|

Focke-Wulf Fw 190D-9

by Jeffery S. Harrison

|

|

|

Focke-Wulf Fw 190D-9 |

HyperScale is proudly supported by

Squadron.com

"Sherman, is the wayback machine ready?"

"Sure thing Mr. Peabody. Where are we going today?"

"We're going into the deepest, darkest recesses of antiquity. Set the

wayback machine for November 1992 - we're going to Philadelphia."

November, 1992. I still live in civilization, still build satellites for

a living, George Bush is about to lose his bid for re-election, Eagle

Editions is 6 years away from releasing their first decal sheet, I won't

own a computer for another a year, sites like Hyper Scale are unheard

of, THE reference for painting Luftwaffe aircraft is The

Official Monogram Painting Guide to German Aircraft 1935--1945 and I

still actually complete models.

At

this time I was working on a Trimaster FW 190A-8 for a club contest and

was less than thrilled with the progress I was making. I wasn't really

into the notion of repairing whatever it was that was wrong (probably

the nose) so I decided that I'd start a new project instead. I had a

little under three weeks to the contest and chose the Trimaster FW

190D-9 as the replacement. At

this time I was working on a Trimaster FW 190A-8 for a club contest and

was less than thrilled with the progress I was making. I wasn't really

into the notion of repairing whatever it was that was wrong (probably

the nose) so I decided that I'd start a new project instead. I had a

little under three weeks to the contest and chose the Trimaster FW

190D-9 as the replacement.

At some point I had been looking through the Broken Eagles 1 book,

written by Carl Hildebrandt and published by Fighter Pictorials, and had

come across a photograph of what appeared to be Ta 152 tail section with

a GI standing on the right horizontal stabilizer. The author identified

the tail as belonging to a FW 190D-9 and claimed that the RVD band was

yellow-white-yellow even though the color appeared darker (he claimed

the dark bands were a result of using orthochromatic film). This became

the basis for my project.

Knowing what I wanted to do the next step was to figure out how to

accomplish it. I turned again to Trimaster. A year or so before I had

built the Trimaster FW 190D-12 (kit #MA-2) by 'accident'. Really, it was

an accident. I had been playing around with the kit seeing how

everything fit and before too long I had most of the major parts of the

airframe complete. At which point I decided to finish it and did so.

There were no fit problems at all and this is what led to my choice of

the D-9 kit for the contest. Trimaster also had model of a FW 190D-12

Torpedoflugzeug which happens to have the enlarged tail section of the

Ta 152. I knew I could switch the fuselage halves of this kit with those

of the 190D-9 for the project I had in mind.

With my project decided, a game plan in place and the deadline fast

approaching it was time for me to get started.

Monday, November 9th, 19:00 local

Work begins. Over the next 3.5 hours I assembled the fuselage,

painted and installed the gun cowl, inserted the cockpit and began

working on the wheel wells. I was helped by the fact that the cockpit

had already been completed when I started this project. It is the

Verlinden cockpit for the FW 190A-8 and had originally been intended for

the project I had been working on prior to this one. Yes, that is the

wrong cockpit but it was available and the differences are small enough

that nobody would call me on it. Aside from the new cockpit and the wing

tip navigation lights the rest of the project was done using the parts

found in the kit.

Tuesday, November 10th, 16:30 local

Day 2 finds me working on the wings. By the end of day 2 I had built

and attached the wings, cleaned up all the seams, re-scribed any panel

lines that had been damaged and painted the bottom color. With two days

of work completed I've managed to put in 7 hours plus an estimated 3

spent earlier on the cockpit.

Wednesday, November 11th, 17:45 local

Day 3 was largely spent on painting the camouflage and cleaning some

seams. The first hour saw the photo-etched reinforcing plates (?)

attached to the wing roots and some minor seams were touched up. Hour

two saw the horizontal stabilizers get cleaned up, the bottom got a

little touch up and most of the RLM 81 upper camouflage color was

applied. The last Hour had the gun sight painted and installed, some

detail painting was completed in the cockpit, the canopy was tacked on

and the bulk of the RLM 83 camouflage was applied. Not too bad -- three

days into the project, approximately 13 hours of work and I have a

mostly complete airframe with the bulk of the camouflage applied.

I'd like to make a brief comment at this point. The color designations

I'm using in this article are what were 'correct' at the time of the

build. At the time RLM 83 was the lighter of the colors 82, and 83 while

the greenish bottom color was tentatively identified as RLM 84 though

nobody had found proof of that yet.

Thursday, November 12th, 17:45 local

Day 4 and I've permanently attached the canopy, attached the

horizontal stabilizers, assembled/painted the cowl and then did some

touch up of the camouflage.

