|

Junkers Ju 87G-1 Stuka

in 1/32 Scale

by Wayne Bowman

|

|

|

Junkers Ju 87G-1 Stuka |

HyperScale is proudly supported by Squadron

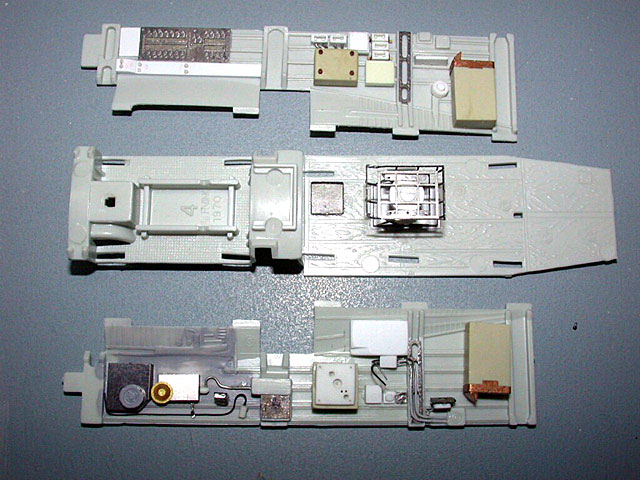

Here is my 1/32 Junkers Ju 87G-1. It utilizes the old Revell Ju 87B (in

this case from Revell of Germany), together with a multimedia kit from

Jerry Rutman to bring it up to the G standard.

The conversion set includes numerous resin components including a new nose

section, under wing radiators, one piece H-Stab struts, interior, as well

as cannon pods, pylons and mounts. Also included are a new vac-formed

canopy, and some photo-etch components.

The set provides a good starting point for this conversion, but as I

researched the subject A/C and got into the build, I found that some

additional effort in the way of, corrections and scratch-building would be

required to bring this conversion up to the level of fidelity that I was

hoping for.

General

The kit’s raised panel lines were all removed and re-scribed (those

appropriate to the G model), and the exaggerated raised rivets were toned

down over the entire model. Pinholes in a number of the resin parts

required some filling effort as well. The fit of the basic kit though, was

surprisingly good considering it’s age.

Interior and Canopy

The resin cockpit, required some clean up in the way of pinholes and a few

areas that were a bit “rough”. This is where I faced my first decision,

weighing whether to make the clean-up effort, or to try to bring the kit B

interior up to a standard resembling the G model via scratch-building.

Given my skill level with the file and filler, I decided that I could

achieve a better result using option 2 and set out to fabricate the

necessary modifications. To this end, I found the Eduard photoetch set

intended for the Ju87 B to be quite helpful, and utilized a number of the

components that were “common” to both B and G models. I found the surface

detail on the resin instrument panel a bit too subtle for my skills to

bring out, so again I elected to use the Eduard panel, modified as I was

able.

No Revi gunsight is included with the resin set, so I modified a Verlinden

resin sight from the spares box, with the defogging tube/line, which is so

conspicuous on the Ju87 D/G series.

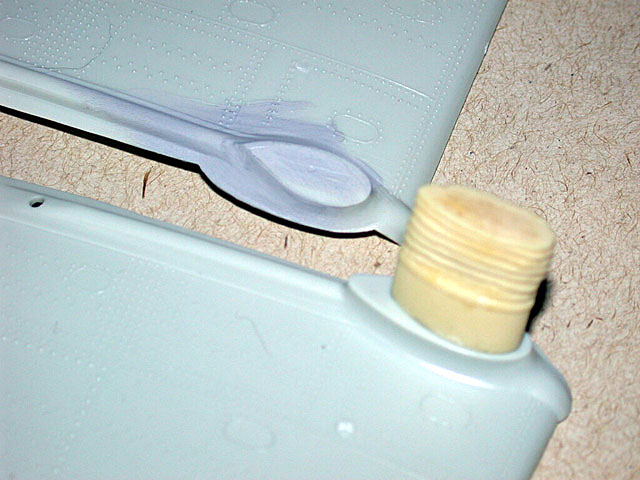

When cutting and mounting the vac-formed windscreen and canopy sections,

some creative filing, filling, and fitting was required to make them align

properly (well, somewhat anyway). On my sample, it appeared that the fore

and aft vac-formed canopy frames on each of the sections, were not quite

perpendicular to the A/C centreline. The canopy of the Ju87 D/G had a lot

of internal framing and this was added to the vac form components using

styrene strip, and lead wire as appropriate (square vs. tubular framing).

A new antenna mast was also scratch-built to replace the kit one, which

had little or no resemblance to the real mast.

