|

MiG-29 Fulcrum Prototype

in 1/32 Scale

|

|

|

MiG-29 Fulcrum Prototype |

by Frank Mitchell

Revell's

1/32 scale MiG-29 is available online from Squadron.com

I have always liked the looks of the prototype

MiG-29, probably because the forward-placed nose gear gave it a stance and

look that no other ’29 has. Therefore, when I got the urge to do another

32nd Fulcrum (I have previously done a MiG-29 UB; see the HS archives),

the search began for information on the Number 1 aircraft.

Although there are a number of photos of the

prototype as it currently exists at the Monino museum, I ran across two

color pictures of the aircraft which were probably taken either at, or

near, roll-out. I based that conclusion on the lack of an IR sensor and

gunsight, several different antenna placements, no belly or underwing

stores or tanks, shortened tailfin extensions, and a different color

scheme (a light brown was added to the more usual gray and green).

As is generally known, the 1/32 Revell kit of the

MiG-29 has some shape problems. While I didn’t attempt to correct all of

them, I did make several modifications which may be of interest to anyone

wanting to give the kit a try.

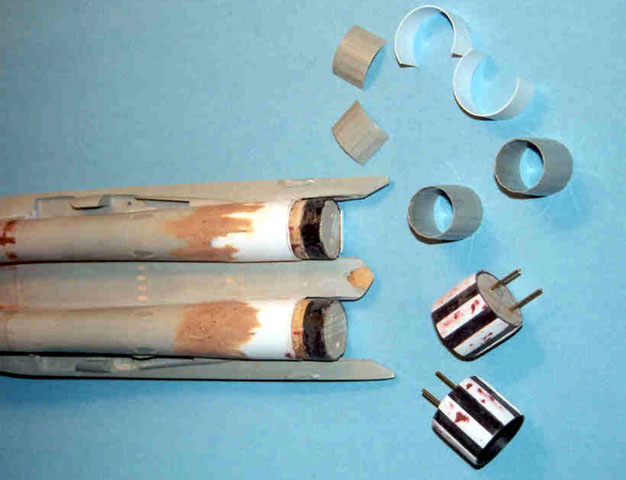

The first, and probably most important problem is the size of the engines.

They are grossly too small in the kit. I essentially used the same

technique as on the ‘UB, but tried to add a bit more detail this time. As

on that model, the outer exhaust outlets started life as 35mm film cans.

The inners are exhausts from the old, original Revell F-4. This

combination gives a result that is much more dimensionally accurate, even

if the shape of the “leaves” is not quite correct. On the bottom of the

fuselage, the shapes of the two engine housings were enlarged with styrene

and epoxy putty. Attempts were also made to include the proper “rig” of

the outlets.

Another obvious shape problem is that the kit’s forward wing extensions go

all the way to the radome. This, in combination with an incorrectly shaped

radome, throws the whole appearance off, at least to me. After using epoxy

and styrene to fill in the inside of the extensions, they were Dremeled to

a more accurate size and profile.

I had previously made a mold for a new epoxy radome for the production

MiG-29, so one of those was simply re-shaped to the smoother outline of

the prototype (I never have used one of those new noses for a later

bird--). These two changes made a great improvement in the appearance of

the fuselage.

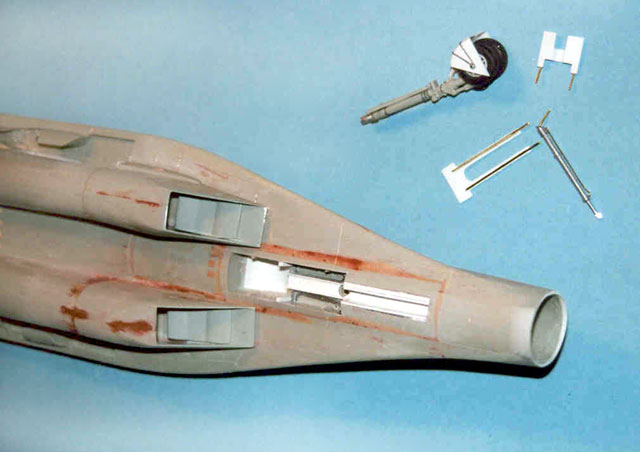

The most obvious difference between the prototype and

later MiG-29s was the location of the nose gear; it was 4 feet 11 inches

forward of the later position. This change turned out to be fairly easy to

model because of the horizontal split of the Revell fuselage. The entire

wheel well area was carefully removed with the Dremel, along with a margin

of about 1/32 all the way around. The resulting hole was enlarged forward

the amount necessary, and the wheelwell was simply moved forward and glued

into place in the forward position. A bonus was the fact that the piece

removed from in front of the kit wheelwell fit perfectly to fill up the

hole behind the new position. While I was in the bottom fuselage half, I

also opened up the main wheelwells, which are far too shallow on the kit.

The landing gear needed a lot of detailing to look more like the real

thing and to add the various hoses, etc. The nose gear also required new

doors which were completely different and more complex. A large splash

guard (which, by the way, didn’t work on the real airplane) was made up

and nose wheels from the scrap box were also used which more closely

resembled the prototype’s spoked ones. The main gear doors also had to be

re-shaped so that they would fit closely against the fuselage.

The kit fins need to be moved to the outer edge of the fuselage and faired

in to the vertical fuselage sides. The horizontal stabilizers should be

re-mounted and small wedges removed from the forward, inner edge. These

wedges are glued to the fuselage. The drag chute covers have to be

re-shaped (the round part needs to be removed).

From here on, the model was built pretty much as any other, although there

were a number of smaller changes. I used a CAM cockpit set (great) and

filled the single gun opening and vent on the port side and drilled in the

two openings that were present at this stage of development. The small

intake on the rear dorsal surface also needs to be moved more to the port

side.

As with any prototype, every available picture shows some detail changes

such as antenna locations, etc., but I tried to always use the earliest

pictures, if there was a choice.

I did cut out and lower the flaps and slats (there are pictures of parked

Fulcrums in that condition), filled all the holes on the bottom of the

wing for pylon attachments, etc. The wingtips were changed to have only a

small navigation light.

As one might expect, this model required lots of priming and sanding (I

use automotive lacquer primer; have for years) and, therefore, lots of

scribing and re-scribing was also necessary since a number of panels were

not the same on this airplane.

The paint was Testor’s Fulcrum Gray and Fulcrum Green

along with a made-up light brown that came as close as I could to that in

the color photos I had. The paint was Testor’s Fulcrum Gray and Fulcrum Green

along with a made-up light brown that came as close as I could to that in

the color photos I had.

Once the color coats were complete, the model was

sprayed with Future and decals for the stars and maintenance markings

(mostly from various CAM and Microscale sheets) were applied.

A final coat of Floquil Flat Finish was then sprayed,

with Testor’s Dull Coat being used on the antiglare panel.

Click the

thumbnails below to view larger images:

Model, Images and Text Copyright © 2002

by Frank Mitchell

Page Created 12 April, 2003

Last Updated

17 March, 2004

Back to

HyperScale Main Page |

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search