Friday, November 13th, 16:15 local

Day 5 was pretty light, guess I needed a break. I only worked for

1.25 hours and spent that time cleaning up the camouflage.

Saturday, November 14th, 08:45 local

Day 6 started bright and early. I was actually working on the model

by 8:45 in the morning (those who know me can tell you that this is

practically bedtime for me most of the time -- I'm definitely what you'd

call a night owl). The first part of the day (8:45-10:30) was spent

attaching the cowl, doing some final touch up of the camouflage and

painting the RVD bands. Later on (3:15-4:30) I touched up the RVD bands,

gloss coated the model and started decaling. I finished up with one

final session (5:30-6:00) where I added some more decals.

Sunday,

November 15th, 20:15 local Sunday,

November 15th, 20:15 local

Day 7 saw the decaling finished. I then chased any silvering and

started working on the landing gear.

To summarize the events so far. I'm 7 days into the project with 5

remaining until our club meeting/contest. I have put about 17.75 hours

work into it (plus approximately 3 for the cockpit) and now have a

complete airframe that has been camouflaged and has most of its decals

in place. Things are looking good but I'm not done yet...

Monday, November 16th, 18:00 local

Day 8 dawned a blustery gray day that was threatening the region with

its first snowfall of the season...OK, I don't remember what the weather

was like, it was 10 years ago but it sounded good. Anyway the first part

of the night (6:00-8:00) was spent chasing the last of the silver,

prepping the landing gear for painting, painting the gear doors and

applying the final gloss coat over the decals. Later that night

(10:45-12:15) I highlighted the panel lines (a technique I've since

decided I don't care for) and then applied the flat coat.

Tuesday, November 17th, 21:00 local

Day 9 was used to paint the wheels and landing gear and then to paint

and install the exhaust stacks. After that I sprayed the exhaust stains

as a kick-off for the weathering process.

Wednesday, November 18th, 19:15 local

Day 10 and I'm into the slow stuff now. No more major changes during

a modeling session. Over the next 3 hours I built/attached the pitot

tube, landing gear, boarding step and IFF antenna. I also unmasked the

canopy, added the main gear doors and did any clean up to the

paint/weathering that was required. Things are definitely slowing down.

Thursday, November 19th, 15:00 local

Day 11 and I'm running out of time, the contest is tomorrow --

fortunately I'm also running out of things to do. This is my last big

push and I worked for a total of 6.5 hours in 3 different sessions.

In that time I attacked what seemed to be a never-ending list of

details. I attached and/or painted the bomb rack, morane mast, tail

wheel, flap indicators, tail light, prop, wing cannons, gear down

indicators, exhaust deflector, antennas, seat belts and finally I made

and attached the wing tip lights, applied the spiral decal to the

spinner and did some more weathering.

Friday, November 20th, 16:15 local

Day 12. It's the day of the contest and I'm doing the final touches.

I attached the shoulder harness, did a little more clean up and broke

off the radio antenna (never did manage to re-attach that).

Grand total for the project was 12 days and 36.75 hours. I even

managed to pull off a first place in the contest.

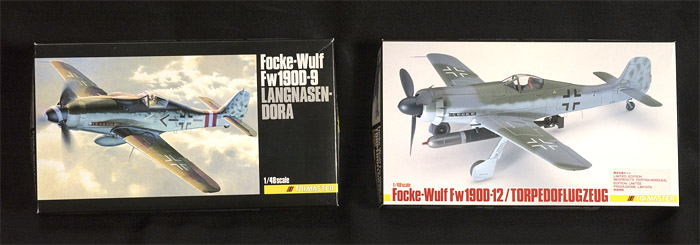

For this project I used two Trimaster kits. The FW190D-9

Langnasen-Dora (MA-1) and the FW190D-12 Torpedoflugzeug (MA-15).

Additionally I used a MSAP decal sheep for the Blue 9 and third group

bars in the RVD band. Decals for the serial number on the tail came from

a source I can't identify. As I mentioned earlier the cockpit came from

a Verlinden detail set for the FW190A-8.

Actual construction was simplicity itself. The

conversion consisted of swapping out the two fuselage halves from the

D-9 kit and replacing them with the fuselage halves from the D-12. The

only problems arose from using the Verlinden cockpit. The parts are

supposed to be a drop-in replacement and for the most part it is. The

problem is that the instrument panels sit too deep in the cockpit making

them almost invisible. Correcting this is a little more complex than it

would seem so I didn't fix it on this project due to time constraints. I

will be using this cockpit one more time to see what I can do with it

but will probably not use it again after that. For the most part it

isn't that much of an improvement over the kit pieces.

