|

Phantom FG.1

by Mike O'Hare

|

|

|

Phantom FG.1 |

HyperScale is proudly supported by Squadron

Hasegawa's series of 1/48

F-4's are classics that truly raised the bar when first released some

twenty years ago. Perhaps the best measure of how good they were is the

fact that they are STILL excellent kits today.

They're certainly the best

kits of the Phantom in 1/48, arguably the only one worth building in the

scale, and their family is one of the most complete ranges of F-4's in any

scale - the only major versions Hasegawa haven't released yet are the

recce RF-4s, though the RF-4B and RF-4E are coming soon. It is also

possible to convert their B/N, C/D and E kits with the Black Box noses in

the mean time.

The kits themselves have something of a history. The original release was

the F-4J, which had raised panel lines throughout. Not long after, a

high-tech version of the kit came out, which was re-tooled to include

recessed panel lines. At present, the F-4E, F-4EJ (and Kai), F-4F, F-4G,

F-4J, F-4K, F-4M and F-4S all have recessed panel lines, and only the

thin-winged F-4B/N and C/D kits have raised panel lines. Each release

includes parts specific to the version it's meant to represent - slatted

or hard wings, slotted or unslotted stabilizers, different radomes, gun

configurations and forward fuselage plugs. The British Phantom kits share

only the cockpit/main landing gear sprue with the rest of the series; the

whole of the airframe proper was re-tooled to accurately depict the

changes, both major and minor, for Spey-engined aircraft. The kit in this

review is from an SP release of Hasegawa's FG.1 - the basic kit, plus a

set of Cartograf printed decals to model "Black Mike", one of the farewell

schemes. It's also available in two regular releases, for RN Phantoms in

Extra Dark Sea Grey over white, and later RAF aircraft with markings for

the Barley scheme. The FGR.2 is largely the same again, save for the

decals.

Click the thumbnails below to view larger

images:

Simple Scratchbuilding, Pt.1

Construction begins, as with most kits, in the cockpit. Hasegawa is known

for decent, though not spectacular cockpit detail, and this kit is no

exception. It looks good straight from the box - particularly the tub

itself, though the five-part seats are nice too - but the detail fans will

want to either scratchbuild or opt for a resin replacement. As I intended

to close the canopies, going all out with a resin cockpit seemed a bit of

a waste, so I opted to just do a bit of scratchbuilding on the sidewalls.

These, as with most models, are the weakest part of the kit's cockpit.

They have some raised detail, but it's very faint, undersized and

unspectacular. At the very least, some ribbing can be added with strip

styrene. I went a bit further, adding details with sheet and rod styrene,

essentially just trying to duplicate (more or less) the basic shapes using

the sidewalls from a Black Box F-4E cockpit as a sort of 3-D, scale

reference. I also added a simple attempt at a throttle - the corners were

rounded over on a section of strip styrene and a line scribed to give the

impression of two halves, it was then painted, lopped off the strip and

glued in place. Finally, I added True Details seats - not strictly correct

for the British Phantoms, but close enough for me.

Click the thumbnails below to view larger

images:

It's Shake and Bake, and I Helped

Construction of the rest of the aircraft is really pretty straightforward

and the model clicks together with little or no problems. The intake ramps

are "hollow" on their back sides, so a bit of sheet styrene and CA will

fill the spaces. They are fairly well hidden between the intake and

fuselage, but it's a simple fix that's worth the effort. Another simple

trick worth noting has to do with the insert for the IFR door on the

fuselage side. It's much easier to add by drilling/filing/carving away

most of the recess, so the part can be manipulated from the rear as well.

This will make it easier to get a perfectly flush fit, though obviously it

means adding the part before joining the fuselage halves or installing the

cockpit.

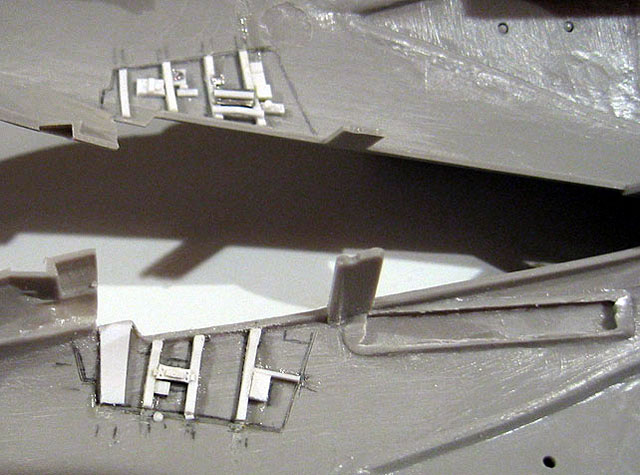

IFR insert recess removed. Also note plastic

strip sidewall detail.

