|

"Drumming Daybreak"

Modelling HMS Victory

by John

Reid

|

|

|

HMS Victory |

HyperScale is proudly supported by

Squadron

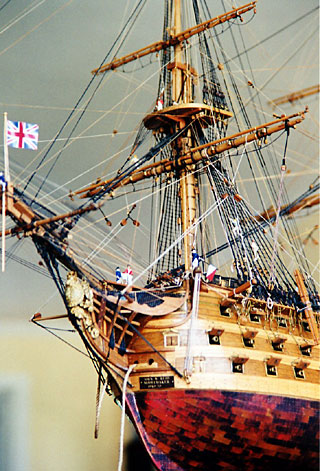

September 1805, Portsmouth Harbour, H.M.S. Victory is undergoing a

refit in preparation for her rendez-vous with history on October 5th that

same year.

It is dawn and the Drumming of Daybreak ceremony is underway.

Having seen, as the saying goes in the Royal Navy, “a grey goose at a

mile”, the marine has just finished his constant drumming and the cannon

is being fired. On the poop deck the Red Ensign is soon to be

raised. Meanwhile the officer astride the bowsprit at the cap, with

telescope in hand is surveying the horizon for enemy ships.

It is common practice in the Royal Navy, at dawn, in harbour, under

bare poles, when very vulnerable to enemy attack, that all hands be at

their battle stations with guns run out. When the all clear is

given, normal ship’s routine can begin.

The Evolution

from Kit to Scratchbuilt

|

I bought the Sergal Kit of Victory in March 1976, with the intention of

building it out of the box. However, upon opening the box the first

thing I discovered was an instruction booklet that was so poorly

translated into English from Italian that it was almost unreadable.

A very ominous sign of things to come.

Reviewing the plans I soon realized, even at this novice stage, that

the information provided was totally inadequate. Luckily I had

noticed at the Hobby Shop that there was a copy of the book “The Anatomy

of Nelson’s Ships” by Nepean Longridge. When I opened the book, to

my amazement, I found myself in information overload. I threw out

the kit plans and decided then and there that the first thing I would

require would be a good nautical dictionary. And so began what I can

only describe as my long 25 year journey from diorama modeling 101 to PHD

(self awarded, of course!).

The Basic Hull

I took some preliminary measurements from Longridge’s plans and decided

that the plywood bulkheads, etc., would join the booklet and plans in the

local dumpster. I made my own in 1/72 scale.

After

much cutting, fitting and shaping of the basic structure, I was at the

planking stage. It was around this time that I decided to keep an

hour-by-hour, day-by-day, year-by-year, decade-by-decade, logbook of the

building process. I used the kit supplied basswood strips for the

first layer of planking from the waterline to the keel. I then took

two part epoxy glue and fiberglass cloth and coated the interior of the

hull about ¼” thick. Two purposes were served here, one to add

strength and weight to the hull and second to provide an excellent base

for the copper nails and bamboo dowels yet to come. I continued the

planking now above the waterline, deck by deck, coating the interior with

two-part epoxy mix. The first layer of planking finished, I now

measured off the gun port openings and started cutting in. After

much cutting, fitting and shaping of the basic structure, I was at the

planking stage. It was around this time that I decided to keep an

hour-by-hour, day-by-day, year-by-year, decade-by-decade, logbook of the

building process. I used the kit supplied basswood strips for the

first layer of planking from the waterline to the keel. I then took

two part epoxy glue and fiberglass cloth and coated the interior of the

hull about ¼” thick. Two purposes were served here, one to add

strength and weight to the hull and second to provide an excellent base

for the copper nails and bamboo dowels yet to come. I continued the

planking now above the waterline, deck by deck, coating the interior with

two-part epoxy mix. The first layer of planking finished, I now

measured off the gun port openings and started cutting in.

It was during this planking process that I noted an important fact in

this ship’s design. The decklines intersect the hull’s shear line

and the gun ports actually cut through the wales at many points on the

hull. I presume that this was the shipwright sacrificing strength

for beauty. Unfortunately, the real ship was then painted “Nelson

fashion” parallel with the waterline (Go figure!).

With the gun ports cut in, the model was now ready for the second layer

of planking using walnut strips, both glued and doweled (trunneled) to the

basswood hull. It was at this point that I made a novice mistake by

deciding not to use anchor stock planking for the wales. I guess I

was still in rush mode (as though a few extra hours would make any

difference) and decided to use fine-grained oak strips for the wales.

The contrast in woods is nice but to my everlasting regret, why is it not

anchor stock? Oh well, live and learn, as they say.

I made trunnels out of bamboo strips, which I drew through a drawplate

(I actually used a drill gauge). After much cursing and swearing,

sore fingers and worn out cloth and rubber gloves, I managed to create

enough dowel for the hull. I used the shipwright’s rule of “room and

space between butts” throughout the model. Building time to date,

April 1978, 650 hours.