Construction techniques were pretty standard for me. Pieces were removed

from the sprue with diagonal cutters. Most part clean up was done with

the ever-popular Xacto #1 handle mounting a #11 blade. Plastic was glued

together using IPS Weld On 3 which I applied using an insulin syringe

(best glue gun ever made for plastic modeling) while PE, white metal and

resin were attached with CA (probably gap filling Zap). No putty was

used in construction. Seams were either filled with plastic ooze that

came out of the joints or possibly CA for the "really bad" seams (and

there were no really bad seams with this kit).

The

only places during construction that require special mention are the

navigation lights on the wing tips and the photo-etched pieces. The

only places during construction that require special mention are the

navigation lights on the wing tips and the photo-etched pieces.

For reasons know only unto themselves Trimaster uses

stainless steel for the PE parts instead of the much more user-friendly

brass that most companies use. To remove these pieces without a] losing

them and b] destroying them I use a pair of needle-nose pliers and my

Dremel tool mounting a cutoff wheel. The navigation lights that came in

the kit were somewhat anemic so I chose to make my own. I did this using

styrene rod, super glue, accelerator and Tamiya clear paints (blue and

red). All you do is take an appropriately size piece of styrene rod and

touch on end of it to a puddle of supper glue. Pull it away, hit it with

accelerator and repeat until you have a clear ball about the right size.

Once you have the right sized "light" just dip it into the appropriate

color of clear paint and let it dry. Insert it into the wing tip and

you're done. Variations of this technique can be used to create

streamlined lights using airfoil shaped stock for the base and some

sandpaper for final shaping. Clear lights are created the same way but

dip them in Future or similar. You can also create colored lights in a

wing tip covered by clear Plexiglas (like on a Bf109) by building the

colored bulb as described here, mounting it into a cut out in the wing

tip then filling the cutout with super glue and filing/sanding to shape.

This model was painted using Floquil, Humbrol and Model Master

paints. The only water based paint used was the final flat coat which is

Polly S Flat Finish. I airbrush everything I can get away with resorting

to a paintbrush only when there is no way to make the airbrush work. All

camouflage colors were lightened with about 15% (my usual for 1/48th

scale) white for scale effect. For the main camouflage I used the

following colors;

-

Humbrol Matte 90 = bottom color

-

New Floquil RLM 83 = RLM "83"

-

New Floquil RLM 71 = RLM 81 (this is a

better match for 81 than it is for the 71 it claims to be)

-

Model Master FS34079 = RLM 71 propeller

blades

-

Floquil RLM 02 = RLM 02

I want to say I used Floquil Reefer Yellow for the RVD band but my

paint chips show that to be more orange than the yellow on the model and

I don't think scale effect can explain the difference. So I'll have to

leave that as a mystery lost to time. Reefer Yellow is a very good match

for RLM 04 though.

All camouflage painting was done using a Badger 150-IL double action

airbrush. Paint was thinned to a milk consistency using Xylene or Xylol

and I typically spray at a pressure of 12-13 PSI. Actual camouflage

painting was done freehand with the only masking being done for the

canopy, RVD bands and to protect the wheel wells. I mask mainly with

Scotch Magic Tape and that was what I used throughout this project.

Finally, weathering consisted of a black-wash to highlight the panel

lines, dark gray/scale black airbrushed for exhaust staining and a light

dry brushing to dirty it up a bit. I purposely kept the weathering light

as this plane would not have been operational very long before the war

ended.

I

submitted this article for two reasons. First, this model had originally

been seen here as part of a mini-gallery that no longer exists. Second,

I recently got a new toy for use in my studio and this was as good a way

to play with it as any. I

submitted this article for two reasons. First, this model had originally

been seen here as part of a mini-gallery that no longer exists. Second,

I recently got a new toy for use in my studio and this was as good a way

to play with it as any.

The new toy in question is a Nikon D1x digital SLR. This is my first

digital camera and I went this route primarily so that I would be able

to use my existing lenses with it. It is way overkill for this purpose

but in photography more is always better.

Anyway, I'm including a picture to show the basic setup I used for these

pictures. The only thing changed between this picture and the actual

setup was that I chose to use gold poster board for the opening shot and

light blue most of the rest of them.

The shots without blue or gold in them were shot with the set up in

the picture.

To the right of the camera you can see the main light source which is

one of my flash heads mounted in a 24" x 30" soft box.

Just outside of the frame to the left is another flash head aimed at

the ceiling as fill light. All exposures were taken using a Nikkor 105mm

F2.8 Micro lens set to between F:16 and F:22.

Click on the thumbnails

below to view larger images:

Model, Images and Text Copyright © 2003 by

Jeffery S. Harrison

Page Created 16 January, 2003

Last Updated 17 March, 2004

Back to HyperScale

Main Page

|

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search