It's also a good idea to

fully assemble the left and right fuselage halves before joining them

together - add whatever nose halves the version requires (in the case of

the Brit Phantoms, it's just a radome half on each side). This will allow

a perfect alignment around the nose and a join with less clean-up required

- any seam work will be along the length of the smooth radome, rather than

around the circumference of the nose/fuselage join, so it's easier to sand

out. You'll also be able to join the parts on a flat surface, to make sure

they're square and true. Finally, once the fuselage is together, attach

the intake parts before gluing on the wings - it's easier to get them

lined up this way.

As

Black Mike never carried drop tanks, the pylon locating holes under the

wings were filled in, and the raised pylon re-enforcement panels tooled on

to the wing sanded off. It did haul a pair of dummy Skyflash bodies in the

forward recesses, so the fins were clipped off of two of the Sparrows

included in the kit and the missiles were turned in a drill lathe to round

them out. Once smooth, the raised strips were added back on with some

strip styrene using the "spare" pair of missiles as a guide. This was

probably excessive, but seemed about the easiest way to erase all traces

of the fins and smooth out the mould line at the same time. As

Black Mike never carried drop tanks, the pylon locating holes under the

wings were filled in, and the raised pylon re-enforcement panels tooled on

to the wing sanded off. It did haul a pair of dummy Skyflash bodies in the

forward recesses, so the fins were clipped off of two of the Sparrows

included in the kit and the missiles were turned in a drill lathe to round

them out. Once smooth, the raised strips were added back on with some

strip styrene using the "spare" pair of missiles as a guide. This was

probably excessive, but seemed about the easiest way to erase all traces

of the fins and smooth out the mould line at the same time.

As mentioned,

with a bit of care and test fitting, the model all but clicks together, so

only a light layer of Gunze's Mr. Surfacer is needed to smooth out all the

seams. Because of the way the fuselage halves are tooled, the rivet detail

tends to fade out around the spine, so this was touched up using a

straight pin in a pin vise, using the impressions on the kit as a guide.

It also meant the rivets weren't obliterated after a light sanding along

that seam.

Once the wings are on and all seams taken care of, the model is ready to

paint. A word of caution here - DO NOT ATTACH THE STABILIZERS UNTIL THE

MODEL IS FINISHED. Resist the urge to test fit them, they go on just fine

without any need for adhesives, via small, easily broken rods. This is

(unfortunately) the voice of experience talking.

Simple Scratchbuilding,

Pt.2

The intakes themselves are a little disappointing - there's no intake

trunk, just a simple bulkhead an inch and a half back on the fuselage

halves. And the bulkheads themselves aren't flat, nor do they cover the

whole of the intake - the model is see-through along the bottom of the

intake. Seamless Suckers have resin intake trunks available for those who

want to look back to the fan and there's also a number of aftermarket

options to do US-style FOD guards. The British Phantoms have different

intakes though, and different intake covers - basically a sheet of plywood

roughly the size and shape of the intake, outlined with a spongy medium to

hold it in place, and a pair of metal handles. In scale form, it's a case

of cutting a piece of sheet styrene roughly to size, tacking it in place,

adding a thin sausage of epoxy putty around the edges and some wire

handles in the centre. The "plywood" portion was then painted red, and the

"foam" sections hand-painted Light Ghost grey and washed to bring out the

detail. A quick search for British Phantom pictures on-line will turn up

dozens of images of the FOD guards for reference

I See a

Phantom and I Want to Paint it Black

Click the thumbnails below to view larger

images:

First, in preparation for a coat of Alclad II, the exhaust area was primed

with Gunze's Mr. Base White 1000, basically just a white version of Mr.

Surfacer 1000, a very tough lacquer-based sandable primer. Its biggest

benefit is the fact that it buffs to a high gloss, which means it's the

perfect smooth, shiny base for metallics. It is also an excellent

choice for any gloss white - a brisk buffing will give it a good shine,

and a bit of Tamiya polishing compound will bring out a mirror-like

finish.