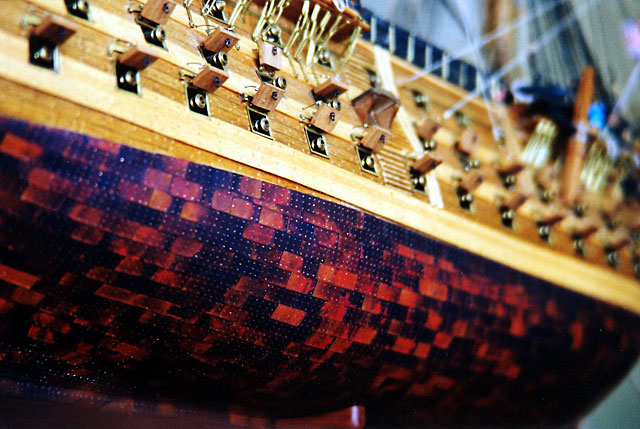

Copper Sheathing

Much has been written about copper sheathing so I won’t repeat it here.

However, where I am a little different from the norm is the weathering and

fastening of the individual copper plates. To weather the plates I

took a butane lighter and heated them red-hot and immediately quenched

them in cold water, which crazed the surface into many different shades of

copper colour.

I then glued them on, and here is the fun part, I made each nail out of

number 22 gauge copper wire. I cut the wire to length about ¼” and

sanded off each end. I then drilled 15 holes in each place through

the two layers of planking into the epoxy beneath. Now it’s January

1979, and I’m almost 1100 hours into the project.

Finishing the Hull

The decks were planked with walnut strips, selected for their

contrasting colour and trunneled on to the plywood decks in the two and

three step method. The hull was walnut planked up to the poop deck

level after all the furnishings, cannons, gratings, and officers’ quarters

under the poop deck, etc., were installed.

A lot of so-called modeling for “God” went on under the poop deck as

most of it can only be seen with great difficulty (and a strong light),

and some of it not at all.

I next tackled the head, waist, quarter and stern galleries.

It was by now September 1980, 2500 hours, and I am just starting to

work the channels and their deadeye fittings.

Click the thumbnails below

to view larger images:

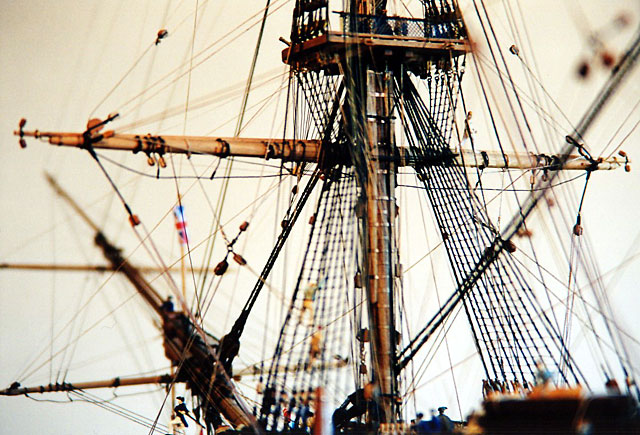

Masts and Rigging

The bowsprit and masts were now stepped and their yards and fittings

made up. Most of the blocks and rigging tackle are made of hard

cherry wood. The masts are select walnut and the yards English fine

grained oak (A little bow to history). The standing and running

rigging is linen line in a variety of diameters. Most of it I spun

on my homemade rope walk, which I made from old mechano parts. The

scale rope was then wormed, parceled and served as required. All the

ratlines were hand knotted unto the shrouds. (Just ask me if I know how to

do a clove hitch).

While Longridge’s book is very good, the information on how he rigged

his ship is confusing. Therefore, for the rigging sequence I used a

great little book that I picked up in 1977 for two dollars. I don’t

know if it is still available, but this little gem is called “H.M.S.

Victory” by Noel Hackney. It contains a very detailed description of

how to rig a plastic airfix model with over 200 steps from flying to jib

boom to rudder pendants. There is even a step-by-step sail rig for

those so inclined. Rigging was completed May 2000, 5300 hours.

Fittings

I used the Sergal fittings wherever I could and scratch built what I

had to if the parts were missing or too far out of scale.

Unfortunately, this meant a lot of scratch building. I call my model

90% scratch built because, from a purely time point of view, that was the

percentage of the total time that was involved in scratch building.

The acid etched transom and quarter galleries were highly modified.

Only the figurehead was used as is although I did spray paint it gold.

Figures

The Royal Navy officers, sailors and marines are in 1/72 scale.

The figures were purchased and then converted from infantry to marine by

simply cutting off unwanted parts and remodeling them in epoxy paste.

