|

De Havilland D.H. 98

Mosquito Prototype

by Scott A. Bregi

|

|

|

De Havilland D.H. 98

Mosquito Prototype |

Tamiya's

1/72 scale Mosquito B. Mk.IV is available online from Squadron.com

Mosquito!

The name that brought fear to many a German

pilots’ heart was by most accounts probably one of the most successful

aircraft designs to come out of WWII.

The “Yellow Bird” was born in a small hanger

disguised as a barn, across a moat from a manor house called Salisbury

Hall, England. Production was later moved to Hatfield for want of a larger

facility. The De Havilland D.H. 98 Prototype was rolled out in all its

bright yellow glory, for the first time on Nov 19, 1940. She was painted

in an overall yellow so AAA gunners would not mistake it for an enemy

aircraft and shoot it down! She would be given a green/brown camouflage

scheme on its upper surfaces at a later date.

Design and construction was radical for it’s

time and was the reason for its phenomenal performance. Constructed of

materials that were not strategically important, it was built in some

respects the same way we modelers build our aircraft kits. It was

primarily constructed from a 3-ply; balsa filled, birch plywood formed

over a mahogany mould. The fuselage halves were fitted out with all

electrical and mechanical equipment before they were cemented together.

The one piece wings were also constructed out of the same plywood sandwich

as the fuselage with two-one piece, spruce spars of box construction,

running from wing tip to wing tip. The only metal was used in the

construction of control surfaces, engine and engine mounting and landing

gear.

Its prodigious performance gave the D.H. 98

its name, “Mosquito”. At the time of its roll out it was one of the

fastest twin engine aircraft produced with a top speed of 382 mph. It was

able to outrun almost all known Axis fighters excepting the Me 262. The

Mossie as she was affectionately known by its aircrews was used in every

conceivable mission known from unarmed high speed reconnaissance to

passenger ferry to target tug! Design work commenced in late 1938 and

construction began on the first Mosquito in Oct 1940. First flight took

place on 25 Nov 1940. In all, 7781 Mosquitoes were built with the last

airframe completed in 1950.

I have always had a soft spot in my heart for

the Mosquito, probably since we have the same birthday albeit 20 years

apart! I just wish I had the time to build more of them. But I just had to

have an example of the prototype, the progenitor of the line, E0234/W4050.

I loved that overall yellow scheme! I’ve nicknamed it the Great Canary!

My odyssey to build (and finally finish) a

model of the prototype began many years ago using the old Airfix kit. Then

along came Hasegawa with their fine rendition so I trashed the Airfix kit

in favor of the Hasegawa kit but I ran into problems using the Paragon

designs resin conversion kit on the Hasegawa kit. Now cut to Tamiya and

their beautiful kit that was pantographed down from their 1/48 scale kit.

I then started anew using the latter. I tend to go for the finesse of the

detail and crispness and quality of the kit over minor shape issues! Some

people will start to argue about this curve not being right or this panel

line not being in the right place. But I think the Tamiya kit has the best

overall detailing especially exterior detailing over the Airfix or the

Hasegawa kit.

On with construction!

Conversion and Backdating

I began construction with the conversion of the wings

and nacelles. This was the most time consuming part of the build. The

first few versions of the Mosquito had short engine nacelles with a single

piece flap. The rear part of the nacelle would hinge down and into the

rear part of the nacelle. The nacelle was modified into the more familiar

longer design after severe buffeting of the tail planes was experienced at

around 240 mph.

I assembled the nacelle and added the rear bulkhead

from the Aires super detail set (#7077). The cutouts over the landing gear

retraction knuckles was filled in with Milliput and smoothed out with a

wet cotton swab. I then filled the back of each nacelle and the cutouts

for the exhausts on the sides of the nacelle with polyester resin and set

them aside to cure.

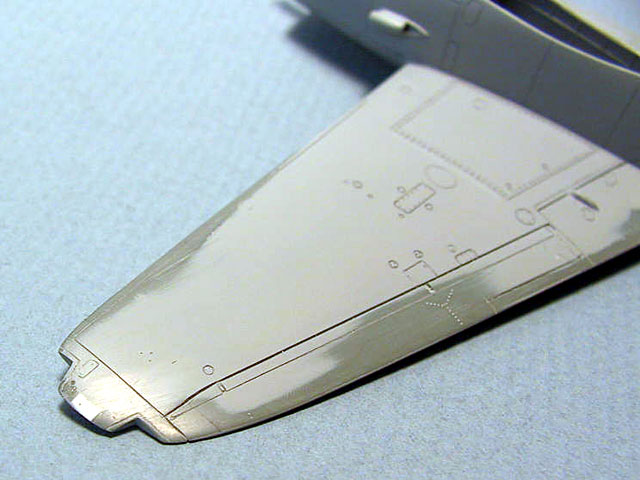

The Wings

The prototypes wingspan was shorter by 20 inches at

52 feet, 6 inches. The wings on production versions were lengthened to 54

feet, 2 inches. So each wingtip had to be shortened 10 inches each. I did

this by cutting of approximately 5/32 of an inch from each wingtip.

