is merging the wings with the fuselage. Take

all the time you need to study how the middle portion of the wing

structure mates with the fuselage bottom. Also pay close attention and

do the best job you can on merging the top portion of the wings to the

fuselage. I do not think there is a way in the world to do it so no

putty will be used. I took a detail shot to show that it can be done

reasonably well and have the wing meet the fuselage in a clean and sharp

way.

The jet exhausts will need some trimming and the receiving portion of

the wing cavity will need some grinding so they can fit good.

When the airframe was all together I used Mr. Primer 1000 because it

polishes so good and it is so tough. With very fine polishing it is a

great primer for metal finishes too (like Alclad II).

I wanted to make the Reserves FH-1 that was included in the decal

choices provided in the kit. I used Testor's Gloss Sea Blue and

International Orange. I used Alclad II for the jet engines and Xtracolor

Interior Yellow for the wheel wells.

The decals are thin and you need to be very careful with them. Do not

touch them or try to move them until they practically fall of the

backing paper.

They are that sensitive.

I used as a reference Phil Juvet's walkaround and some plans I got

from a Russian site. The completed model looks like an FH-1 but the

canopy area is a bit short when viewed from the side. The Ginter book on

the FH-1 is a great reference with a lot of pictures showing the canopy

issue as well as another small item. It is the way the tail blends into

the fuselage. It should be a smooth transition without any tail vertical

surfaces attaching at almost right angles to the fuselage (the maker

made the tail to fuselage joint much like the one of the Banshee). None

of these two issues take too much away from the overall look of the

plane, in my eyes at least.

Now I am eagerly awaiting the release of the newly mastered F2H-3/4.

Done by the expert hands of my favorite maker who makes no shape

mistakes and knows how to correct plans and understands how to interpret

photos. It will also be molded in Medina MN where QA does have some

meaning. Am I excited?

You bet! I already ordered two of the Big Banjos sight unseen!

Click on the thumbnails

below to view larger images:

Model, Images and Text Copyright © 2003 by

Fotios Rouch

Page Created 25 August, 2003

Last Updated 17 March, 2004

Back to HyperScale

Main Page

|

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search