Heads, legs, arms and torsos were cut into pieces and repositioned

depending upon the activity I wanted to portray. (Sounds gruesome

doesn’t it).

After the figures were carved and painted with acrylics, I superglued

and pinned them down, usually through the feet, into various positions.

Painting the sailors was fairly easy because in the Royal Navy, at the

time, there was no standard issue uniform. The differences in rank

would be minor and not really noticeable at this scale.

I really enjoy using figures for two reasons. They give the

viewer a sense of scale as to how big these ships really were and they

also give life to the model both through their action and colour.

I prefer to employ various fine hardwoods rather than paint to simulate

the ship’s colour scheme, as I know that wood develops a wonderful patina

over time. The figures seem to add just enough colours to keep the

overall effect from looking too drab.

Case,

Base, Dolphins and Nelson Case,

Base, Dolphins and Nelson

The model is now resting on its base of African cherry wood, which is

attached to the case’s base of American walnut. The dolphins were

hand carved out of American cherry. This combination of all three

wood species reflects the colours in the ship’s hull.

The Nelson statue I obtained many years ago. On the front of the

base it reads “British Sailors’ Society”, and on its sides are written,

“Presented by King E.R. VII” and “contains copper from Nelson’s ship

Victory”.

I wrote the British Sailors’ Society and they told me that they made a

few busts of Nelson as presentation pieces, to commemorate the 100th

Anniversary of Nelson’s death and the battle of Trafalgar. The

copper that it contains was made from the original copper plates that were

removed from Victory around this time.

The busts are especially valued as they most surely contain copper that

was present at Trafalgar.

Model finished and in its case June 6th, 2000.

Total hours 5500.

My goal in making this Victory diorama was to appeal to the curiosity

of the twelve-year-old kid in all of us (before the discovery of girls and

fast cars). Personally, I prefer not to build admiralty type models,

as I find the interest in them is usually limited to my fellow modelers or

a few collectors.

I

have noticed over the years that, in general, people are mostly attracted

to models that have human figures involved in telling a story.

Although the Drumming Daybreak ceremony is the main storyline, there are

many other mini stories going on here, sort of dioramas within a diorama.

I also wanted to depict some aspects of daily life aboard a warship. I

have noticed over the years that, in general, people are mostly attracted

to models that have human figures involved in telling a story.

Although the Drumming Daybreak ceremony is the main storyline, there are

many other mini stories going on here, sort of dioramas within a diorama.

I also wanted to depict some aspects of daily life aboard a warship.

My objective is to broadly educate and not necessarily to show things

as they actually were. A good example of this is the two sailors

hauling on the davit ropes to raise the boat. In reality, there

would probably be twenty men on those ropes. Another example is the

two sailors par buckling the barrels up the rails on the hull (let’s hope

they’re empty!).

The most important factor in doing a good diorama, I believe, is to

tell a story, to capture a moment in time, to take the viewer back to a

different era, to hopefully raise an emotional response to what is being

seen and thereby create a three dimensional work of art.

In my work I am not a purist or a rivet counter, however, I do like to

have lots of detail to keep it interesting. I try to be as accurate

as I can but I will use artistic license for effect. I spend a lot

of time both before and during a project researching the ship and its

history.

I did not work on Victory continually over the twenty-five year period

of her construction, as my other interests are woodcarving and building

World War I aircraft dioramas. However, it was never long out of my

mind. During the periods I was not actively building, I was doing

research, pouring over pictures and plans, writing letters and

daydreaming.

I am a retired pilot and flight operations officer. I spent 28

years in aviation doing everything from sweeping hangar floors to flying

instructor.

In the 1960s, I helped my father restore a full size 1929 Curtis-Wright

Travelaire biplane D4D (CF-JLW) that now resides at the Reynolds Museum in

Alberta.

The last 17 years I spent in the visual arts, teaching woodcarving and

making decorative birds of prey sculptures.

I have been married to the same women for 40 years, as only she

(Micheline) could put up with me and my hobbies.

I presently have a Neiuport 28 – 1/16” diorama underway and am

also working on a Wright Brothers Flyer. I hear through the

grapevine that Model Airways has a 1/16” scale Jenny in mind. Hmmm!

Now if I can only keep this 62 year old body in shape.

This model is dedicated to all those hard-bitten sailors of yesteryear

who knew that, in the age of sail, the sea could only be truly loved from

the land.

In conclusion, thank you for letting me tell my story. If I can

be of assistance to anyone building future models of Victory please feel

free to e-mail me.

Cheers!

Click the

thumbnails below to view larger images:

Model, Images and Text Copyright © 2003

by John Reid

Page Created 13 August, 2003

Last Updated

17 March, 2004

Back to

HyperScale Main Page |

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search