Then I cut each wingtip (part #B5/B6) in half

spanwise down the center between the lights and glued the forward edge of

the front piece up against the leading edge and the aft portion lining it

up with the trailing edge of the wing. I then filled in the resulting gap

with plastic strip and filed and sanded to match the rest of the wing.

The Nacelles

After allowing the resin to cure I commenced to

reshape the rear of each nacelle using the drawings in the Aerodetail no.

23 on pg. 104. Rescribing the one-piece flap was accomplished by first

filling all flap actuator access surface detail over the nacelle with

Tamiya putty and then connected the inboard line with the outboard line.

E0234 and all first generation Mosquitoes came equipped with automobile

style exhaust manifold resulting in a small scoop shaped exhaust stub.

Blistering of the engine cowling necessitated the later redesign to the

stub style we are more familiar with. The cutouts for the exhausts were

smoothed over and the exhaust fairings added from the Paragon Designs

conversion set. All surface details were rescribed by first primering with

Gunze Mr. Surfacer 1000 and scribing into the paint not the plastic. This

yields a cleaner line that does not have to be rescribed over and over

again. Radiator face detail came from the Eduard detail set.

These wings were designed to be masters for a set of

one piece resin wings that may be marketed in the future. Above are the

masters and below are the resin copies. My model was built using a set of

resin copies. These only need the modeler to add the kit parts for landing

gear and doors, lower radiator flap and wing tip lights and attach to the

fuselage like normal using the spars as installed in step 10 of the kit

instructions.

Click the

thumbnails below to view larger images:

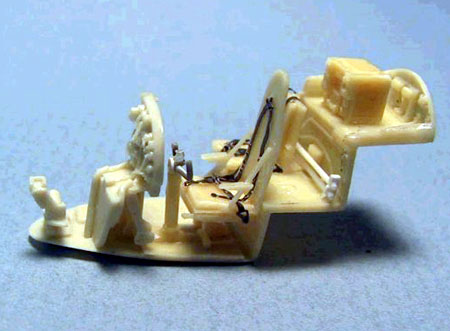

The Cockpit

The cockpit was built with a combination of CMK

(#7037), Aires (#7067) and Eduard (#72-314) detail sets. The Aires set

making up the lion’s share of the added detail. The CMK set providing the

floor, instrument panel, rudder pedals and control column.

All the side panel detail from the Aires set was

sanded free of the sidewall and attached to the inside of the fuselage

halves with CA.

Other details were added using plastic rod and fine

multi-stranded wire that is marketed as model railroad switch wire!

Click the

thumbnails below to view larger images:

The Rest of the Story

The rest of the model was built as per the kit

instructions with the following exceptions and changes. The horizontal

tail planes on E0234 were 9 feet 9 ¾ inches and production versions were

10 feet, 4 1/3 inches in length measured from fuselage center line to tip.

Each tail plane was shortened 5/32nd of an inch each

and reshaped and surface detail rescribed. The gear door guides on the

landing gear were replaced with ones from the Eduard brass set. Remove the

longitudinal strengthening rib on the right side of the fuselage and

delete the antenna mast.

I added another camera window to the center of the

rear access

Painting,

Decals and Weathering

|

The model was prepared for painting by masking off

the clear parts with an Easy-mask set and was then primered with Mr.

Surfacer 1000. She was then airbrushed with Testors Model Master Insignia

yellow overall.

The model was then prepared for decaling by spraying

on two coats of Future floor wax and set aside to dry for 1 week. Decals

came from several sources : Fuselage: 45" Type A1 (blue-white-red) from

the Modeldecal sheet # 39; Upper wing: 54" Type B (blue-red) from Micro

Scale sheet # 72-292; Lower wing: 50" Type A1 (blue-white-red) from Micro

Scale sheet # 72-292; Finflash: 24x27" (blue-white-red) from Aeromaster

sheet 72-003 cut from the Hurricane flash to fit.

The tail codes were graciously provided by my friend

and fellow mosquito modeler Rob de Bie over in the Netherlands. Thanks

Rob. The decals were custom designed and printed by him and went on

perfectly.

After decaling was completed I then gave it a quick

overspray of Future and set it aside to harden. A very light was given to

the panel lines with Windsor-Newton Burnt Umber oil paint thinned with

Turpenoid. This was kept to a minimum as the acft was new and did not get

a chance to collect a lot of grime.

I feel very pleased that this project is finally

finished and is a “bright” addition to my growing 1/72nd scale aircraft

collection. For my next conversion project I plan on doing the Mk XVIII

with the 6 pound Molins gun in the belly using the Tamiya FB MK VI! At

Tsetse Mosquito I can’t wait! And a special thanks to Rob de Bie for all

the help in researching this project and for providing me with the serial

number decals!

Click on the thumbnails

below to view larger images:

Model, Images and Text Copyright © 2003

by Scott Bregi

Page Created 06 October, 2003

Last Updated

17 March, 2004

Back to

HyperScale Main Page |

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search