|

Preparation

I decided to follow one of Dave Aungst's tips and mask the

canopy with Parafilm "M". For details of how to use this interesting

masking material, see

Dave's

article in the Reference Library.

Wheel wells were stuffed with tissue then the

undercarriage doors were tacked in place with Blue-Tack.

I cut out a circle from a Post-It Note to mask off the big

annular radiator, which had already been painted and received a wash of

black oil paint.

This Fw 190D was from the 500XXX werknummer batch.

Aircraft from this batch shared some interesting colour attributes,

including the lower wing with a grey forward half and natural metal

trailing half. The fuselage of these aircraft also seem to be finished in

one of the late-war “Sky” shades. Just to add even more variety, the lower

engine cowl of "Brown 18" is a different shade to the rest of the

fuselage, suggesting that it might be yellow or natural metal; and JG 26

added their own unique colours to the mix with a Black and White RV band

and “greened-up” top surface camouflage.

Painting

The first task was depicting bare metal on the lower wing.

I like Tamiya's AS-12 Bare-Metal Silver from the spray

can, but the aerosol application sometimes leaves a slight orange-peel

texture. I therefore took a small container, covered it with Cling Wrap,

poked a small hole in the corner and sprayed some of the contents of the

can into the hole. This is definitely an outdoor job. Keep your

face away from the billowing toxic lacquer vapours too!

The cling wrap was removed and the contents poured into an

empty Testor glass jar. I left the jar open for a few minutes before use

to permit some of the remaining aerosol to evaporate.

Now the silver paint can be used just like normal lacquer.

I poured the thin liquid straight into my Aztek paint cup and covered the

rear part of the lower wing with a slightly dull, perfectly smooth and

metallic finish. This is a great undercoat for Testor Metalizers. In fact,

I mixed Metalizer with the Tamiya lacquer in the paint cup to vary the

shade of selected panels.

Final tip for the decanted spray paint - take care the

first time you re-open the jar as the contents may repressurize slightly.

The metallic rear section was masked and I pre-shaded the

remaining panel lines with narrow lines of black paint applied with the

airbrush. Next, the black and white of the RV band was sprayed and masked,

followed by the yellow undercowl. The remaining colours of the patchwork

underside were then painted - RLM 75 Grey Violet for the forward lower

wing; RLM 76 Light Blue for the ailerons, wing tips and horizontal tail

surfaces; and "sky green" (RLM 76 variation) using RAF Sky.

The one known decent photo of this aircraft (on page 303

of Axel Urbanke's wonderful book, "Green Hearts - First in Combat with

the Dora 9") indicates a fairly high, hard demarcation line on the

fuselage side with almost no mottling. The fin has a line of dark

camouflage on the leading edge, but only sparse mottling aft of this. The

rudder has been removed in the photo so camouflage of this area is

anyone's guess.

Upper surfaces were painted with RLM 82 Dark Green and RLM

83 Bright Green in accordance with JG 26's camouflage practices. I painted

the rudder RLM 76 Light Blue. The mottle comprised RLM 81 Brown Violet

(presumably field applied) and RLM 83 Bright Green.

A few weathering features are apparent in the reference

photo, including chipped paint on the RV band and putty/primer on the gear

doors.

When all the masking was removed I applied a narrow strip

of self-adhesive aluminium foil each side of the fuselage extension join.

This was rubbed down into position then smaller strips were sliced off the

top and the bottom. These strips represent metal under damaged paint -

fairly common in this spot on Doras.

I also brush-painted beige and dull red spots on the main

undercarriage doors representing patches of putty and primer.

Click the thumbnails below

to view larger images:

|

|

|

|

The natural metal rear section of the wing was first painted with Tamiya Airframe Silver from a spray can, decanted into a jar.

|

|

|

|

Testor Metalizer was used to add variety in panel shades.

|

|

|

|

The airframe was pre-shaded with thinly applied flat black.

|

|

|

|

Camouflage colours were applied to permit a hint of the pre-shading to show through.

|

|

|

|

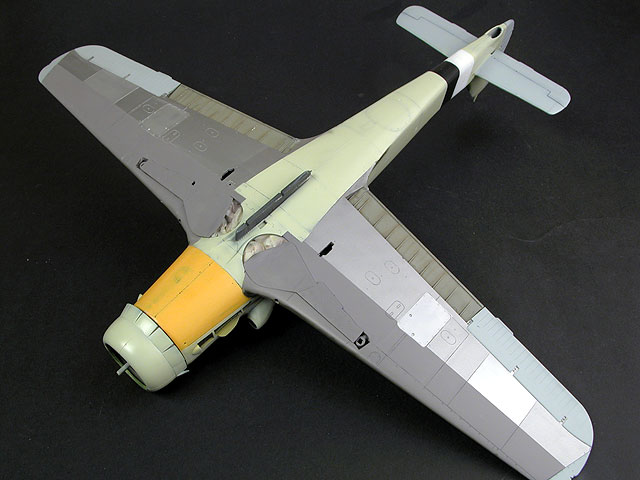

Ready for decals!

|

|

|

Decals and Finishing Touches

With the large expanse of pale paint on the fuselage side,

I decided to subtly highlight the panel lines with a very thin wash

of Lamp Black and Raw Umber oil paint.