Fuselage & Horizontal/Vertical Stabilizers

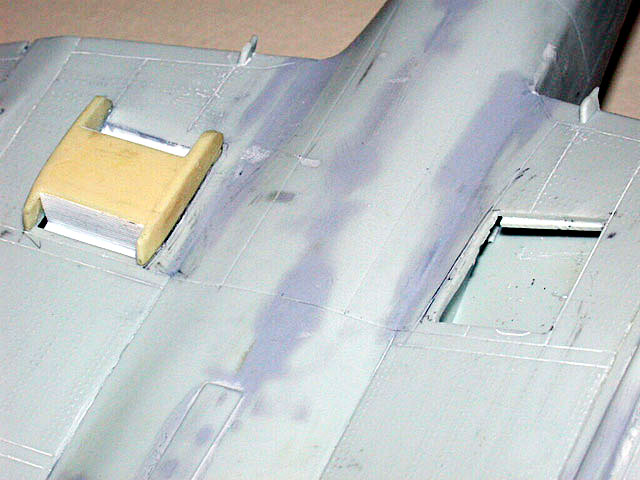

On the fuselage, I opened up the fuselage hand holds, and filled the

attachment point for the starboard foot step, as the G series machines

only appear to have the port one in place. A significant amount styrene

and milliput was required to fair the fuselage into new resin nose by

reshaping the area in question to make it a bit more “square”. I also

replaced the upper aft engine mount fairing with scratch-built ones which

I felt where a bit closer to the proper shape. Another area that required

some attention was around the exhausts. Here, I dispensed with the resin

forward fairing, and built up the fairing area to more closely match the

proper profile. I replaced the resin exhaust stubs with a set of Moskit

stubs that were intended for the old Hasagawa Fw190 D9 (Jumo 213). The

actual Ju 87 exhausts (Jumo 211) look very similar to the 190’s, and while

the Moskit stubs look a smidgeon oversize for this application (they look

fine on the 190 though), I still felt they were an improvement over both

the kit and the resin examples. The slots for the exhaust in the resin

nose were suitably deepened to accommodate the Moskit exhausts.

A rather large hole was opened up in the upper fuselage just aft of the

canopy and a well inserted for the scratch-built PRE4 RDF antenna. A piece

of clear styrene was used to fabricate the transparent cover with some

bare metal foil strips added on the inner surface to represent the

dielectric strips.

Various bits of appliqué armour were made from styrene, brass or copper,

and added in areas below the pilot’s canopy, forward of the windscreen,

and at the wing root.

The spinner was opened up at the three blade locations to ensure that the

prop cuff nested below the spinner surface.

A drain tube and the 13th exhaust stub were also added to the starboard

side at the engine join line.

Actuators were added to the v/stab and h/stab trim tabs, and control horns

and cables were added to the rudder.

Landing Gear

I realised early that due to difference in the foot print for the main

landing gear between the B and D/G, that I’d have to reshape the attach

point on the wing lower surface. Before I buttoned the upper and lower

wing sections together, I filled the backside of the attach point so as to

provide some backing for when I filed these areas back to accommodate the

new resin landing gear leg.

The kit main wheels, when installed in the new resin spats, looked far too

narrow, so I inserted some styrene between the two wheel halves to give

them a bit of a “fatter” appearance. The Rutman white metal tail wheel

yoke on my sample was broken on receipt so I elected to modify one from

the spares box. (NOTE: I’m sure that Jerry Rutman would have happily

replaced this part, and I would have gone that route if I didn’t have an

alternative readily available).

Wing

The left & right one-piece aileron/flap components were separated to allow

the inboard and outboard flaps to be mounted in the lowered position. I

had decided to build my example as a G1 model, thus necessitating the

addition of fairings over the machinegun ports in the wing leading edge,

and the omission of the resin wing extensions.

All the kit actuator rods for the flaps and ailerons, were replaced by

scratch-built versions, as were the aileron counterbalances. Tie-down

rings were also added to the wing lower surface.

The resin under-wing radiators were made to be simply affixed to the lower

wing surface, but references show that much of the radiator was actually

buried into the wing. This was accomplished by deepening the radiator

faces on the resin parts, then making cut outs in the lower wing surface

to sink them.

The references I had showing the G1’s upper wing surface seamed to

indicate that they utilized to wide anti-slip walkways so I utilized to

photoetched ones from the Eduard set.

I performed some major surgery in respect to the 37mm cannons. I elected

to try scratch-building more accurate forward and aft cannon mounts versus

the resin components provided. I also decided that I’d like to open up one

of the cannon pods to show the breach. Here is were I crossed scales a bit

and used the breach from Tamiya’s 1/35 Flak 38 ( I hope the purists can

forgive my “breach” of the laws of scale – and my bad puns). I did this by

cutting our the middle section of the resin pod and substituting an

equivalent length of brass tubing with a section cut out for the door. The

resin ends were hollowed out, styrene strip used to replicate internal

framing, the interior painted RLM02 (a guess on my part) and the breach

mounted internally.

Painting,

Markings and Weathering

|

I used Mr. Surfacer as a primer base, followed by Gunze RLM 65, 70 and 71.

Decals were a mix of the Eagle Strike and various spares, to represent one

of the early machines operated by SG77.

After decaling, came a coat or two of PollyScale clear gloss, followed by

an oil wash and a couple of coats of PollyScale clear flat. Some more

local weathering with the airbrush, pastels, and silver pencil crayon and

there it was done.

The final picture in the series is of my buddy, and consummate modelling

supervisor, Fred the cat.

From the time that I started back into modelling, Fred enjoyed nothing

more than to sit on my lap during the build process and supervise, much to

the amusement of my wife. Many a contortion was achieved by yours truly,

while trying to glue three parts together simultaneously, at least one of

which inevitably had no interest in sticking, all the while trying to make

sure that Fred’s tail didn’t become part of the assembly.

Sadly, my companion passed away from cancer just before I completed this

model. It was our last project together.

This model is dedicated to the memory of my buddy Fred.

Click on the thumbnails

below to view larger images:

Model, Images and Text Copyright ©

2003 by Wayne Bowman

Page Created 06 November, 2003

Last Updated

17 March, 2004

Back to

HyperScale Main Page |

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search