With the primer

coat down, the Alclad could be painted. The aluminium sections are,

surprisingly enough, aluminium, but with a hint of steel added to take the

edge off. I then sprayed lightly along the panel lines with a slightly

darker version of the base shade (more steel added). For the burnt metal

portions, the process was reversed - steel with a touch of aluminium to

lighten, and a slightly lighter version sprayed down the centres of the

panels. The exhausts were painted with a base coat of aluminium, and

detail painting done with a variety of shades and techniques - the

"feathers" are Model Master Metalizer gunmetal on the inside, titanium on

the outside, while the darkest band around the exhaust itself is Metalizer

magnesium. The lighter band is Humbrol matte coat. It's interesting to

note that the Metalizers seem to stick very well to the Alclad underneath.

With the natural metal portions taken care of, they were masked over and

attention turned to the rest of the aircraft. With the primer

coat down, the Alclad could be painted. The aluminium sections are,

surprisingly enough, aluminium, but with a hint of steel added to take the

edge off. I then sprayed lightly along the panel lines with a slightly

darker version of the base shade (more steel added). For the burnt metal

portions, the process was reversed - steel with a touch of aluminium to

lighten, and a slightly lighter version sprayed down the centres of the

panels. The exhausts were painted with a base coat of aluminium, and

detail painting done with a variety of shades and techniques - the

"feathers" are Model Master Metalizer gunmetal on the inside, titanium on

the outside, while the darkest band around the exhaust itself is Metalizer

magnesium. The lighter band is Humbrol matte coat. It's interesting to

note that the Metalizers seem to stick very well to the Alclad underneath.

With the natural metal portions taken care of, they were masked over and

attention turned to the rest of the aircraft.

One of the main reasons

Black Mike vaulted to the top of my To-Build pile is the relatively simple

paint scheme: it's black. The problem with this, though, is that it can be

pretty boring visually if a model actually IS black. Because of this, I

added a few drops of Gunship Grey to my paint cup full of Humbrol matte

black paint to lighten it ever so slightly, allowing me to pick out the

panel lines with a truly black wash later on. Wheel, airbrake and

auxiliary engine wells were painted with Gunze's Mr. Base White, along

with the associated doors and landing gear. Once it had set, the engine

bays and doors were sprayed with Gunze's gloss red.

The gloss coat is Model

Master Metalizer Sealer - a laquer based gloss coat that goes on

beautifully smooth and dries to a rock-hard finish. I find it's best to

mist on a few light coats, then a couple of wetter, heavily thinned ones.

The result isn't quite a "wet paint" kind of high shine, but it is nice

and smooth, and glossy enough for any decal.

Decal, Wait, Repeat

As this is an SP release, the decals aren't standard Hasegawa fare. The

ones in this release were printed by Cartograf, and were beautifully thin,

completely legible, and in perfect registration. This was a lucky thing,

as most of the major markings, such as the roundels, nose and tail badges,

aircraft numbers and so on, were printed in two parts. The first part a

white slug to serve as a backing, the second the marking proper, again

printed over a layer of white. While it is something of a hassle applying

the major markings twice, everything lined up perfectly, and the clear

film on each piece is a different size so the decals blend in better. And,

with a bit of Gunze's Mr. Mark Softer, they all melted in to the model's

surface. With decalling done, the residue was rinsed off and the model

gloss coated again to even out the surface.

Click the thumbnails below to view larger

images:

Final

Assembly, Final Comments

|

Final assembly began by adding the landing gear and gear doors. The white

metal wheel hubs were polished with a motor tool, then sprayed white and

added to the gear struts. The canopies were attached after securing the

seats and adding both the scratchbuilt inner and kit supplied outer

portions of the side periscope. The airbrake doors were given a light wash

of white paint, then added to the wings, and the flaps attached. All that

remained was to pick out the assorted lights and probes and the model was

finished.

It really is a classic kit, and one that's hard to screw up. That's a

lucky thing, as there's dozens of fantastic users, camo schemes and

special markings that can be built with the various Phantom kits. It's

eminently buildable straight out of the box, while a little bit of (very

simple) effort will help to flesh out the cockpit sidewalls for the more

advanced modeller. And if you want to go all out, there's a slew of

gorgeous resin and etch products from Black Box, AiRes and Eduard to make

superdetailing easy.

Model,

Images and Text Copyright © 2003

Mike O'Hare

Page Created 04 November, 2003

Last Updated

17 March, 2004

Back to

HyperScale Main Page |

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search