Decals for Brown 18 were sourced from EagleCals' brand new

sheet number EC#58. A

detailed review of these decals may be seen elsewhere on HyperScale.

The decals behaved perfectly on application.

Click the thumbnails below

to view larger images:

|

|

|

|

The resin cigar fuel tank from Jerry Rutman. The resin sway-brace mounts were sliced off the front position and relocated to suit the kit parts.

|

|

|

|

The kit fittings only needed a little work to adapt to the Rutman drop tank.

|

|

|

|

|

Panel lines were slightly highlighted before decals were added.

|

|

|

|

After the decals had thoroughly dried, I sprayed a sealing

coat of Polly Scale Flat. There was still some work to be done though.

The reference photo shows a dark exhaust streak on the

forward part of the aircraft. I mixed some Flat Black, Red Brown and a

spot of Flat Base with approximately 80% thinner. This thin mix was first

applied in tiny vertical streaks on the fuselage sides, then along panel

lines that were destined to lie under the stain, and finally built up

gradually for the entire length of the dirty streak.

Scuffing and chipping of paint along the wing roots was

achieved with a silver artist's pencil. It is important to keep the pencil

sharp for the whole job. I re-sharpened the pencil several times before I

was finished.

The characteristic toe-in and forward angle of Fw 190

undercarriage legs has been a problem for model companies until now.

On my kit, the undercarriage legs were such a tight fit

that I could not dry fit them in the locating holes without risking

damage. Fortunately, a thin application of glue was enough to lubricate

the plastic and they almost clicked into place for a magnificent fit and

perfect alignment.

By the way, I accidentally sliced off the locating pins

for the retraction struts on both main undercarriage legs when removing

them from the sprues. This is an easy mistake to make, but also an easy

one to fix. I drilled a shallow hole in the appropriate position on each

leg and superglued a short pin of brass rod as a replacement.

Small detail parts such as the striped Morane mast and

footstep were painted and glued to the model.

Focke-Wulf 190 aircraft equipped with the standard (flat)

hood had a pulley system inside the canopy that kept the antenna wire taut

whether the sliding section was open or closed. The blown hood did not

have this mechanism. The wire simply hooked onto the top of the canopy and

slackened off when the hood was open.

I usually use invisible mending thread for antenna wire,

but I have not had much luck getting this material to look convincingly

slack. I therefore stretched a length of dark green sprue using a candle.

The stretched sprue can be positioned to a certain extent. A long section

of stretched sprue was strung between the fin antenna post and the top of

the canopy. A short piece was curled at one end to depict the slack

lead-in wire on top of the fuselage entry point.

The Dora was finished, and in fairly quick time. I

estimate that construction took around 12 hours, with painting and

detailing another 15 hours or so.

Since its release in late 2001, I have seen far more

photos and articles of Hasegawa 1/32 scale Bf 109G-6 submitted to

HyperScale than any other single model – and with good reason. That kit is

quite accurate, pleasant and fast to build, offers a staggering range of

finishing options, is an impressive size without making big demands on

display space, is not burdened with esoteric gimmicks and the price is

affordable.

Hasegawa’s new 1/32 scale Focke-Wulf 190D-9 continues this

sensible philosophy with all the same qualities as the earlier Gustav.

The Dora is slightly more demanding than the Bf 109 with respect to the

wing/fuselage join, but it is still well within the scope of most

modellers.

I think that Hasegawa’s 1/32 scale Focke-Wulf Fw 190D-9 is a terrific kit

that deserves great sales success. It will look good built straight from

the box, but also represents an excellent platform for superdetailers to

weave their magic.

Tamiya, Revell and Trumpeter are doing a good job with large scale jets.

We can only hope that Hasegawa continues to cover more 1/32 scale WWII

subjects. Who wants to see a state-of-the art Mustang, Fw 190A/F/G, a late

mark Spitfire or a Hurricane in this scale?

Who wouldn’t!

This project was a much more enjoyable experience thanks

to the assistance of:

-

Jerry Crandall from

Eagle Editions for the

commentary on his construction; assistance with reference questions on the

subject aircraft and the provision of decals.

-

Jerry Rutman of

J. Rutman Productions for the

provision of the resin "cigar" fuel tank last year in the "Focke-Wulf

Fw 190D-9 Late Style Conversion" (for the old Hasegawa Dora)

-

Meteor Productions for the review

sample Fw 190A-8 cockpit way back in 2000 - I knew that I would use

it eventually!

Click the

thumbnails below to view larger images:

Model, Images and Text

Copyright © 2003 by

Brett Green

Page Created 26 April, 2003

Last Updated

17 March, 2004

Back to

HyperScale Main Page |

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search